Method for making methyl acetate through carbonylation of dimethyl ether and the modified molecular sieve catalyst and modification method thereof

A technology of methyl acetate and molecular sieve, which is applied in molecular sieve catalysts, physical/chemical process catalysts, catalyst protection, etc., to achieve the effects of improving conversion rate, prolonging life, and inhibiting side reactions of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

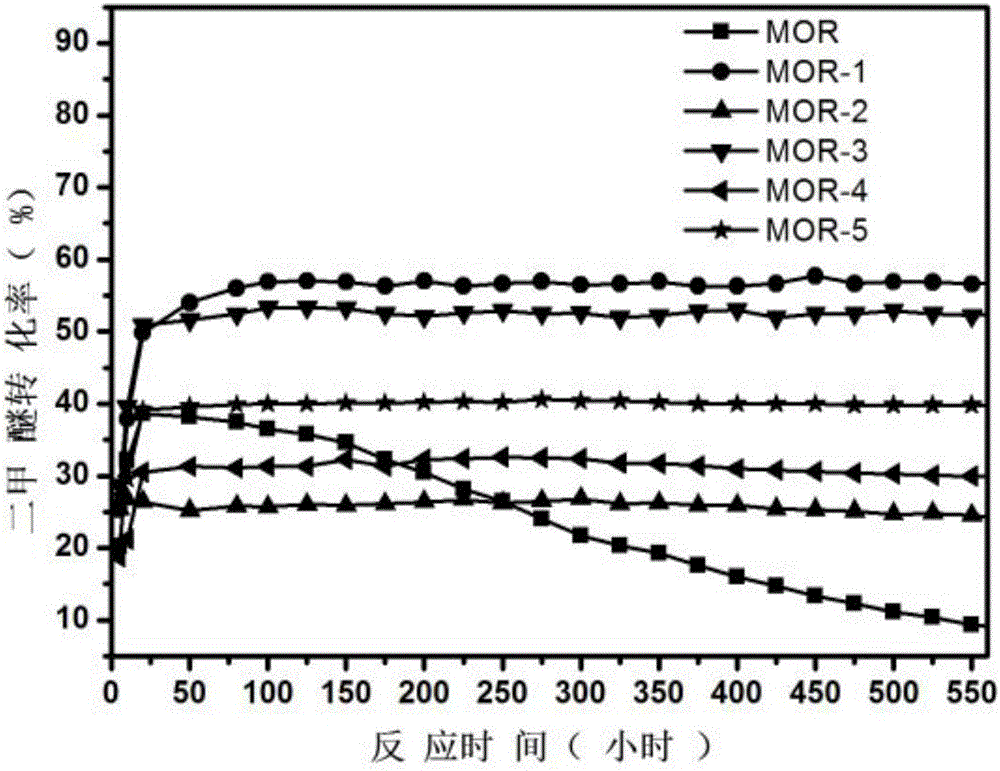

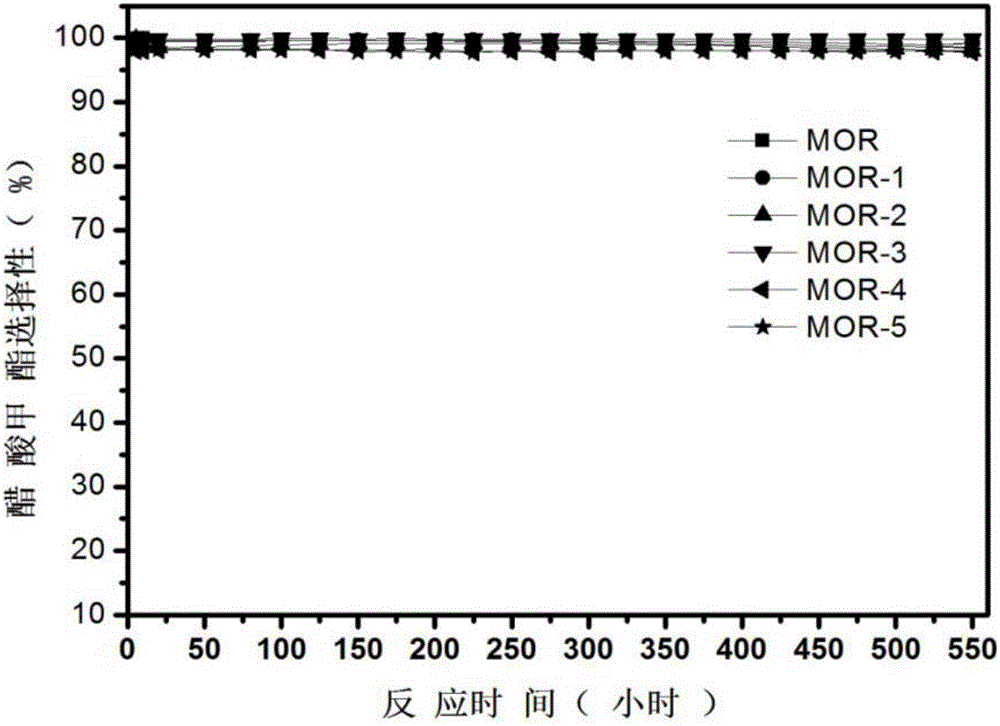

[0037] 200 g of hydrogen-type mordenite molecular sieves with a silicon-aluminum ratio of 7:1 were calcined at 500° C. for 4 hours in a dry air atmosphere. Take 10 g of the powder sample, press it into tablets, and crush it into 12-20 mesh granule samples for the test of dimethyl ether carbonylation activity. Weigh 3.0 g of the sample and put it into a stainless steel reaction tube with an inner diameter of 20 mm and activate it at 400 °C under normal pressure and nitrogen atmosphere for 2 hours, the nitrogen flow rate is 100 mL / min, then cool down to 280 °C, and use nitrogen bubbles to modify the liquid The substance methyl acetate causes chemical adsorption to occur on the hydrogen-type mordenite molecular sieve, the nitrogen flow rate is controlled to 200mL / min and the adsorption time is 2 hours, the flow rate of methyl acetate is controlled to 0.05mL / min, and then nitrogen is purged with the same flow rate hours, and then lowered the temperature to 230°C, and the modified ...

Embodiment 2

[0040] The implementation steps are the same as in Example 1, except that the modified substance methyl acetate is replaced by methyl alcohol, and the modified catalyst is called MOR-2. The activity test results of the modified catalyst are shown in Figure 1a and Figure 1b .

Embodiment 3

[0042] The implementation steps are the same as in Example 1, except that the modified substance methyl acetate is replaced by ethyl acetate, and the modified catalyst is called MOR-3. The activity test results of the modified catalyst are shown in Figure 1a and Figure 1b .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com