Continuous synthesis method and continuous synthesis device of lithium hexafluorophosphate

A technology of lithium hexafluorophosphate and its synthesis method, which is applied in the direction of lithium hexafluorophosphate, phosphorus compounds, chemical instruments and methods, etc., can solve problems such as high risk, and achieve the effects of reducing production costs, reducing three wastes, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

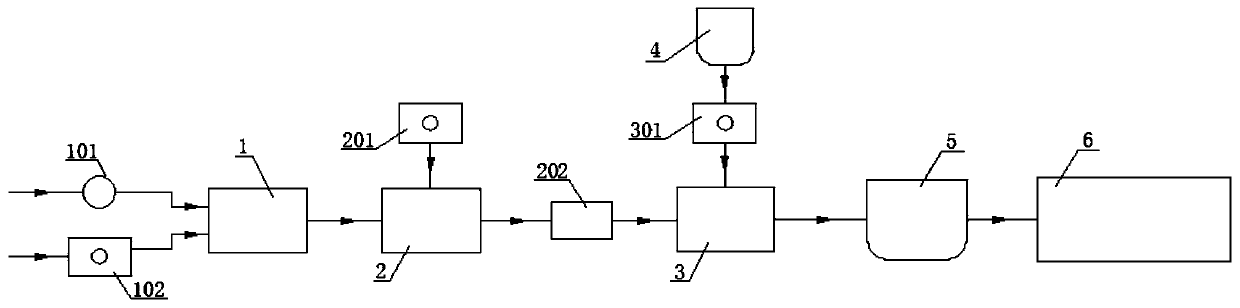

[0029] Provide a kind of lithium hexafluorophosphate continuous synthesis device in the present embodiment, such as figure 1 Shown, comprise: the first microreactor 1, the second microreactor 2 and the 3rd microreactor 3, the first microreactor 1 is communicated with flow meter 101 and first metering pump 102, and flow meter 101 is used for Import the amount of chlorine in the first microreactor 1 to measure, the first metering pump 102 is used to continuously import the phosphorus trichloride liquid in the first microreactor 1, and it is metered, the first microreactor 1 uses Phosphorus pentachloride is synthesized by reacting chlorine gas with phosphorus trichloride. The first microreactor 1 communicates with the second microreactor 2 to introduce the synthesized phosphorus pentachloride into the second microreactor 2 .

[0030] The second microreactor 2 is communicated with a second metering pump 201, and the second metering pump 201 is used for introducing anhydrous hydro...

Embodiment 2

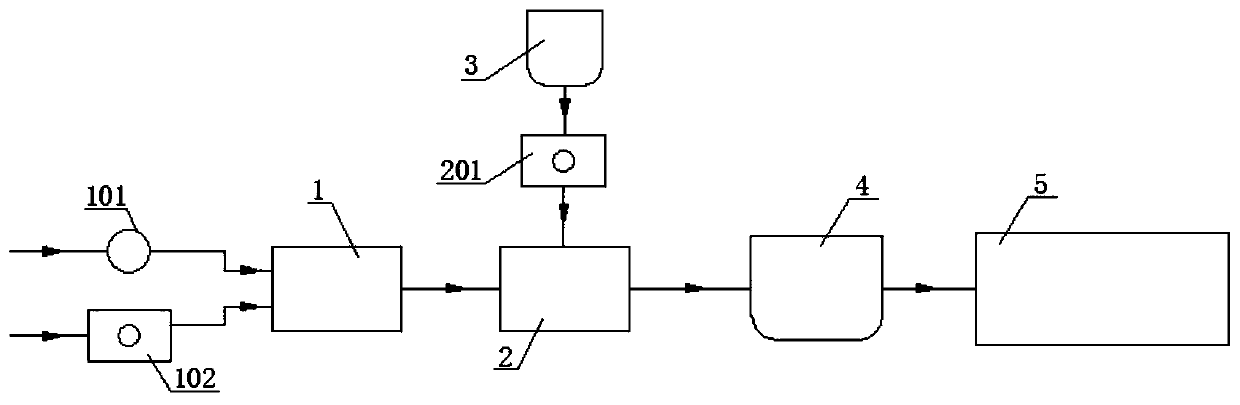

[0038] Provide a kind of lithium hexafluorophosphate continuous synthesis device in the present embodiment, such as figure 2 As shown, it includes: a first microreactor 1 and a second microreactor 2, the first microreactor 1 is communicated with a flowmeter 101 and a first metering pump 102, and the flowmeter 101 is used to import the first microreactor 1 The amount of chlorine in the middle is metered, and the first metering pump 102 is used for continuously introducing phosphorus trichloride liquid in the first microreactor 1, and it is metered, and the first microreactor 1 is used for supplying chlorine and trichloride Phosphorus reacts to synthesize phosphorus pentachloride. The first microreactor 1 communicates with the second microreactor 2 to introduce the synthesized phosphorus pentachloride into the second microreactor 2 .

[0039] The second microreactor 2 is communicated with a second metering pump 201, and the second metering pump 201 is used to import lithium fl...

Embodiment 3

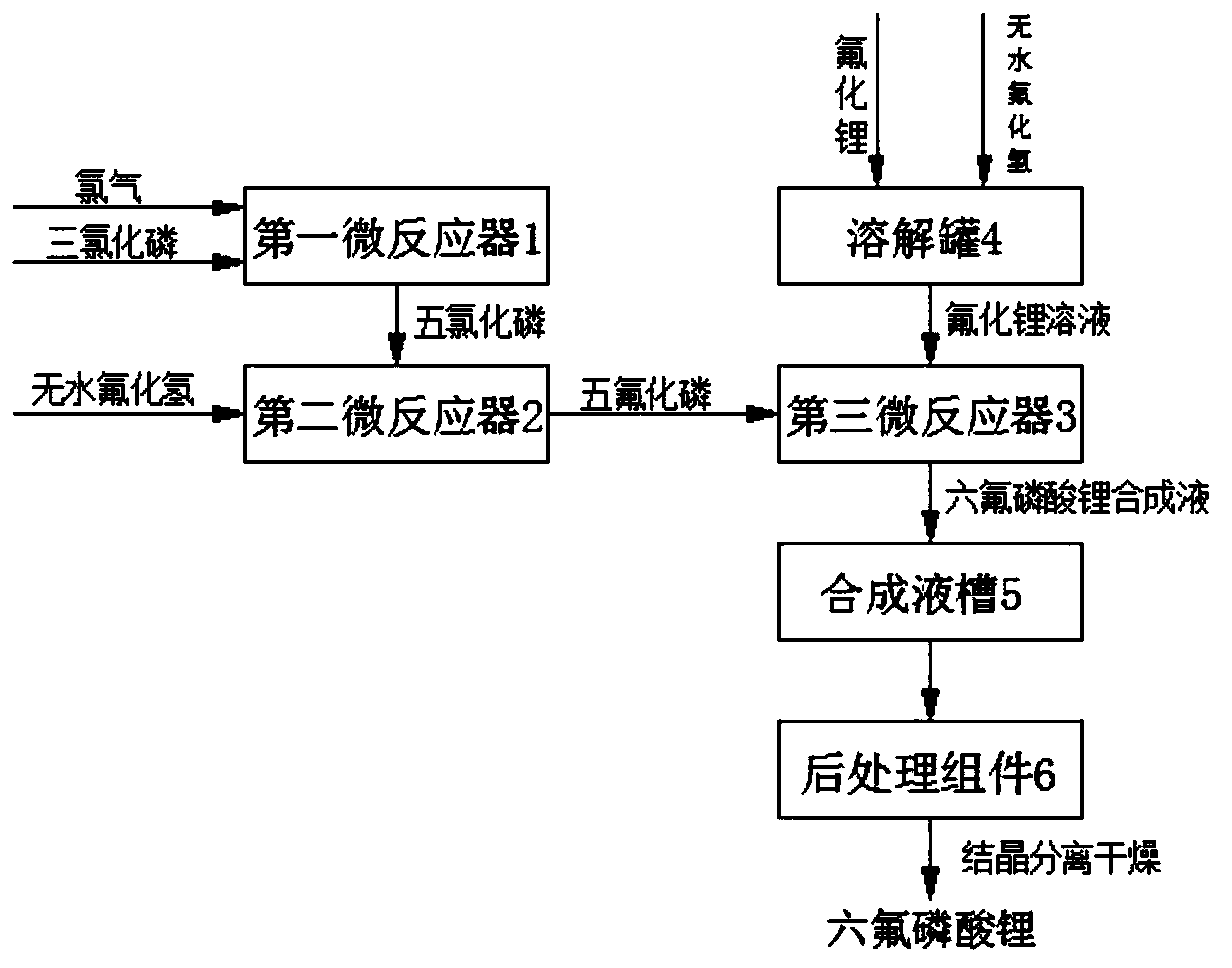

[0043] This embodiment provides a continuous synthesis method of lithium hexafluorophosphate. The synthesis device in Example 1 is used to measure chlorine gas through a flow meter 101, and the introduction rate of chlorine gas is controlled to be 70 g / min; the first metering pump 102 is turned on, and the first In the microreactor 1, continuously import phosphorus trichloride and chlorine reaction to generate phosphorus pentachloride, control the import speed of phosphorus trichloride to be 130g / min, in the present embodiment, the mol ratio of chlorine and phosphorus trichloride is 1: 1.01, control the reaction temperature of chlorine gas and phosphorus trichloride to be 150°C, and the reaction pressure to be 0.3MPa.

[0044] The phosphorus pentachloride synthesized in the first microreactor 1 is introduced in the second microreactor 2, and starts the second metering pump 201, and anhydrous hydrogen fluoride is continuously introduced into the second microreactor 2 and pentach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com