A process and system for preparing propylene oxide by direct oxidation of propylene with oxygen and hydrogen

A technology of propylene oxide and propylene oxide, which is applied in the field of process and system, can solve the problems of incomplete treatment of impurities, large environmental pollution, high energy consumption of the system, and achieve the effects of easy retention time, low equipment investment, and simple equipment form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

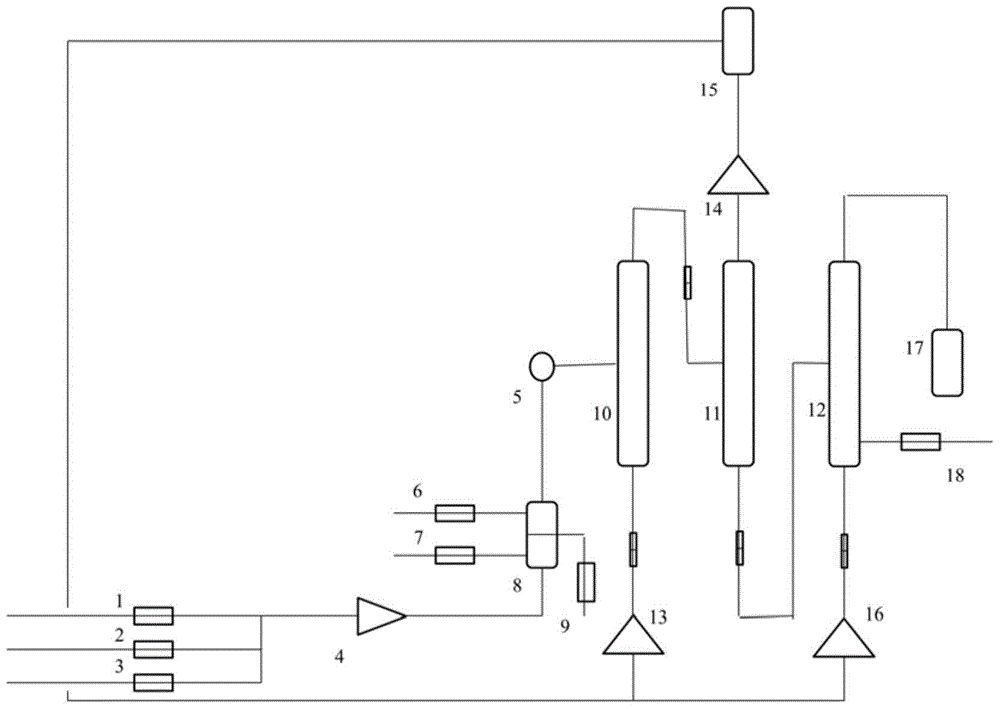

[0039] (1) Add propylene, recycled propylene, and dialkyl sulfide to a mixed solvent in which the ratio of methanol and hydrazine hydrate is 10:2, mix in mixer 4, and then mix it in a mixture containing palladium catalyst and TS-1 titanium silicon Oxidation reaction is carried out in the reactor 8 of salt molecular sieve, the ratio of hydrogen and oxygen is 1:2, the reaction pressure is 0.5MPa, and the reaction temperature is 50°C. Finally, a crude product of propylene oxide is produced.

[0040](2) After the reaction product is cooled, it is pumped into the crude fractionation tower 10, the pressure at the top of the crude fractionation tower is 0.15 MPa, and the temperature of the bottom of the tower is controlled at 120°C. Remove organic sulfides and high-boiling by-products, and enter the crude component recovery tower 13 from the bottom of the tower after separation of organic sulfides and high-boiling by-products.

[0041] (3) The remaining propylene and propylene oxide...

Embodiment 2

[0044] (1) Add propylene, circulating propylene, and dialkyl sulfide to a mixed solvent in which the ratio of methanol and hydrazine hydrate is 5:1, mix in mixer 4, and then add ruthenium catalyst and TS-1 titanium silicon Oxidation reaction is carried out in the reactor 8 of salt molecular sieve, the ratio of hydrogen and oxygen is 1:1, the reaction pressure is 3MPa, and the reaction temperature is 30°C. Finally, a crude product of propylene oxide is produced.

[0045] (2) After the reaction product is cooled, it is pumped into the crude fractionation tower 10, the pressure at the top of the crude fractionation tower is 0.05 MPa, and the temperature of the bottom of the tower is controlled at 110°C. The organic sulfides and high-boiling by-products are removed. After the organic sulfides and high-boiling by-products are separated, they enter the crude component recovery tower 13 from the bottom of the tower.

[0046] (3) The remaining propylene and propylene oxide mixture en...

Embodiment 3

[0049] (1) Add propylene, recycled propylene, and dialkyl sulfide to a mixed solvent with a ratio of 15:5 of methanol and hydrazine hydrate, mix in mixer 4, and then add gold catalyst and Ti-MWW titanium silicon The oxidation reaction is carried out in the reactor 8 of acid salt molecular sieve, the ratio of hydrogen and oxygen is 50:1, the reaction pressure is 1MPa, and the reaction temperature is 80°C. Finally, a crude product of propylene oxide is produced.

[0050] (2) After the reaction product is cooled, it is pumped into the crude fractionation tower 10, the pressure at the top of the crude fractionation tower is 0.2 MPa, and the temperature of the bottom of the tower is controlled at 130°C. Remove organic sulfides and high-boiling by-products, and enter the crude component recovery tower 13 from the bottom of the tower after the organic sulfides and high-boiling by-products are separated.

[0051] (3) The remaining propylene and propylene oxide mixture enters the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com