Clostridium beijerinckii and application thereof

A technology of Clostridium beijerinckii and microbial strains, applied in the field of microorganisms, can solve the problems of reducing the proportion of butanol, the cells cannot grow normally, and increasing energy consumption, so as to reduce the pressure of butanol recovery and prevent the cells from not growing. phenomenon, the effect of reducing the energy consumption of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

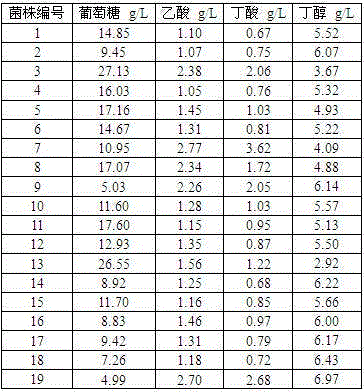

[0031] The screening process of embodiment 1 Clostridium beijerinckii XH0906 bacterial strain

[0032]In June 2012, forest soil and livestock manure were collected from the surrounding areas of Fushun City, Liaoning Province, mixed with corn stalk powder and placed in a sterile triangular flask, and an appropriate amount of sterile water was added to enrich the gas-producing bacteria anaerobically. After 2 weeks of enrichment, bubbles were found in the anaerobic culture, and 0.2 mL of the culture was inoculated into 4.8 mL of liquid medium placed in a test tube. The composition of the liquid medium is: peptone 10 g / L, beef extract 6 g / L, glucose 40 g / L, sodium chloride 0.5 g / L, ammonium sulfate 0.9 g / L, iron sulfate 0.1 g / L, magnesium sulfate 0.3 g / L, calcium chloride 0.1 g / L, pH 7.0, sterilized at 121°C for 15 minutes. After static culture for 72 h, a large number of air bubbles can be observed during the culture process. The culture fluid was centrifuged to take the super...

Embodiment 2

[0036] Example 2 Production of butanol by non-anaerobic fermentation of Clostridium beijerinckii XH0906

[0037] Liquid medium components: peptone 10 g / L, beef extract 6 g / L, glucose 40 g / L, sodium chloride 0.5 g / L, ammonium sulfate 0.9 g / L, iron sulfate 0.1 g / L, magnesium sulfate 0.3 g / L L. Calcium chloride 0.1 g / L, pH 7.0, sterilized at 121°C for 15 minutes. Solid media add 1% agar to liquid media.

[0038] Production of butanol by non-anaerobic fermentation of Clostridium beijerinckii XH0906: (1) Inoculate the Clostridium beijerinckii XH0906 on a solid medium slant, place in an anaerobic environment, and cultivate at 30°C for 24 hours; (1) Scrape 1-2 rings of the cultivated Clostridium beijerinckii from the slant and put them into the shake flask seed medium, no need to feed N 2 , 35 ℃ static culture for 24h; (3) The seed liquid cultivated in step (2) was inserted into the liquid fermentation medium with an inoculum of 10%, and no N was needed. 2 , natural pH, fermented ...

Embodiment 3

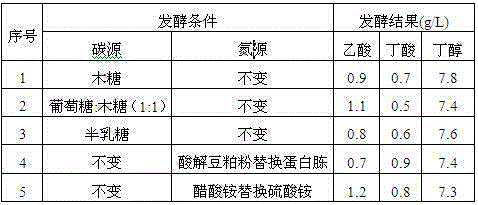

[0040] The fermentation process and operating conditions are the same as in Example 2, except that different carbon sources and nitrogen sources are used to replace the glucose, peptone or ammonium sulfate in the original culture medium. The fermentation results are shown in Table 3.

[0041] Table 3 Fermentation results with different carbon and nitrogen sources in the medium

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com