Novel process for recovering PTA (purified terephthalic acid) wastewater

A technology of resource utilization and new process, which is applied in the new process field of PTA wastewater recycling and utilization, can solve the problems of limited energy saving in the separation of acetic acid wastewater, and achieve the effects of reducing energy consumption, reducing heat load and high resource recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

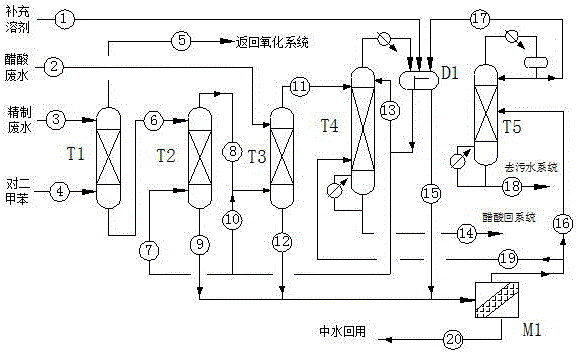

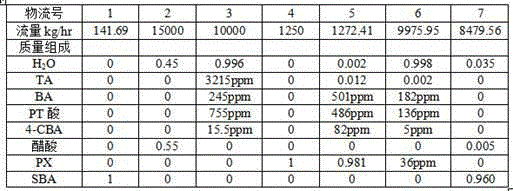

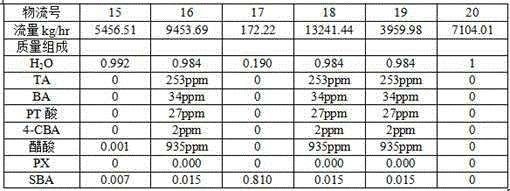

[0036] The treatment capacity of refined wastewater is 10t / hr (including TA3215ppm, BA245ppm, PT acid 755ppm, 4-CBA15.5ppm), and the treatment capacity of acetic acid wastewater is 15t / hr (containing 55% acetic acid). The aromatic compound extraction tower (first-stage extraction tower) is a plate-type extraction tower with a theoretical plate number of 8, and the feed volume ratio of PX to refined wastewater is 1:8. The PX extraction tower (second-stage extraction tower) is a packed extraction tower with 7 theoretical plates, and the feed volume ratio of solvent sec-butyl acetate (SBA) to refined wastewater is 1:1. The acetic acid extraction tower (the third-stage extraction tower) is a packed extraction tower, the height of which is equivalent to 10 theoretical plates, and the feed volume ratio of acetic acid wastewater to solvent is 0.6:1. The azeotropic distillation column adopts plate type and packing structure, and the number of theoretical plates is equivalent to 50. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com