Separation method of difficult separation system containing triethylamine

A separation method and technology of triethylamine, applied in chemical instruments and methods, purification/separation of amino compounds, preparation of organic compounds, etc., can solve the difficulty of recycling triethylamine and isopropanol and the difficulty of selecting extraction agents , product purity is difficult to guarantee and other issues, to achieve the effect of limited evaporation, saving investment costs, and controllable energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

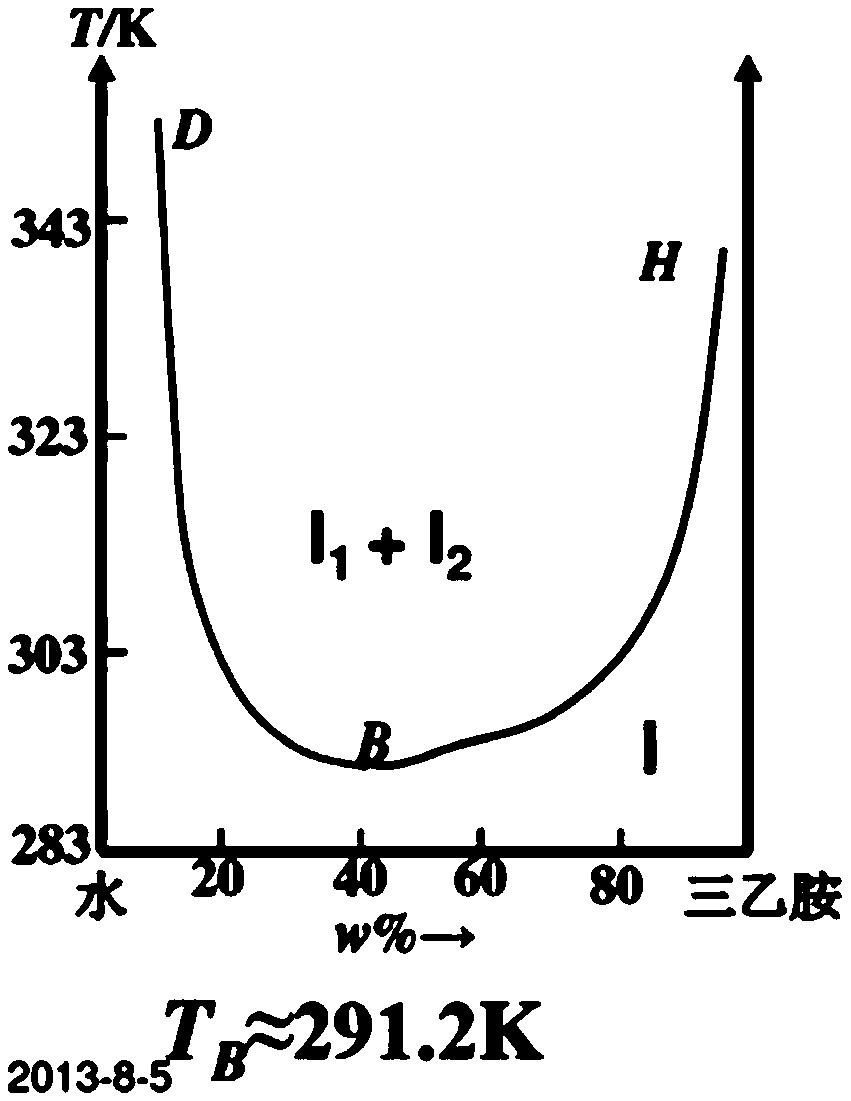

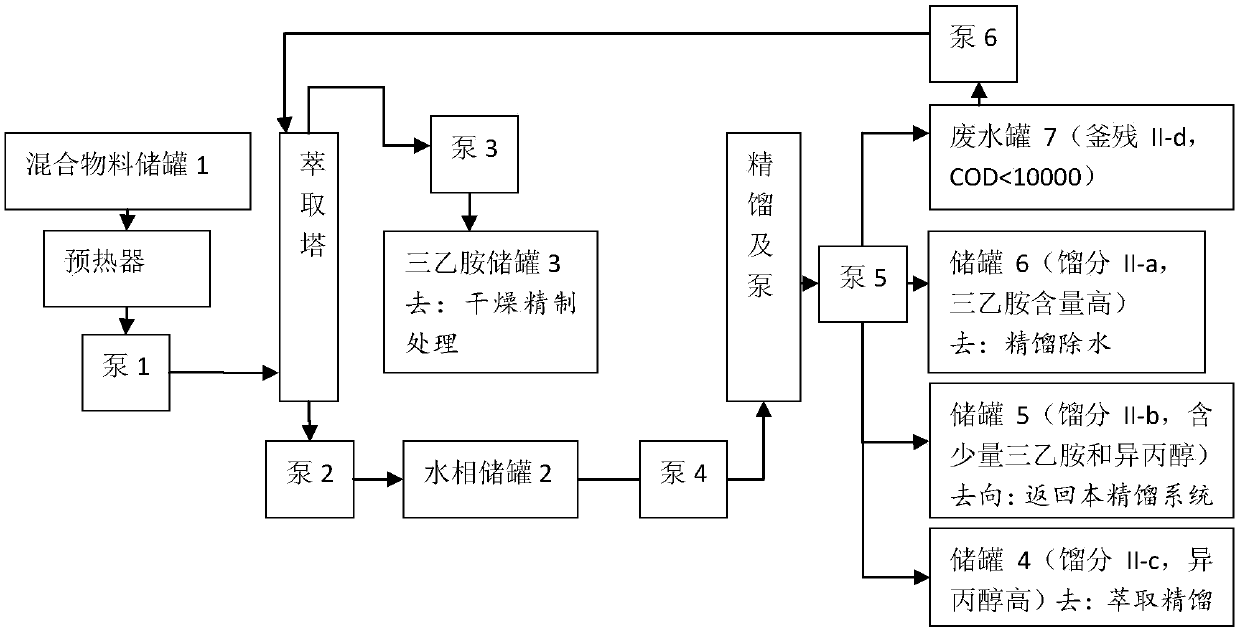

Method used

Image

Examples

Embodiment 1

[0038]In this embodiment, water is used as the extractant (containing 0.02% caustic soda), and continuous extraction is used to separate triethylamine and isopropanol. The mass composition of triethylamine-isopropanol mixture (raw material liquid) is triethylamine 45%, isopropanol 50%, water 5%, and raw material liquid is sent into the bottom of continuous rotary disk extraction tower with the speed of 1kg / hour, and extractant water At a rate of 6kg / hour, it is sent to the top of the rotary disk extraction tower, and the operating temperature of the rotary disk extraction tower is 50-60°C. After continuous extraction, the extract phase is obtained at the top of the rotary disk extraction tower, and its content is 97% of triethylamine, 2.5% of water, and 0.5% of isopropanol; the heavy phase at the bottom is the raffinate phase, and its composition is 88% of water, isopropanol 8-10%, triethylamine 2-4%.

Embodiment 2

[0040] In this embodiment, water is used as the extractant (remove the salt or alkali), the extraction temperature is 60° C., and triethylamine and isopropanol are separated by a three-stage batch extraction process. The mass composition is 45% of triethylamine, 50% of isopropanol, 200g of triethylamine-isopropanol mixture (raw material solution) of 5% of water is added in a 1L Erlenmeyer flask, 400g of water is added, fully shaken and mixed, and allowed to stand 30min; separate the upper extract phase, add 400g water for a second extraction, mix well and let stand for 30min; continue to separate the upper extract phase, and repeat the extraction operation again. After three stages of intermittent extraction, the composition of the extraction phase is 96% of triethylamine, 3% of water and 1.0% of isopropanol. The raffinate phases obtained by the three-stage extraction were mixed to obtain a raffinate phase to be treated, which was composed of 88% water, 9% isopropanol and 3% t...

Embodiment 3

[0042] The heavy phase (about 88% of water, 8-10% of isopropanol, 3-4% of triethylamine) obtained by continuous extraction of embodiment 2 can separate triethylamine, isopropanol and triethylamine in water by simple rectification (distillation) distillation propanol. This unit obtains four stocks of materials: a) triethylamine containing a small amount of isopropanol and water (87% of triethylamine, 10% of water, 3% of isopropanol), removed from the triethylamine refining unit; b) containing a small amount of triethylamine , the mixed material of water and isopropanol (triethylamine 15%, water 30%, isopropanol 55%), return the fine (distillation) distillation of this section; c) the mixture of isopropanol and water (isopropanol 89% %, water 11%), sent to isopropanol refining for further processing; d) the residue in the tower kettle, the recovery of extractant water, can be sent to the continuous extraction unit for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com