Castor oil-based flame retardation polyol composition, and preparation method and applications thereof

A flame-retardant polyol, castor oil-based technology, applied in the field of castor oil-based flame-retardant polyol composition, can solve the problems of reduced flame-retardant durability, large addition amount, and poor flame-retardant performance, and achieve high resistance Combustibility, low cost, and abundant output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

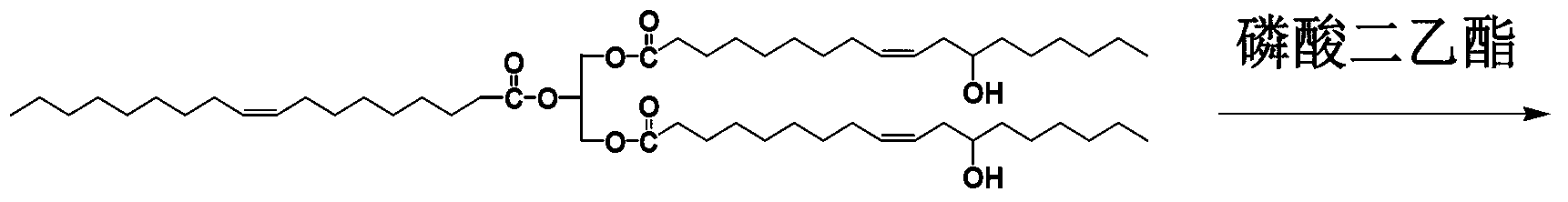

[0042] Step 1: Mix 40-50 parts by mass of castor oil, 10-15 parts by mass of glycerin, and 0.3-0.4 parts by mass of catalyst evenly, heat up to a temperature of 190-220° C., and react for 2-4 hours. The quality of castor oil can choose 40 parts, 42 parts, 44 parts, 46 parts, 48 parts, 50 parts, the quality of glycerin can choose 10 parts, 11 parts, 12 parts, 13 parts, 14 parts, 15 parts, and the catalyst can be selected 0.3 parts, 0.32 parts, 0.34 parts, 0.36 parts, 0.38 parts, 0.4 parts, the temperature can be selected from 190°C, 200°C, 210°C, 220°C, and the reaction time can be selected from 2h, 2.5h, 3h, 3.5h, 4h.

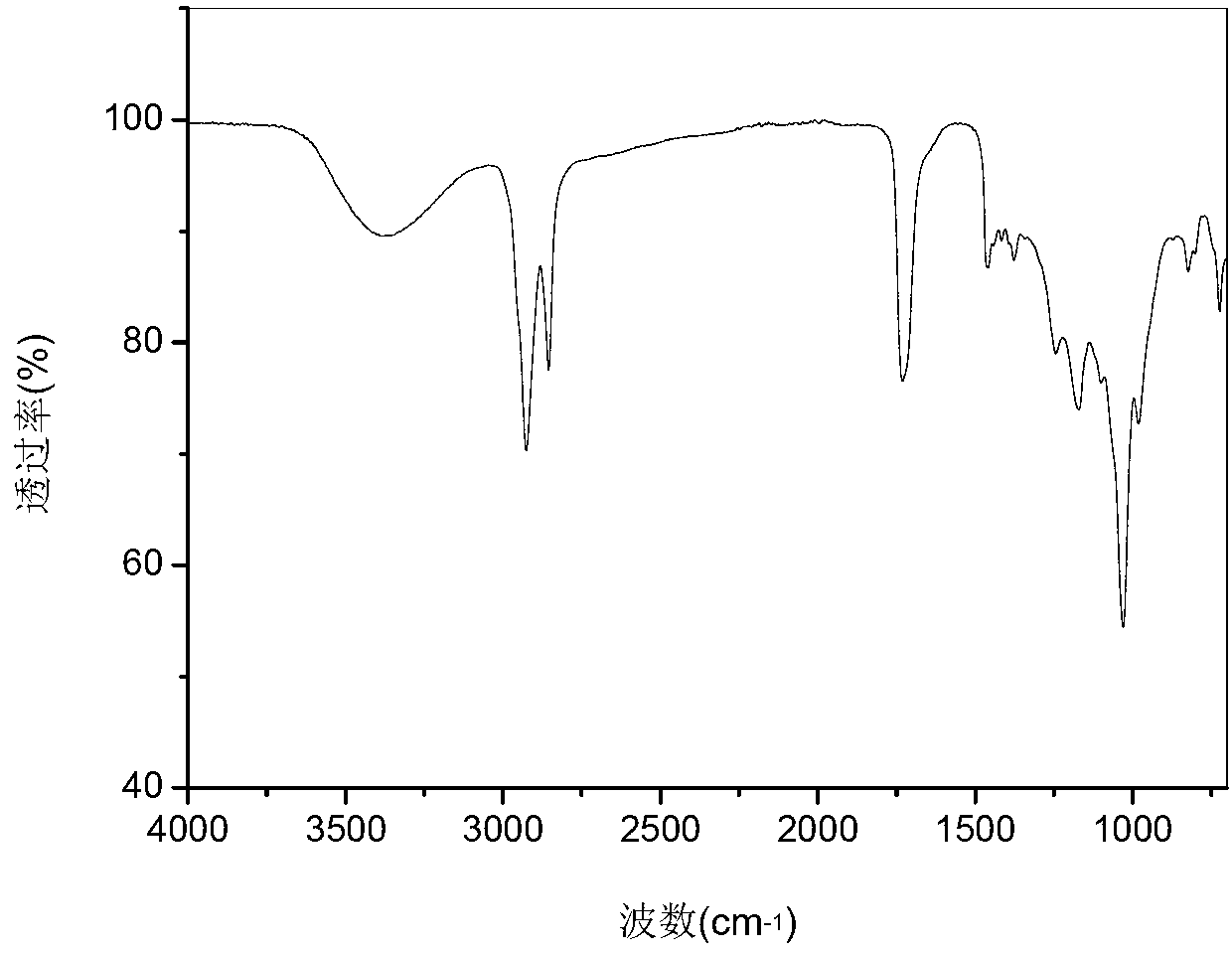

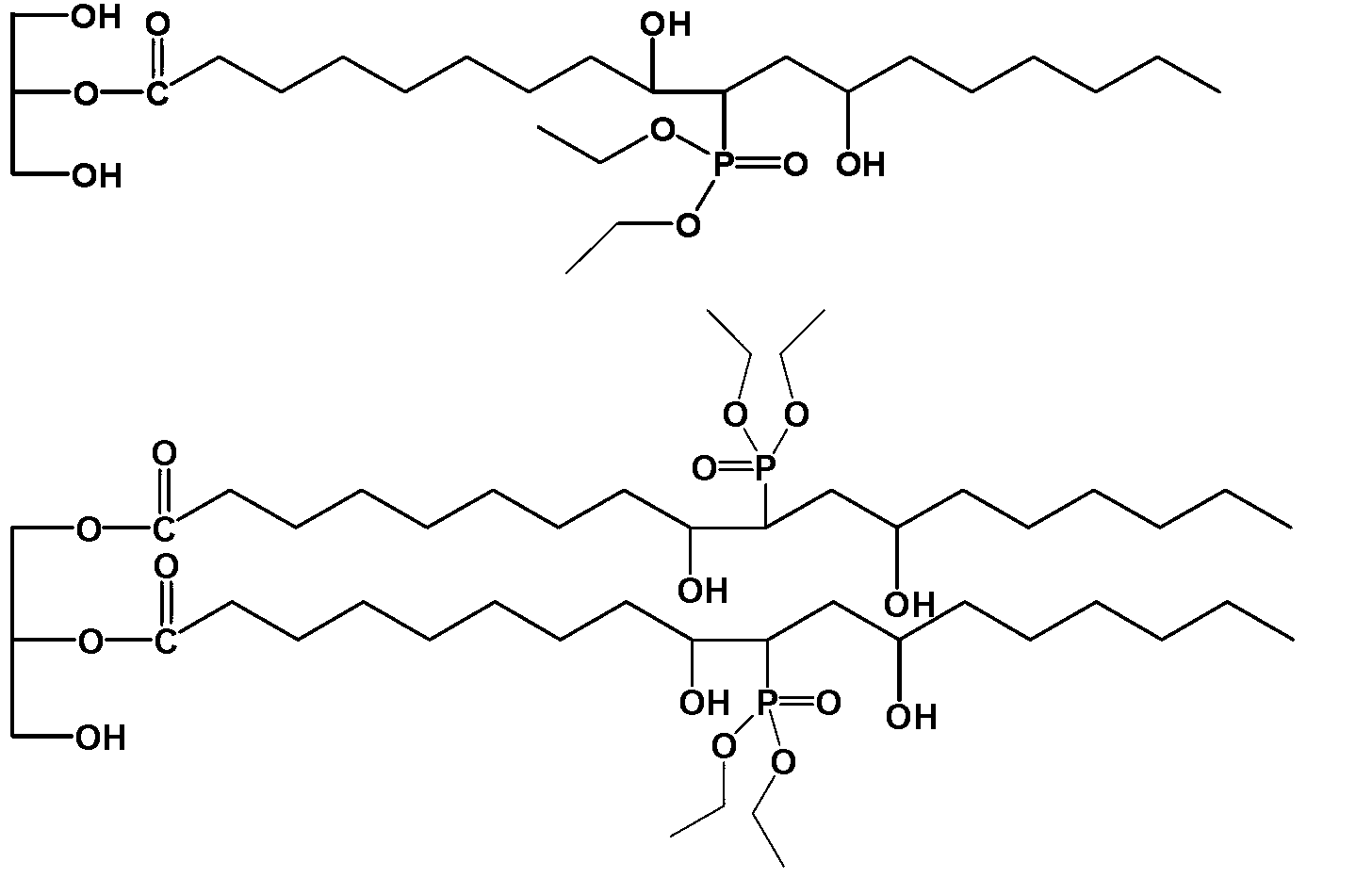

[0043]Step 2: Mix 20-30 parts by mass of raw materials obtained in step 1, 1.5-2 parts by mass of formic acid, 10-15 parts by mass of hydrogen peroxide, and 0.05-1 part by mass of phosphoric acid, and react at 50-60°C for 3 ~6h. The mass parts of alcoholyzed castor oil obtained in step 1 can be selected from 20 parts, 20.2 parts, 20.4 parts, 20.6 parts, 20.8...

Embodiment 2

[0046] Weigh 50 parts of castor oil, 10 parts of glycerin, 0.3 parts of a mixture of sodium methoxide and triethanolamine, stir evenly, and react at 200° C. for 3 hours to obtain a transparent light yellow castor oil polyol. Then weigh 20 parts of castor oil polyol, add 1.5 parts of formic acid, 14 parts of hydrogen peroxide, and 0.05 parts of phosphoric acid, and react at 50° C. for 3 hours. Wash with water and ethyl acetate until pH = 5, then wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C to obtain white viscous liquid epoxy alcoholylated castor oil. Weigh 20 parts of epoxy alcoholylated castor oil, 8 parts of diethyl phosphate, 0.1 part of triphenylphosphine, and 10 parts of toluene, react at 70°C for 4 hours, then wash with water and ethyl acetate until pH = 5, and then use Wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C. A castor oil-based flame-retardant polyol composi...

Embodiment 3

[0048] Weigh 50 parts of castor oil, 11 parts of glycerin, 0.3 parts of a mixture of sodium methoxide and triethanolamine, stir evenly, and react at 200° C. for 3 hours to obtain a transparent light yellow castor oil polyol. Then weigh 20 parts of castor oil polyol, add 1.5 parts of formic acid, 15 parts of hydrogen peroxide, and 0.05 parts of phosphoric acid, and react at 50° C. for 3 hours. Wash with water and ethyl acetate until pH = 5, then wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C to obtain white viscous liquid epoxy alcoholylated castor oil. Weigh 20 parts of epoxy alcoholylated castor oil, 8 parts of diethyl phosphate, 0.1 part of triphenylphosphine, and 10 parts of toluene, react at 70°C for 4 hours, then wash with water and ethyl acetate until pH = 5, and then use Wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C. A castor oil-based flame-retardant polyol composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com