Front silver paste for silicon solar cells and preparation method thereof

A technology of silicon solar cells and silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of high photoelectric conversion efficiency, failure to reach solar cells, and low photoelectric conversion efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

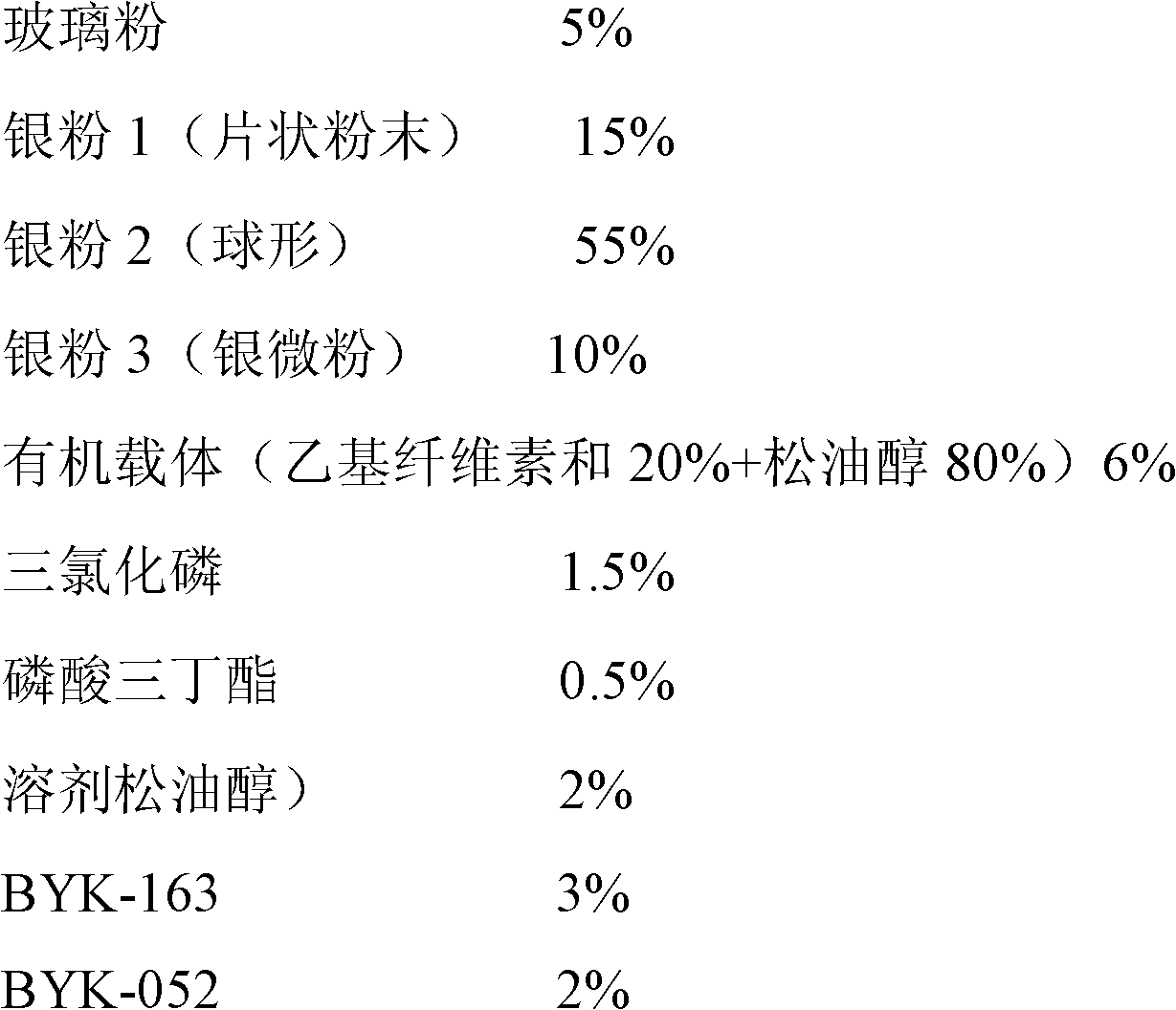

[0017] A front silver paste for silicon solar cells, composed of:

[0018]

[0019] The glass powder is Bi 2 o 3 -B 2 o 3 -ZnO system glass powder, the particle diameter of glass powder is 2-6 microns, the particle diameter of flake powder silver powder is 4-6 microns, the particle diameter of spherical silver powder is 2-4 microns, and the particle diameter of silver micropowder is 50-100 nanometers .

[0020] First prepare the organic carrier, put 20% ethyl cellulose and 80% terpineol into the reaction kettle, heat to 70°C with a water bath, and stir with an electric mixer at a stirring speed of 100 rpm. After that, the temperature was kept constant for 4 hours until the resin ethyl cellulose in the reaction kettle was completely dissolved, and each component was in a homogeneous phase. After cooling, filter through a 300-mesh screen to obtain an organic vehicle.

[0021] The components of the silver paste were weighed according to the above proportions, mixed with ...

Embodiment 2

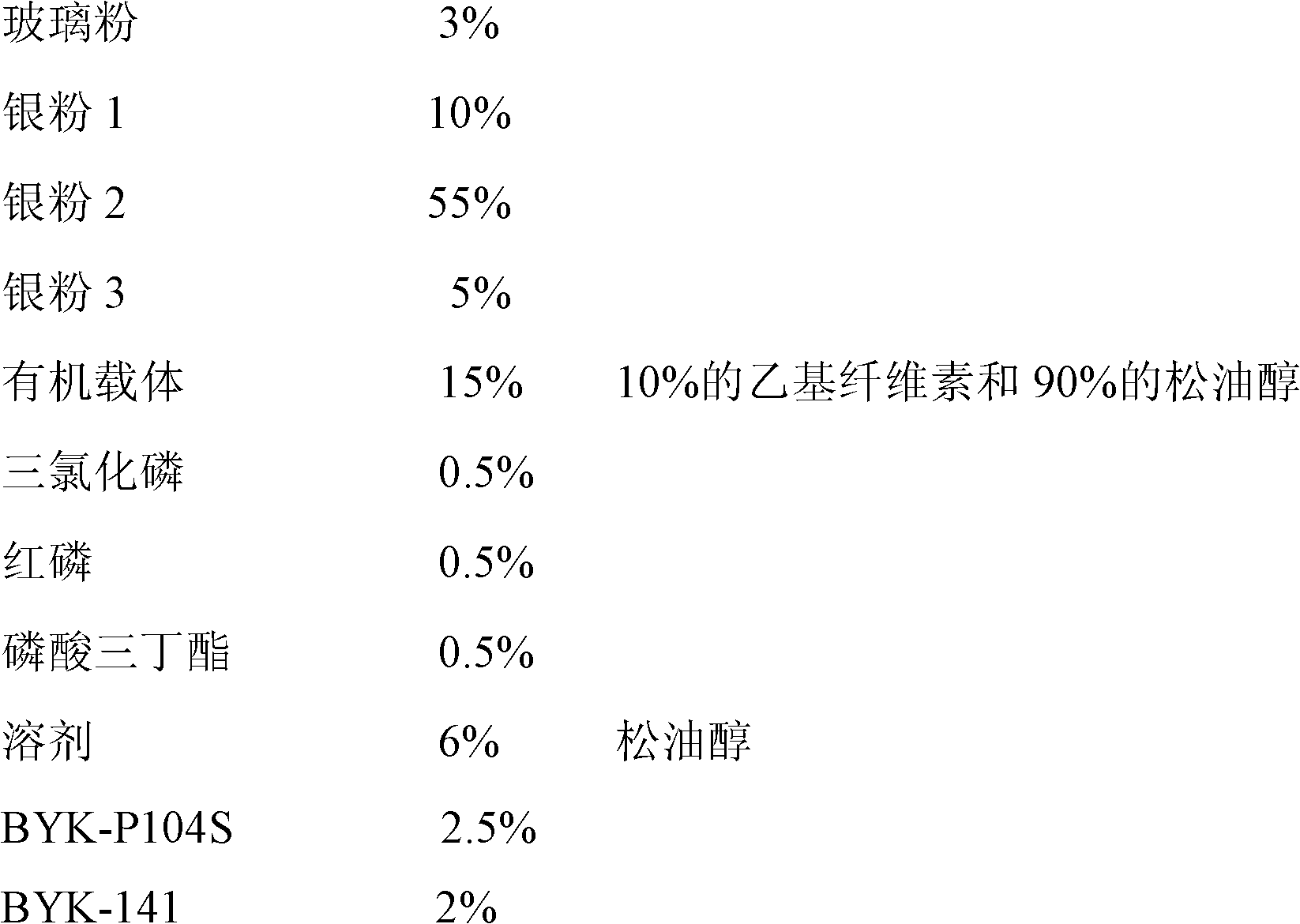

[0023] A front silver paste for silicon solar cells, composed of:

[0024]

[0025] The glass powder is Bi 2 o 3 -B 2 o 3 -ZnO system glass powder, the particle diameter of glass powder is 2-6 microns, the particle diameter of flake powder silver powder is 4-6 microns, the particle diameter of spherical silver powder is 2-4 microns, and the particle diameter of silver micropowder is 50-100 nanometers .

[0026] First prepare the organic carrier, put 10% ethyl cellulose and 90% terpineol into the reaction kettle, heat to 80°C in a water bath, and stir with an electric mixer at a stirring speed of 200 rpm. After that, the temperature was kept constant for 5 hours until the resin in the reactor was completely dissolved and each component was in a homogeneous phase. After cooling, filter through a 300-mesh screen to obtain an organic vehicle.

[0027] The components of the silver paste were weighed according to the proportions mentioned above, mixed with a defoaming mixer...

Embodiment 3

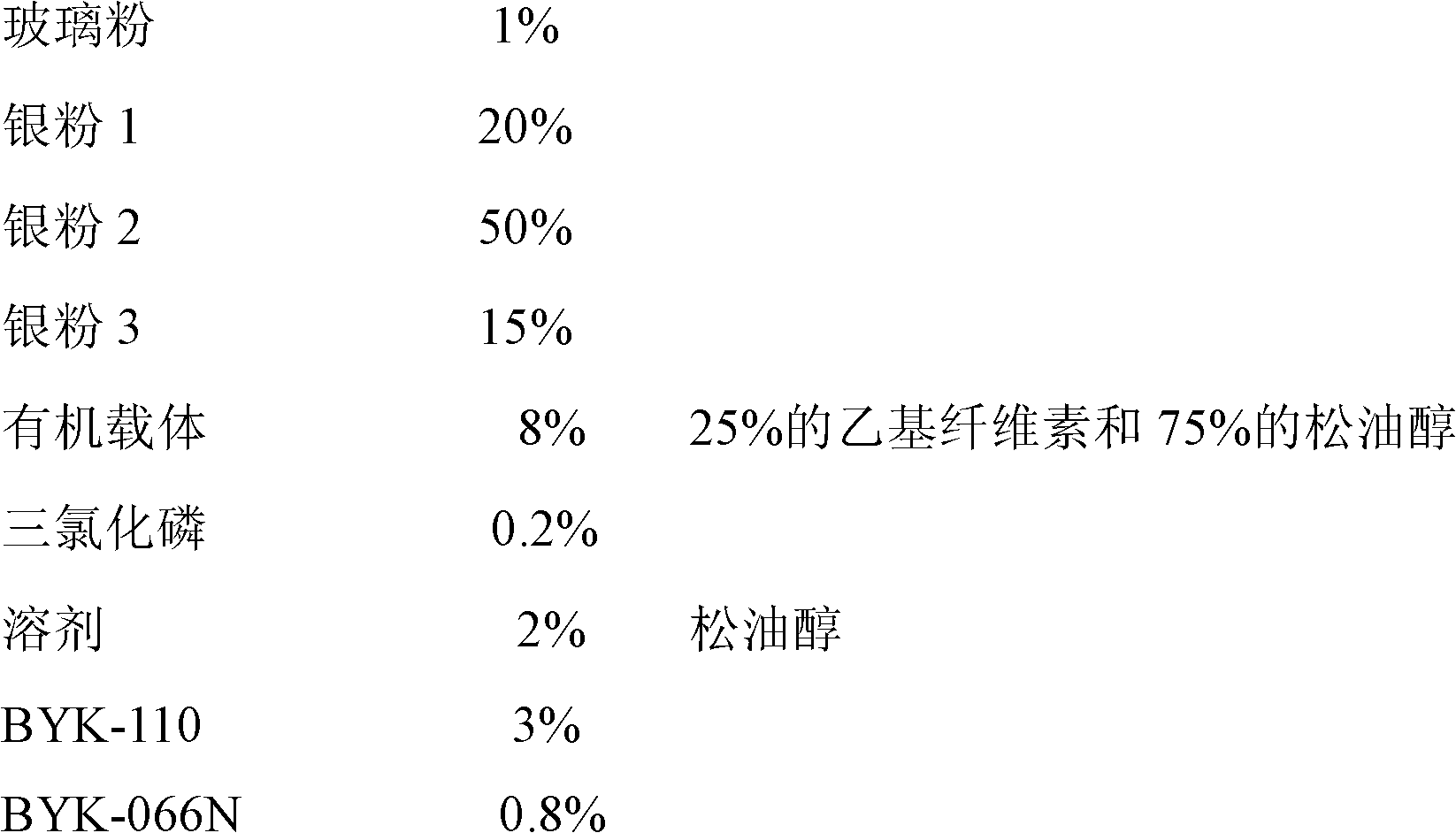

[0029] A front silver paste for silicon solar cells, composed of:

[0030]

[0031] The glass powder is Bi 2 o 3 -B 2 o 3 -ZnO system glass powder, the particle diameter of glass powder is 2-6 microns, the particle diameter of flake powder silver powder is 4-6 microns, the particle diameter of spherical silver powder is 2-4 microns, and the particle diameter of silver micropowder is 50-100 nanometers .

[0032] First prepare the organic carrier, put 25% ethyl cellulose and 75% terpineol into the reaction kettle, heat to 70°C with a water bath, and stir with an electric mixer at a stirring speed of 100 rpm. After that, the temperature was kept constant for 4 hours until the resin in the reactor was completely dissolved and each component was in a homogeneous phase. After cooling, filter through a 300-mesh screen to obtain an organic vehicle.

[0033] The components of the silver paste were weighed according to the above proportions, mixed with a defoaming mixer, rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com