Cardanol-based phosphatefire-retardant plasticizer and preparation method thereof

A technology of cardanol-based phosphate and cardanol-based diethyl phosphate, applied in the field of preparation of environmentally friendly bio-based flame-retardant plasticizers, to achieve the effects of reducing production costs, shortening reaction time, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

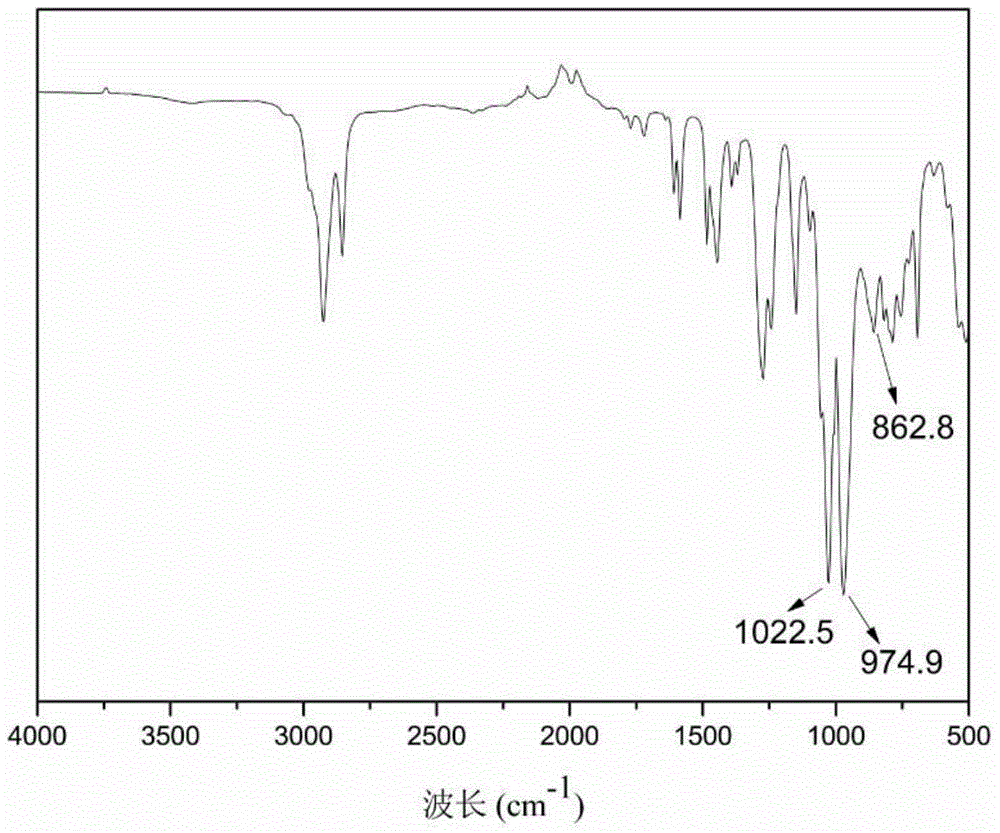

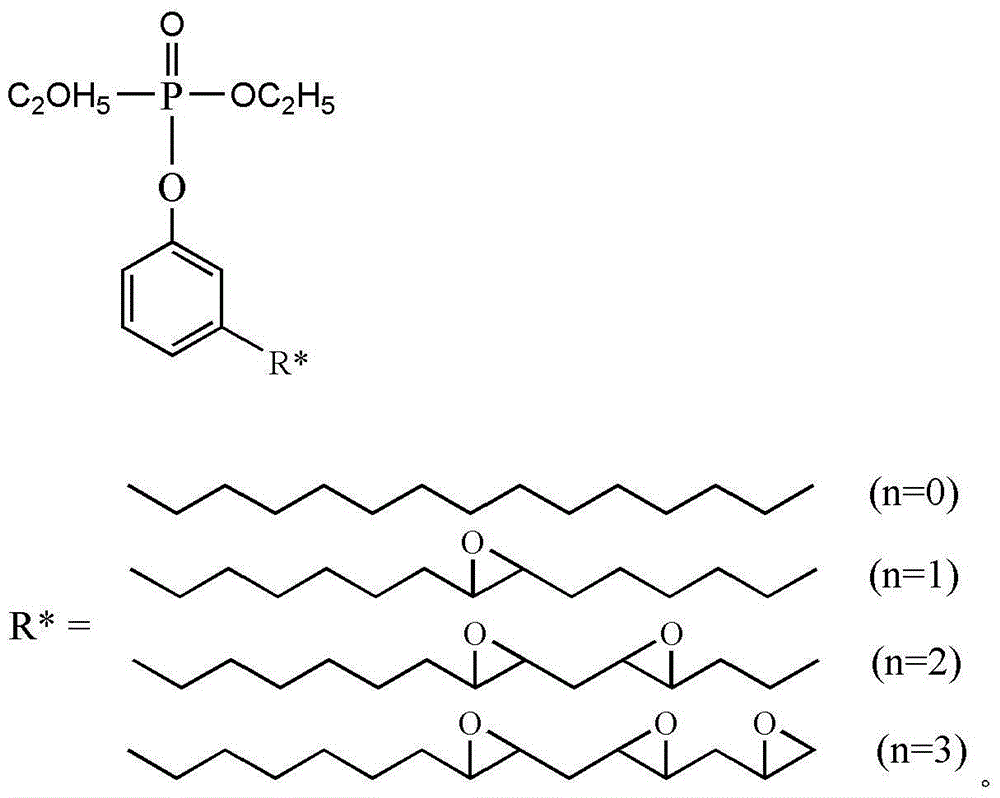

[0026] A preparation method of cardanol-based phosphate flame-retardant plasticizer, the steps are:

[0027] Step 1: Take 10-20g of cardanol, 6-8g of diethyl chlorophosphate, and 1.2-2.5g of acid-binding agent, add them to 20-40mL of solvent, mix and stir to heat up to 60-80°C, and react for 2-4 hours; Filtration and vacuum distillation treatment to obtain cardanyl phenolic diethyl phosphate; Step 2: Weigh 5 to 10 g cardanyl phenolic diethyl phosphate, peroxyphosphotungstate phase transfer catalyst (accounting for cardanyl phenolic diethyl phosphate 2% to 5% of the mass), stir evenly with 10 to 30mL solvent, heat the reaction system to 40 to 50°C, add a peroxygen source dropwise, and react at 55 to 70°C for 0.5 to 3 hours to obtain epoxy cardanyl diethyl phosphate The crude ester is filtered, washed and dehydrated to obtain the finished epoxy cardanol-based diethyl phosphate plasticizer.

[0028] The acid-binding agent is one or two or more of sodium hydroxide, potassium carb...

Embodiment 1

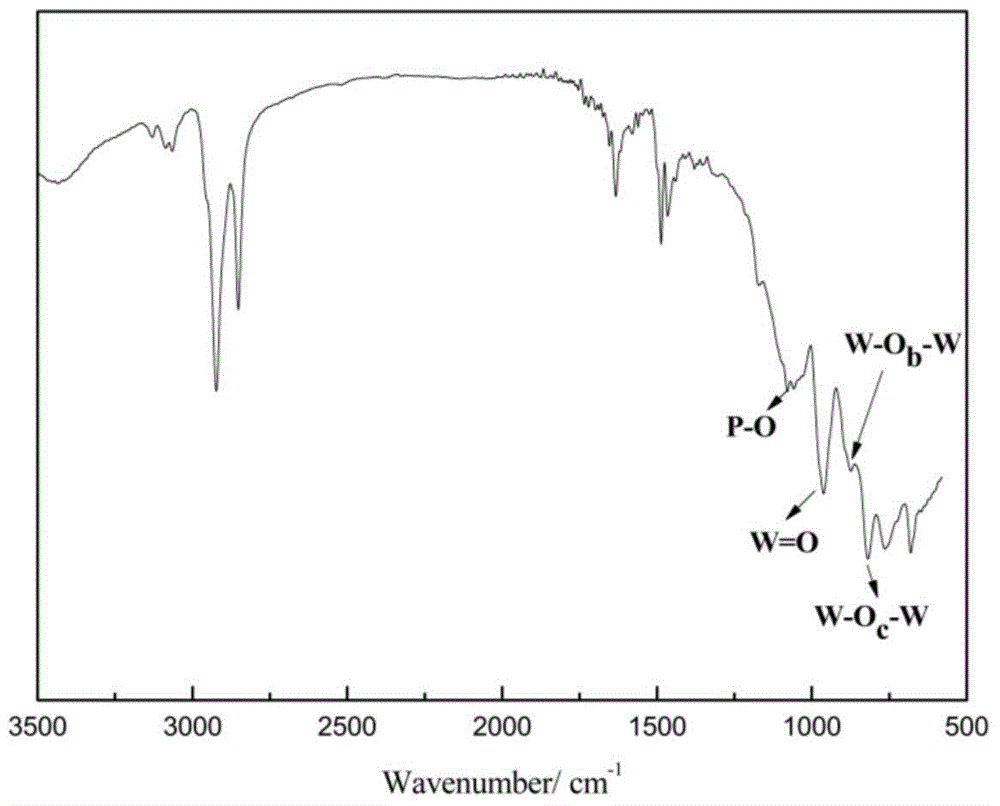

[0036] Put 2.5mmol tungstic acid in a 50mL beaker, add 20mmol H 2 o 2, stirred vigorously until the pale yellow precipitate disappeared, added 1.5mmol phosphoric acid (89% concentration) dropwise, and 5mL distilled water, raised the temperature to 60°C, and stirred for 30min to obtain a colorless and transparent solution; Dissolve methyl ammonium chloride in 20mL ethyl acetate, mix and add dropwise to the above solution, drop it within 5min, a small amount of light yellow precipitate appears, continue stirring for about 30min, until the phase of docosyl peroxyphosphotungstate The transfer catalyst polymerized and precipitated at the oil-water two-phase interface; the catalyst was taken out by filtration, rinsed with deionized water until the washing liquid was neutral, placed in a vacuum drying oven, fully dried and ground at room temperature.

Embodiment 2

[0038] Put 2mmol tungstic acid in a 50mL beaker, add 15mmol H 2 o 2 , stirred vigorously until the light yellow precipitate disappeared, then added dropwise 0.5mmol phosphoric acid (89% concentration) and 2mL distilled water, raised the temperature to 60°C, and stirred for 30min to obtain a colorless and transparent solution; take 1mmol octadecyldimethyl Dissolve ammonium chloride in 15mL of dichloromethane, mix and add dropwise to the above solution, within 5 minutes, a small amount of light yellow precipitate appears, continue to stir for about 30 minutes, until the octadecyl peroxyphosphotungstate phase transfer catalyst is in the Polymerization and precipitation occurred at the oil-water two-phase interface; the catalyst was taken out by filtration, washed with deionized water until the washing liquid was neutral, the catalyst was placed in a vacuum drying oven, fully dried and ground at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com