Two-component polyurethane structural adhesive and preparation method thereof

A two-component polyurethane and structural adhesive technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of poor impact resistance of power battery protection materials and inability to achieve impact resistance , anti-vibration, harsh synthesis conditions and other issues, to achieve the effect of high strength, high bonding strength and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of two-component polyurethane structural adhesive comprises the following steps:

[0037] (1) Preparation of component A:

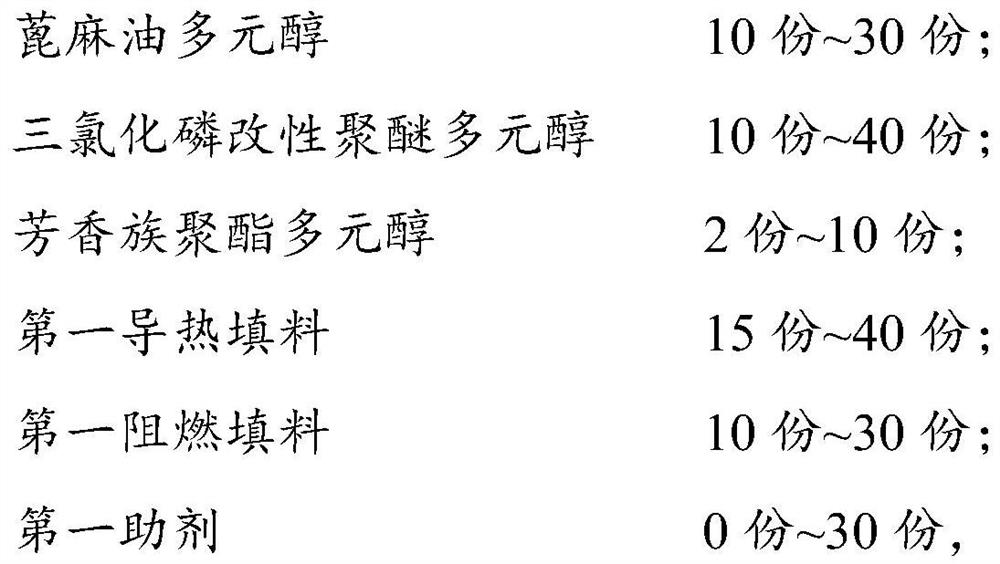

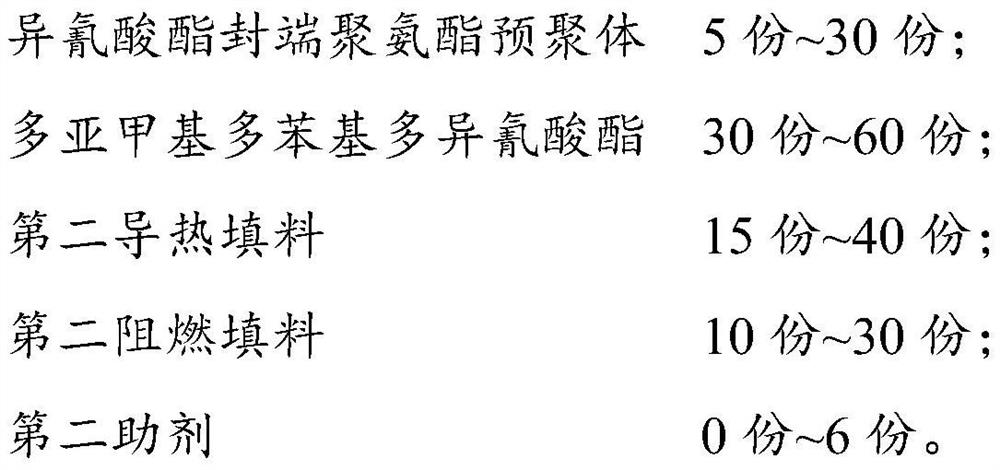

[0038] In parts by weight, the raw materials for the preparation of component A include the following components:

[0039]

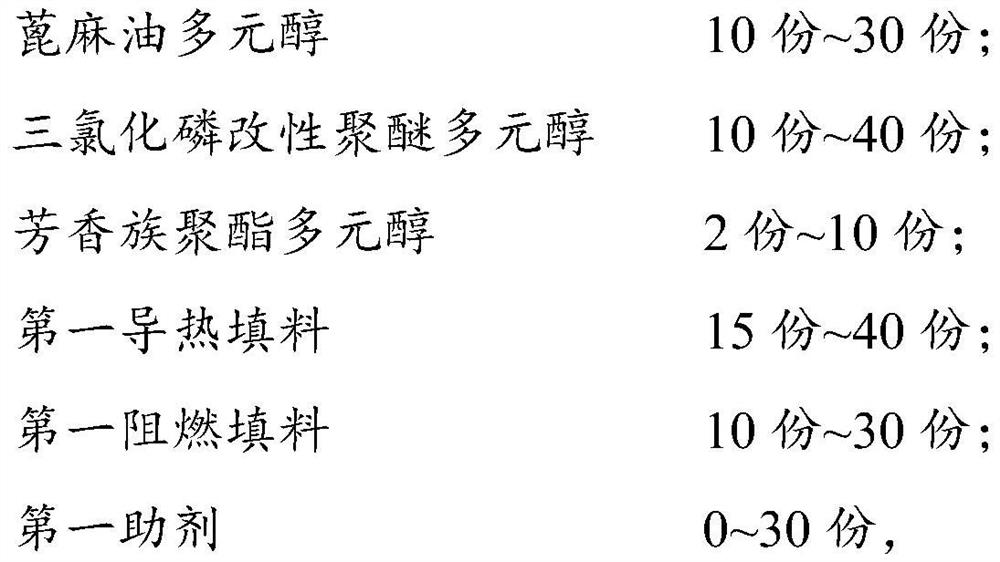

[0040] Wherein, the first auxiliary agent comprises the following components:

[0041]

[0042] Among them, the selected castor oil polyol has a molecular weight of 930, the phosphorus trichloride modified polyether polyol uses tris(dipropylene glycol) phosphite, and the aromatic polyester polyol is PS-1752 with a molecular weight of 600. The first heat-conducting filler is flaky magnesium oxide with a length of 5 μm and a width of 2 μm, the first flame-retardant filler is 5 parts of aluminum hydroxide particles and 5 parts of melamine uric acid ester passed through a 200 mesh sieve, and the thixotropic agent in the first auxiliary agent is gas phase White carbon black, dewatering agent is 3A mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com