Method utilizing micro-channel to prepare tris(2-chloroethyl)phosphite

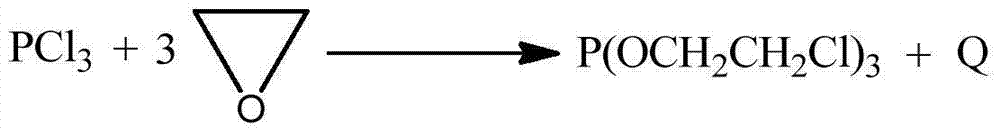

A technology of phosphite and chloroethyl, which is applied in the field of preparation of tri-phosphite, can solve problems such as low production efficiency, instability, and limited heat exchange area, and achieve air isolation, avoid oxidation and hydrolysis, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

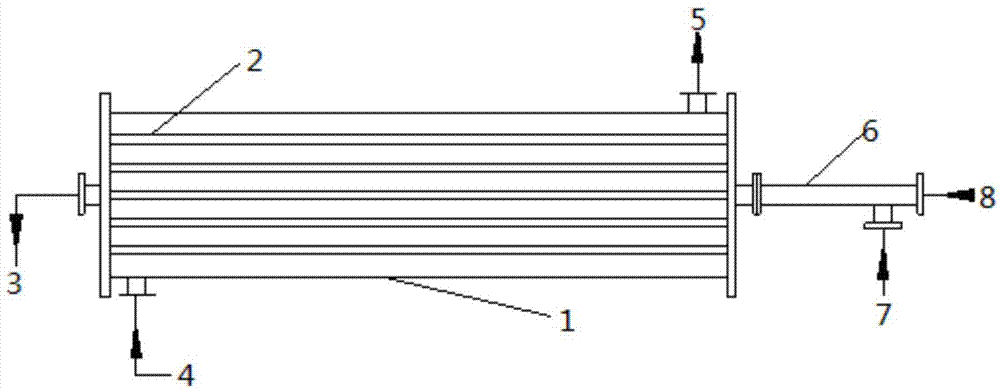

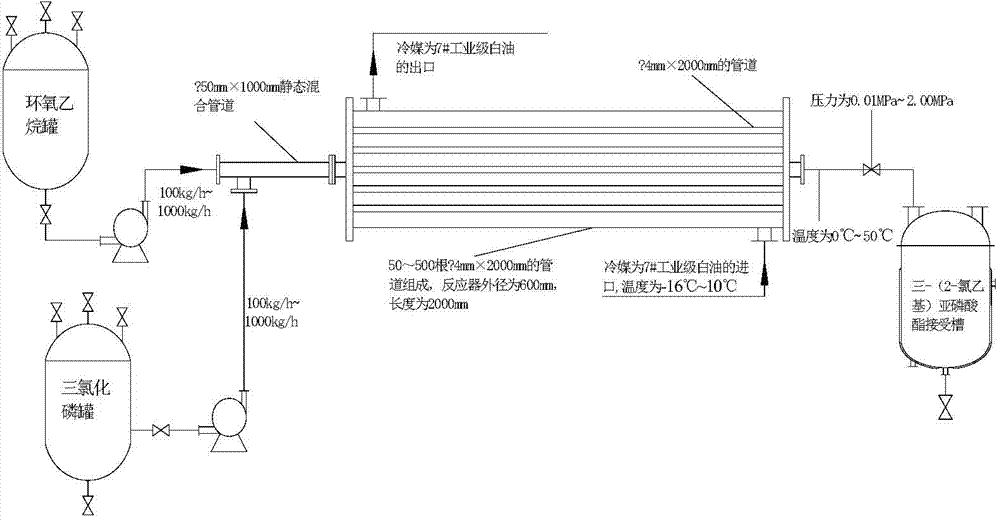

[0026] The microchannel reaction device is a two-level series (that is, two groups of microchannel reactors are connected in series), and each stage of microchannel reactors consists of 200 Composed of pipes, the outer diameter of the reactor is 600mm, and the length is 2000mm;

[0027] Phosphorus trichloride and ethylene oxide are pumped continuously into the pipeline premixer (by In static mixing pipeline composition), the mass flow rate of phosphorus trichloride is controlled to be 100kg / h, and the mass flow rate of ethylene oxide is 100kg / h; Enter the microchannel reaction device in two series series, carry out exothermic reaction in the microchannel reaction device, and open the refrigerant cooling equipment (refrigerant is 7# industrial grade white oil) coupled to the microchannel reactor at the same time for cooling, and the temperature of the refrigerant is - 16 ~ 10 ℃, control (adjusted by the outlet of the back pressure valve in the last section of the microchanne...

Embodiment 2

[0029] The microchannel reactor is a four-level series (that is, four groups of microchannel reactors are connected in series), and each level of microchannel reactor consists of 250 The pipe is composed of a reactor with an outer diameter of 600mm and a length of 2000mm.

[0030] Phosphorus trichloride and ethylene oxide are pumped continuously into the pipeline premixer (by Static mixing pipeline composition), control the mass flow of phosphorus trichloride to be 300kg / h, and the mass flow of ethylene oxide to be 300kg / h. The mixture of phosphorus trichloride and ethylene oxide pre-mixed by the pipeline mixer enters the four-stage series microchannel reactor, and the exothermic reaction is carried out in the microchannel reactor, and the coupling with the microchannel reaction system is opened at the same time. Refrigerant cooling equipment (refrigerant is 7# industrial grade white oil) for cooling, the temperature of the refrigerant is -16 ~ 10 ℃, and the temperature of th...

Embodiment 3

[0032] The microchannel reactors are six stages in series (that is, six groups of microchannel reactors are connected in series), and each stage of microchannel reactors consists of 300 The pipe is composed of a reactor with an outer diameter of 600mm and a length of 2000mm.

[0033] Phosphorus trichloride and ethylene oxide are pumped continuously into the pipeline premixer (by Static mixing pipeline composition), control the mass flow of phosphorus trichloride to be 500kg / h, and the mass flow of ethylene oxide to be 500kg / h. The mixed solution of phosphorus trichloride and ethylene oxide pre-mixed by the pipeline mixer enters the six-stage series microchannel reaction device, and the exothermic reaction is carried out in the microchannel reaction device, and the coupling with the microchannel reactor is opened at the same time. Refrigerant cooling equipment (refrigerant is 7# industrial grade white oil) for cooling, the temperature of the refrigerant is -16 ~ 10 ℃, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com