Synthesizing method for preparing N-acryloyl morpholine

A technique for the synthesis of acryloylmorpholine and its synthesis method, which is applied in the field of synthesis of high-purity N-acryloylmorpholine, and can solve the problems that acryloylmorpholine is prone to thermal polymerization, thermal cracking reaction is difficult to control, and raw materials are difficult to obtain, etc. Achieve the effects of low cost, easy control, and less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

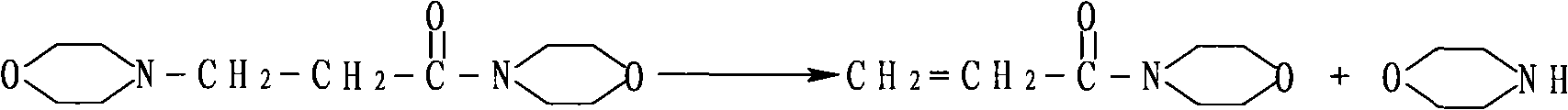

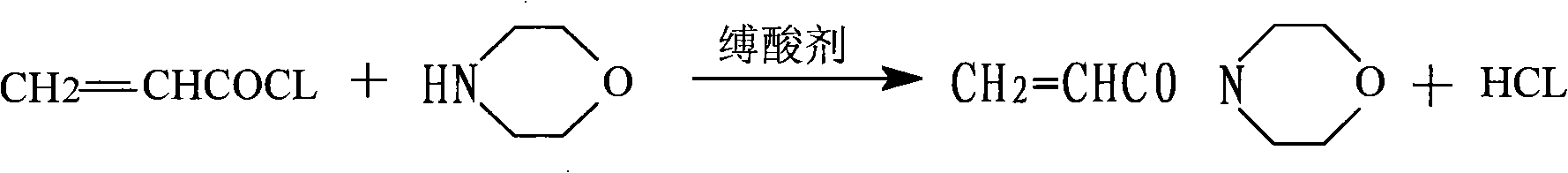

Method used

Image

Examples

Embodiment 1

[0030] Add 134 grams of acrylic acid to a 500ml reactor equipped with paddle stirring and a constant temperature water bath, start stirring, control the stirring speed at 80 rpm, raise the temperature to 30-35°C, and then use a constant pressure funnel to drop it within 0.5-1 hour. Add 86 grams of phosphorus trichloride (mass content 95%), the temperature will rise slowly during the dropping process, and the dropping rate is controlled so that the temperature during the dropping process does not exceed 45°C. After the dropwise addition, keep at 40-45°C for 3 hours. Separate the supernatant, then carry out rectification with a rectification tower, and the intermediate product acryloyl chloride is directly collected in a carbon tetrachloride constant pressure funnel equipped with 200 grams of solvent for subsequent use.

[0031] Add 121 grams of morpholine and 90 grams of solid powder of sodium carbonate, an acid-binding agent, into a 1L reaction kettle with a low-temperature wa...

Embodiment 2

[0033] Intermediate product solvated acryloyl chloride is prepared with embodiment 1

[0034] Add 121 grams of morpholine and 125 grams of acid-binding agent tripropylamine into a 1L reaction kettle with a low-temperature water bath in sequence, and the reaction kettle is emptied and equipped with a tail gas absorption device. Start the agitator, control the stirring speed at 100 rev / min, cool down to 0°C, then add the solvated acryloyl chloride dropwise through the constant pressure funnel, the dropwise addition is completed in 3 to 3.5 hours, and keep for another 3 hours; the temperature is controlled throughout the reaction process Between 0 and 5°C, then filter the supernatant. The supernatant after filtering is added to rectifying in the rectification under vacuum tower that 0.5 gram composite polymerization inhibitor (parahydroxyanisole 25%; Hydroquinone 25%; Cuprous chloride 50%) is housed, finally 124.7 g of N-acryloylmorpholine product with color number No. 20 (plati...

Embodiment 3

[0036] Add 335 grams of acrylic acid to a 1L reaction kettle equipped with paddle stirring and a constant temperature water bath, start stirring, control the stirring speed at 80 rpm, raise the temperature to 30-35°C, and then use a constant pressure funnel to drop it within 0.5-1 hour Add 215 grams of phosphorus trichloride (mass content 95%), the temperature will rise slowly during the dropping process, and the dropping rate is controlled so that the temperature during the dropping process does not exceed 45°C. After the dropwise addition, keep at 40-45°C for 3 hours. Separate the supernatant, and then carry out rectification with a rectification tower, and the intermediate product acryloyl chloride is directly collected in a trichloromethane constant pressure funnel equipped with 450 grams of solvent for subsequent use.

[0037] Add 302 grams of morpholine and 350 grams of acid-binding agent sodium bicarbonate solid powder into a 2L reactor with a low-temperature water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com