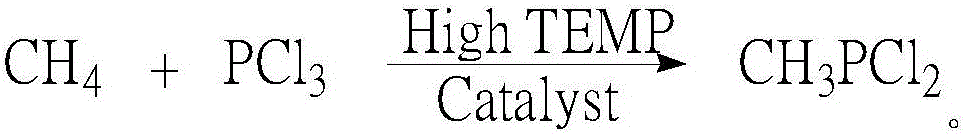

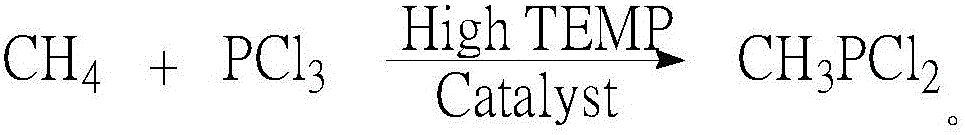

Green synthesis method of methyl phosphorus dichloride

A green synthesis technology of methyl phosphorus dichloride, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of difficult recycling of aluminum trichloride and large solvent consumption , complex solid waste and other issues, to achieve high yield, reduce separation steps, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

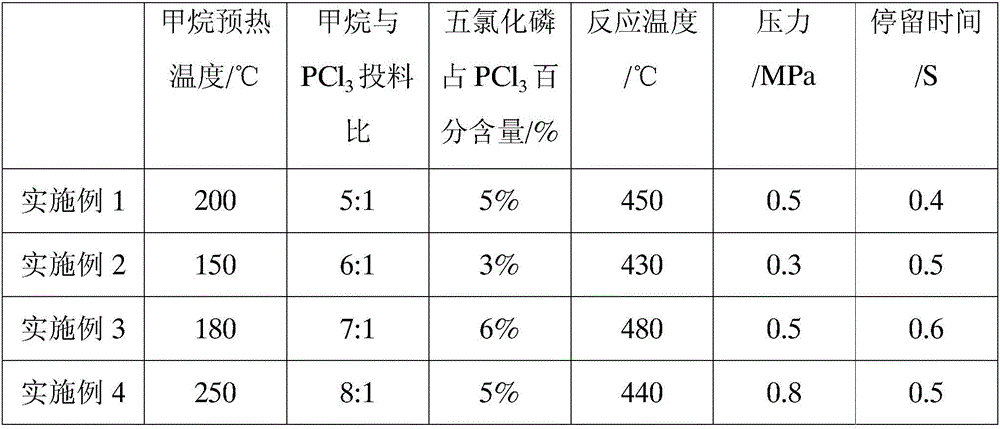

Embodiment 1

[0021] First, preheat methane to 200°C, then heat phosphorus trichloride and phosphorus pentachloride to form steam and fully mix with methane, methane and PCl 3 The feed ratio is 5:1, and the amount of phosphorus pentachloride accounts for PCl 3 5% of the percentage content, the mixed gas is uniformly passed into the tubular reactor, the reaction temperature is controlled at 450°C, the pressure is controlled at 0.5MPa, the residence time is 0.4s, the conversion rate of phosphorus trichloride is 45.0%, and the converted trichloride In terms of phosphorus chloride, the yield was 94.2%.

Embodiment 2

[0023] First preheat methane to 150°C, then heat phosphorus trichloride and phosphorus pentachloride into steam and fully mix with methane, methane and PCl 3 The feed ratio is 6:1, and the amount of phosphorus pentachloride accounts for PCl 3 3% of the percentage content, the mixed gas is uniformly passed into the tubular reactor, the reaction temperature is controlled at 430°C, the pressure is controlled at 0.3MPa, the residence time is 0.5s, the conversion rate of phosphorus trichloride is 49.7%, and the converted trichloride In terms of phosphorus chloride, the yield was 91.2%.

Embodiment 3

[0025] First preheat methane to 180°C, then heat phosphorus trichloride and phosphorus pentachloride to form steam and fully mix with methane, methane and PCl 3 The feed ratio is 7:1, and the amount of phosphorus pentachloride accounts for PCl 3 6% of the percentage content, the mixed gas is uniformly passed into the tubular reactor, the reaction temperature is controlled at 480 ° C, the pressure is controlled at 0.5 MPa, the residence time is 0.6s, the conversion rate of phosphorus trichloride is 41.4%, and the converted trichloride In terms of phosphorus chloride, the yield was 93.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com