Method for disproportionation and transalkylation of toluene and heavy aromatic hydrocarbon

A disproportionation alkylation and alkylation transfer technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problem of low processing capacity of polycyclic aromatic hydrocarbons, improve processing capacity, reduce energy consumption for separation, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

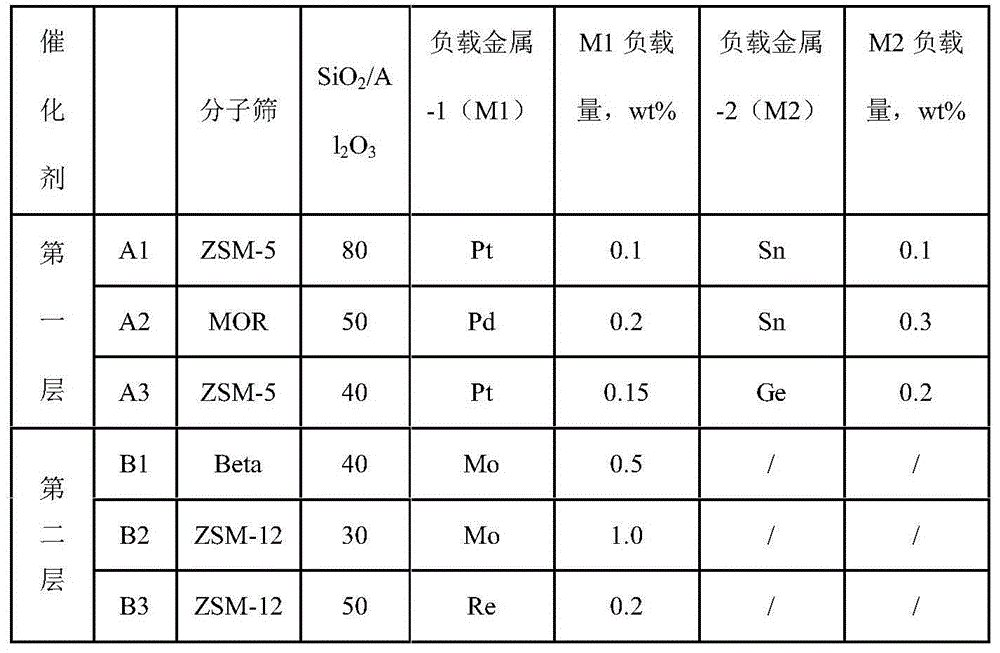

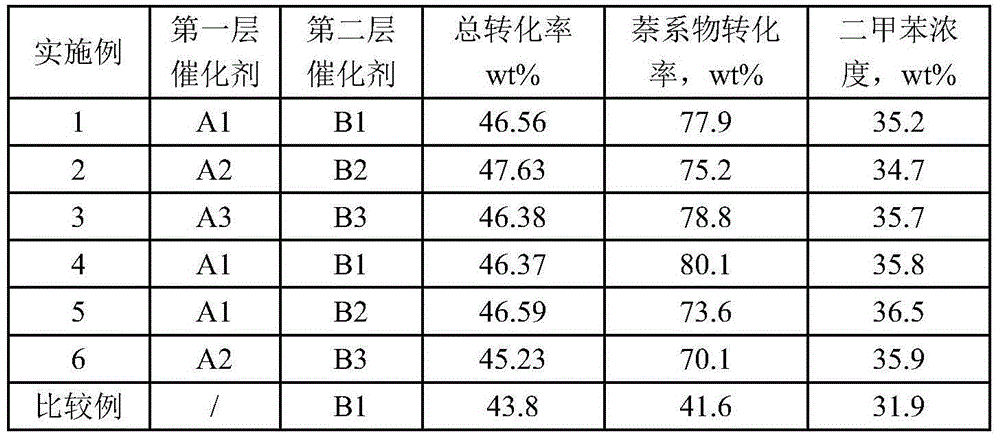

Embodiment 1

[0014] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of ZSM-5 molecular sieve with a molecular ratio of 80 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O57.1 g is evenly mixed, then a certain amount of dilute nitric acid and Tianqing powder are added and kneaded evenly, extruded into strips, roasted to make a carrier, and placed in an impregnation container after pelletizing. Dissolve a certain amount of chloroplatinic acid and stannous chloride in an appropriate amount of water, mix them evenly, and co-impregnate the surface of the carrier, dry at 120°C for 4 hours, and bake at 500°C for 3 hours to prepare the first layer of catalyst A1.

[0015] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of Beta molecular sieve with a molecular ratio of 40 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O57.1 g was uniformly mixed, then added a certain amount of dilute nitric acid and ammonium mol...

Embodiment 2

[0018] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of Mor molecular sieve with a molecular ratio of 50 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O57.1 g is evenly mixed, then a certain amount of dilute nitric acid and Tianqing powder are added and kneaded evenly, extruded into strips, roasted to make a carrier, and placed in an impregnation container after pelletizing. Dissolve a certain amount of palladium chloride and stannous chloride in an appropriate amount of water, mix them evenly, impregnate them on the surface of the carrier, dry at 120°C for 4 hours, and roast at 500°C for 3 hours to prepare the first layer of catalyst A2.

[0019] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of ZSM-12 molecular sieve with a molecular ratio of 30 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O57.1 g was uniformly mixed, then added a certain amount of dilute nitric acid and ammonium mo...

Embodiment 3

[0022] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of ZSM-5 molecular sieve with a molecular ratio of 40 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O57.1 g is evenly mixed, then a certain amount of dilute nitric acid and Tianqing powder are added and kneaded evenly, extruded into strips, roasted to make a carrier, and placed in an impregnation container after pelletizing. Dissolve a certain amount of chloroplatinic acid and germanium tetrachloride in an appropriate amount of water, mix them uniformly, impregnate them on the surface of the carrier, dry at 120°C for 4 hours, and calcinate at 500°C for 3 hours to prepare the first layer of catalyst A3.

[0023] Na 2 O content less than 0.1% (weight), SiO 2 / Al 2 o 3 66.7 grams of ZSM-12 molecular sieve with a molecular ratio of 50 and Na 2 γ-Al with O content less than 0.1% by weight 2 o 3 ·H 2 O57.1 g is evenly mixed, then a certain amount of dilute nitric acid is added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com