Patents

Literature

970results about "Fuel gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

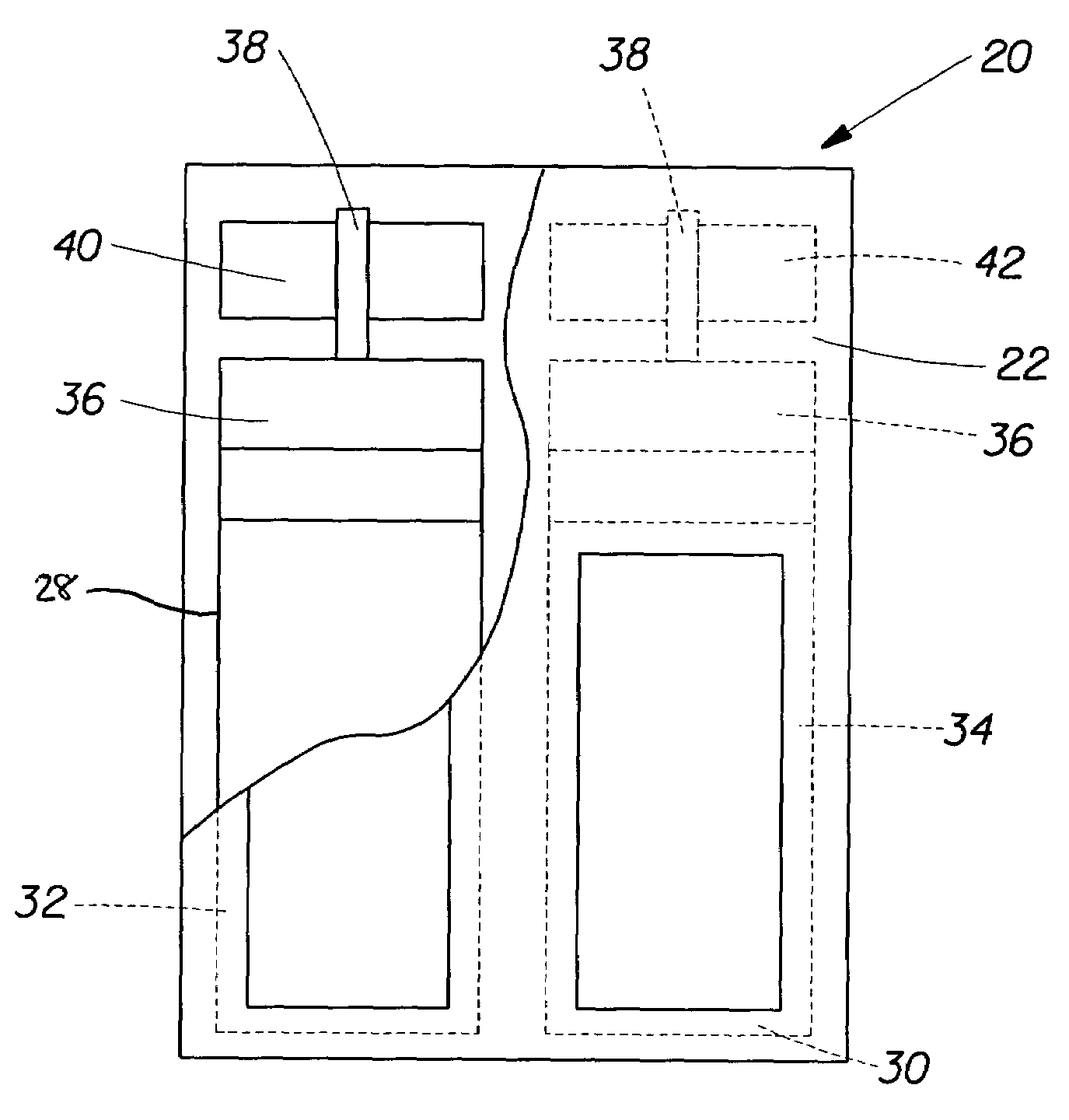

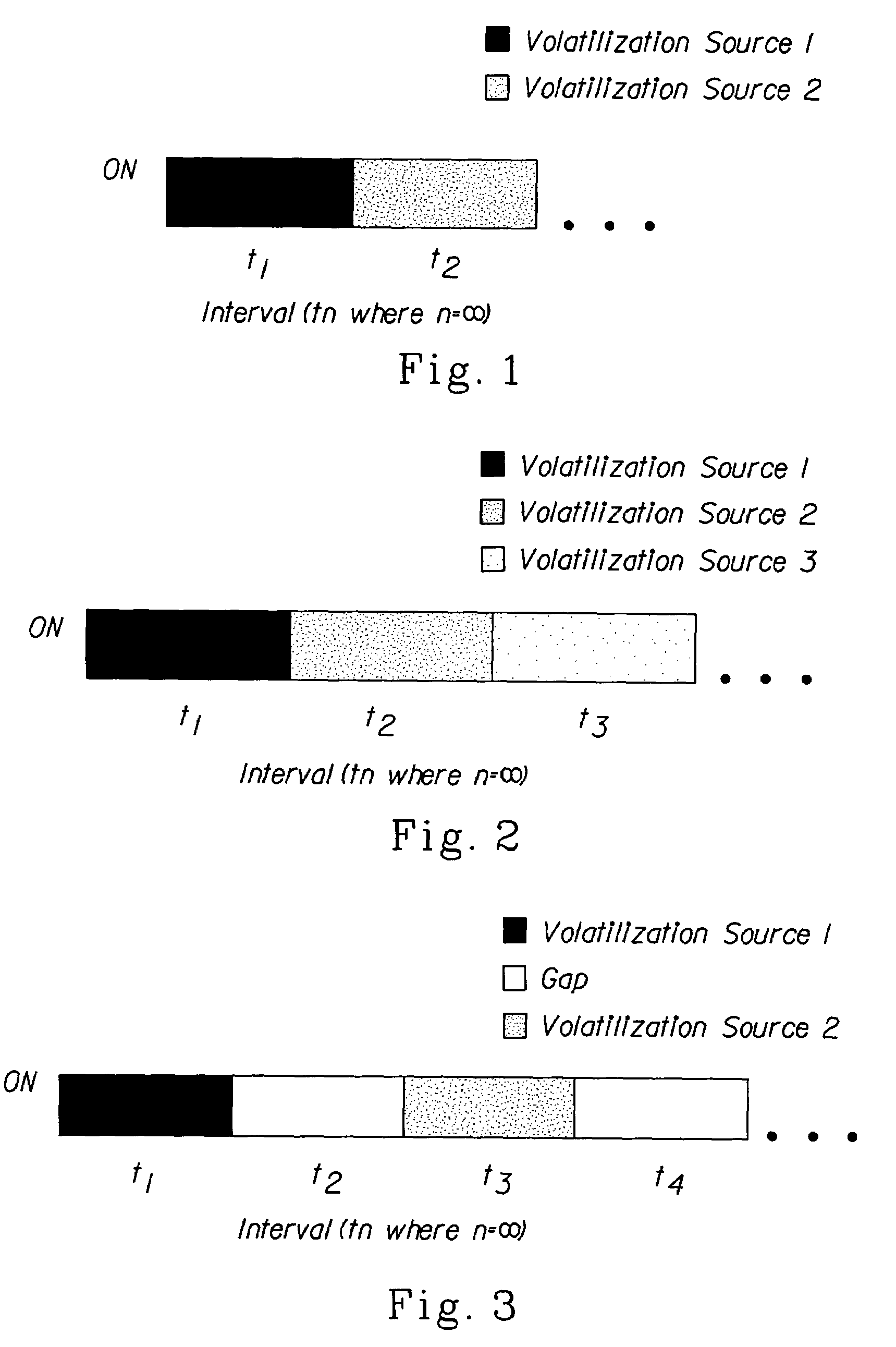

Methods for emitting volatile compositions

InactiveUS7223361B2Maximize perceptibilityLighting and heating apparatusUsing liquid separation agentEngineeringComposition methods

Owner:THE PROCTER & GAMBLE COMPANY

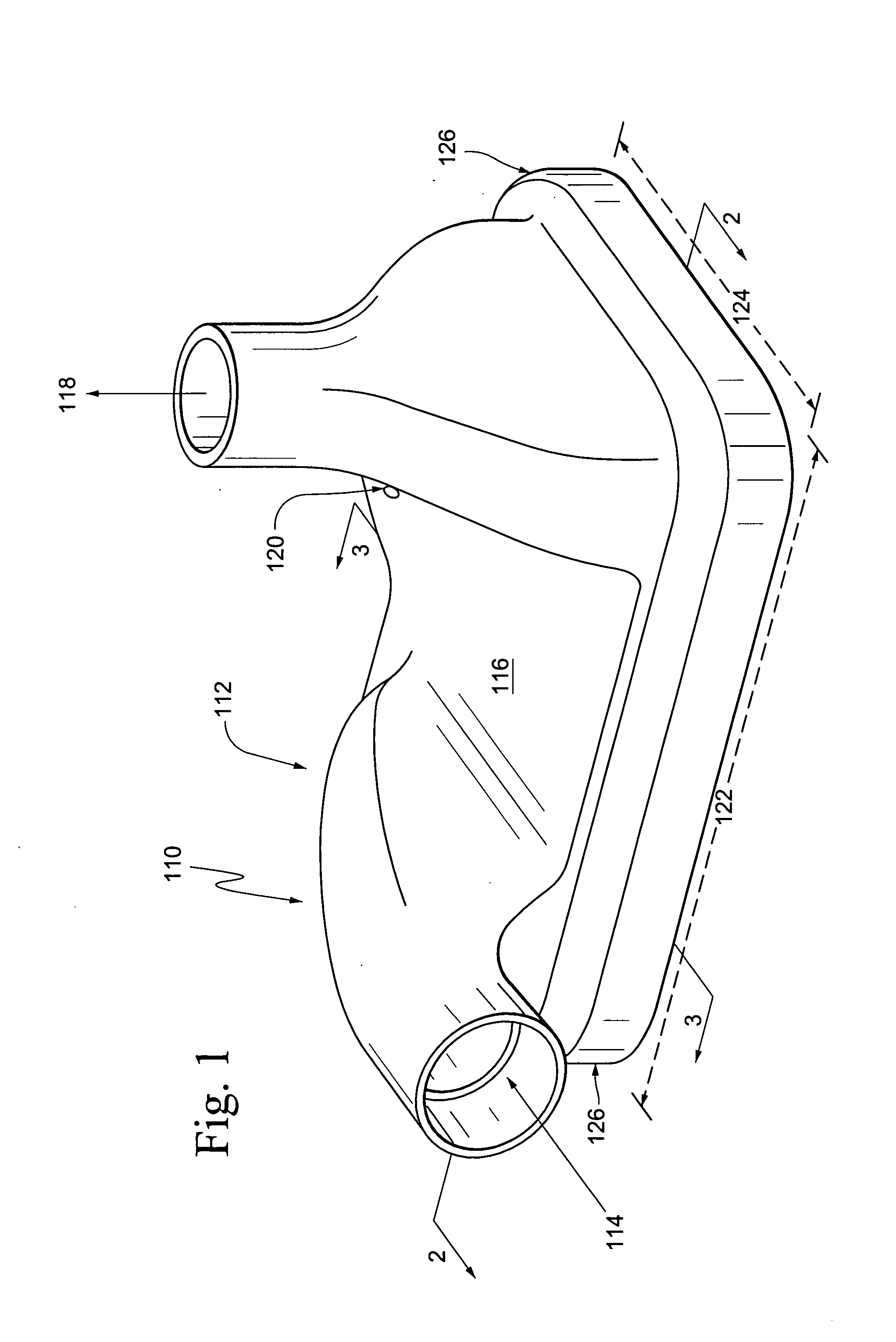

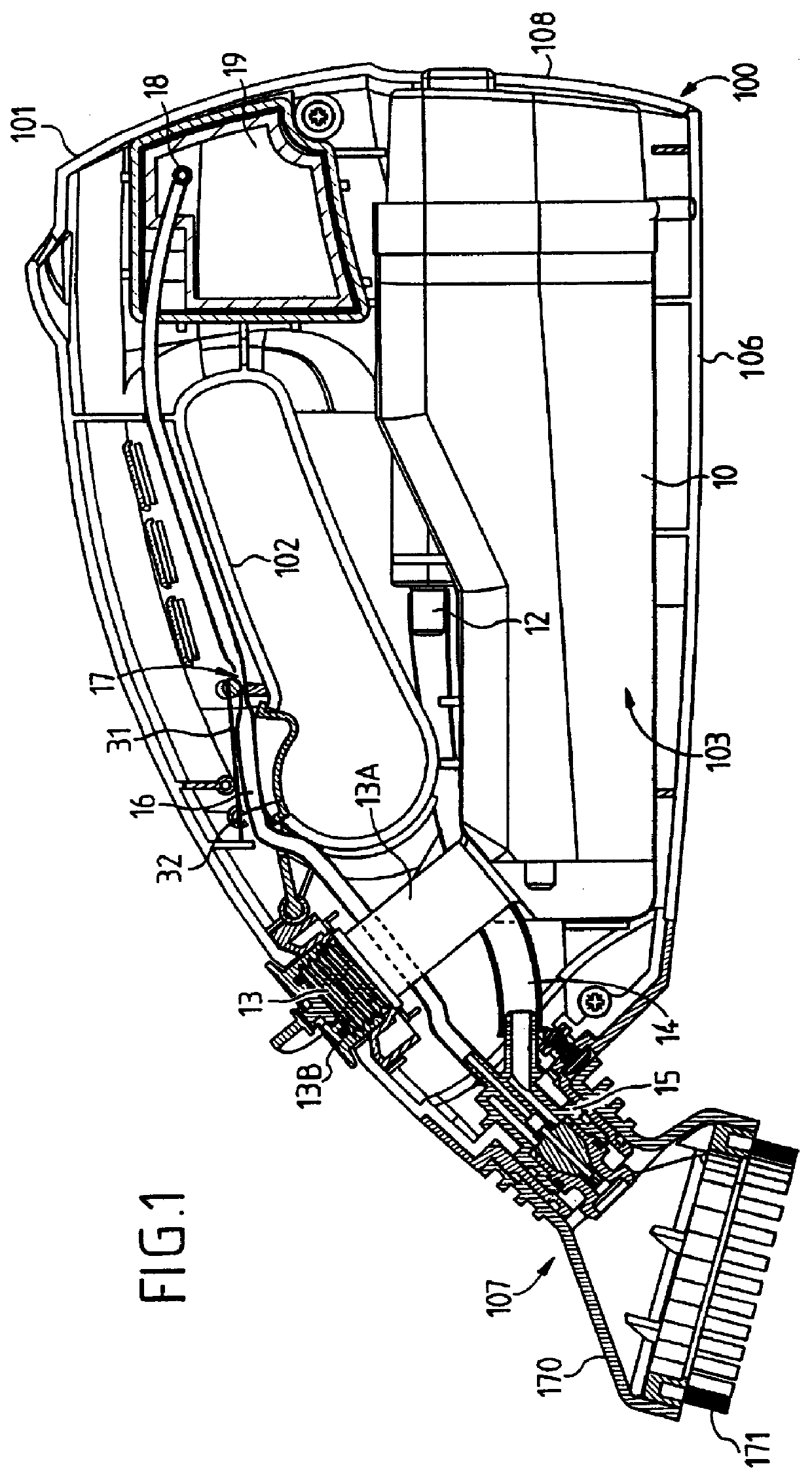

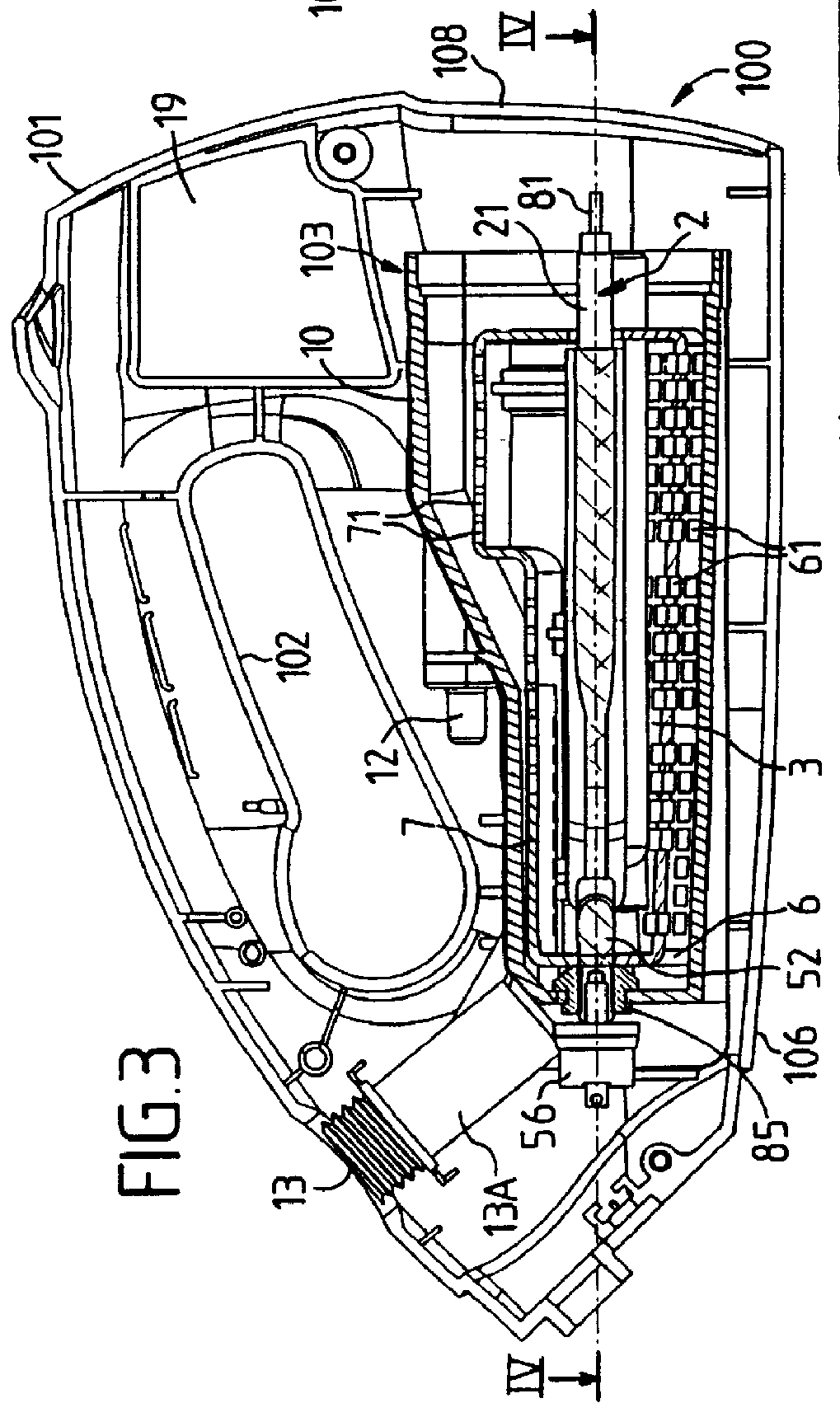

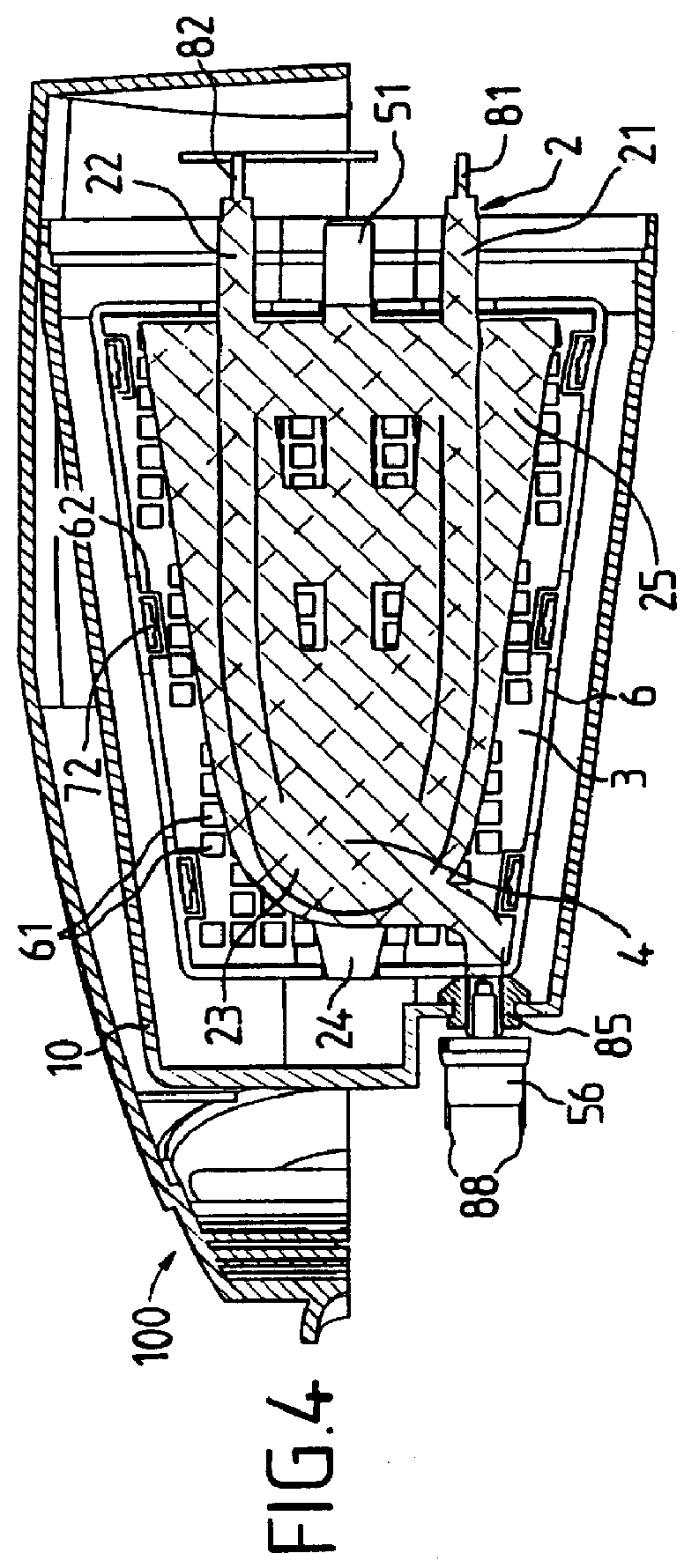

Removable and/or replaceable humidifier

ActiveUS20090000620A1Improved vaporizationUsing liquid separation agentMedical devicesWater vaporEngineering

Humidifier apparatus for a respiratory apparatus includes a housing providing a gas flow path, a heater apparatus, and a water supply distribution member configured and arranged to deliver water vapour to the gas flow path. The water distribution member is provided to the housing and in thermal communication with the heater apparatus.

Owner:RESMED LTD

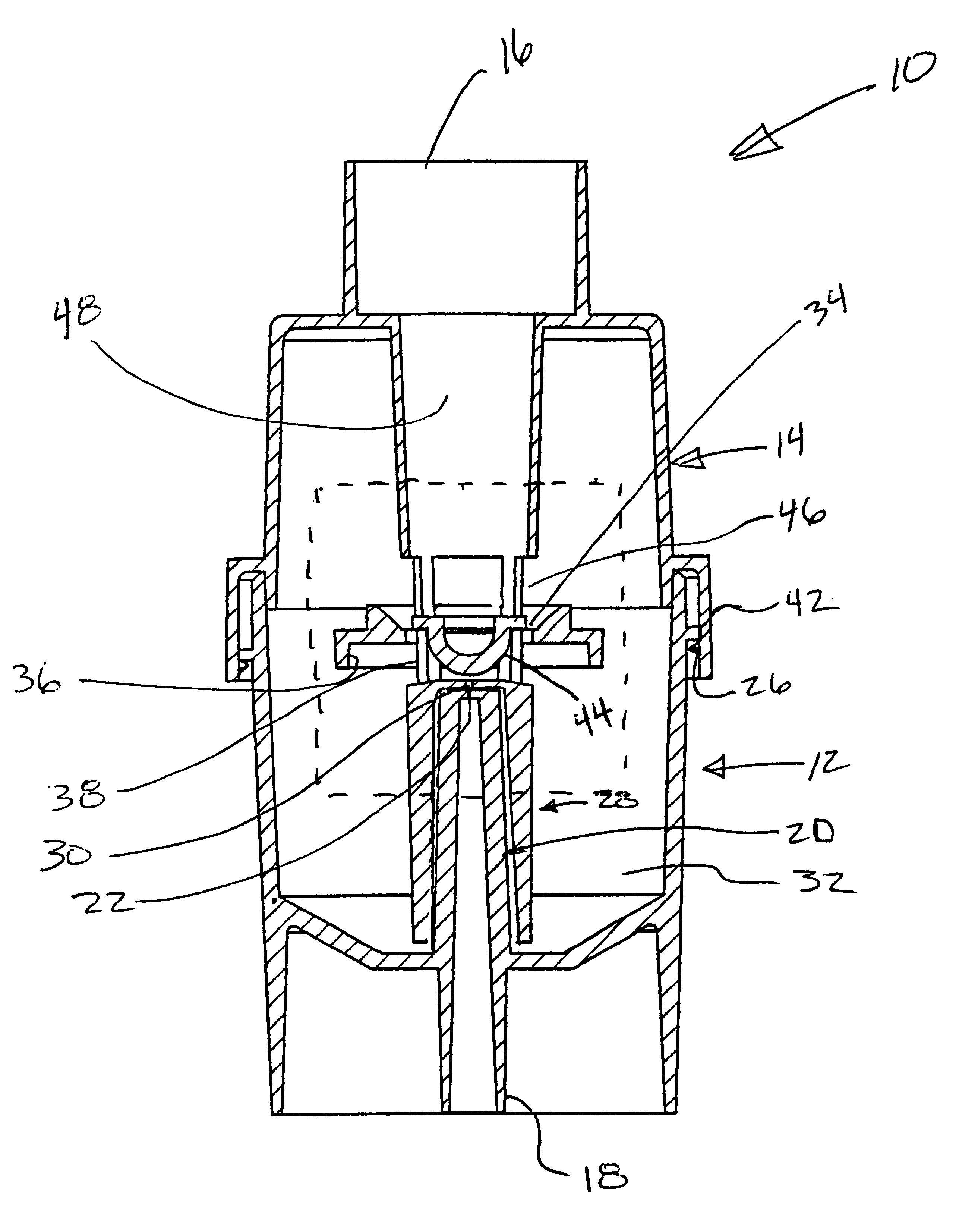

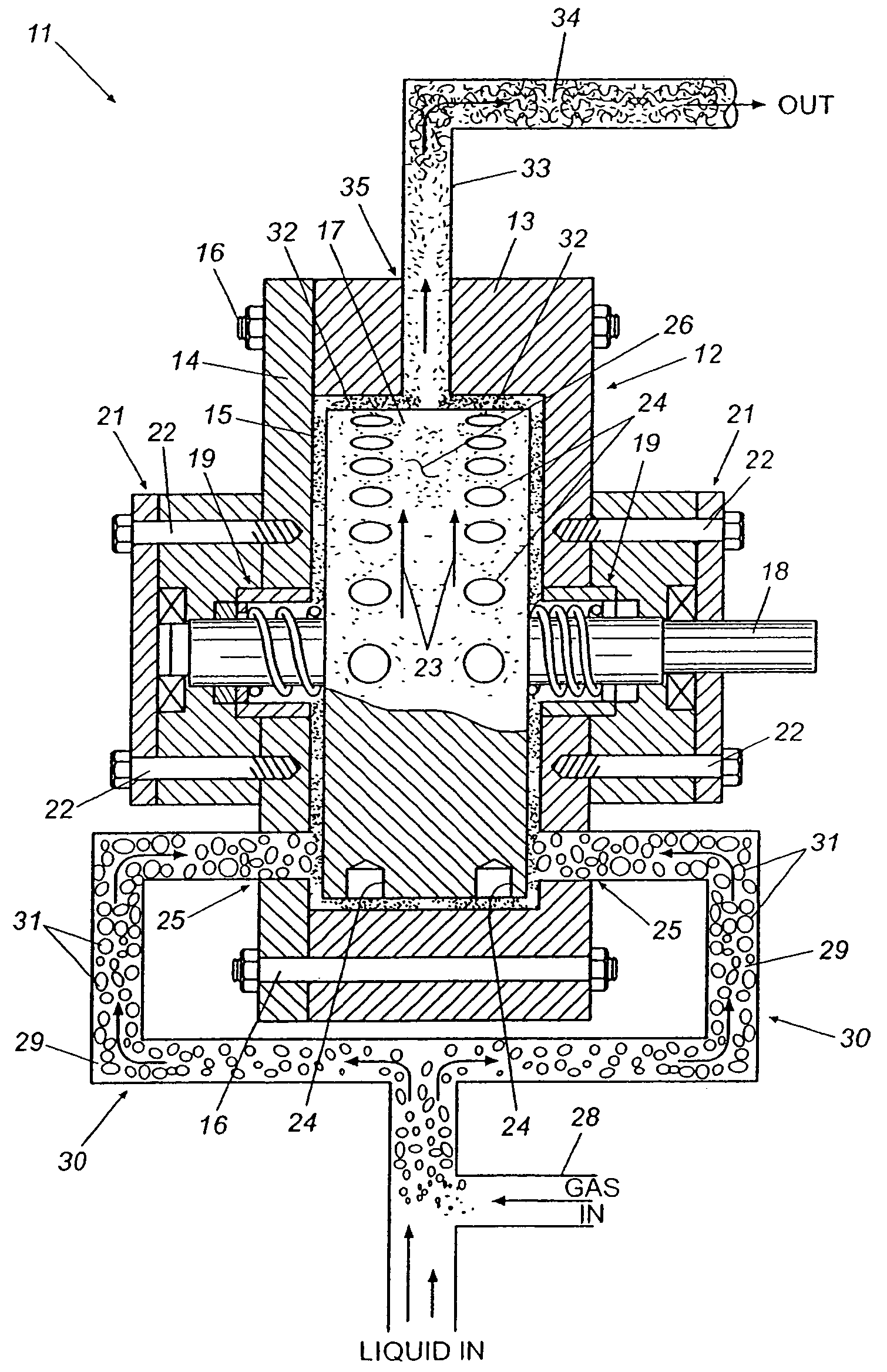

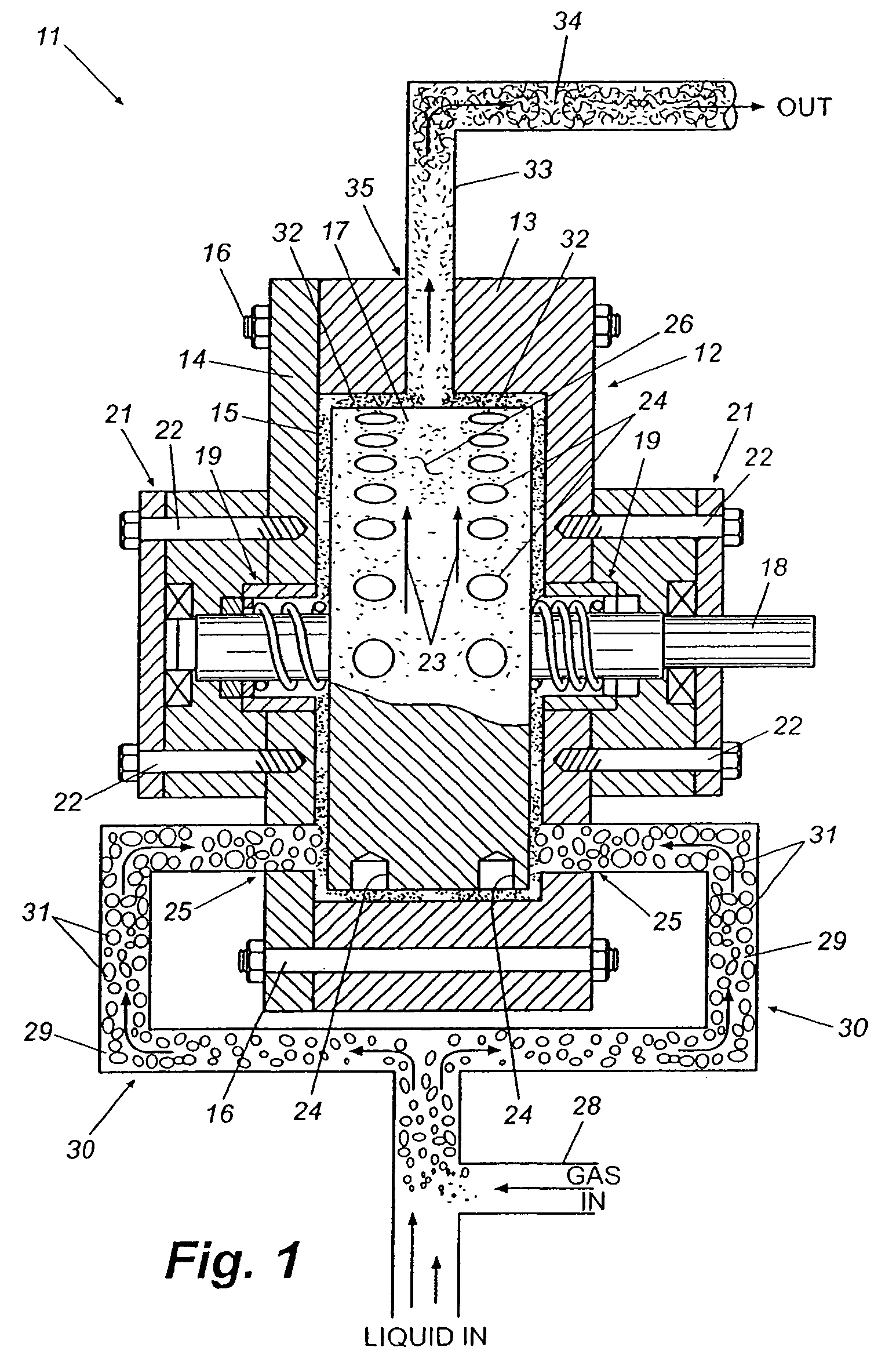

High efficiency medical nebulizer

A pneumatic nebulizer that produces a high volume of aerosols for inhalent delivery of medications and other constituencies. High pressure gas formed into a gas jet is passed through a thin choked region of fluid that is entrailed and impinged upon an aerosol amplifier which creates a spray whose aerosol components are directed up through vents to an aerosol outlet for delivery. Larger-sized liquid particles are caused to pool up in a region surrounding the aerosol amplifer and then drip down back into the liquid medication reservoir.

Owner:MERCURY ENTERPRISES

System and method for therapeutic application of dissolved oxygen

InactiveUS20050047270A1Rotary stirring mixersUsing liquid separation agentCavitationAqueous solution

A system and method for generating an oxygen enriched aqueous solution for therapeutic application includes a diffuser comprising a first diffusing member having a surface incorporating surface disturbances, and a second diffusing member positioned relative to the first diffusing member to form a channel through which an aqueous solution and oxygen gas may flow. A reservoir containing the aqueous solution is connected to a pump that draws the aqueous solution from the reservoir and inputs the aqueous solution into the diffuser. The aqueous solution is moved through the channel relative to the surface disturbances to create cavitation in the aqueous solution to diffuse the oxygen gas into the aqueous solution to produce an oxygen enriched aqueous solution.

Owner:REVALESIO CORP

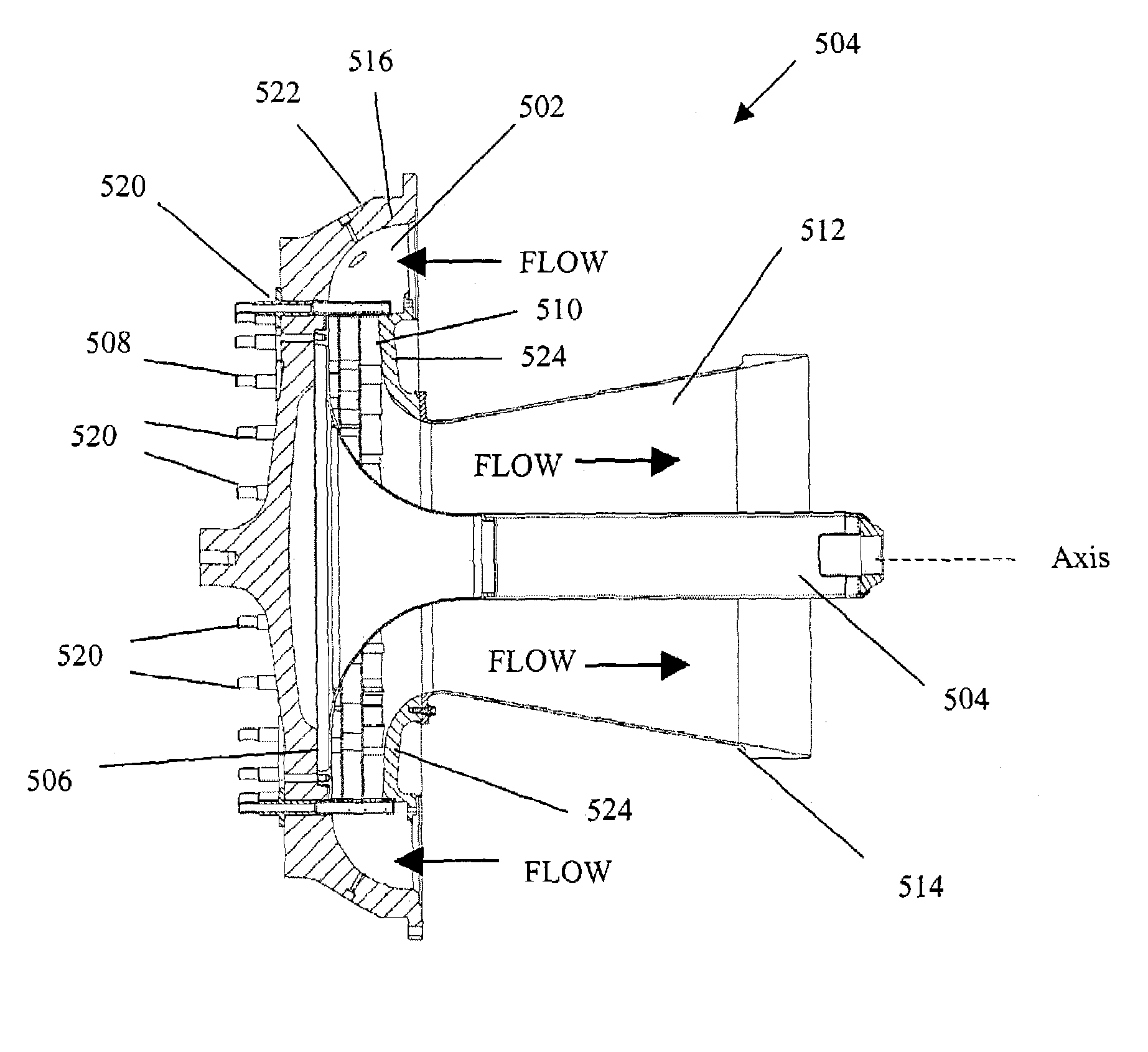

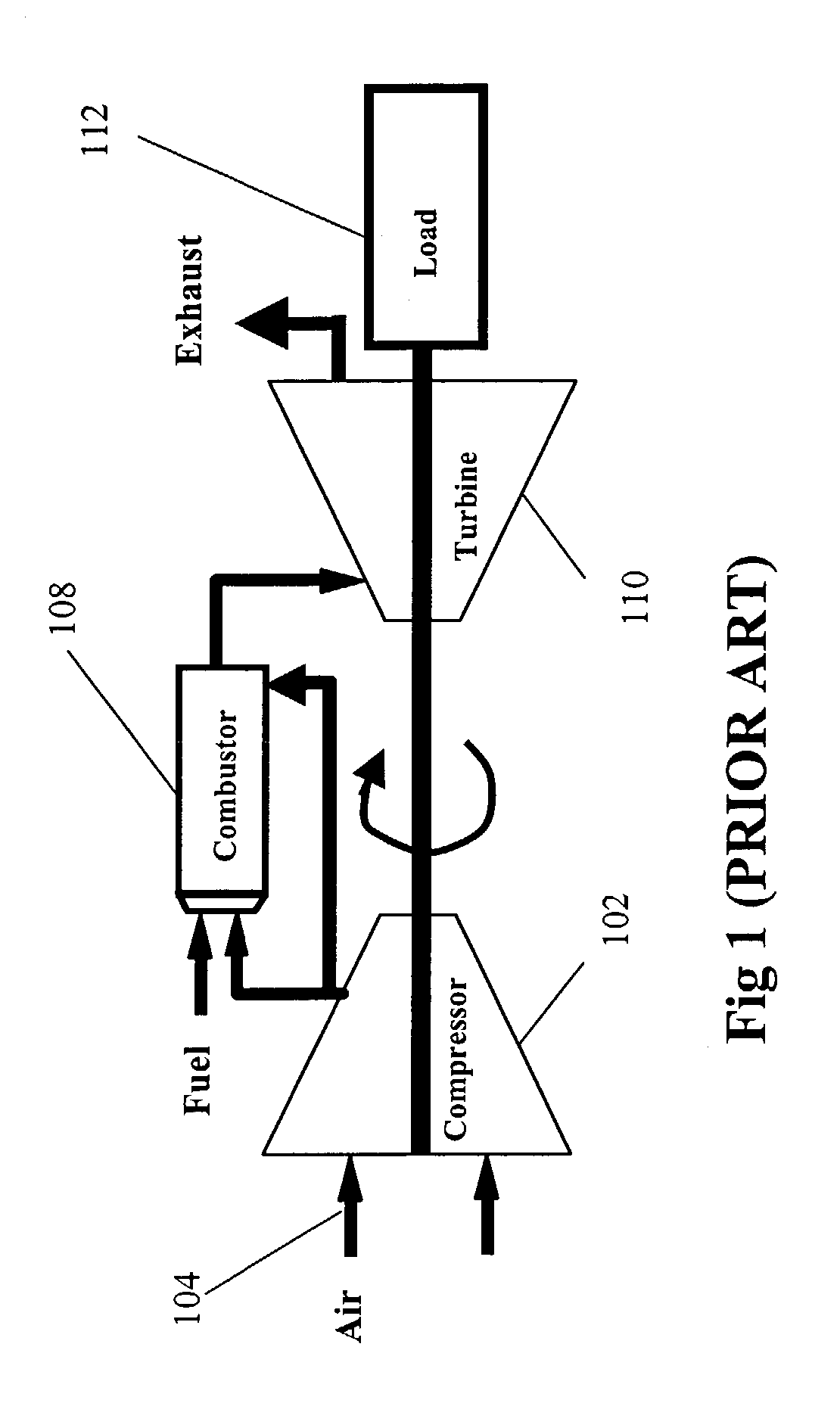

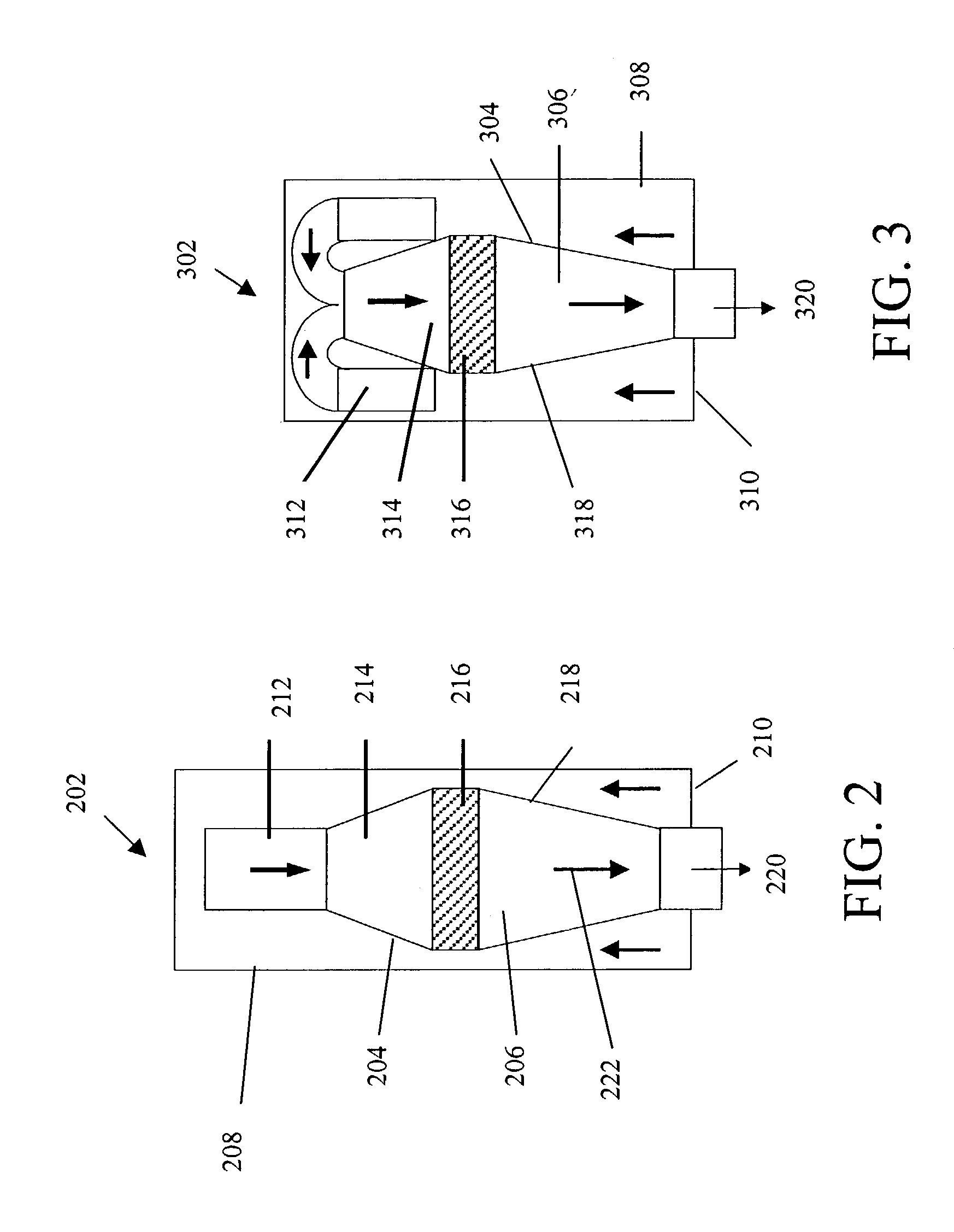

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

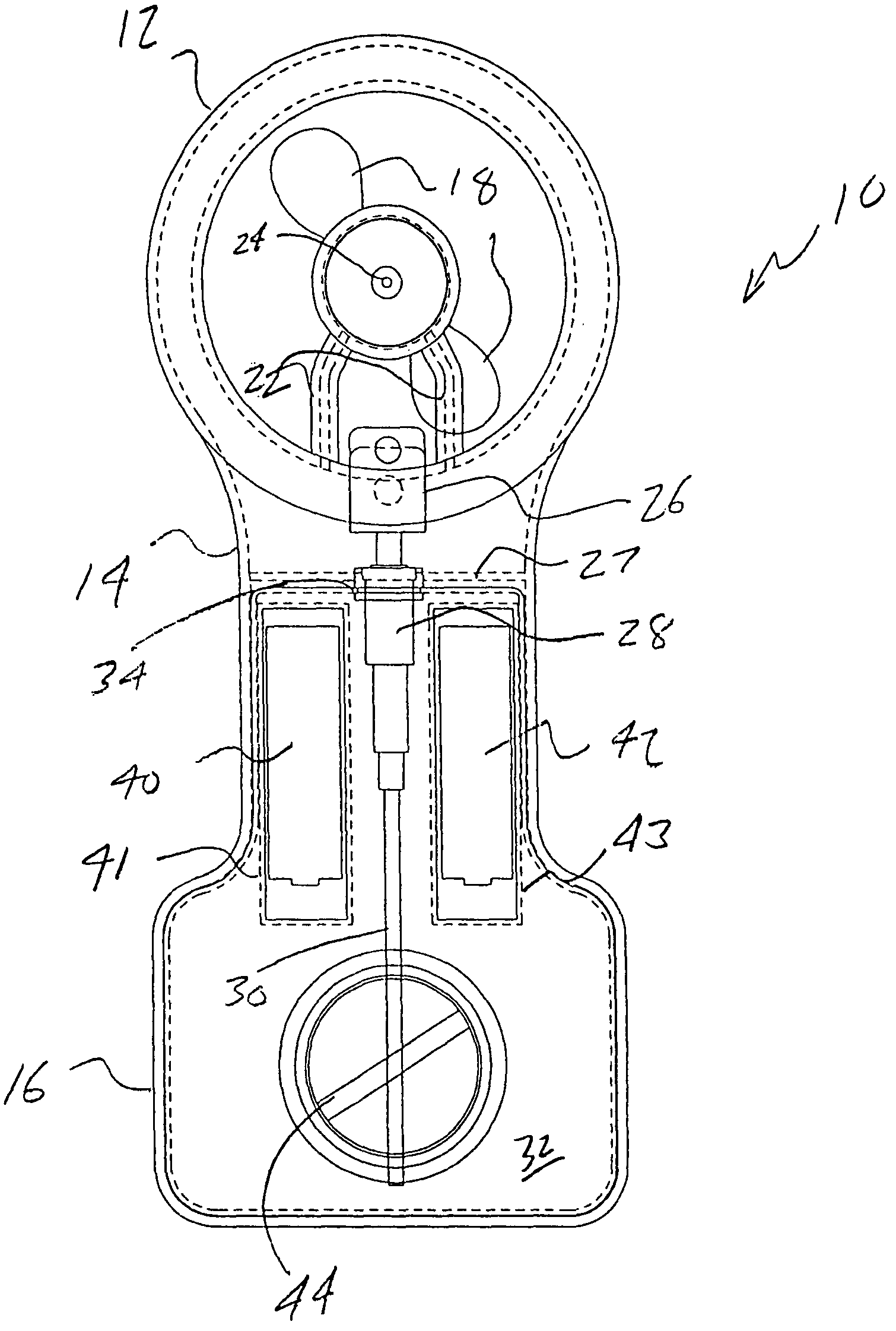

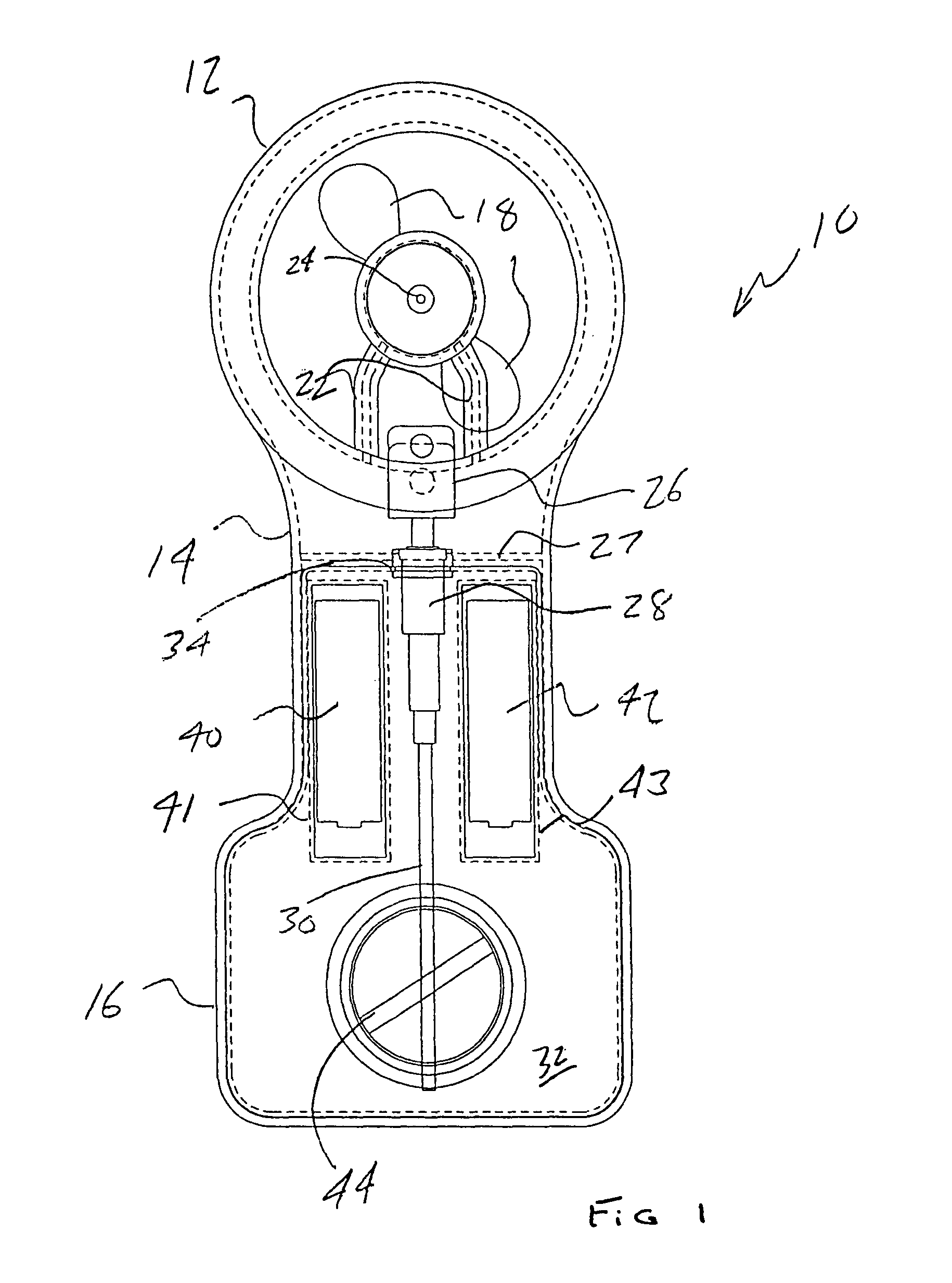

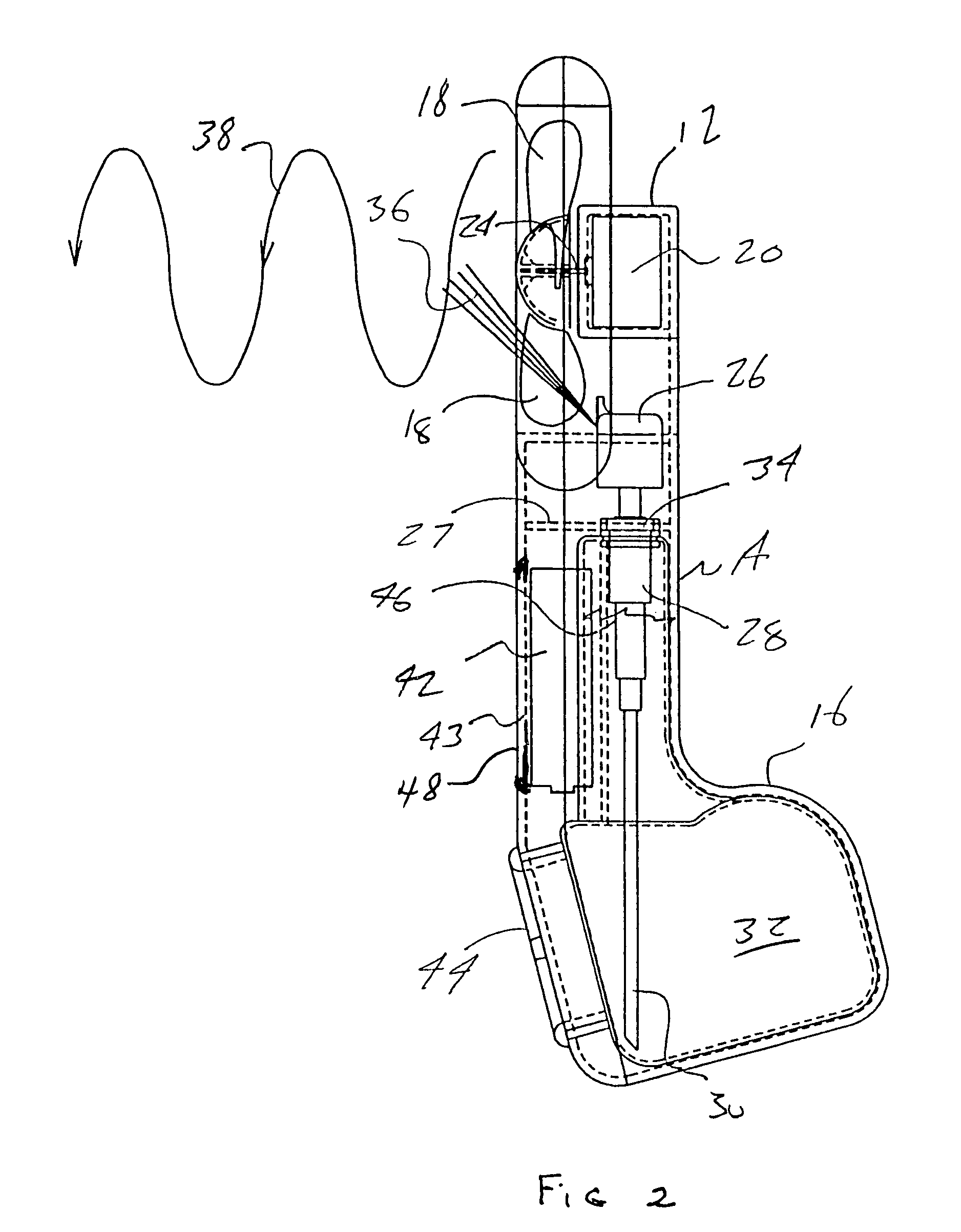

Handheld water misting fan with improved air flow

The present invention is directed to an improved handheld water misting fan device wherein the power source compartment is positioned within the device at a location remote from the fan motor thereby to remove any structure from the area bounded by the fan shroud. The relocation of the power source compartment leaves the area bounded by the shroud substantially unobstructed thereby to improve air flow. The device is formed in a dog bone shaped configuration to provide a narrow handle section for improved grippability, and an enlarged fluid reservoir at the lower end thereof for greater reservoir capacity.

Owner:O2COOL

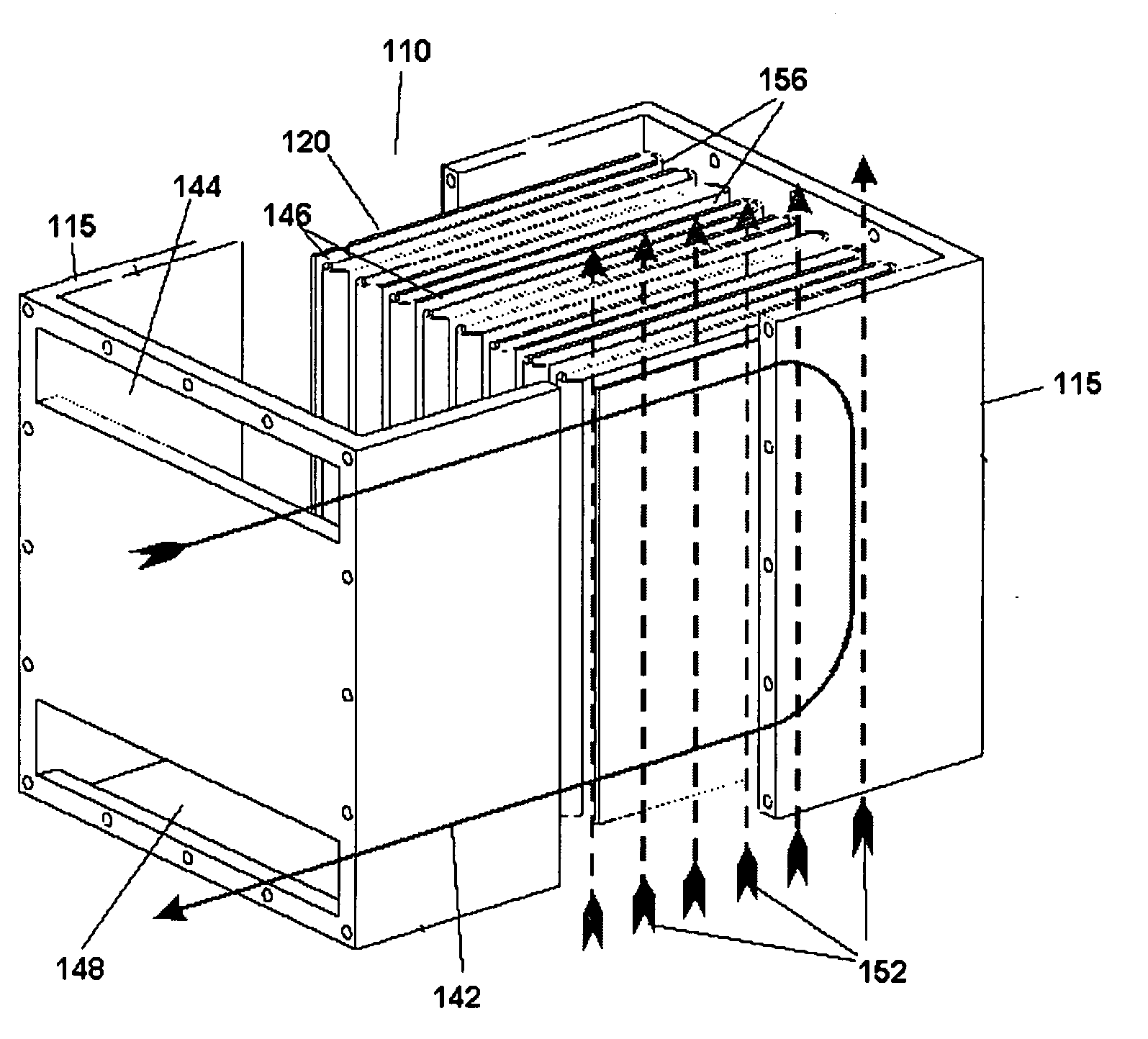

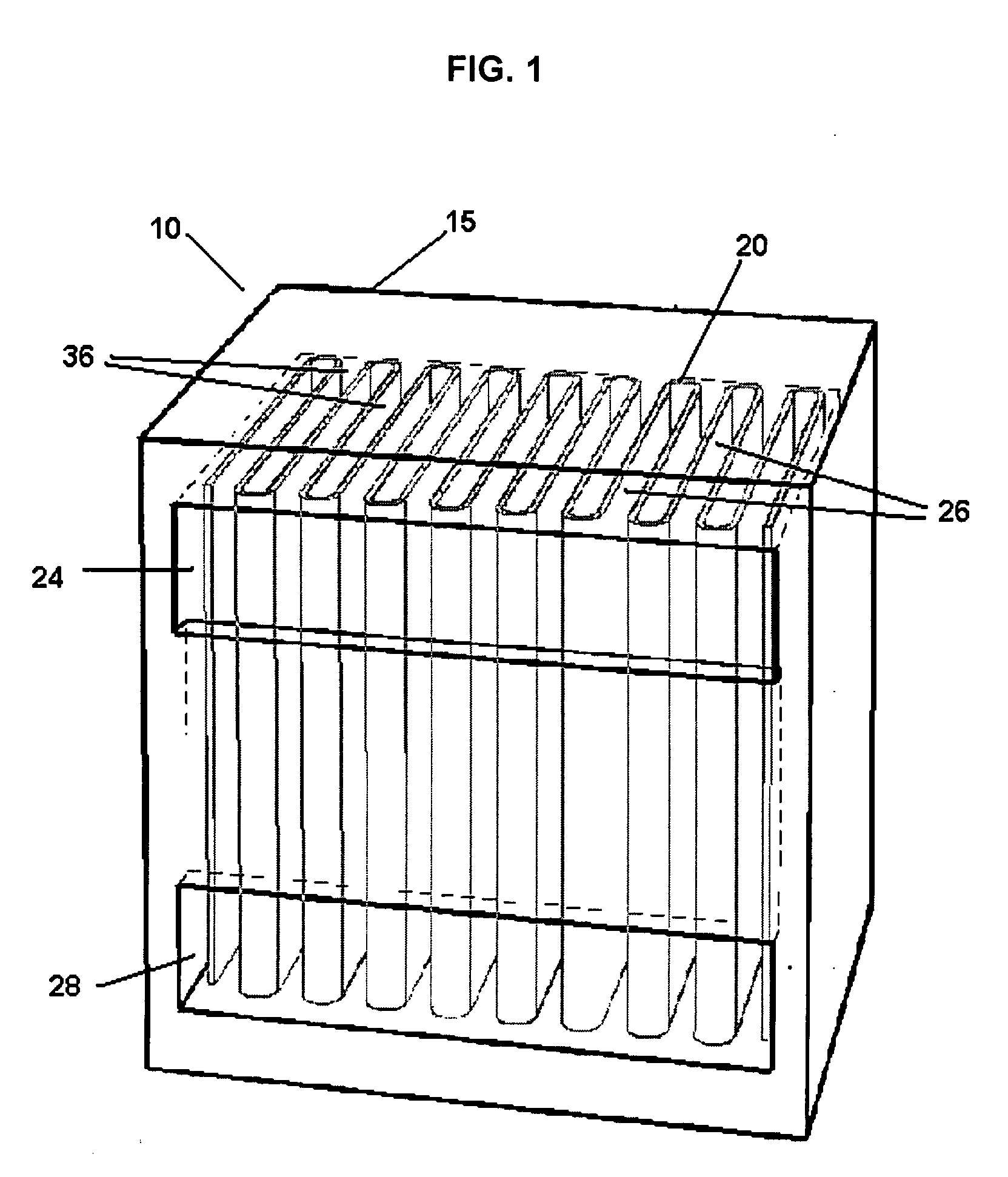

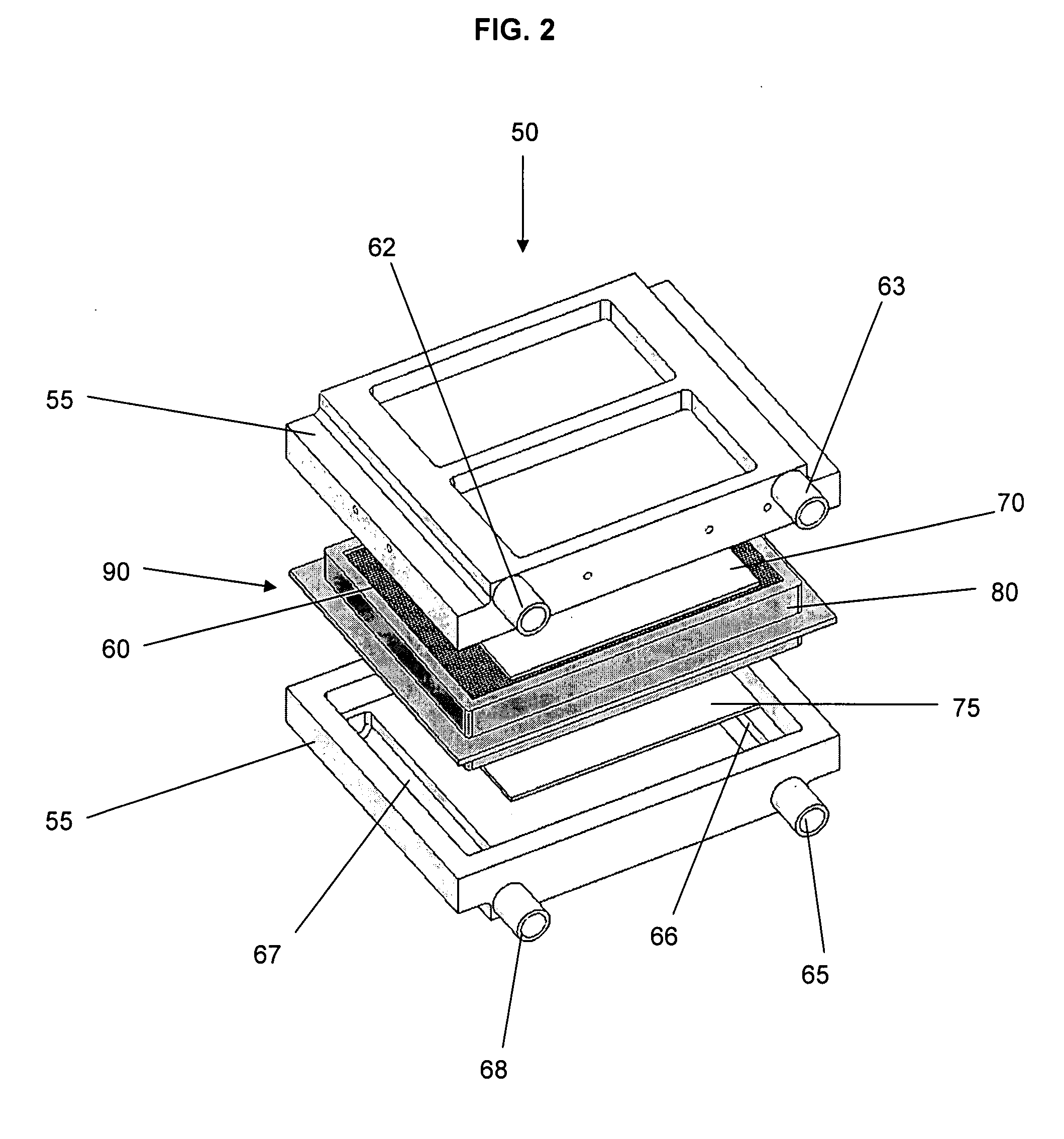

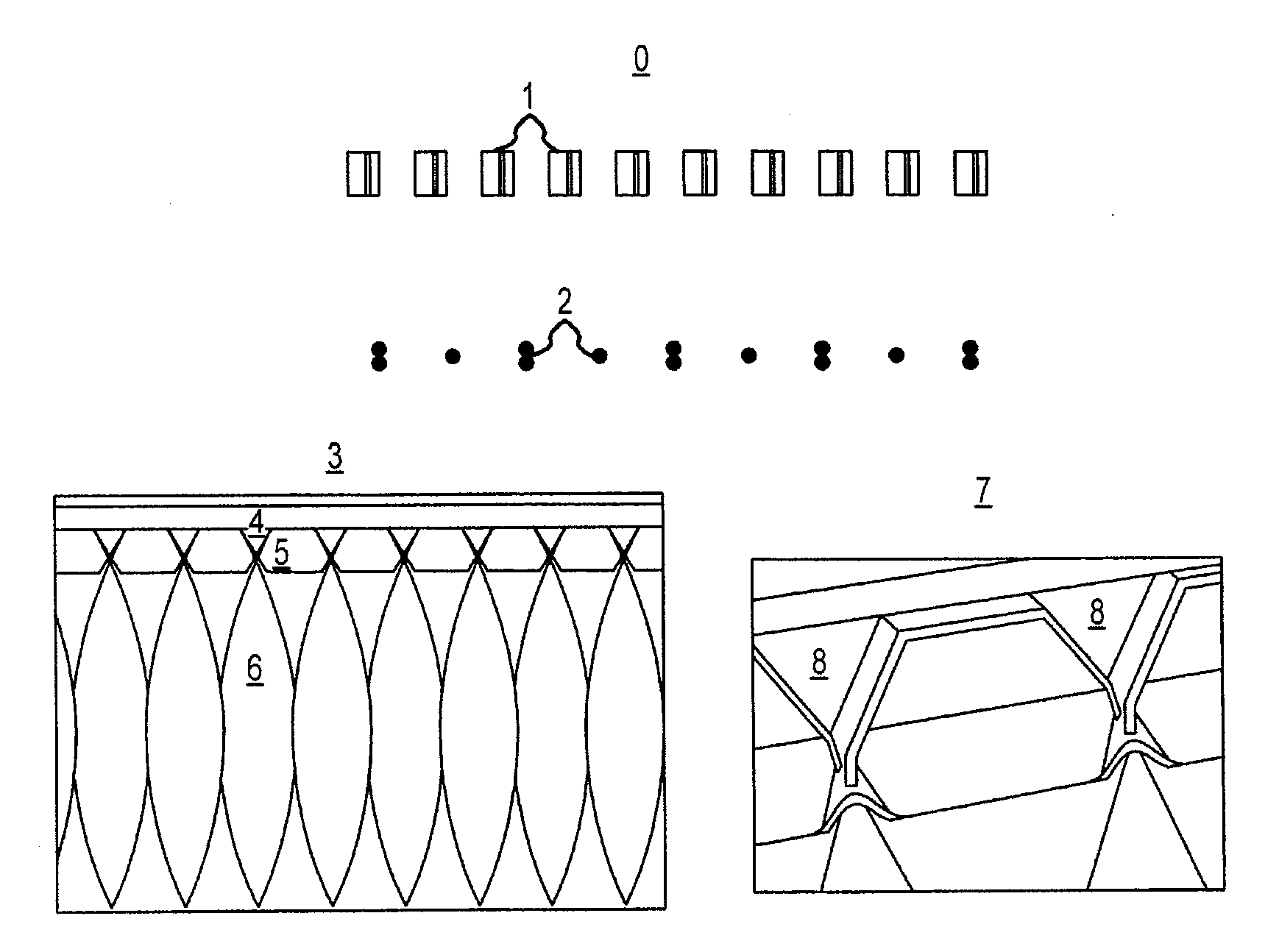

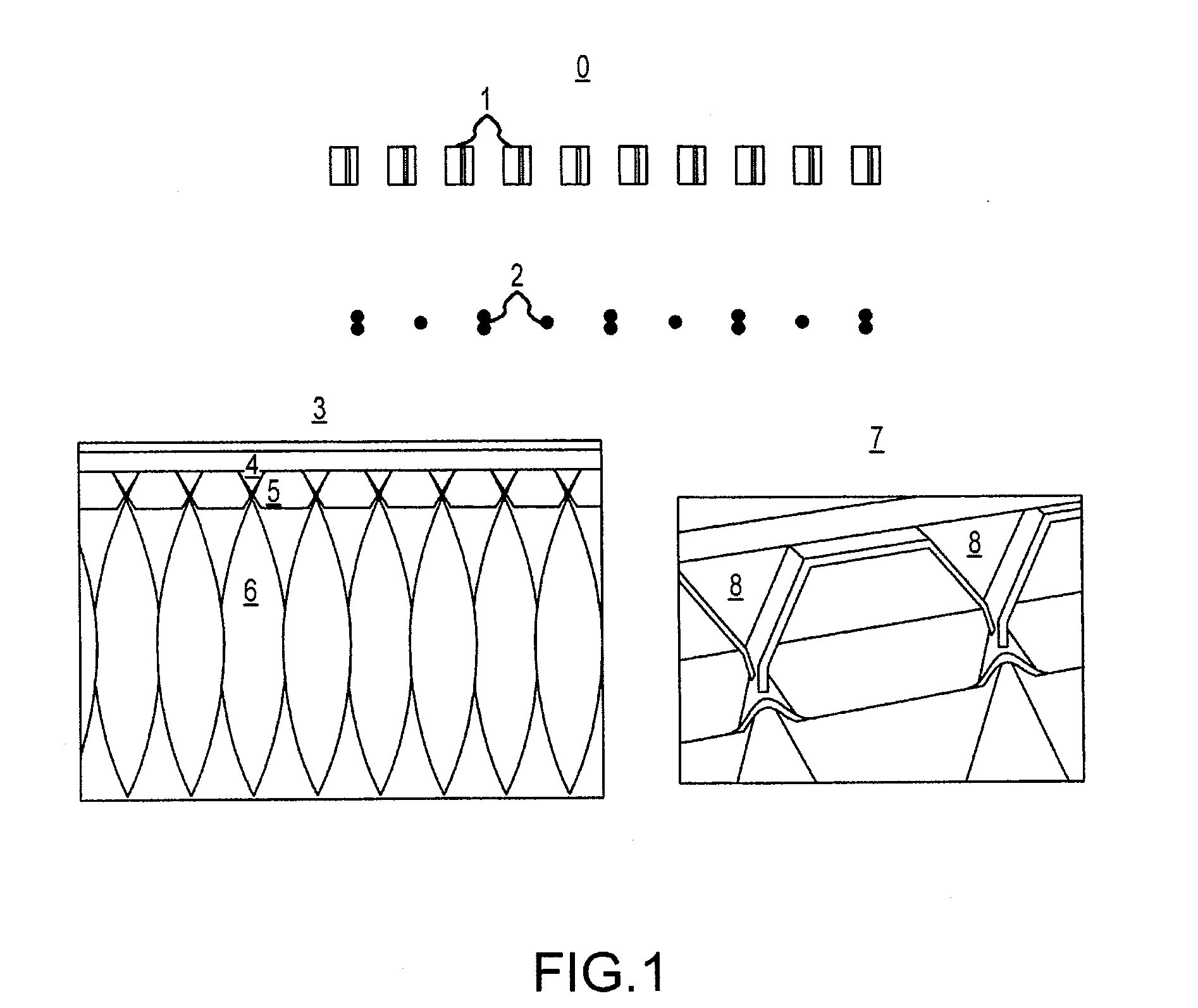

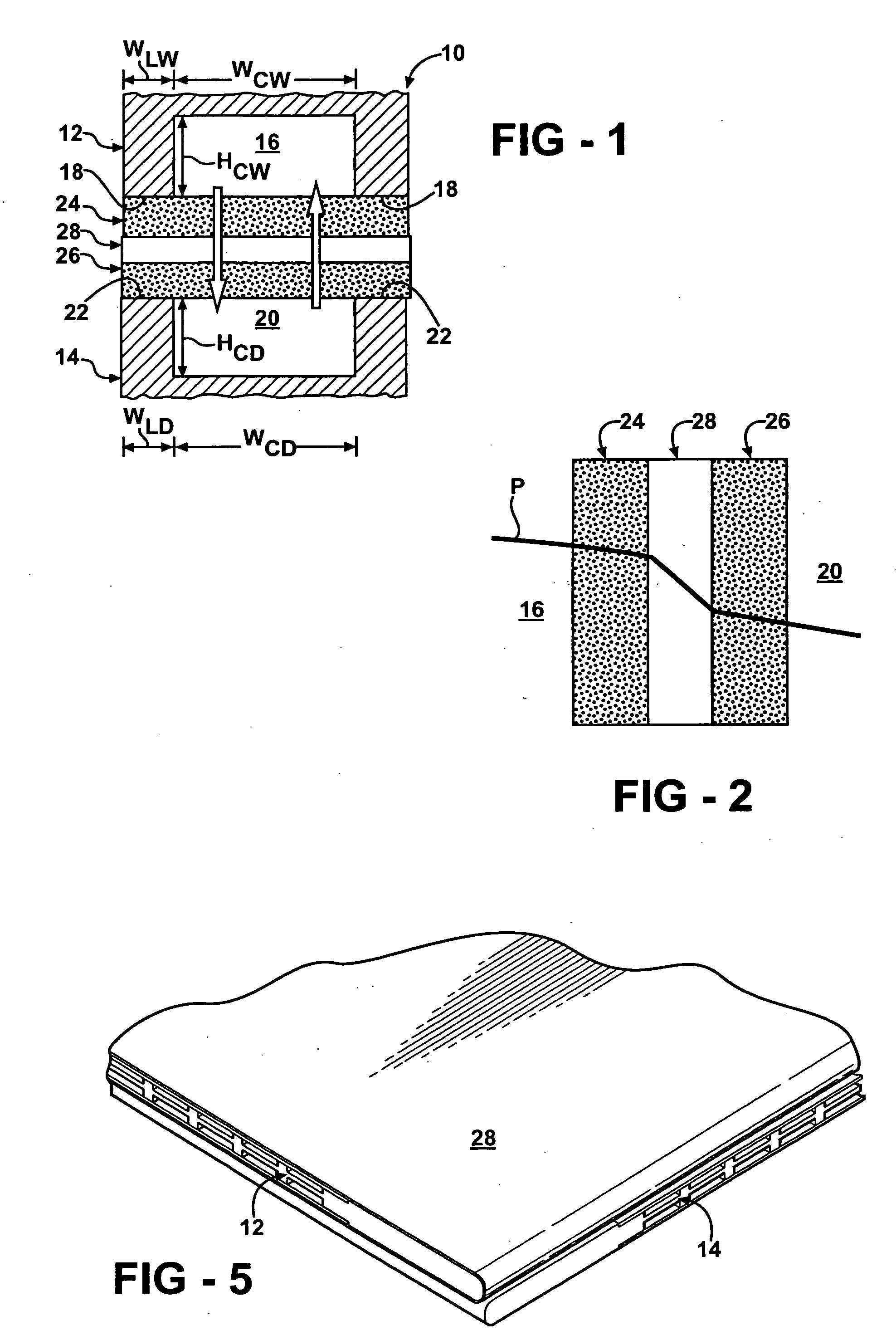

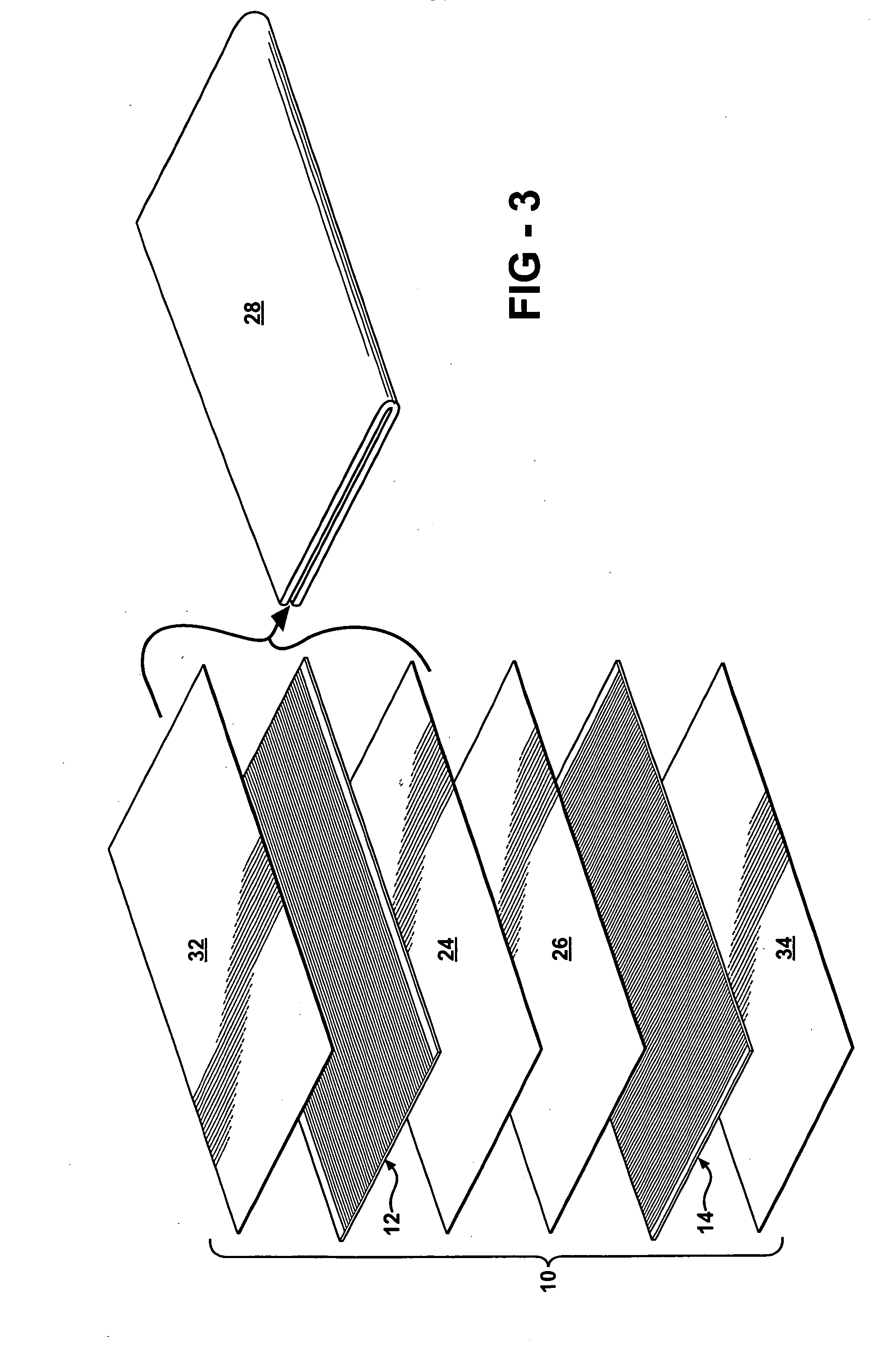

Pleated heat and humidity exchanger with flow field elements

InactiveUS20080085437A1Fuel cell heat exchangeUsing liquid separation agentFuel cellsMembrane surface

A heat and humidity exchanger comprises a pleated membrane cartridge disposed in a housing. The cartridge comprises a pleated water-permeable membrane via which heat and humidity can be transferred between two fluid streams. A flow field element is disposed within some or all of the folds of the pleated membrane, for directing the stream over the inner surfaces of the folds. The flow field path defined by the flow field element enhances flow distribution across one or both membrane surfaces, controlling the relative flow paths of the two streams on opposite sides of the membrane and reducing the pressure drop across the heat and humidity exchanger. The flow field elements provide improved water transfer and allow for a more compact device. The flow field elements can also assist in supporting the pleated membrane and controlling the pleat spacing within the pleated membrane cartridge. The heat and humidity exchanger is particularly suitable for fuel cell and energy recovery ventilator (ERV) applications.

Owner:DPOINT TECH

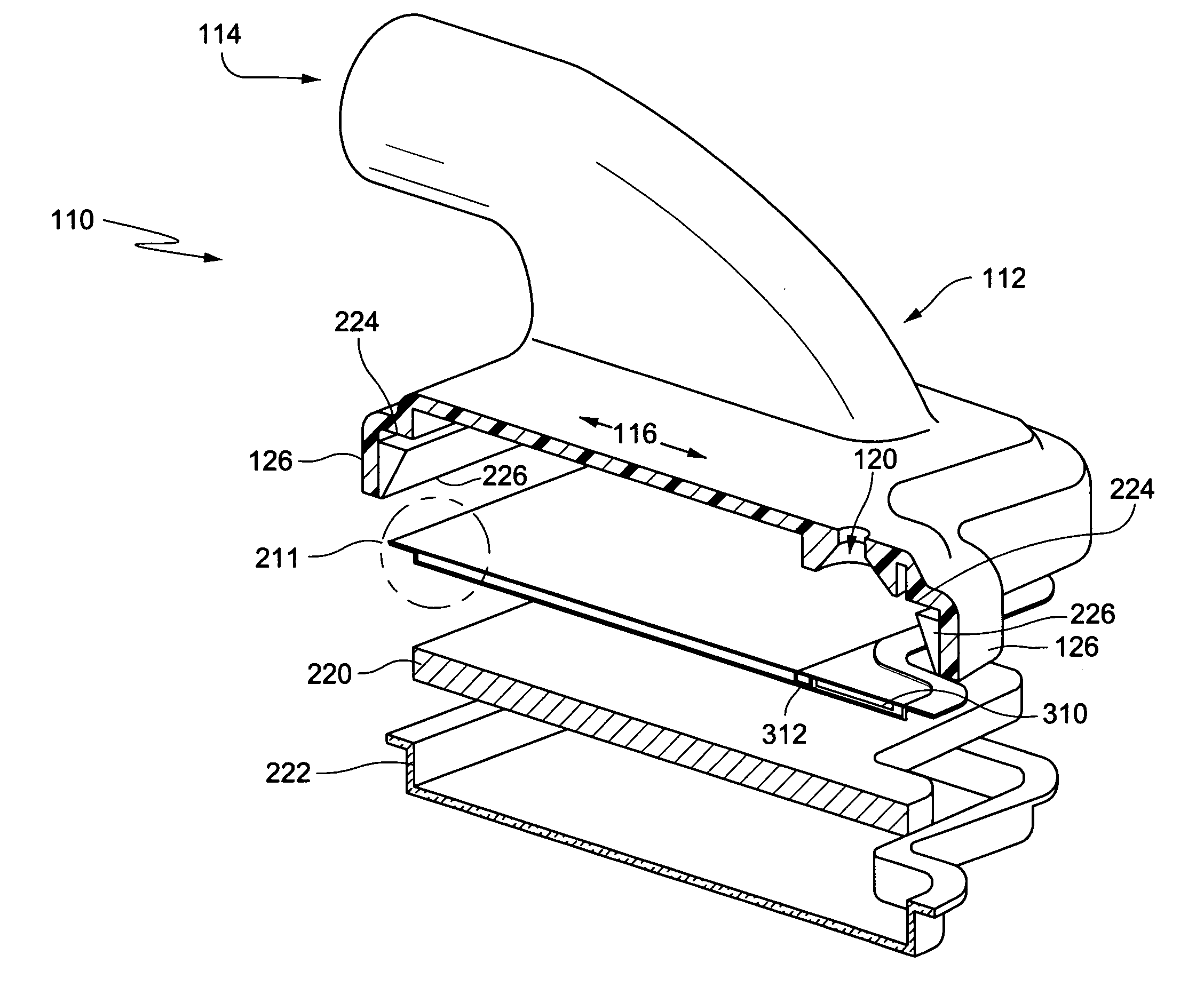

Omnidirectional portable appliance for steam cleaning hard or flexible surfaces

InactiveUS6031969ALow costStart fastUsing liquid separation agentCleaning machinesElectricityElectrical resistance and conductance

The omnidirectional portable appliance for steam cleaning surfaces both hard and flexible, comprises a case provided with a handle, a water feed orifice, an electricity power cord, a cleaning head, a steam generator included in the case and a venturi device [means for selectively] delivering steam to the cleaning head. The instantaneous steam generator having low thermal inertia operates at atmospheric pressure and comprises a capillary body for storing in divided form all of the supply of water to be evaporated, [in divided form] the capillary body being compressed around [the electrical heater means which comprise] a [metal-clad] resistance element and a heater body constituted by a [having a] material that is a good conductor of heat, is overmolded on the resistance element and [thereon to form a heater body which] is associated with at least one heat transmission element connected to [the] a hottest portion of the heater body and provided with a temperature sensor enabling the control of power fed to the [metal-clad] resistance element to be optimized so as to be safe regardless of the orientation in three dimensions of the steam generator.

Owner:SUPERBA SAS

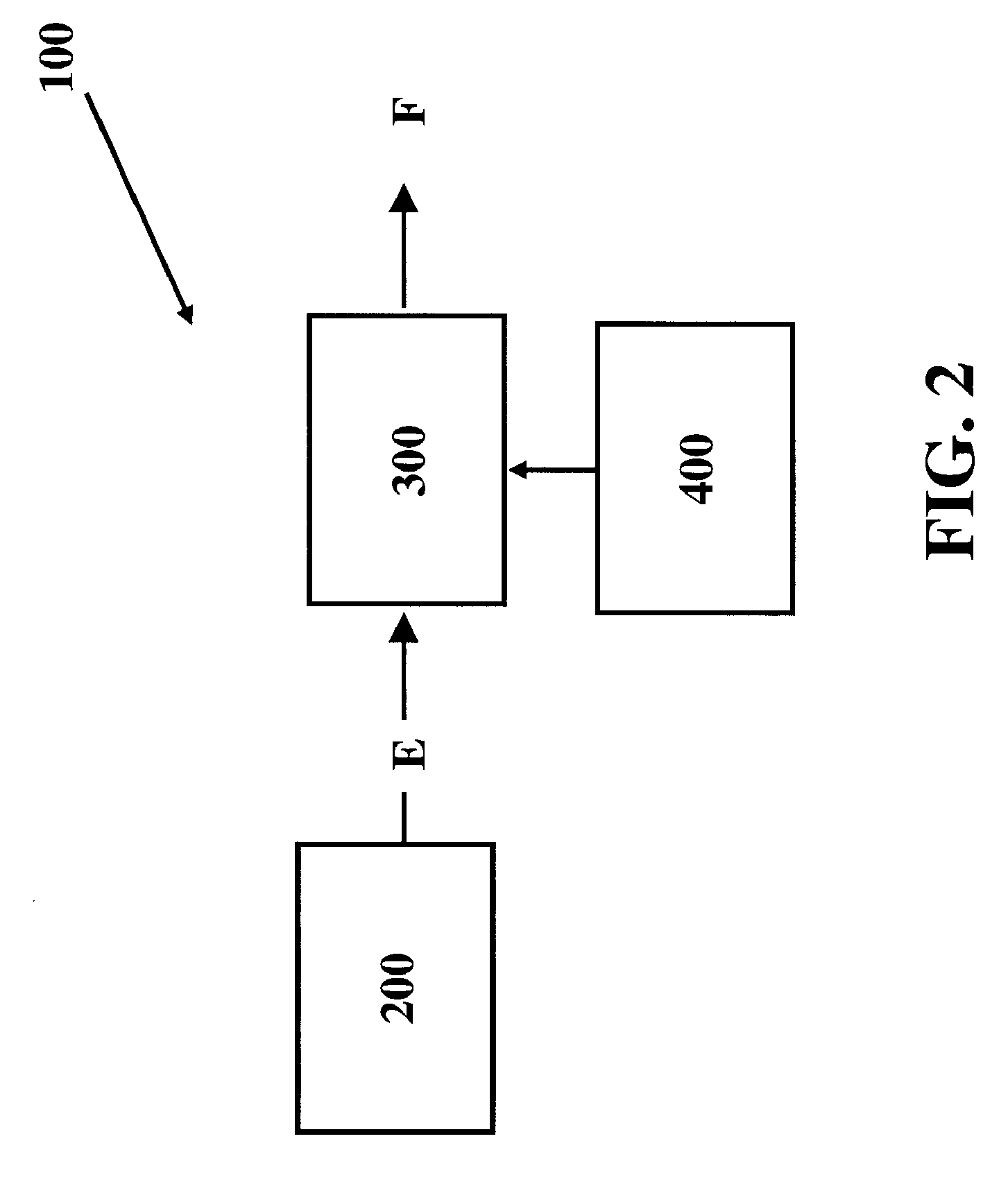

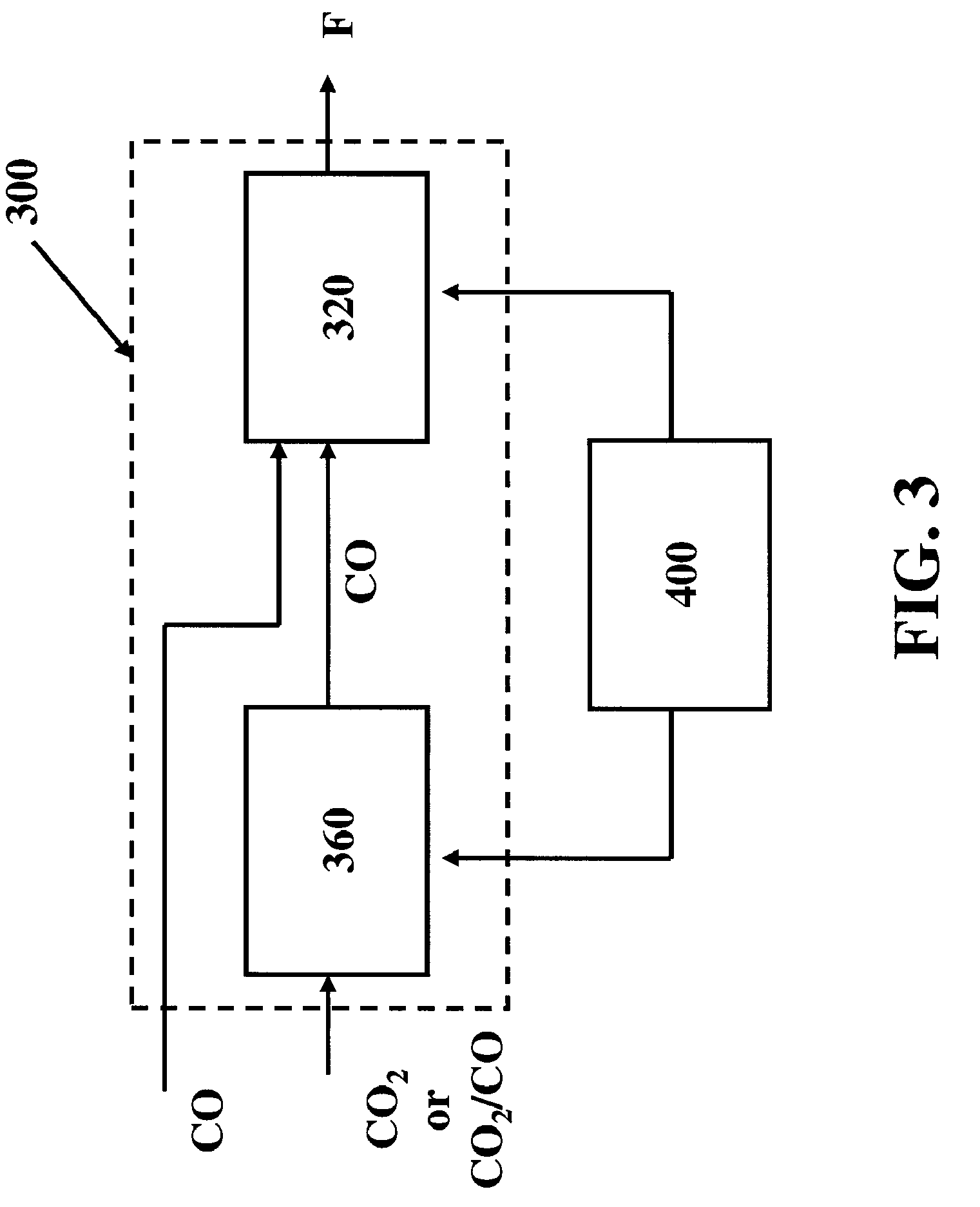

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS20060211777A1Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneHydrocotyle bowlesioides

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolysing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

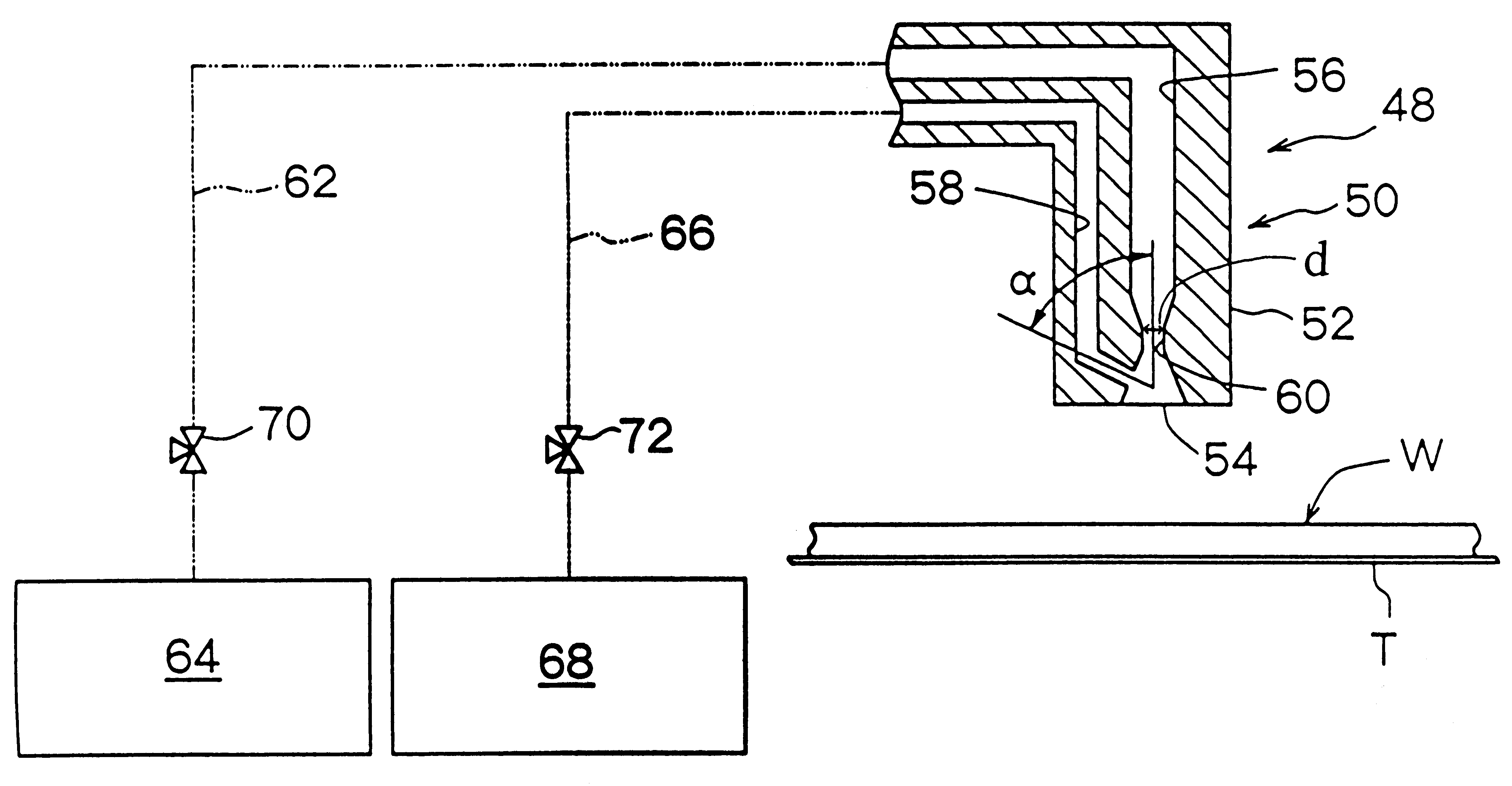

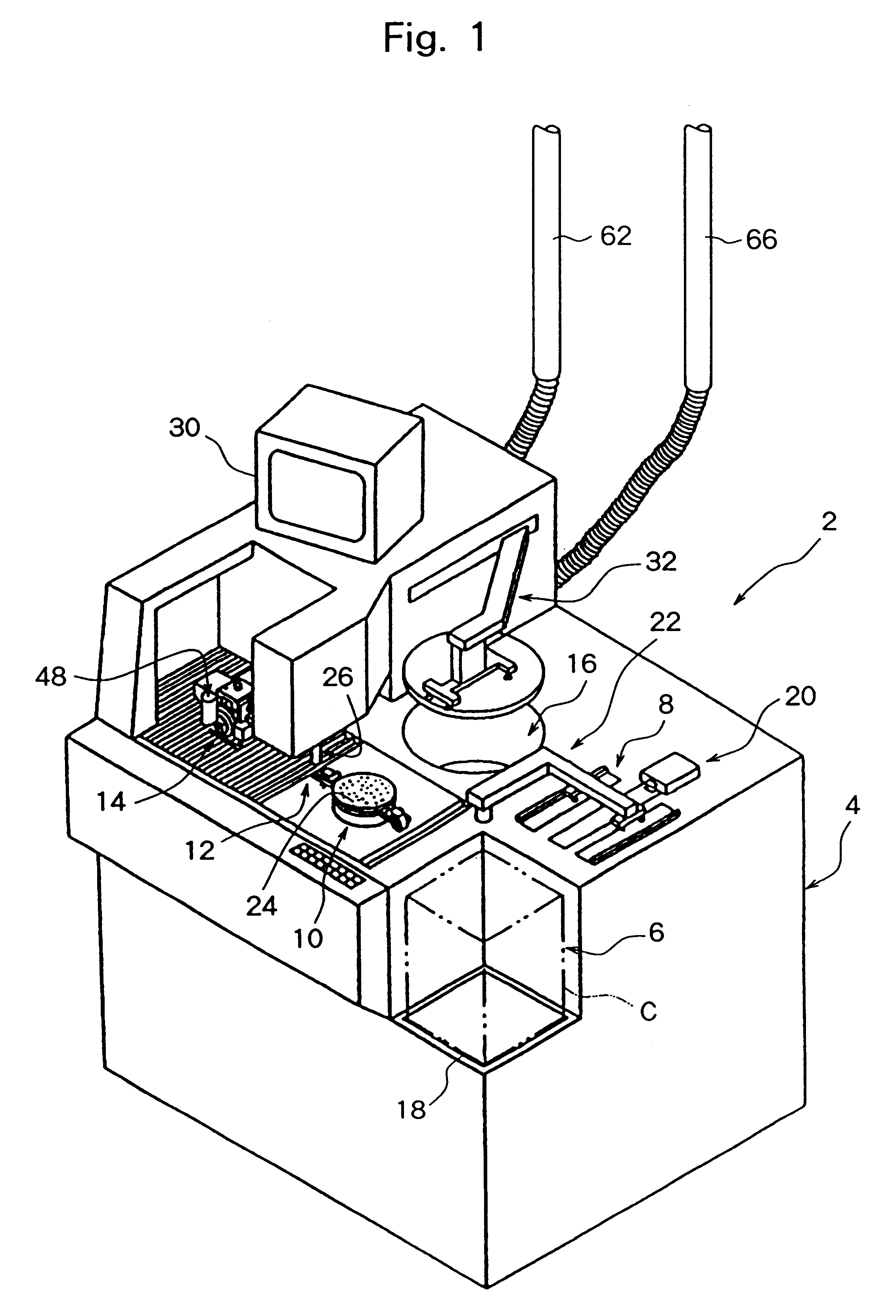

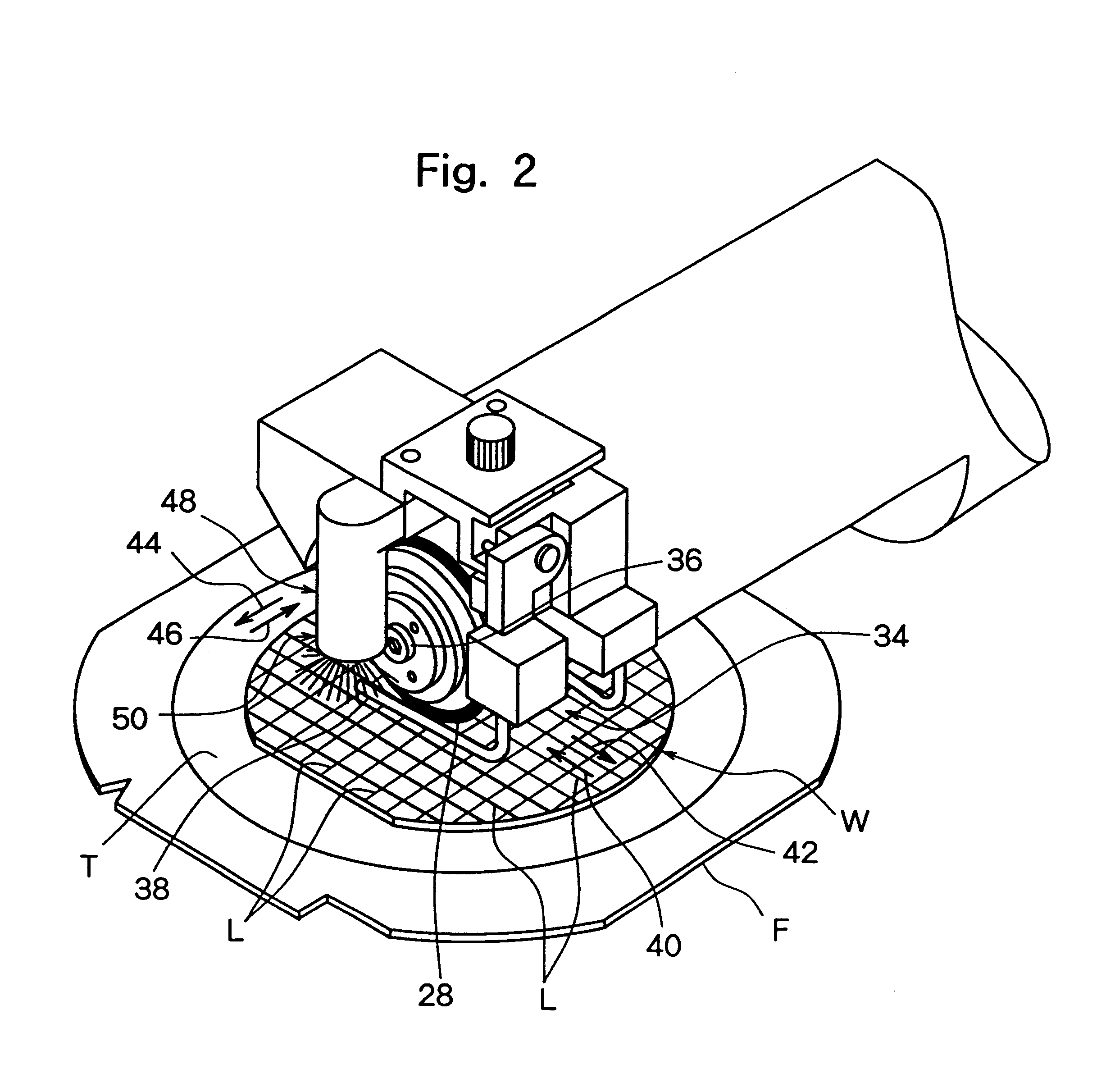

Cleaning apparatus

InactiveUS6386466B1Sufficient cleaning effectCleaning apparatus can be rendered considerably compact and inexpensiveUsing liquid separation agentMixing methodsEngineeringNozzle

A cleaning apparatus includes a nozzle having an ejection port, a cleaning liquid path communicating with the ejection port, and a compressed gas path communicating with the ejection port. The cleaning apparatus further includes a cleaning liquid feeding component for feeding a cleaning liquid to the cleaning liquid path, and a compressed gas feeding component for feeding a compressed gas to the compressed gas path. The compressed gas is ejected from the ejection port through the compressed gas path, while the cleaning liquid is ejected from the ejection port through the cleaning liquid path.

Owner:DISCO CORP

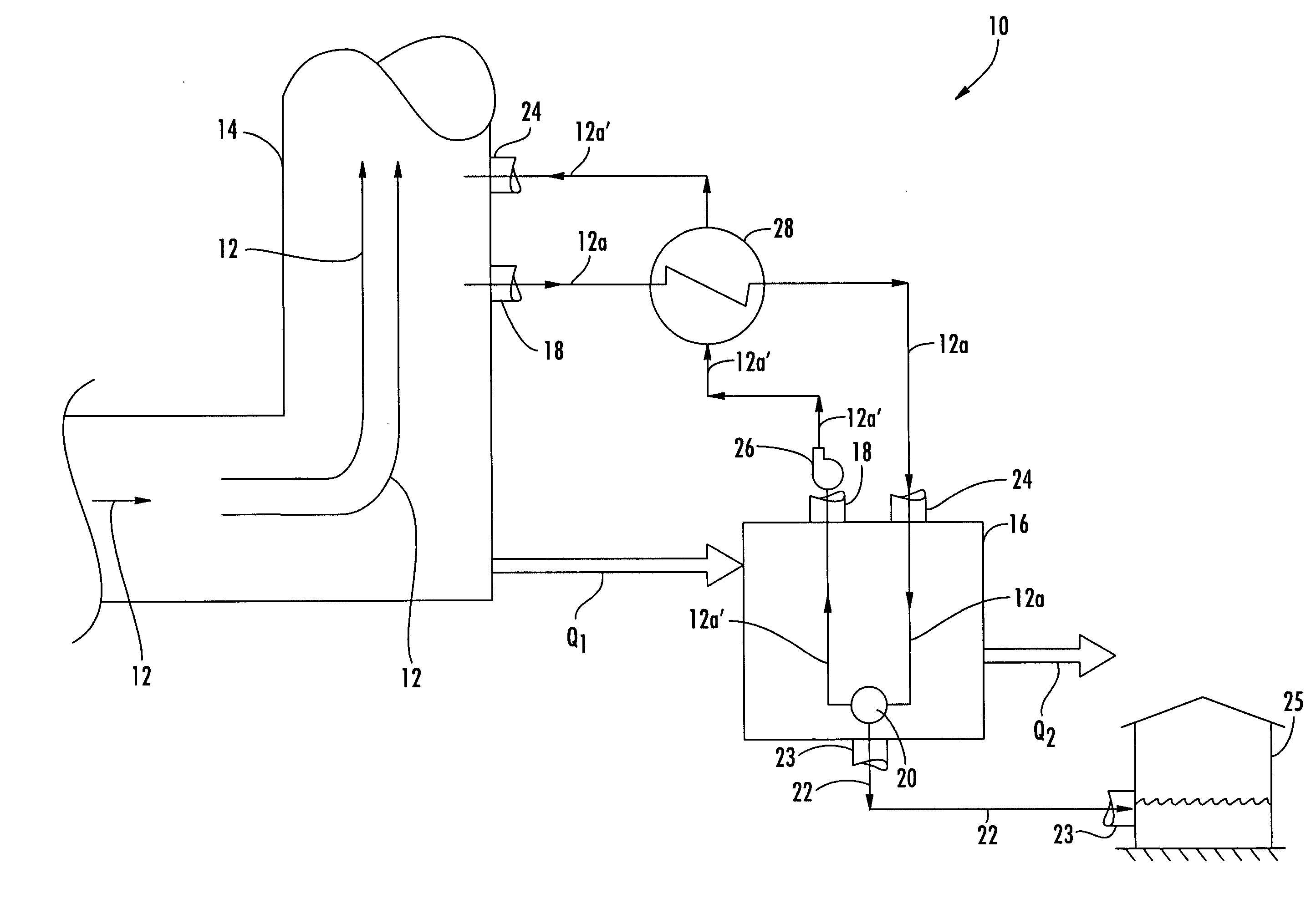

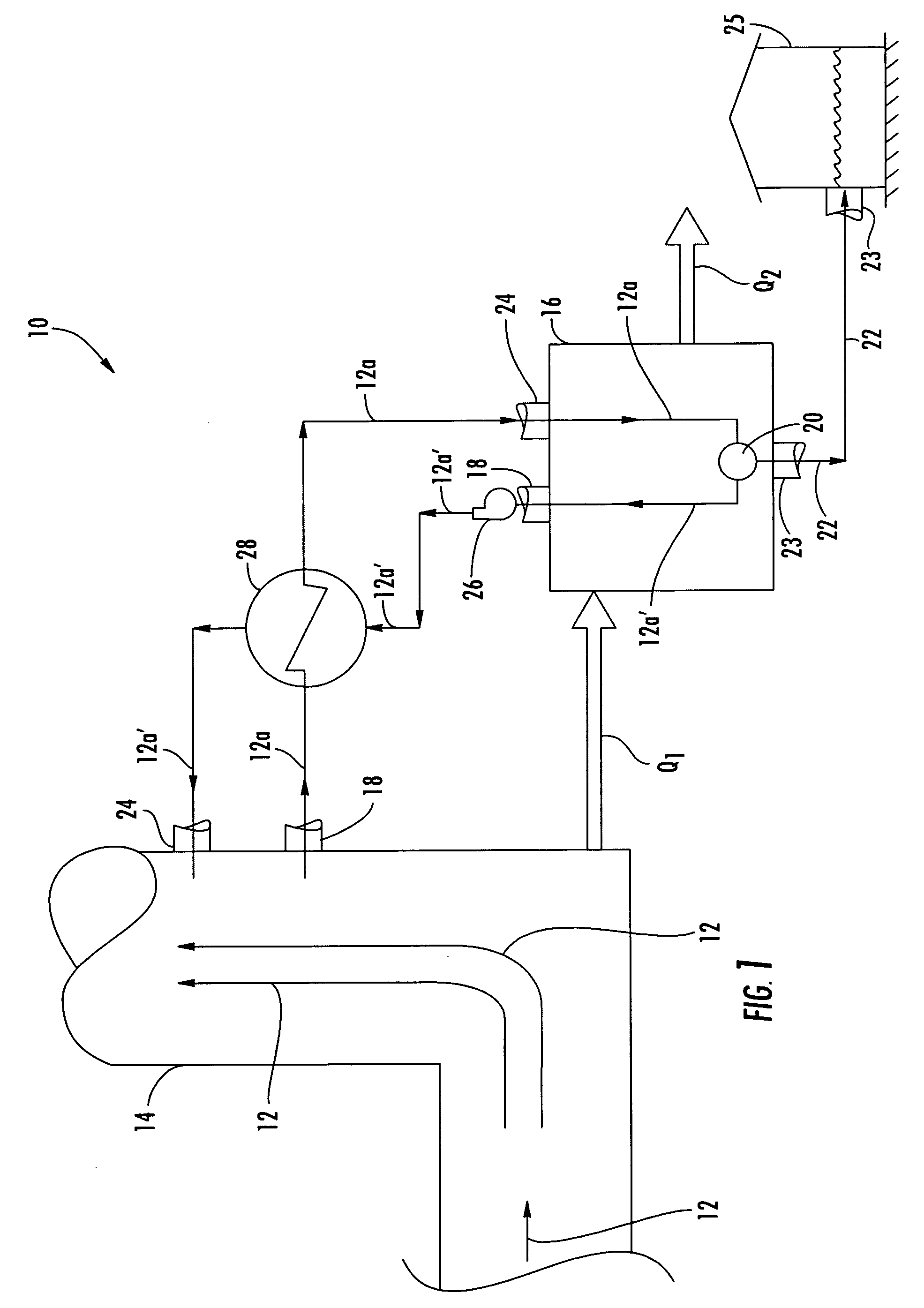

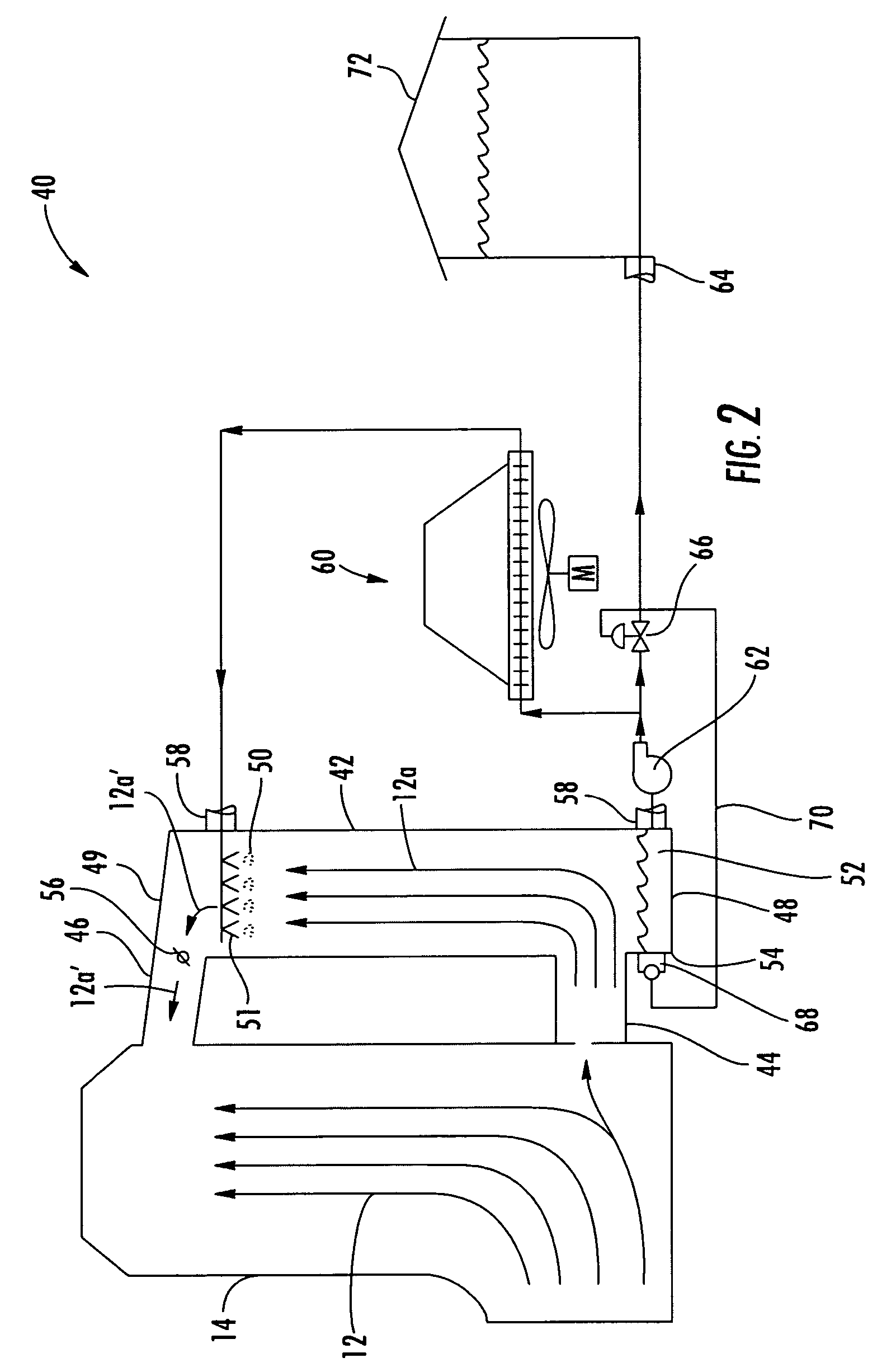

Turbine exhaust water recovery system

ActiveUS7194869B2Reduce the temperaturePromote sportsUsing liquid separation agentGas turbine plantsWater sourceLiquid water

The exhaust gas of a turbine engine can include water vapor. Aspects of the invention relate to various systems for recovering water from the exhaust gas of a gas turbine engine. In one system, a portion of the exhaust gas can be routed to an absorption chiller. In another system, a portion of the exhaust gas can be routed to a direct contact heat exchanger. In a third system, a portion of the exhaust gas can be routed to a fin-fan cooler. In each of these systems, the portion of gas can be cooled below its dew point temperature to release a portion of its humidity as liquid water. Aspects of the invention can be used with the turbine exhaust of simple and combined cycle power plants. A water recovery system according to aspects of the invention can minimize or eliminate a power plant's dependence on local water sources.

Owner:AMEC FOSTER WHEELER IND POWER CO INC

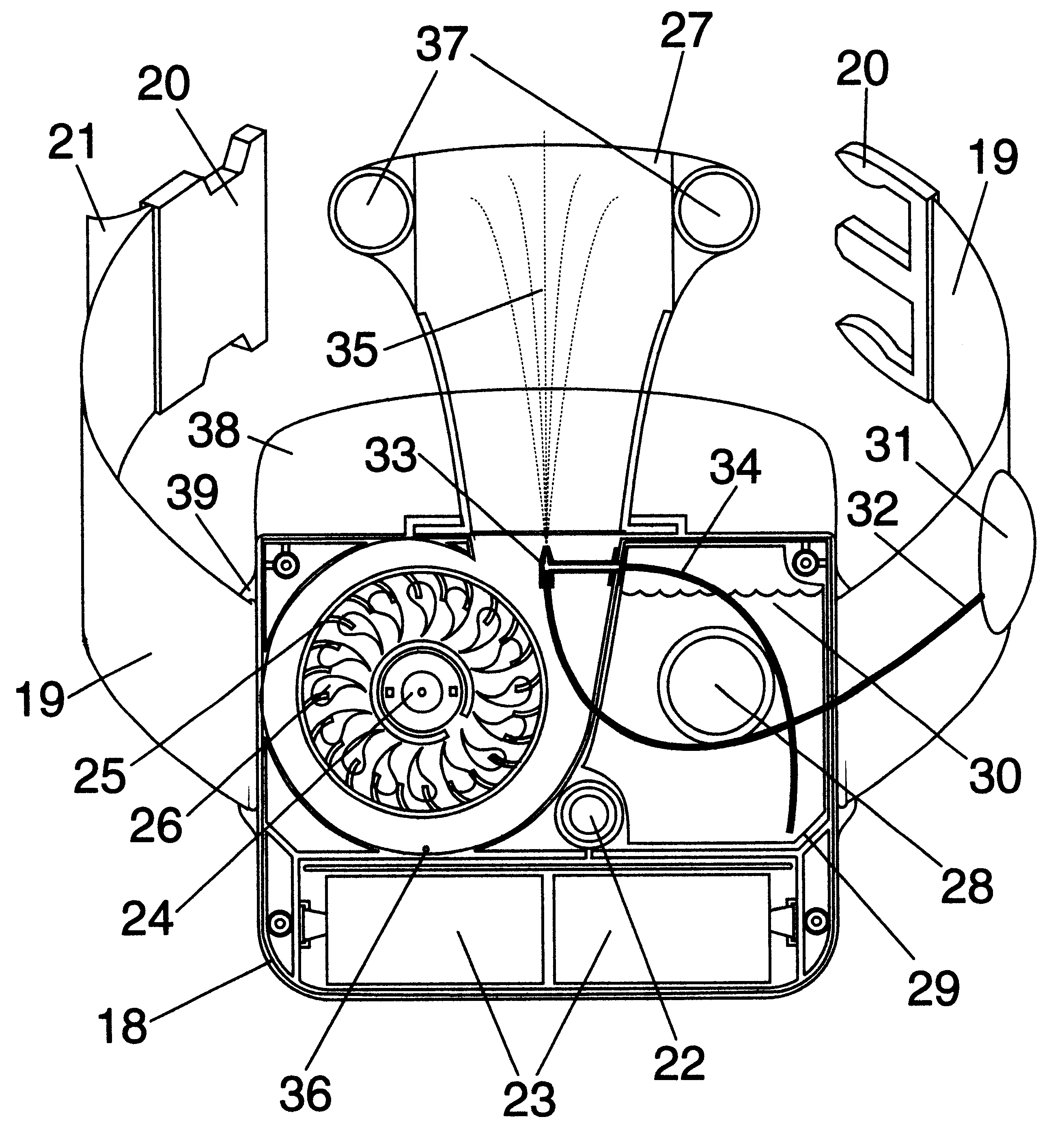

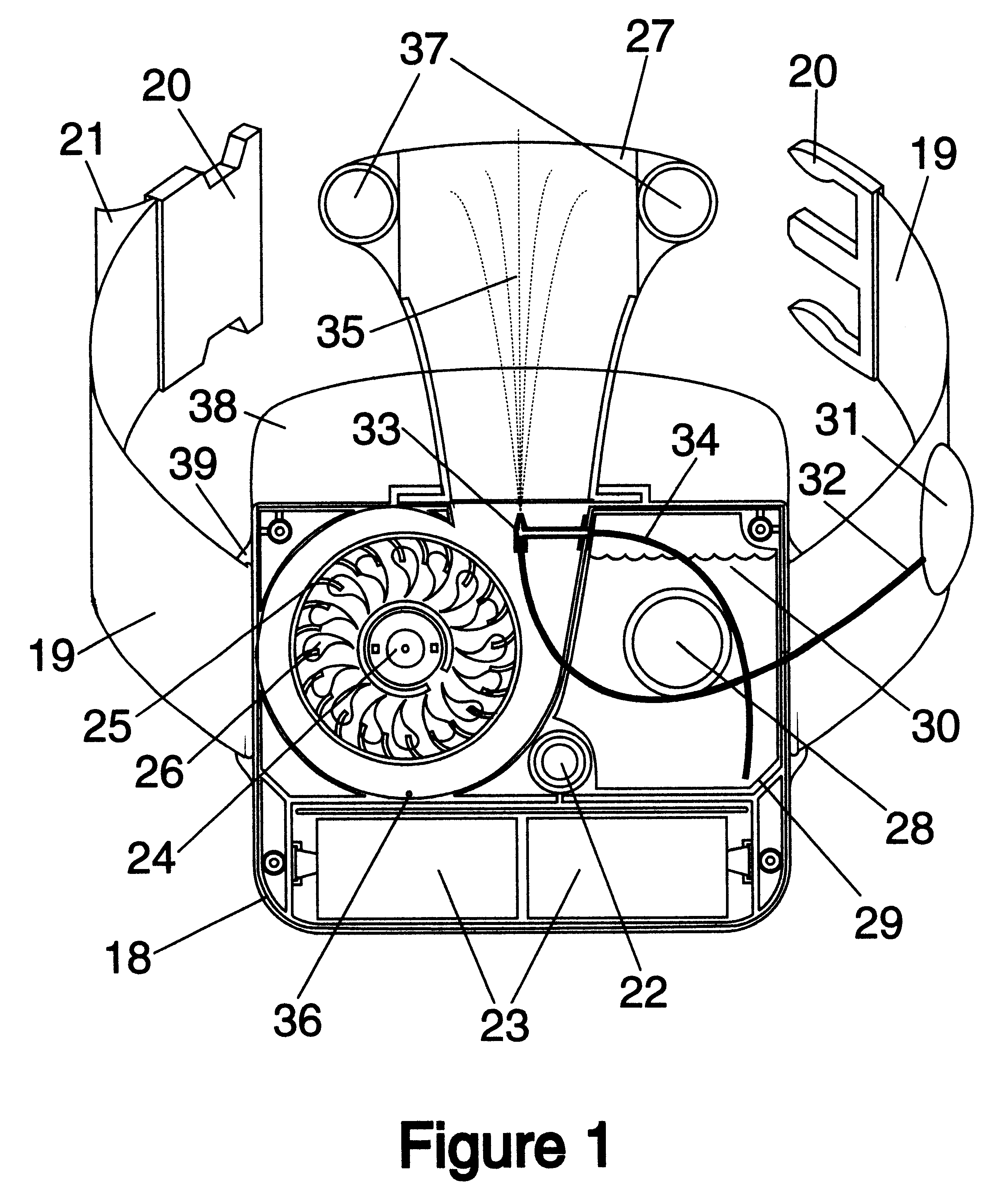

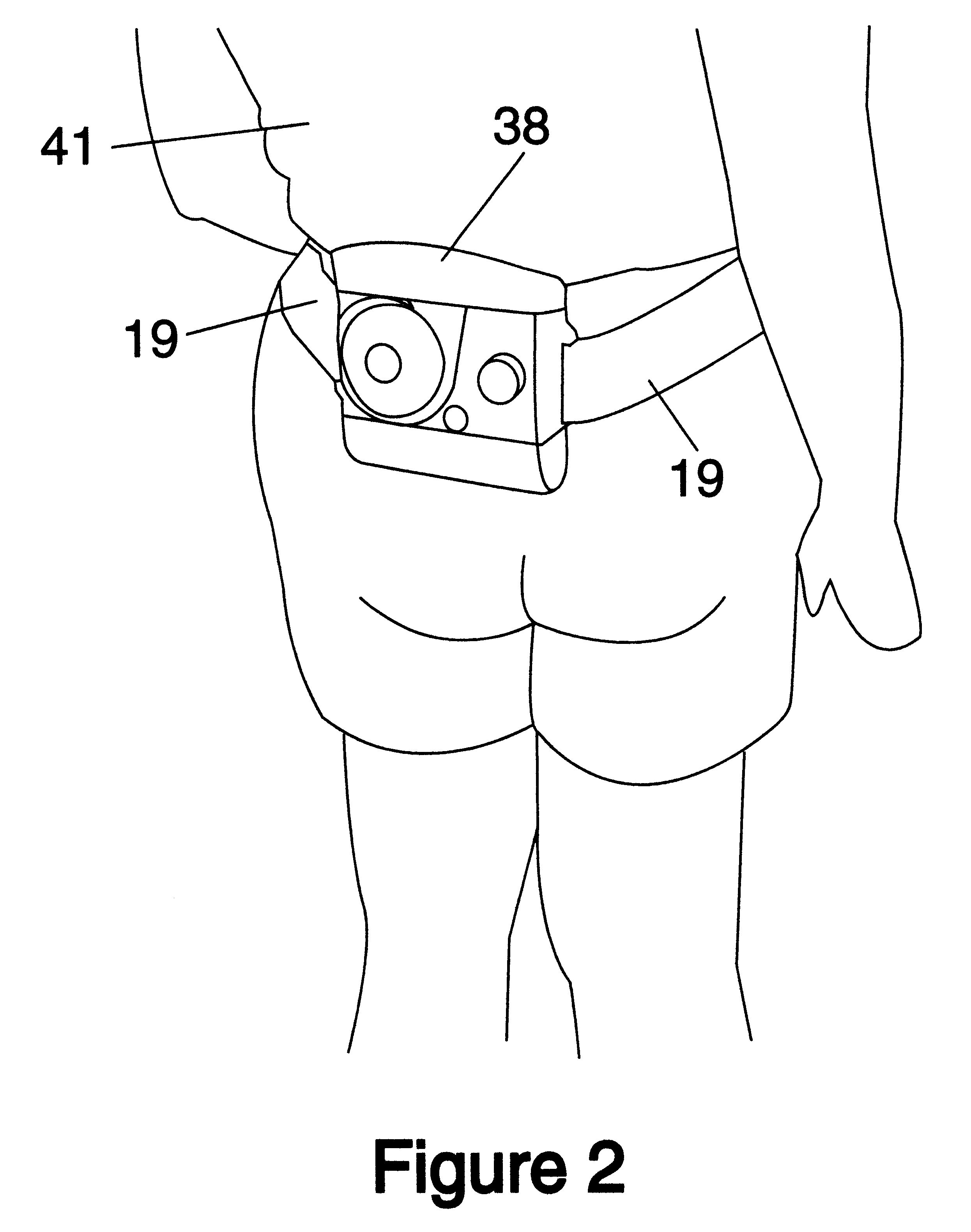

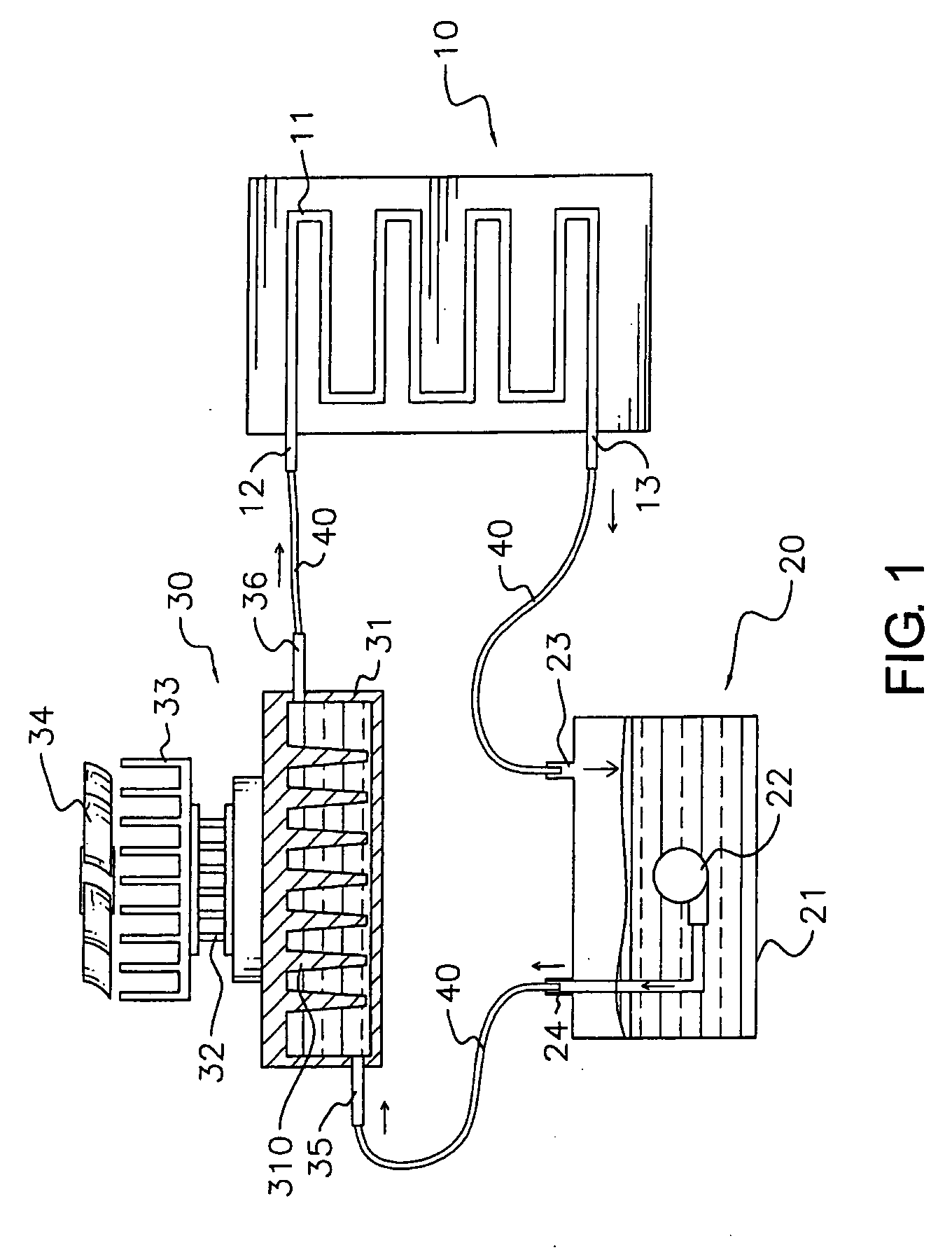

Waist-mounted evaporative personal cooler

A waist-mounted evaporative personal cooling device designed to cool the back of a user, comprises a blower (25), a liquid reservoir (29), a means to deliver liquid from the reservoir a mist of droplets into blower-forced air (33) or directly onto the skin area to which the forced air will be directed (45), and a duct (27) to guide forced air under the user's shirt or blouse and directly onto or across the skin of the user's back. The device improves on prior art coolers by delivering a powerful evaporative cooling effect directly to a user's back, while being compact, comfortably wearable, and requiring the user to do little or nothing to get its benefit.

Owner:STRAUSS TED

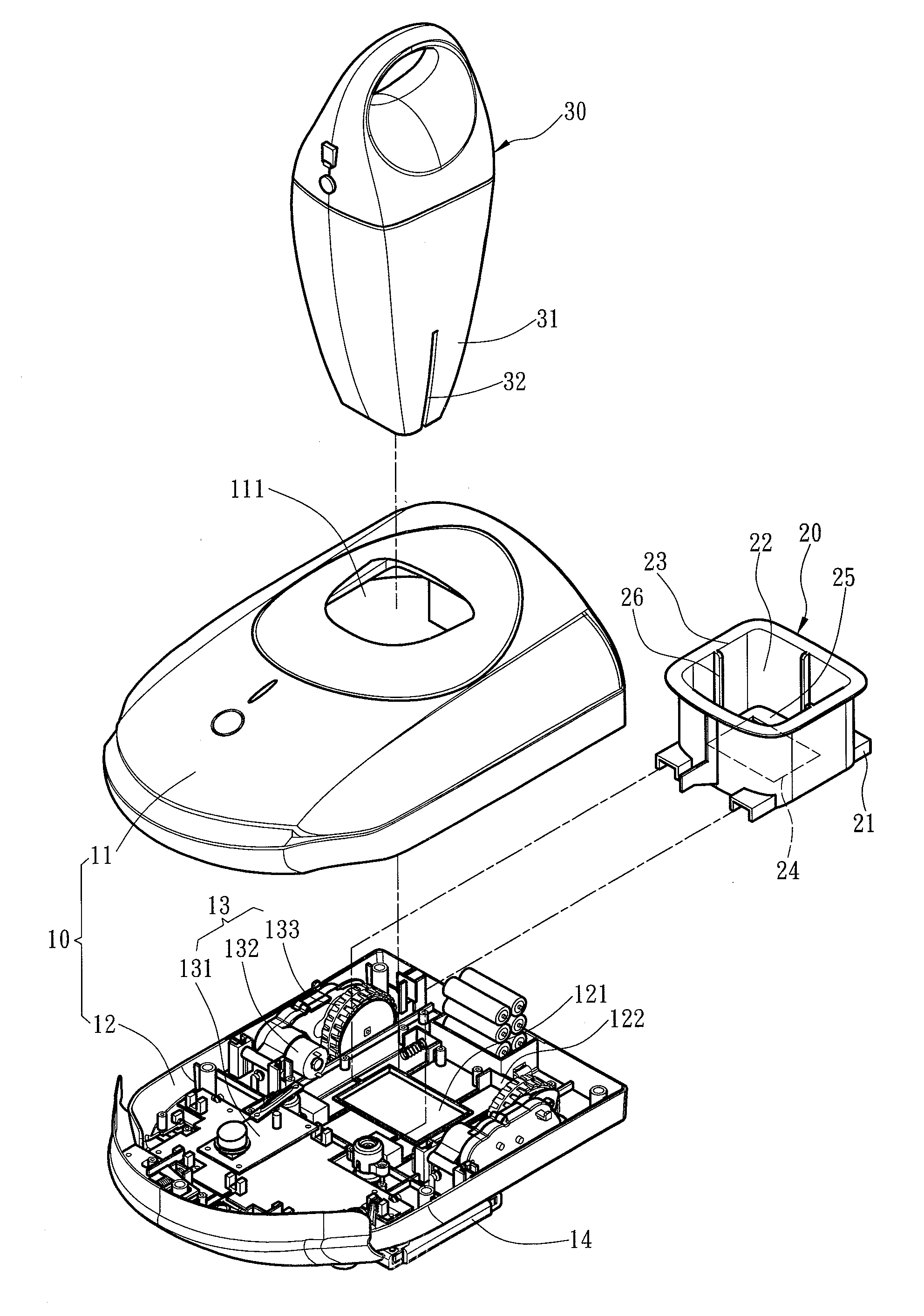

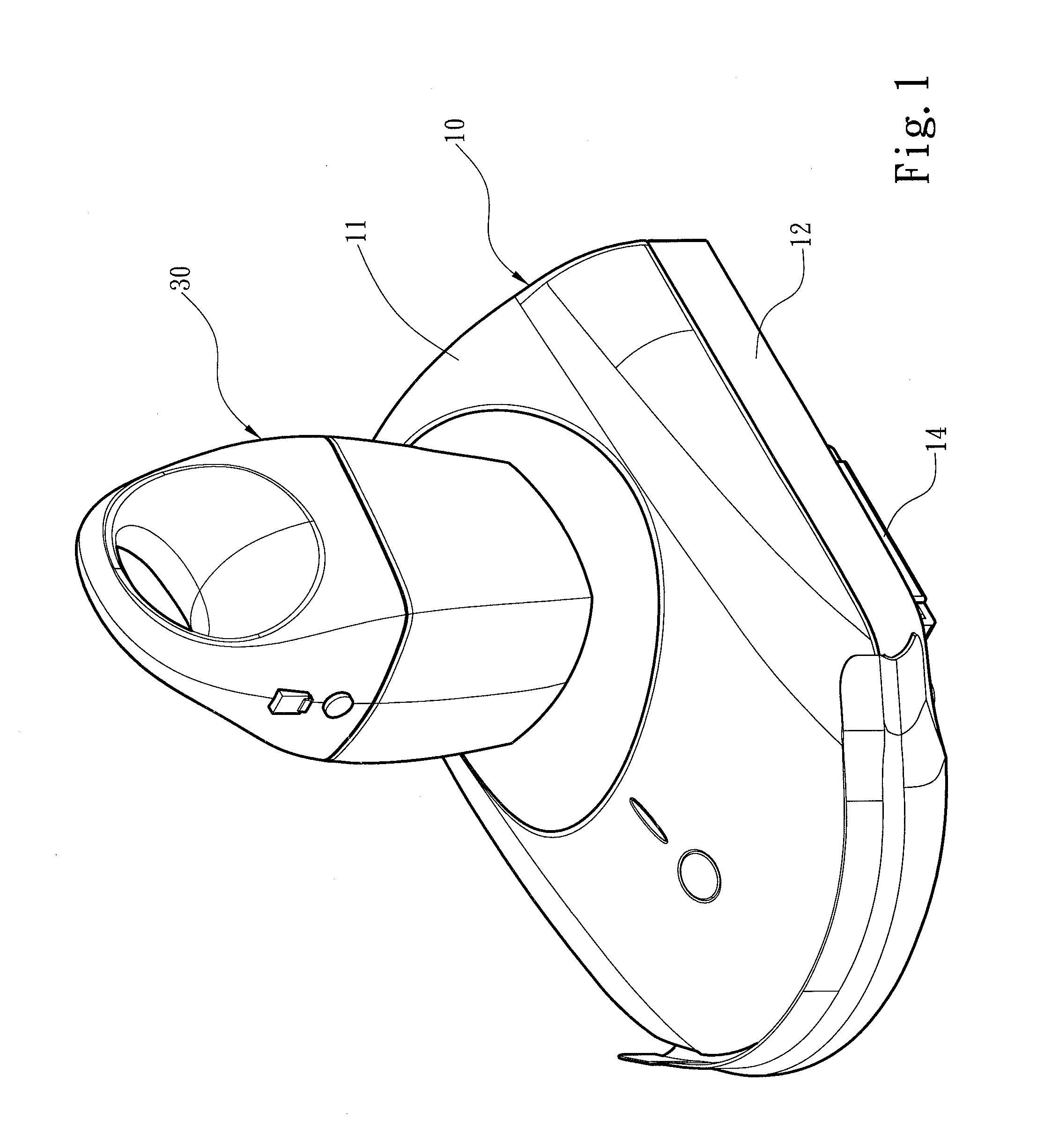

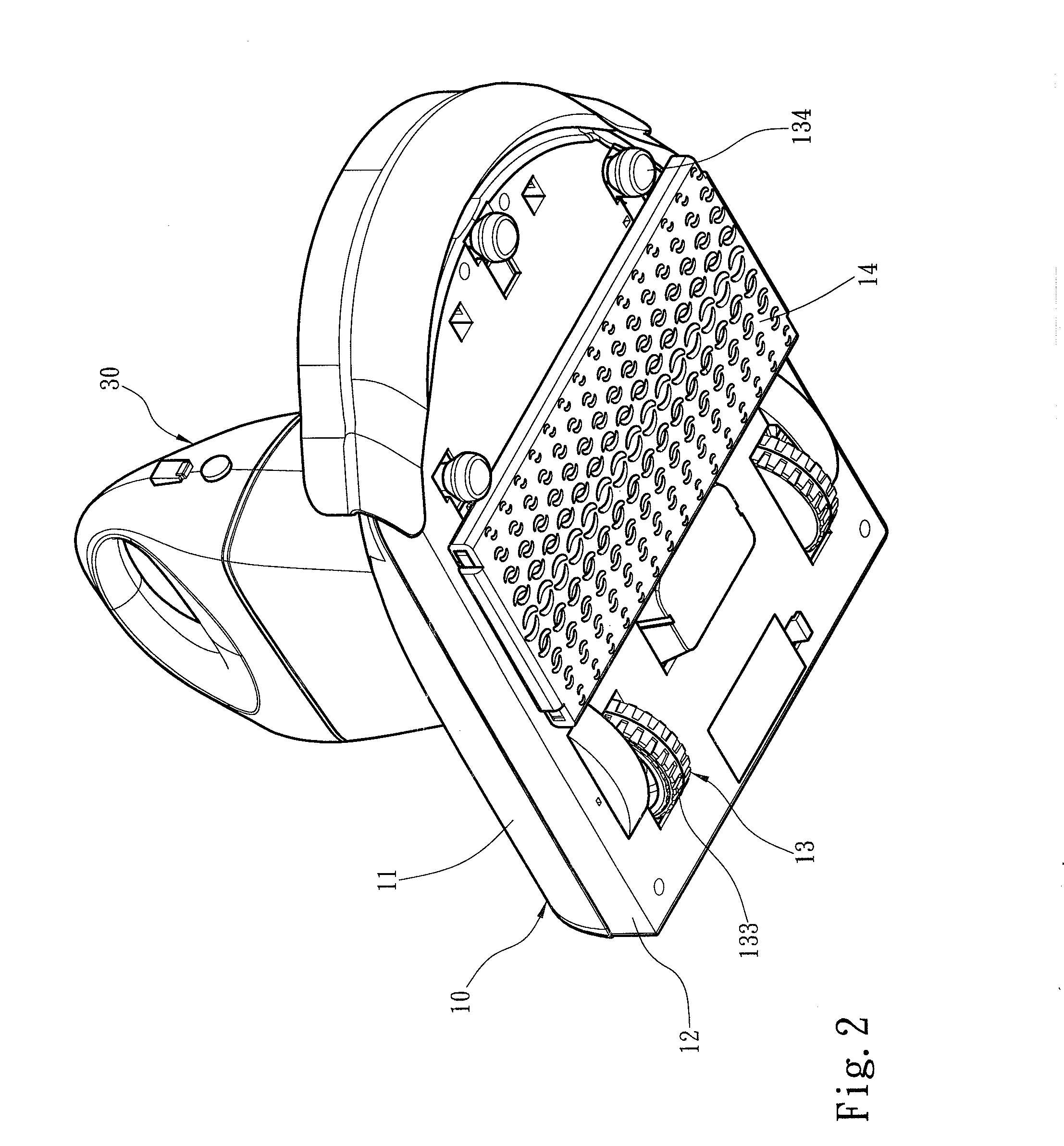

Modular automatic traveling apparatus

A modular automatic traveling apparatus includes a seat and an external coupling device mounted onto the seat. The seat includes a moving device to allow the seat to move automatically and an assembling passage which has two ends formed respectively an inlet and a holding orifice. The holding orifice has a detent portion on the perimeter thereof. The external coupling device has an installation portion which is inserted into the assembling passage through the inlet and latched on the detent portion and anchored on the holding orifice, thus is movable automatically with the seat. Users can change the external coupling devices with varying functions such as a vacuum cleaner, odorator and the like to automatically perform different types of tasks through the automatic movement of the seat.

Owner:KO JOSEPH Y

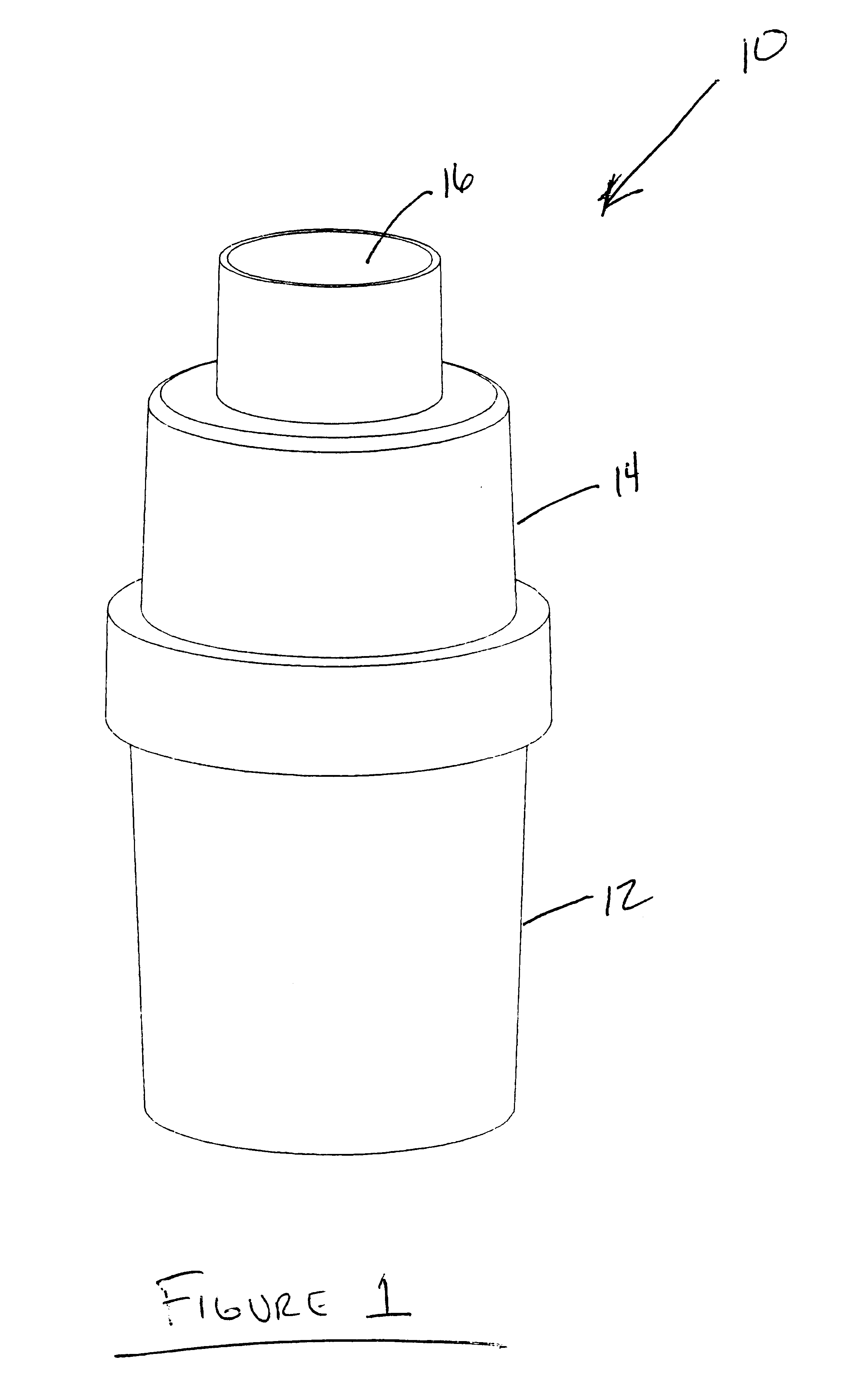

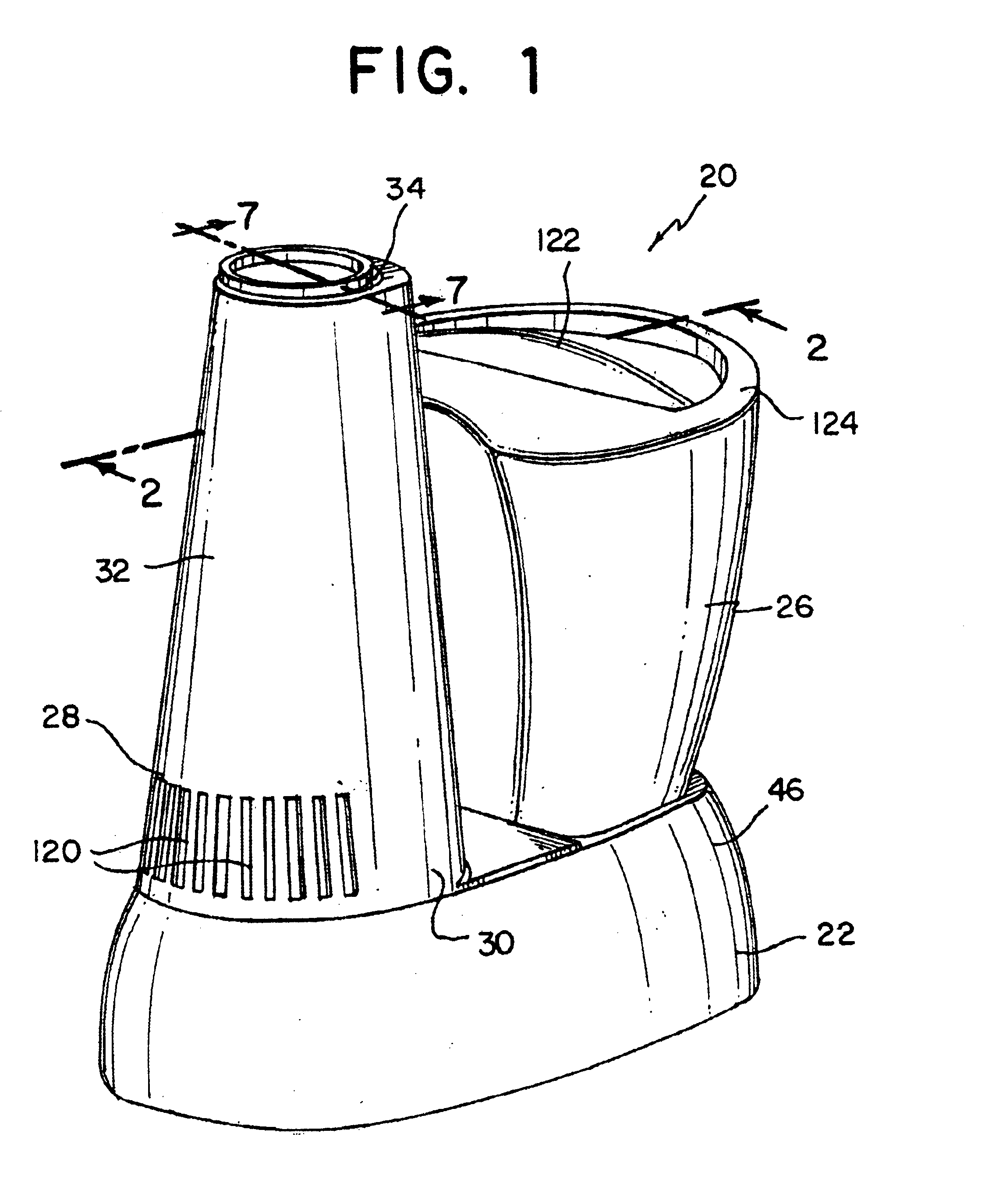

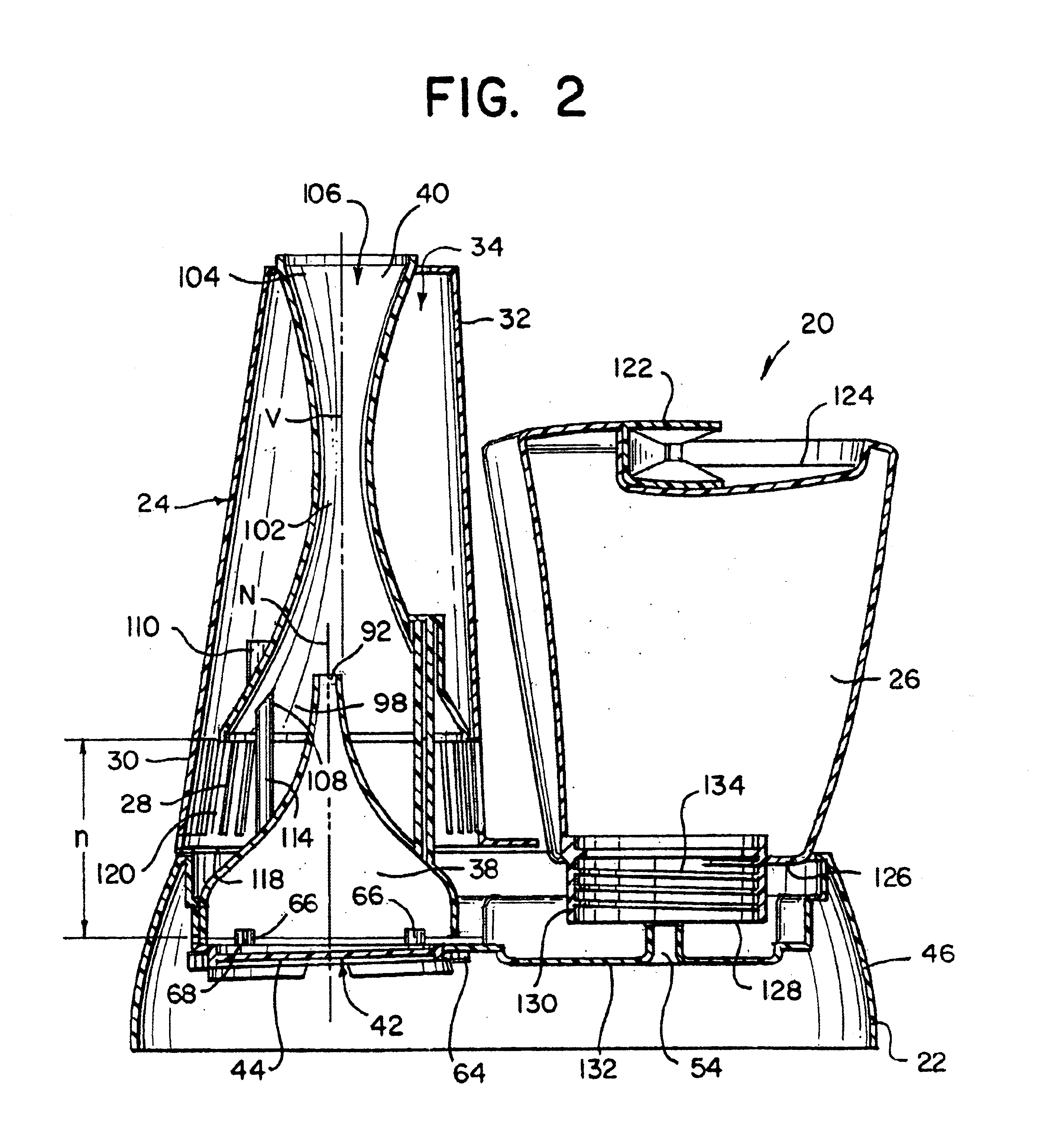

Humidifier with a heating disc

InactiveUS6874771B2Lighting and heating apparatusMixing methodsLiquid storage tankMechanical engineering

A humidifier includes a base defining a reservoir for retaining liquid, a humidification device for inducing dispersion of liquid withdrawn from the reservoir into the environment and a liquid storage tank having an outlet for feeding liquid into the reservoir. The humidification device includes a heated disc for evaporating a stream of liquid delivered from the reservoir to the heated disc by a delivery mechanism. The delivery mechanism may deliver the stream of liquid as a mist, a thin film or a controlled stream of liquid onto the disc.

Owner:HELEN OF TROY LIMITED

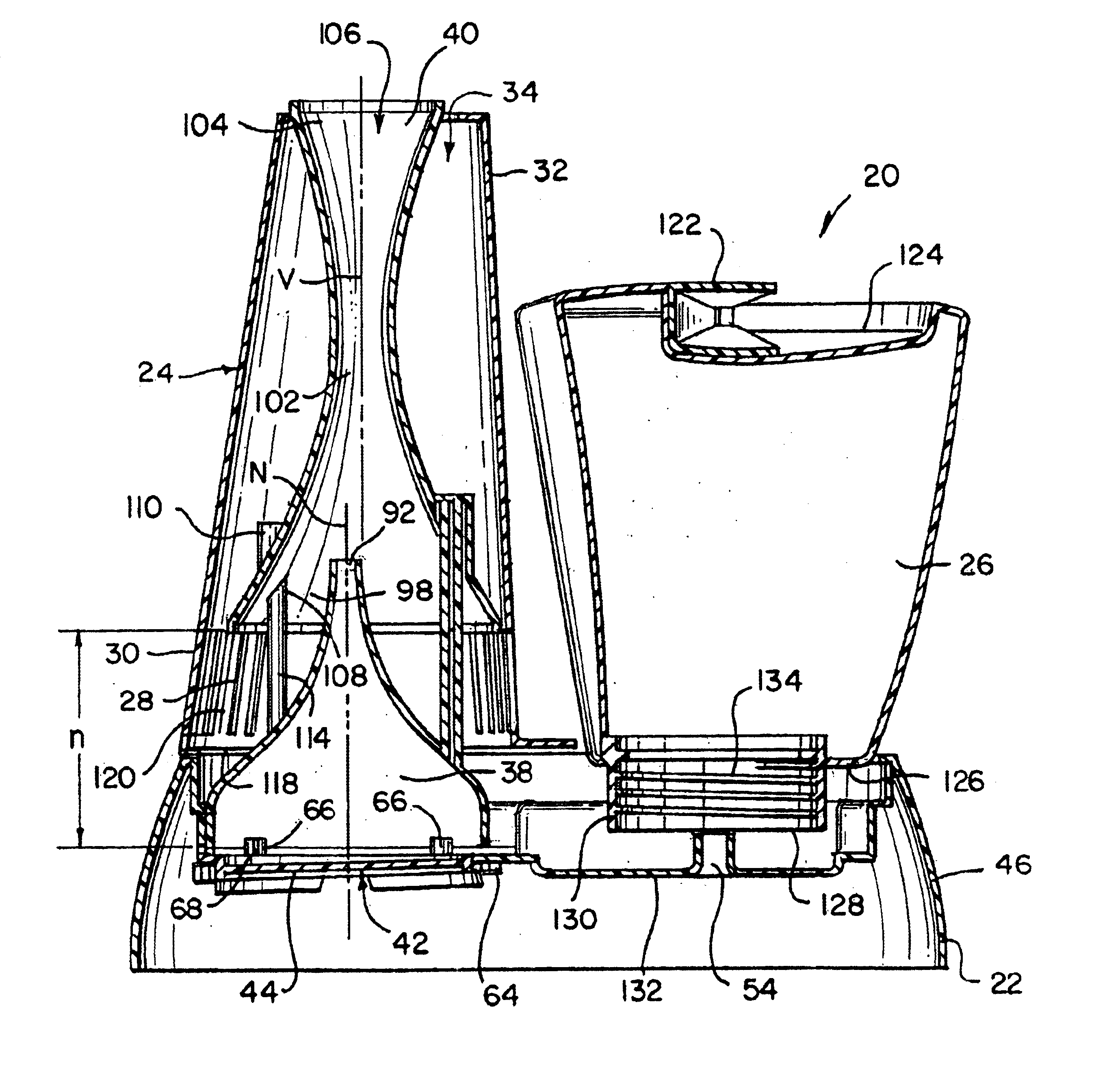

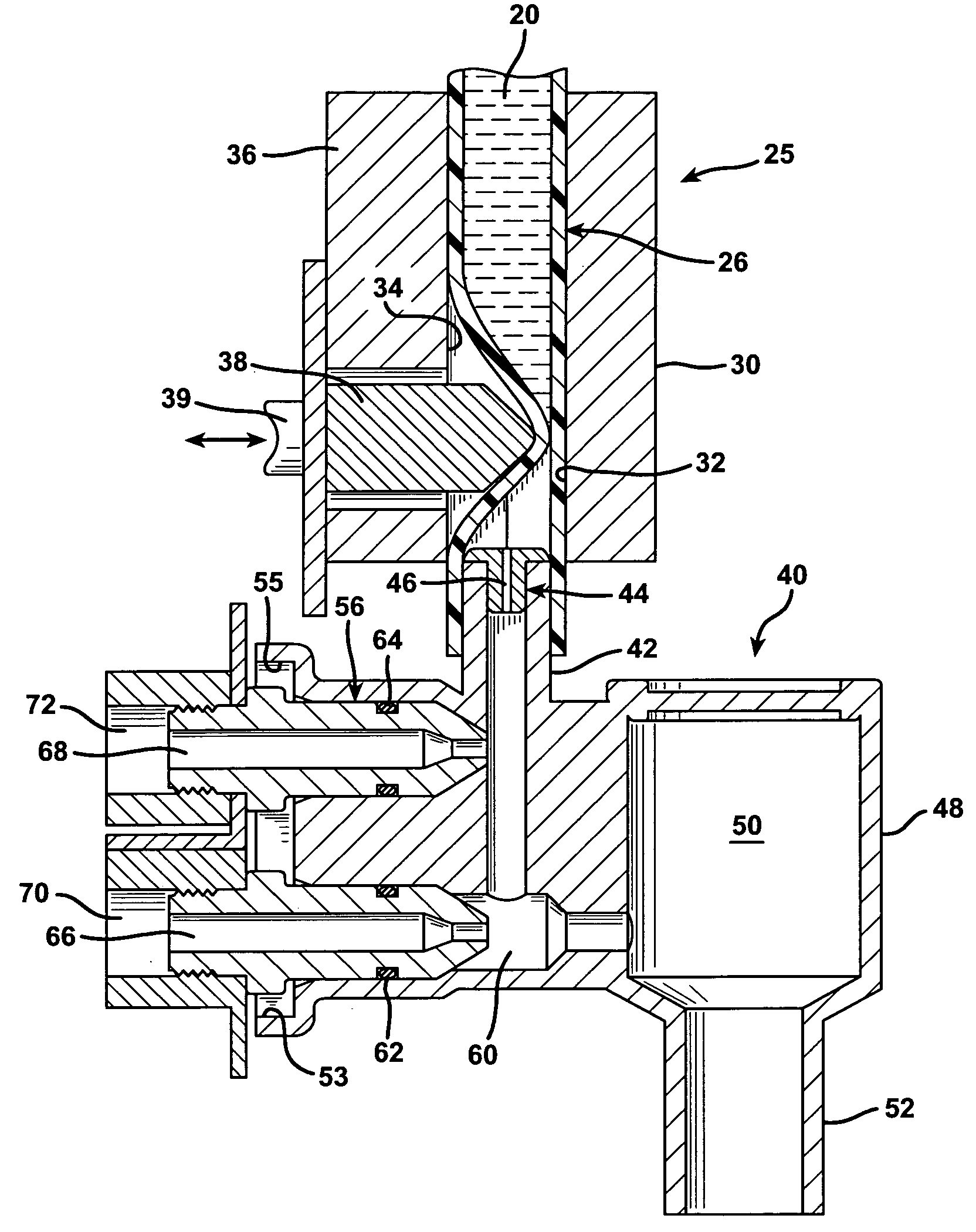

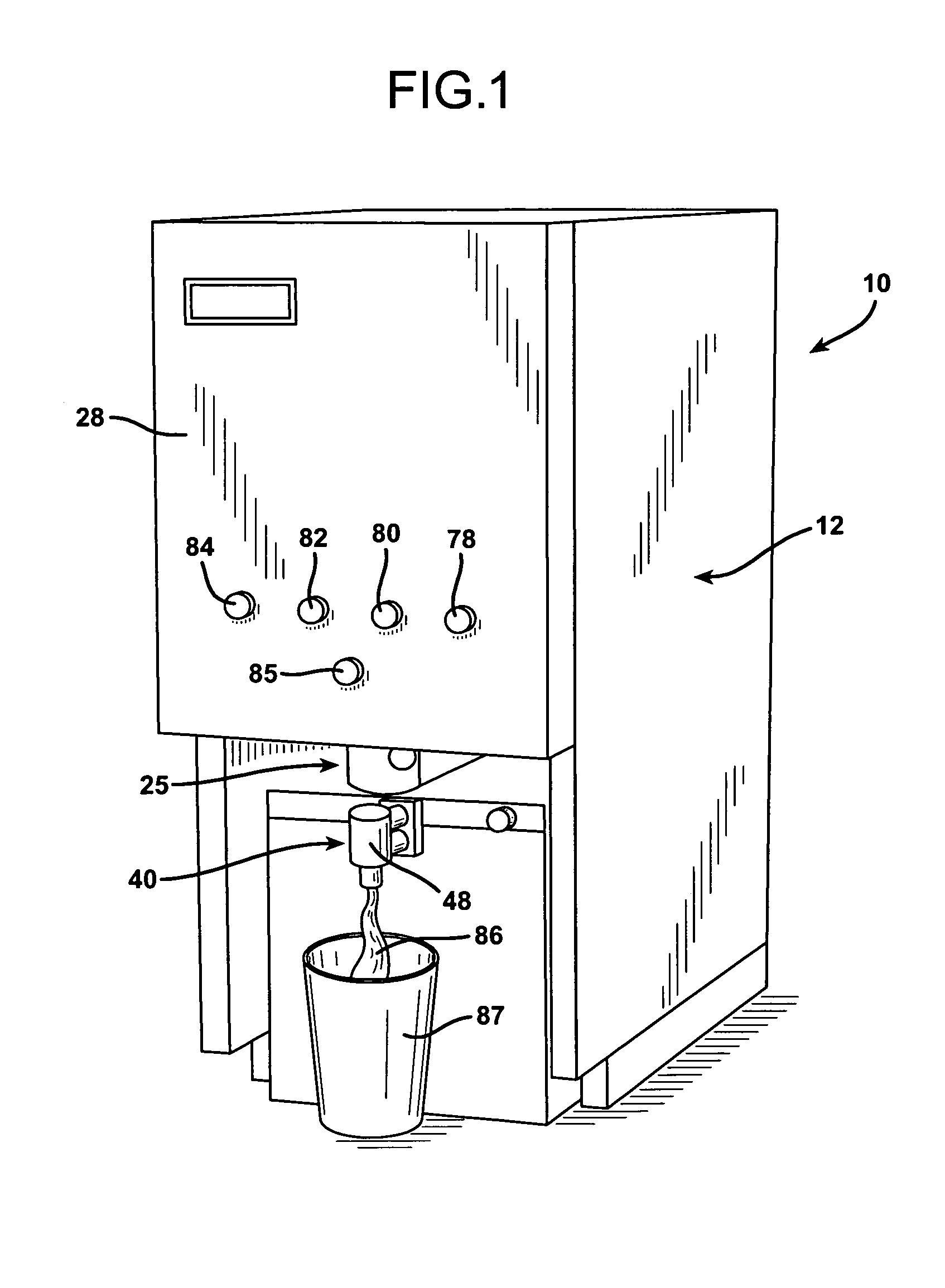

Hot dairy-based beverage dispenser

InactiveUS7021206B2Reduce eliminateConstant flowLighting and heating apparatusUsing liquid separation agentPinch valveEngineering

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a “bag in box” cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

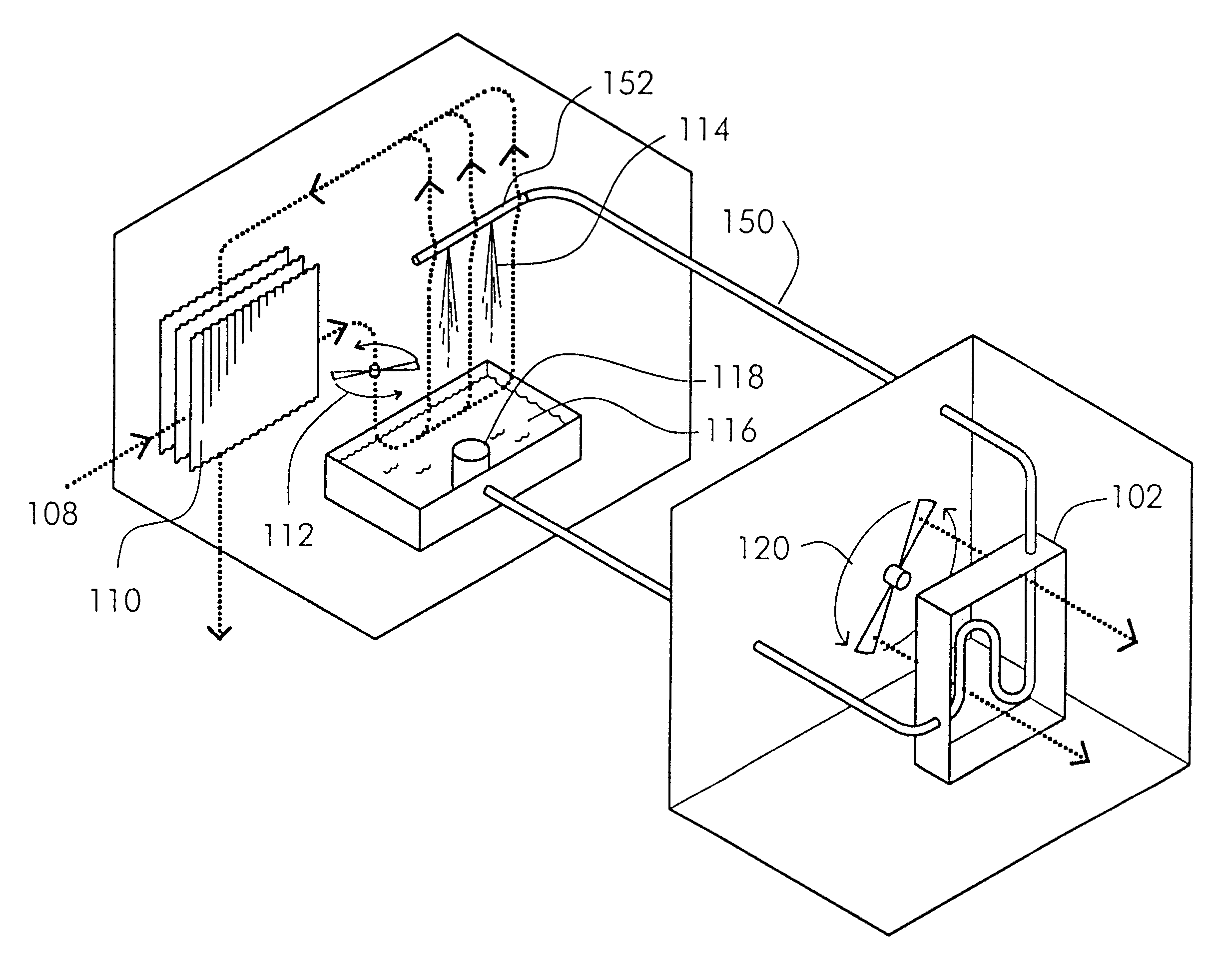

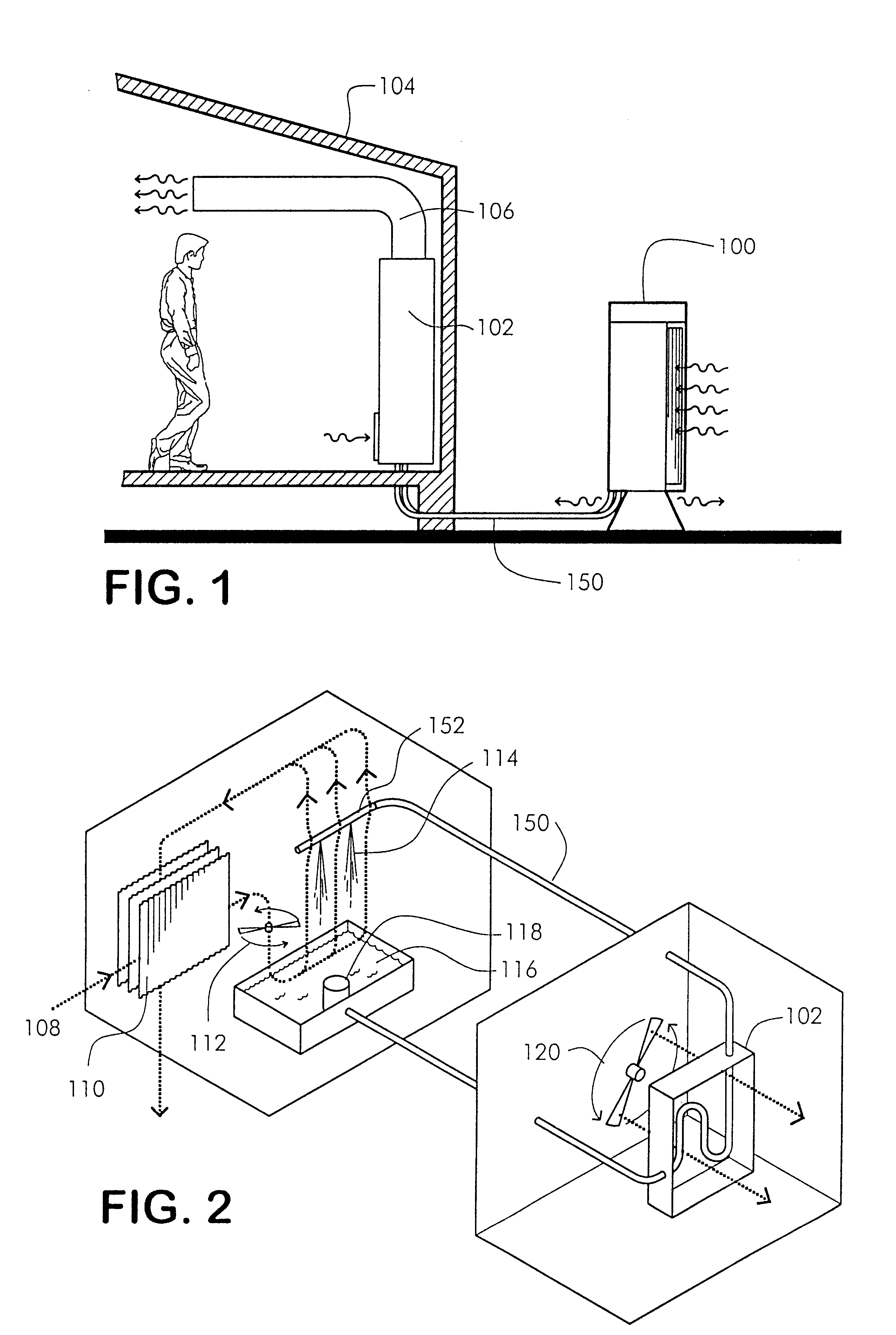

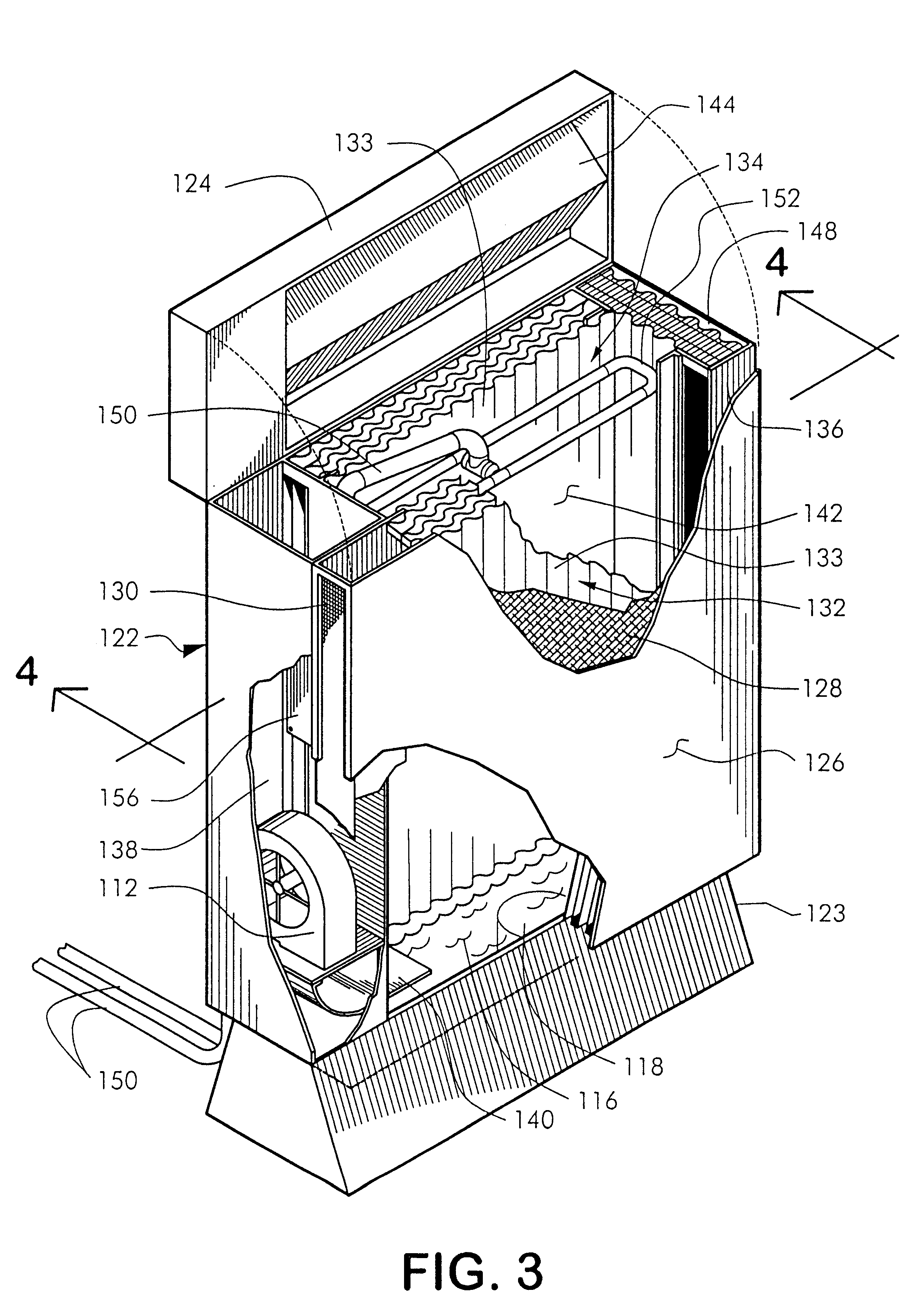

Cooling system

A system is disclosed that incorporates a generator for generating a liquid coolant. This invention provides a self-contained water (or similar liquid coolant) chilling system of suitable capacity to cool small to medium size structures, such as private residences and manufactured homes. The system utilizes an arrangement of heat-exchanging panels to pre-condition an ambient temperature air-stream, prior to passage through a pump-driven coolant spray. The system also provides several sub-systems for automatic coolant monitoring, chemical addition and periodic coolant replacement.

Owner:CONSOLI ART

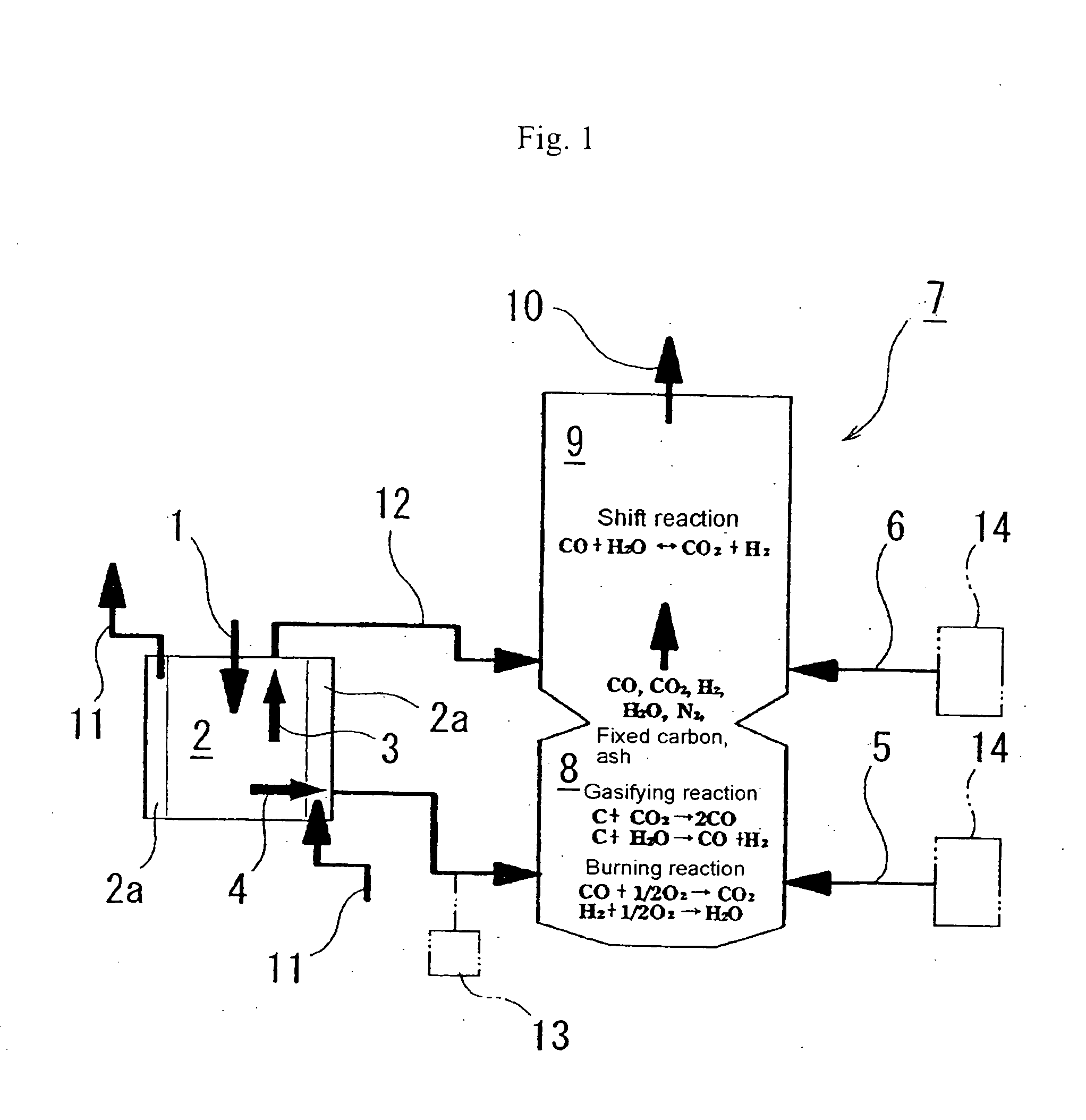

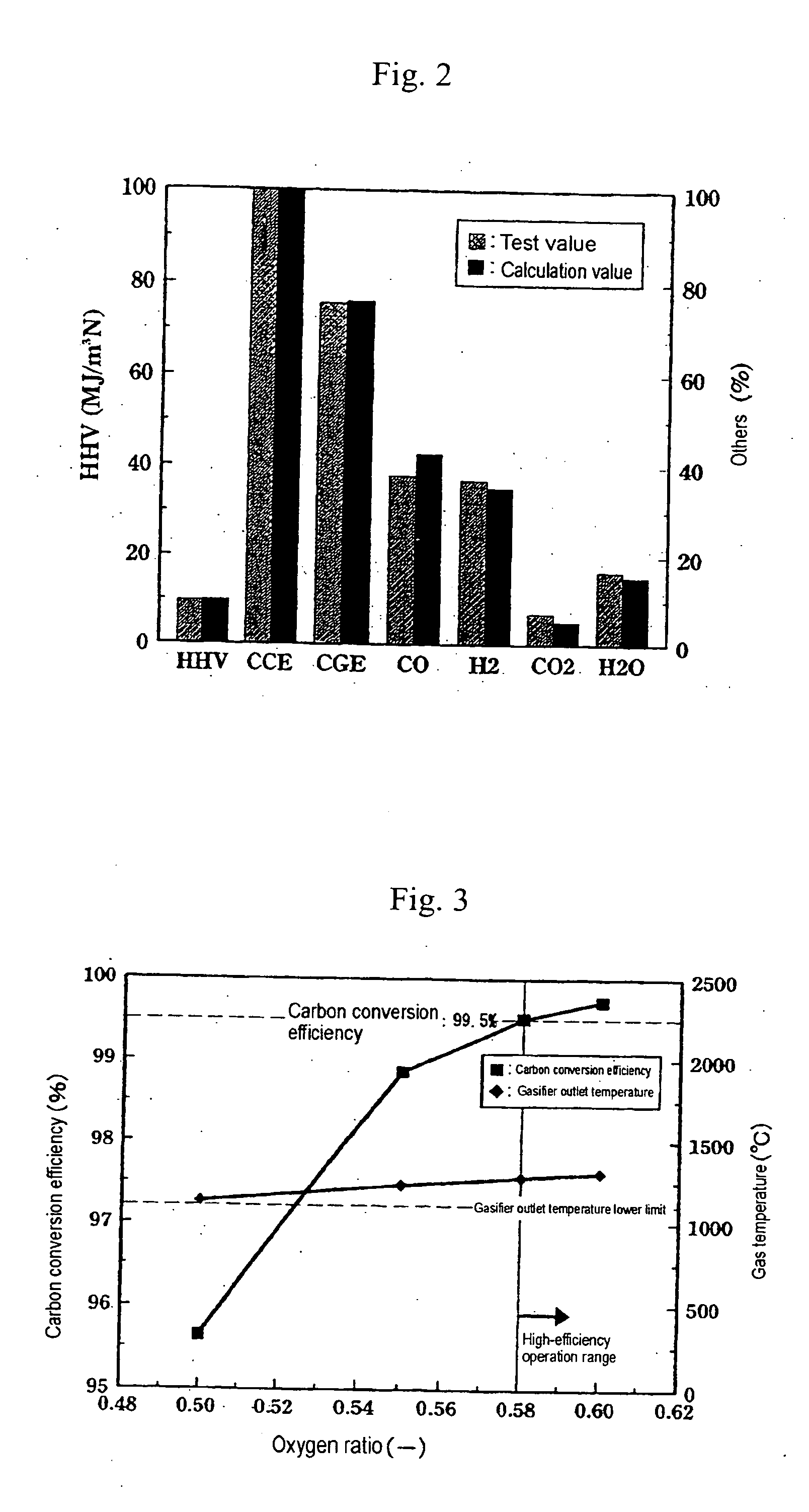

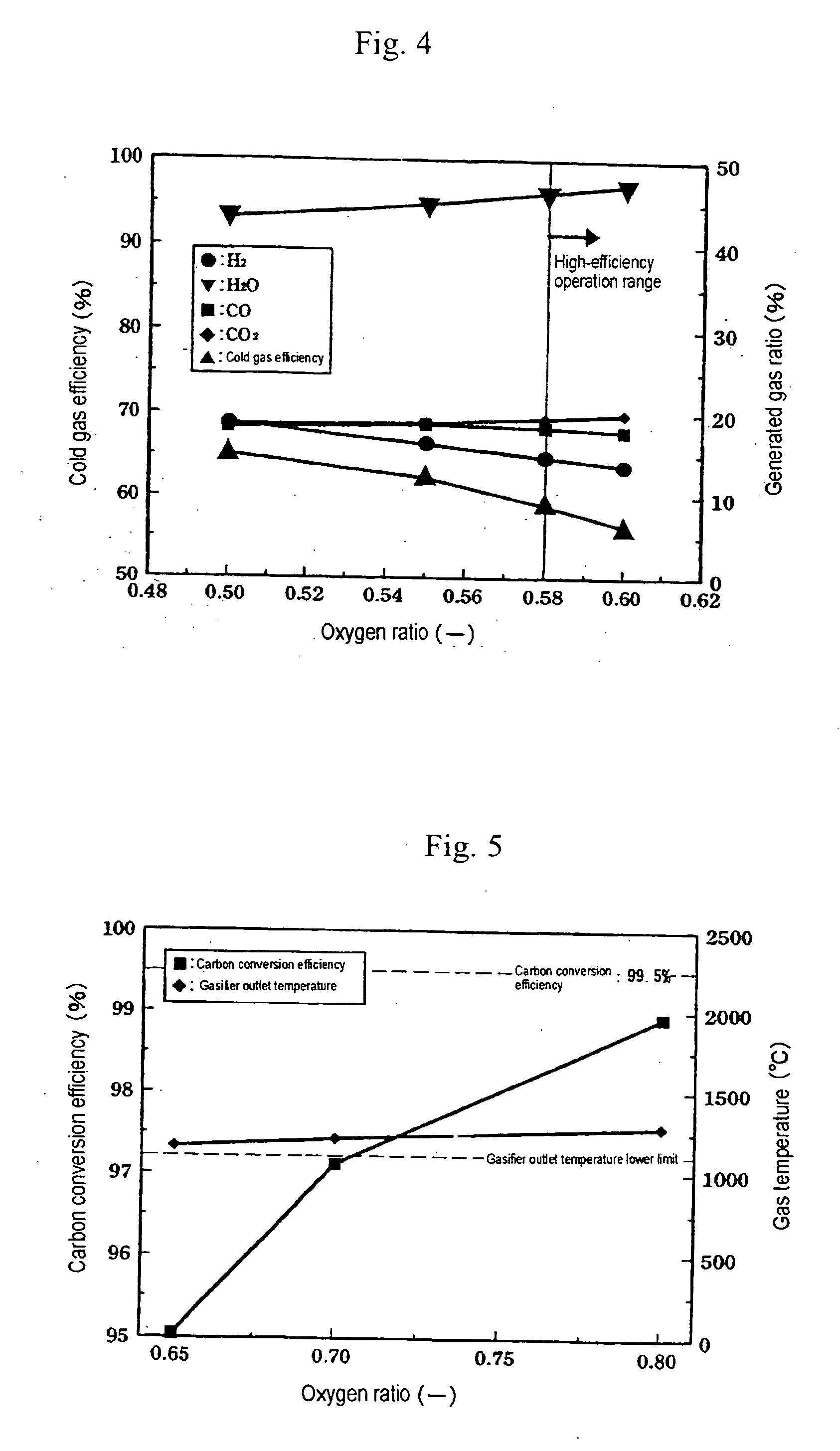

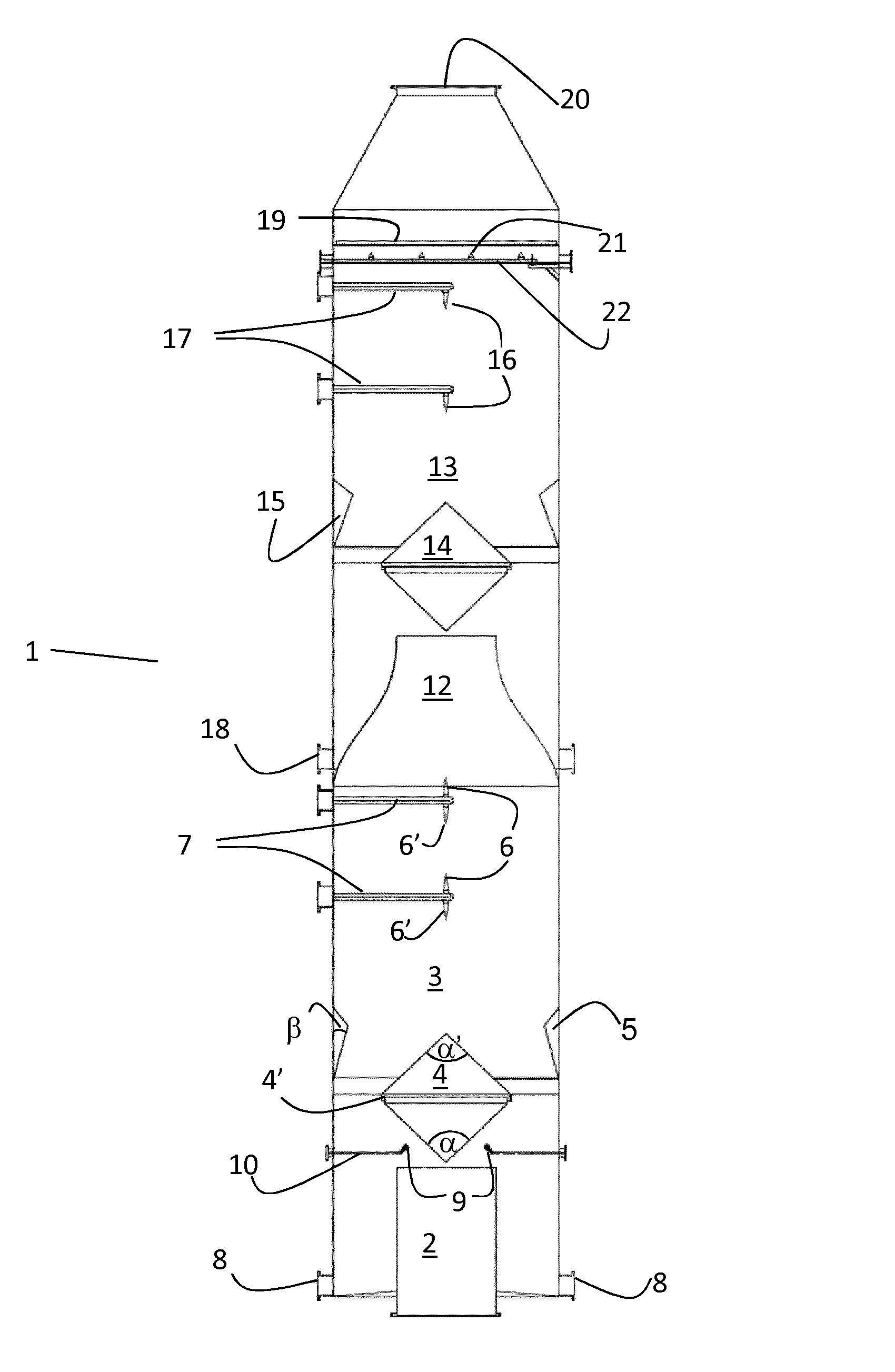

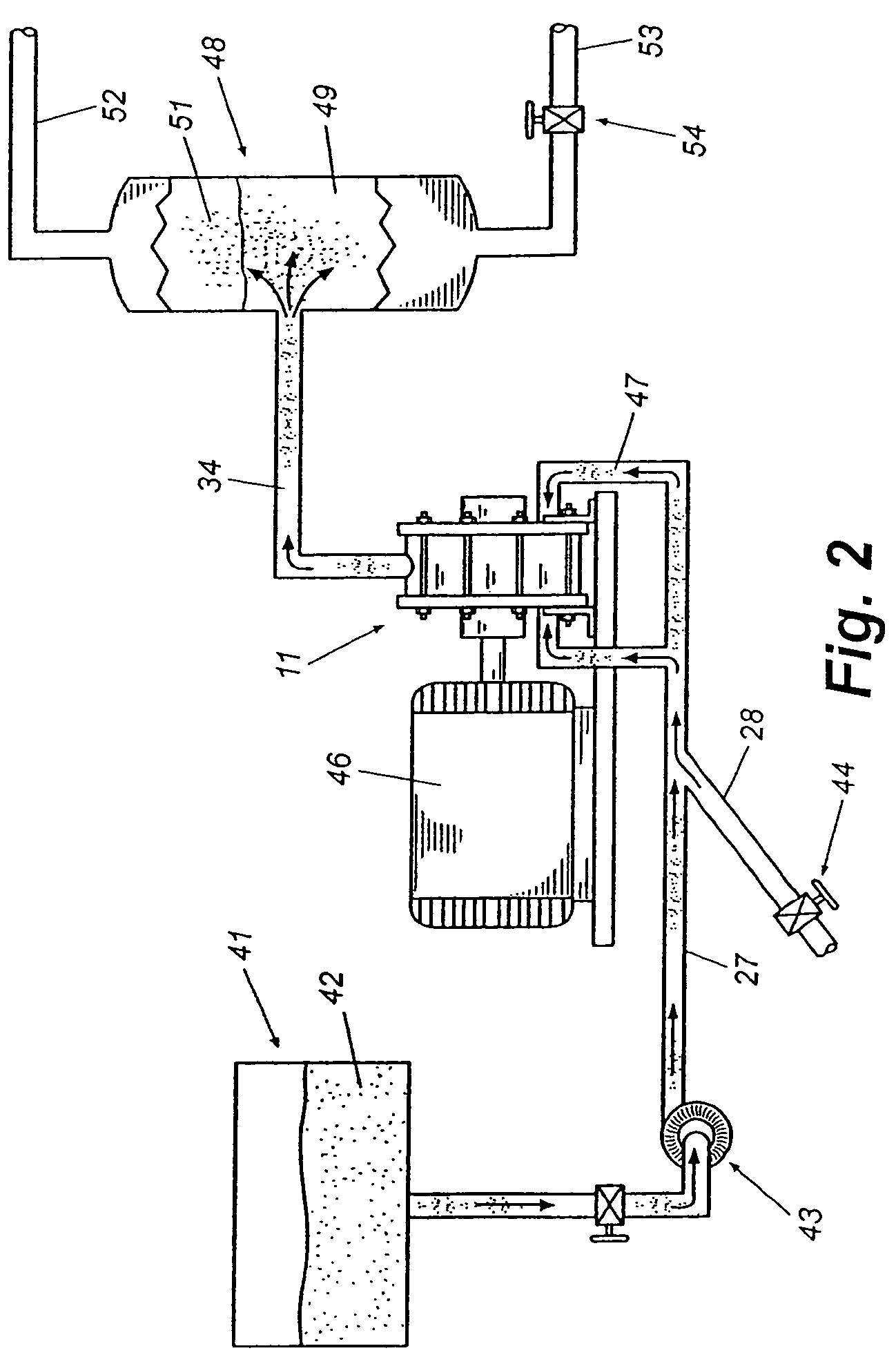

Carbonization and gasification of biomass and power generation system

InactiveUS20050247553A1Increase temperatureHigh thermal efficiencyBeehive ovensCombustible gas catalytic treatmentCarbonizationTar

Biomass, including waste biomass, is gasified by a process in which the biomass is first carbonized, and the char and pyrolysis gas from the carbonizer are respectively fed to a high temperature gasifying part and a gas reformer part of a two-stage gasifier. A gasifying agent is continuously fed to the gasifying part, and intermittently fed to the gas reformer, to maintain the temperature required to avoid tar formation in the gas reformer stage. Multiple carbonization chambers are operated in rotation. When the carbonization / gasification apparatus is used to provide fuel to an electric power generator set, exhaust heat from the generator power plant is fed back to the carbonizer, and can be supplemented by exchange of heat from the gas delivered to generator power plant from the outlet of the gasifier.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

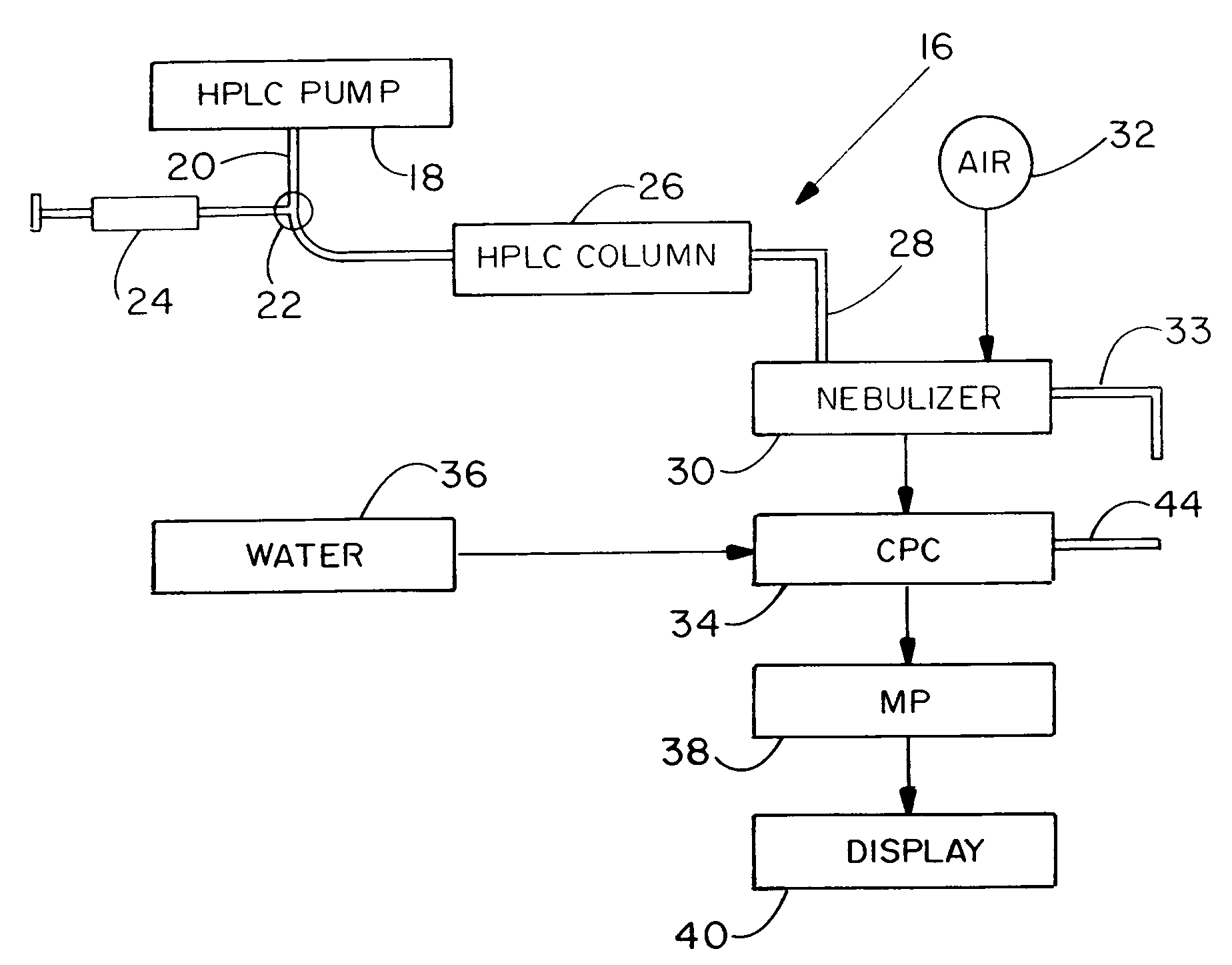

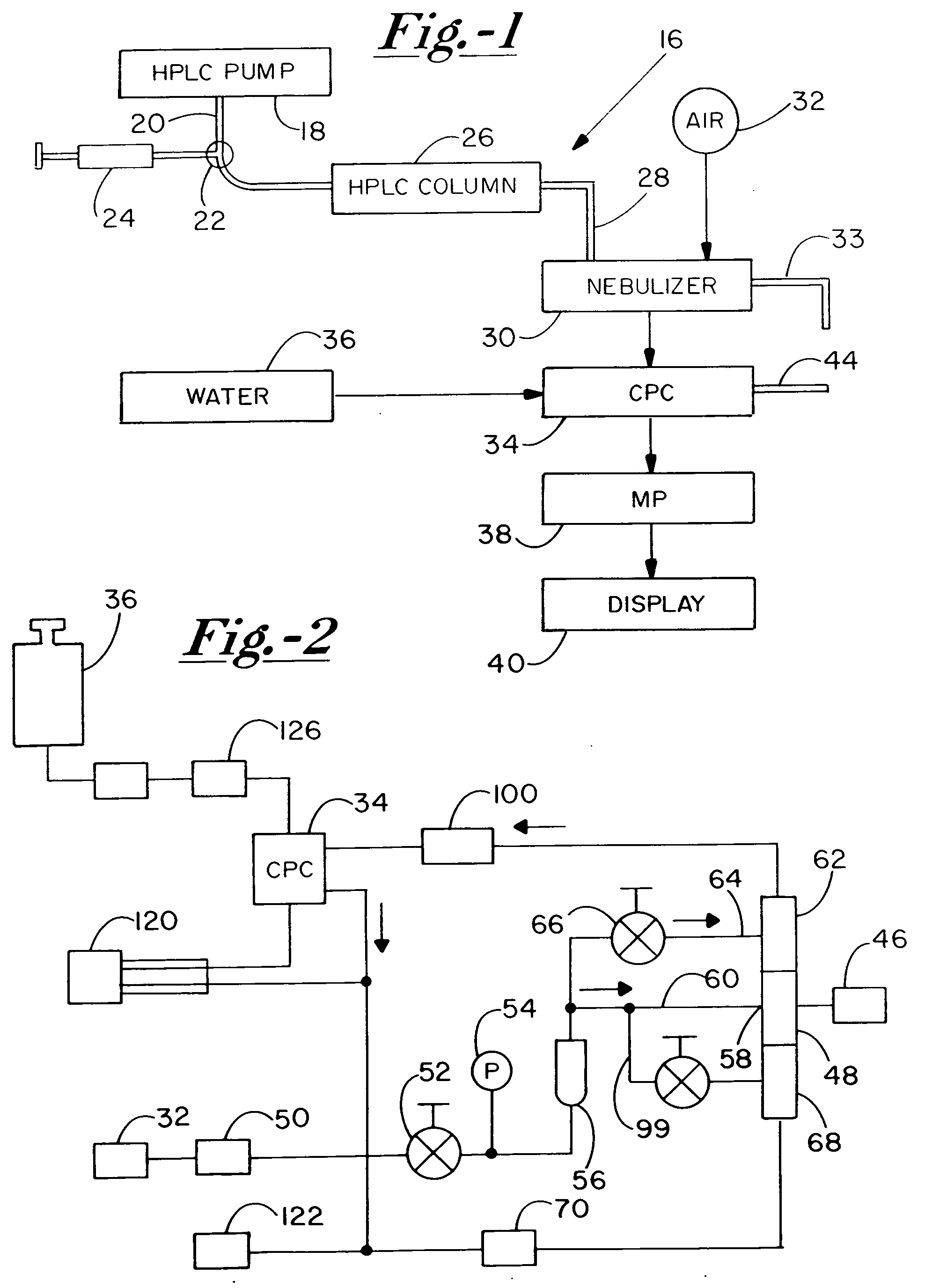

Measuring Analyte Concentrations in Liquids

InactiveUS20080137065A1Higher kinetic energy mixingSmall dropletSamplingComponent separationElectrical mobilityDroplet size

A high performance liquid chromatography system employs a nebulizer with a flow restriction at the exit of its mixing chamber to produce finer droplets, and an adjustable impactor for increased control over droplet sizes. Downstream of the mixing chamber, the nebulizer can incorporate tubing that is permeable to the sample liquid, to promote aerosol drying through perevaporation. A condensation particle counter downstream of the nebulizer uses water as the working medium, and is adjustable to control threshold nucleation sizes and droplet growth rates. A particle size selector employing diffusion, electrostatic attraction or selection based on electrical mobility, is advantageously positioned between the nebulizer and the CPC.

Owner:TSI INC

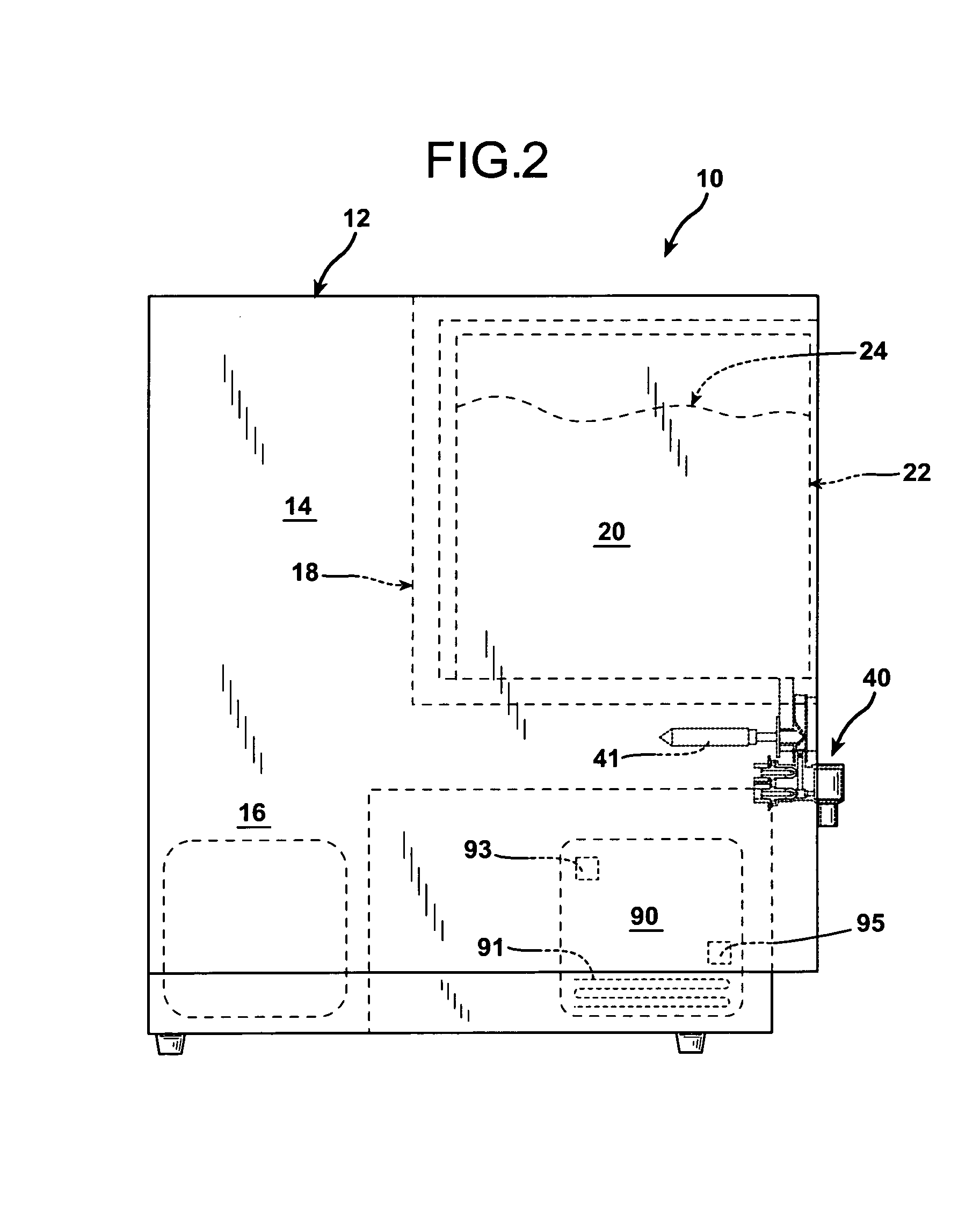

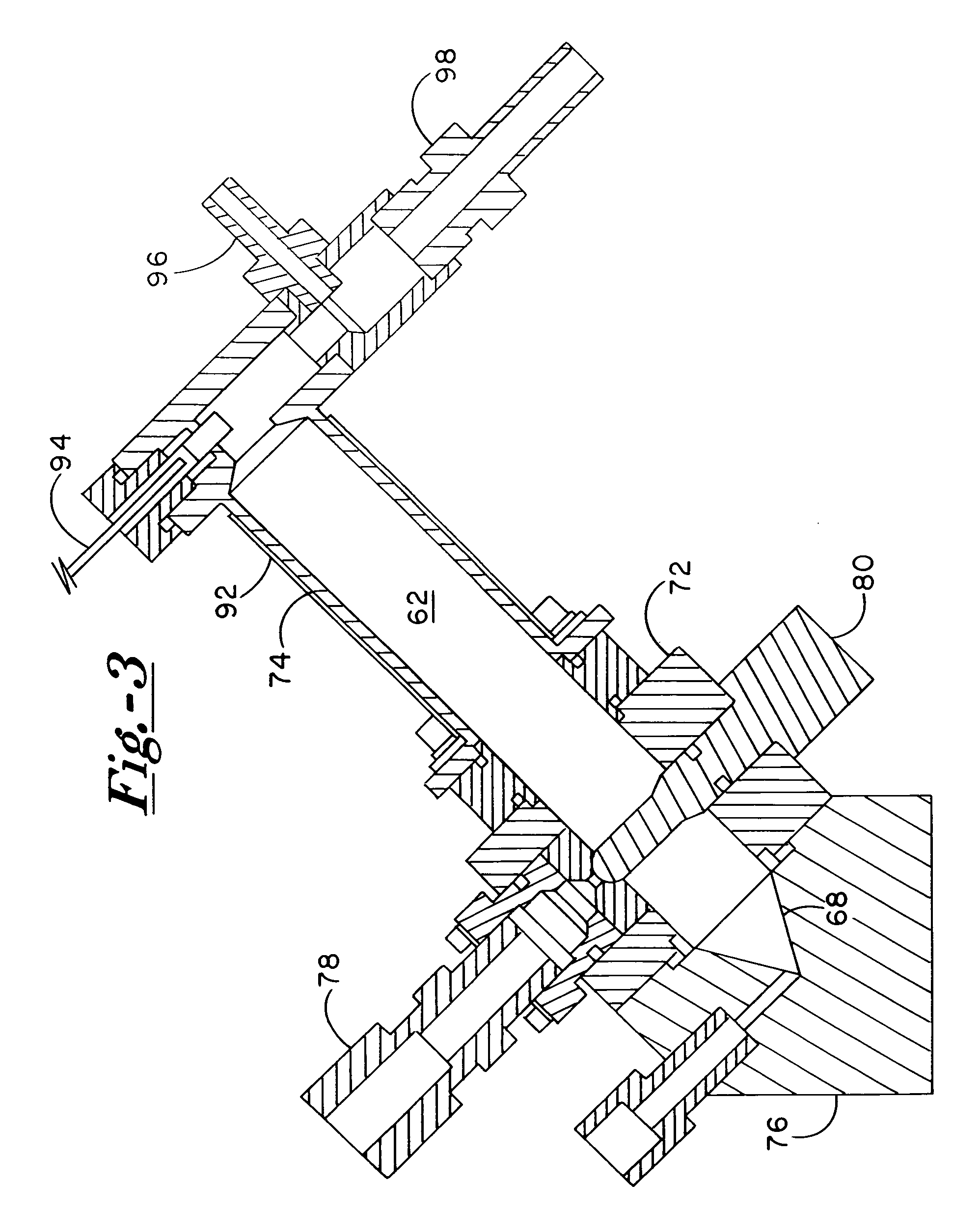

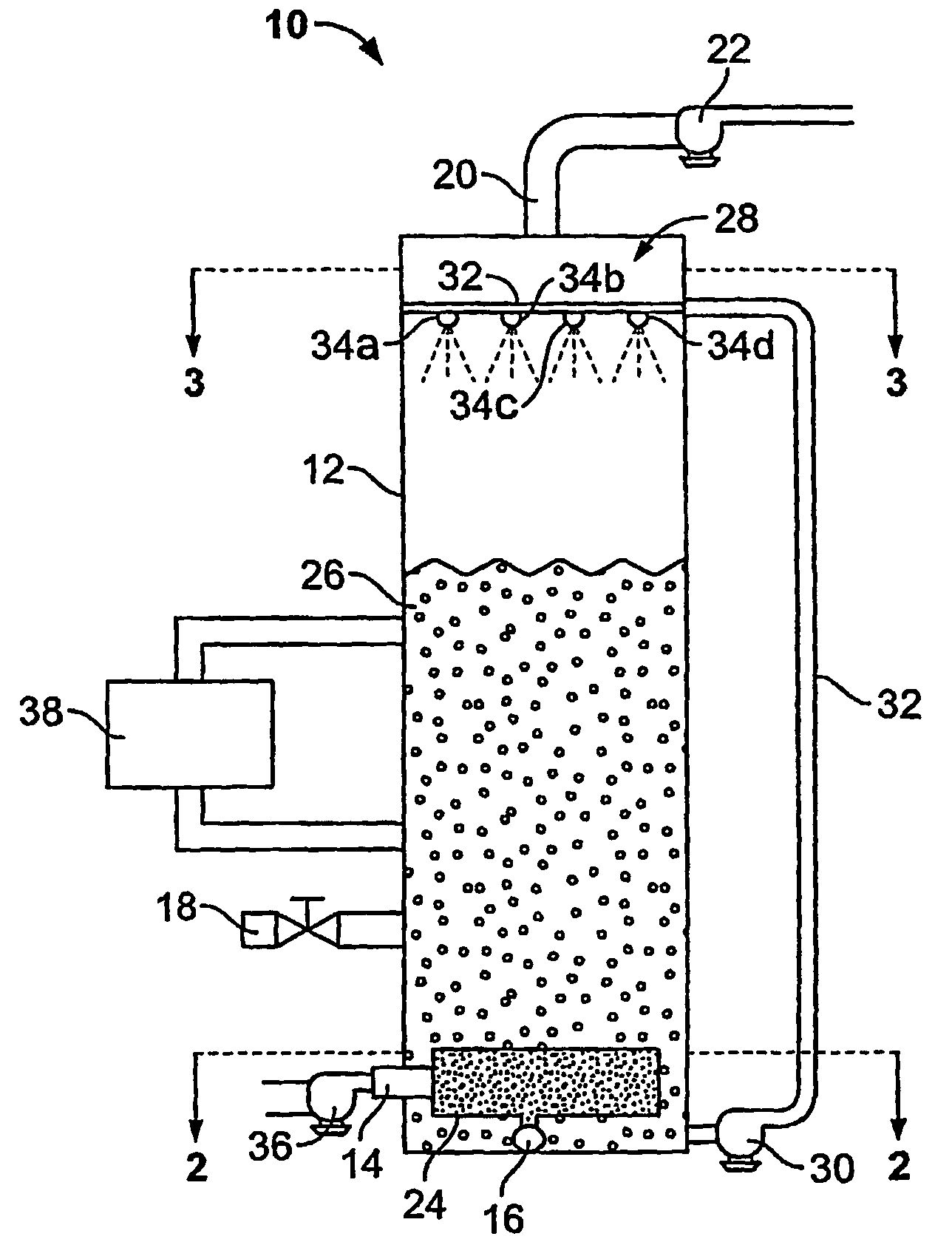

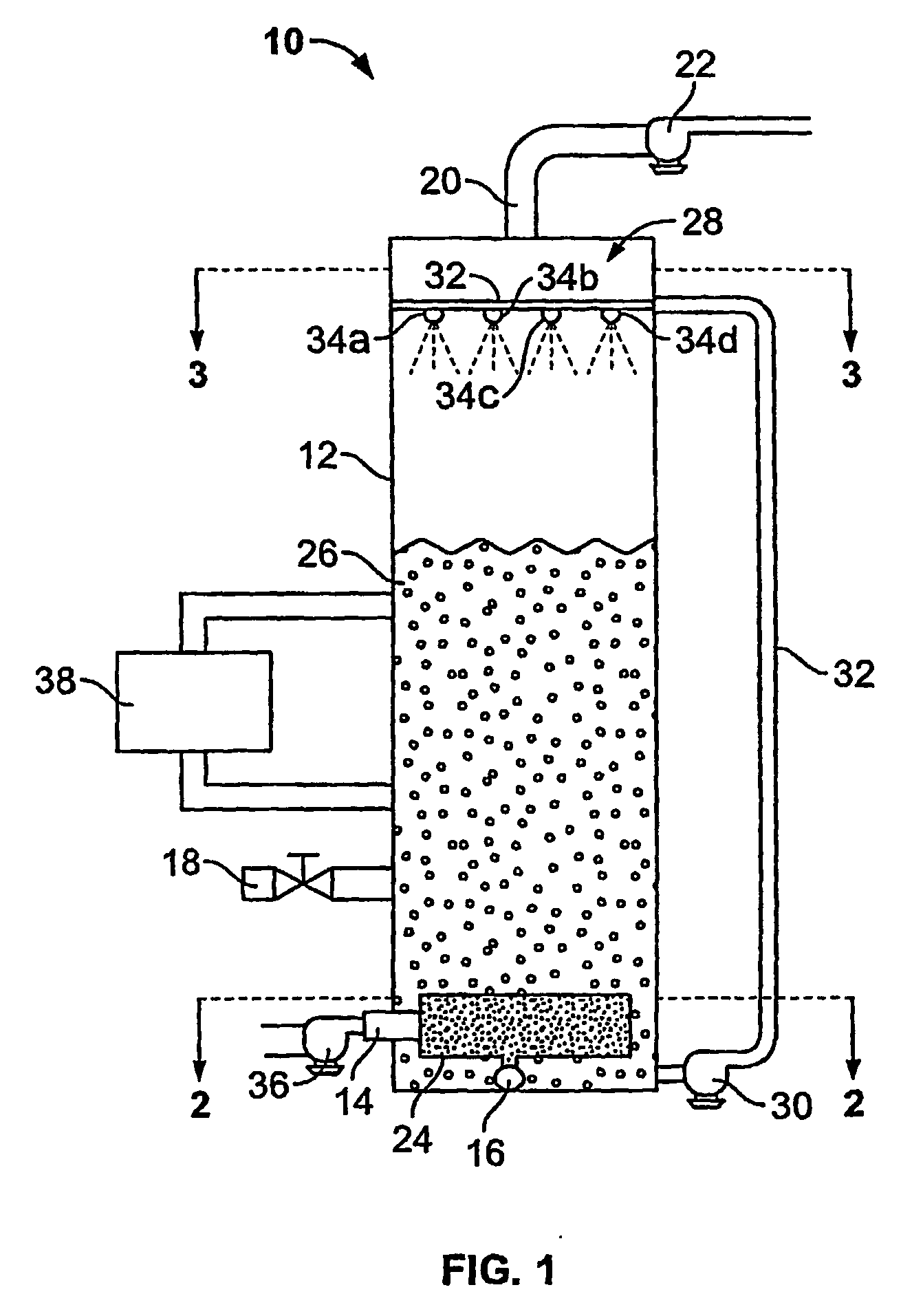

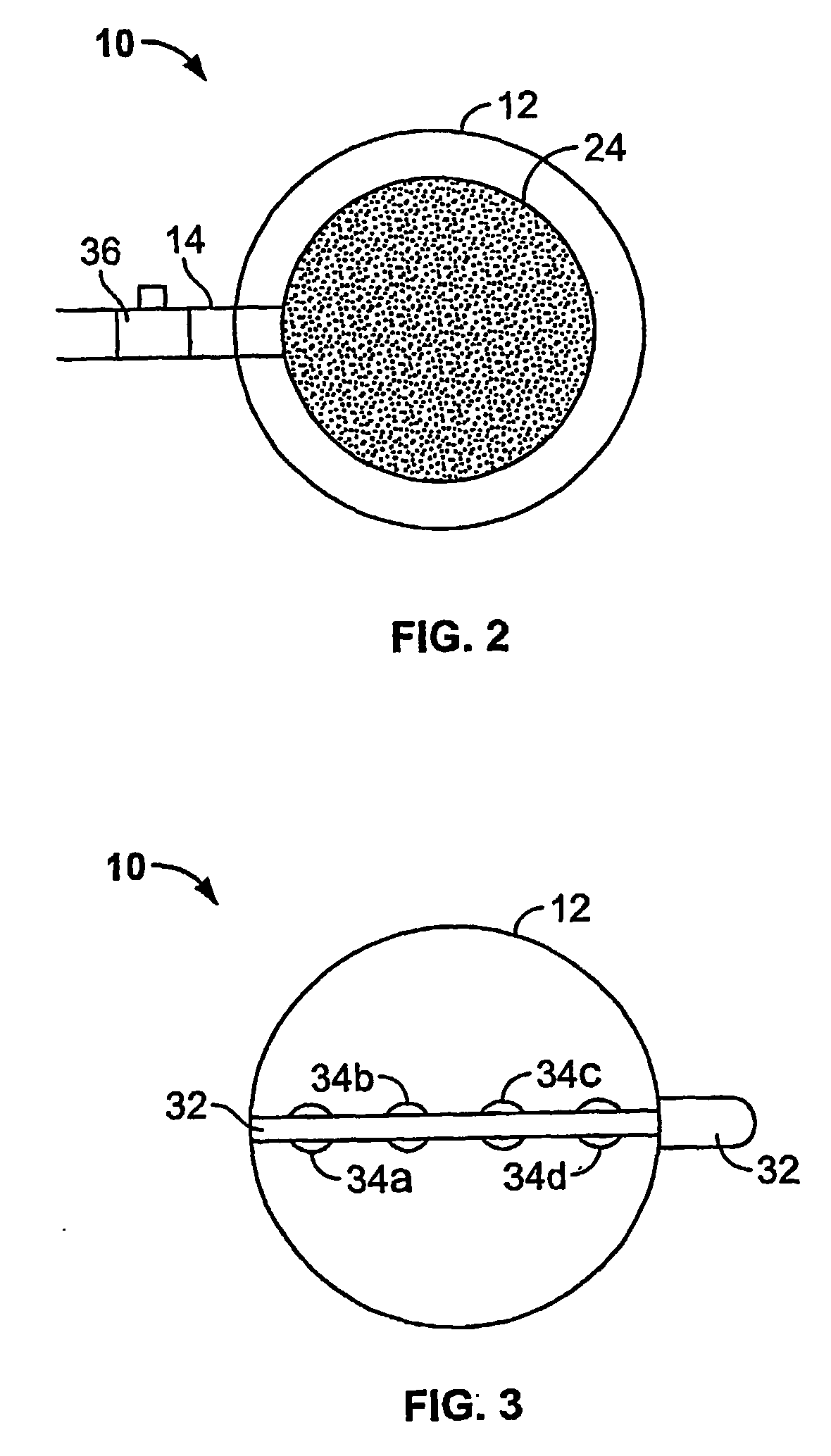

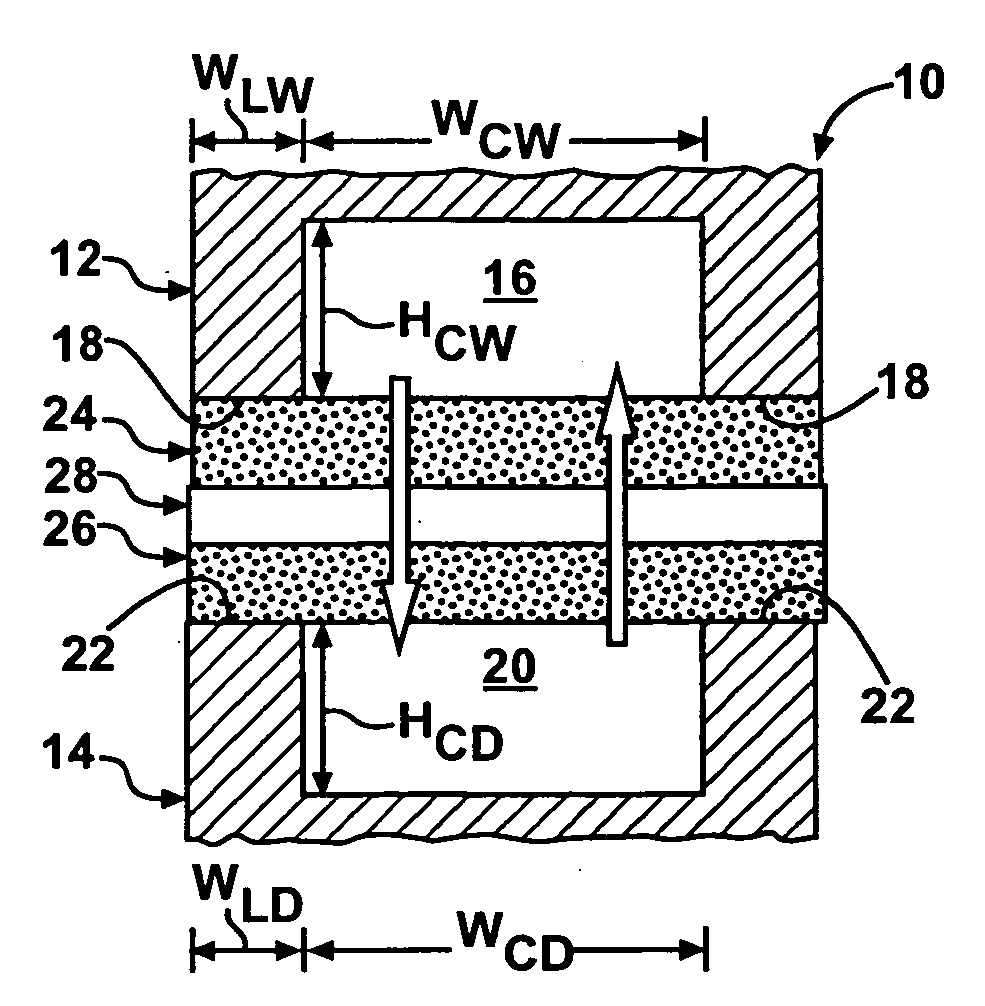

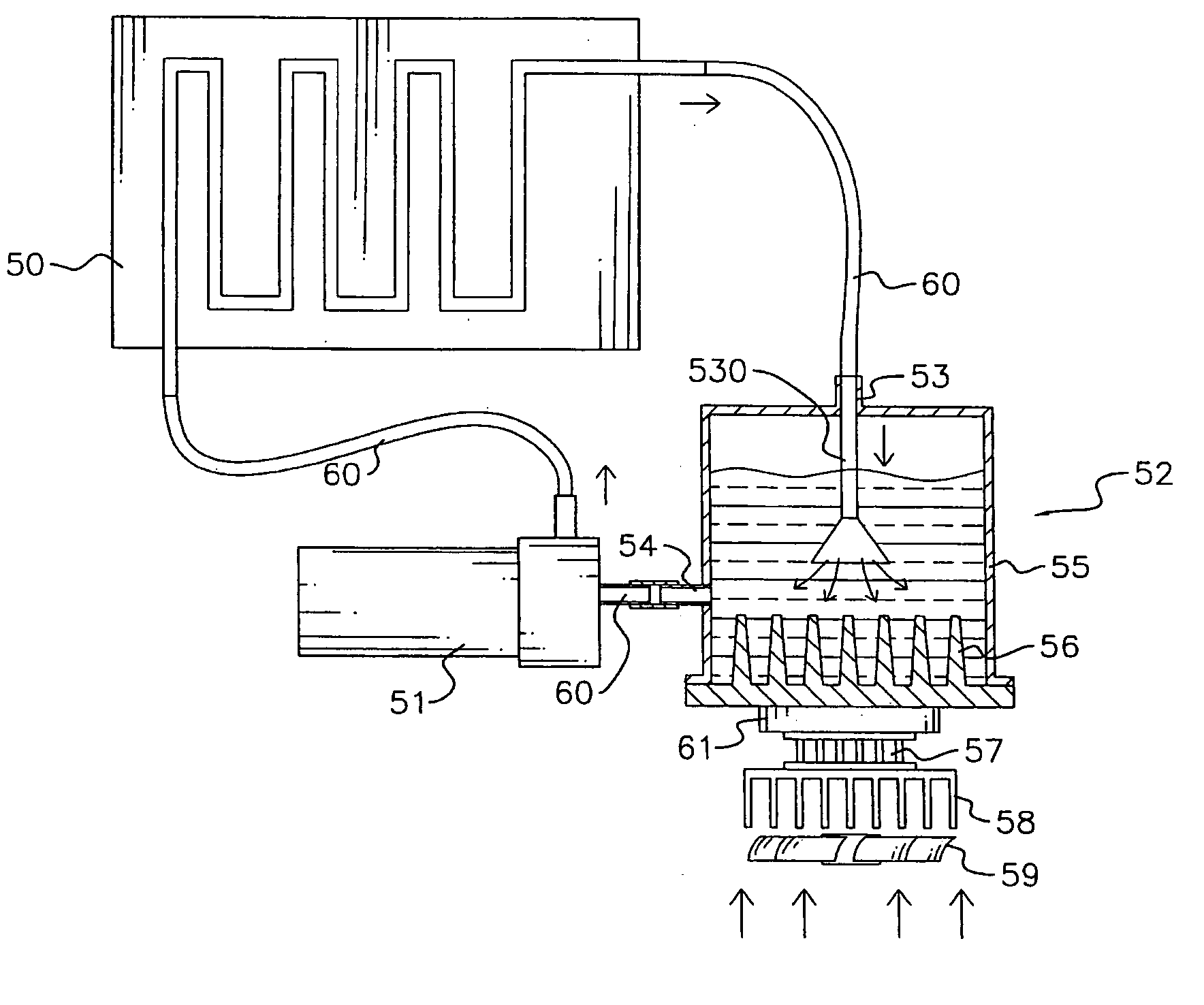

Apparatus and method for extracting heat from contaminated waste steam

InactiveUS6019819ALess energyHotter cooling water temperatureCombination devicesAuxillary pretreatmentAtmospheric airEngineering

Disclosed is a contaminated waste steam heat recovery apparatus 10 and method therefore which includes a primary condensing unit 38, a low pressure water washing unit 26, a liquid to liquid heat exchanger 36 and a vent fan 31. Waste gas is ducted from fryer 11 to a de-super-heating chamber 14 wherein superheated steam is converted to saturated steam by spraying water into the steam using spray nozzles 15. The gas is then introduced into a vertically disposed air to liquid heat exchanger 16 and is drafted downward therethrough. As heat is removed from the waste gas, water vapor in the steam condenses and in the process, collects some of the oil and hydrocarbons present. A plurality of condensate trays 19 are disposed below the bottom end of heat exchanger 16 in a cascading fashion to collect hold the condensate in the airflow path such that it will absorb some of the heat still present in the remaining waste gas. An oil outlet 22 is provided at the top of collection basin 22 for drawing off concentrated oil 23. The waste gas is pulled into a low pressure water washer 26 where it is washed by a second set of spray nozzles 15. Waste gas and water are sucked downward through a set of turbulence inducing baffles 28. The remaining waste gas is sucked out though exhaust tube 30, using vent fan 31, and vented to the atmosphere.

Owner:ALPHA ENGINEERS

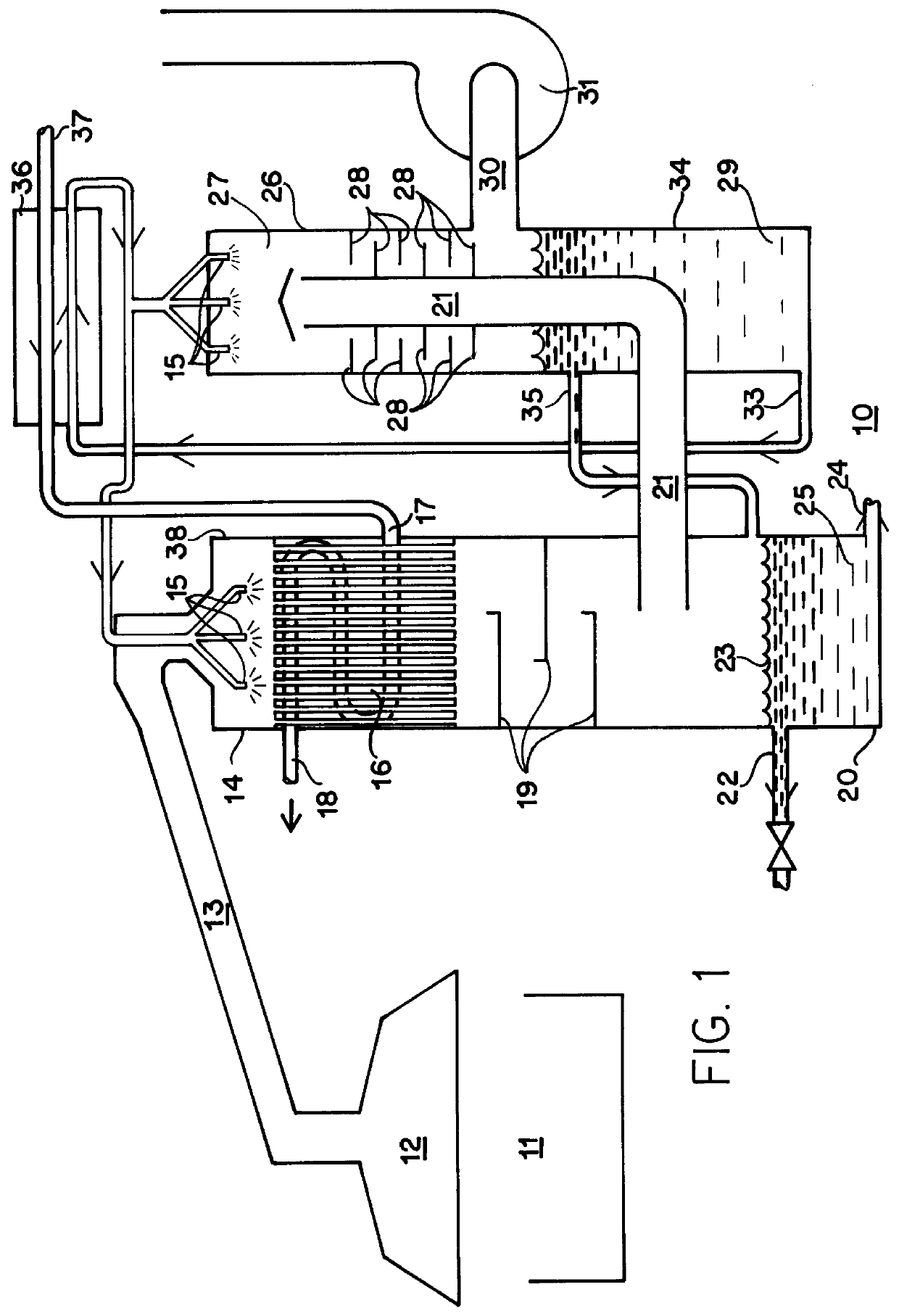

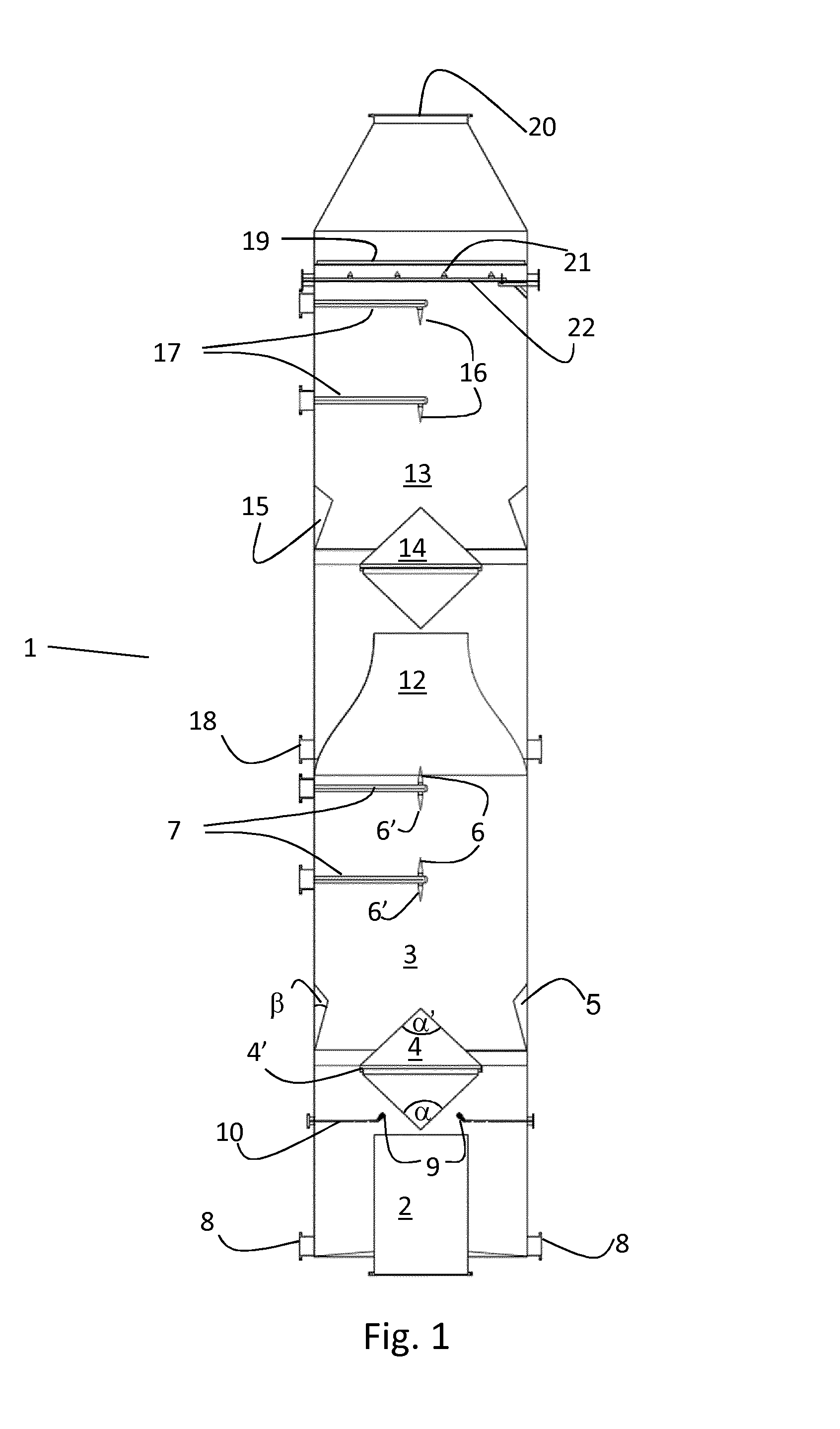

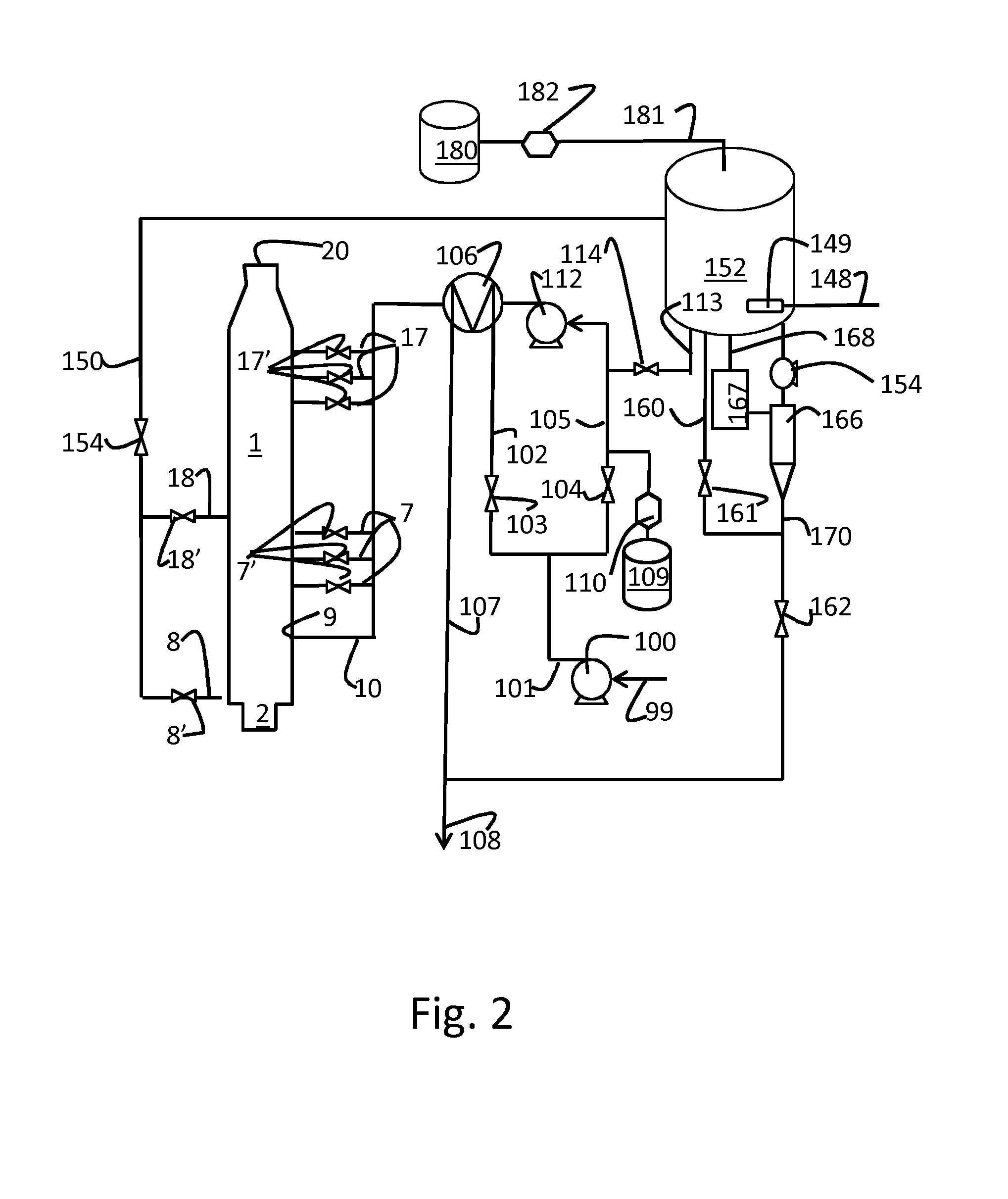

Marine exhaust gas scrubber

ActiveUS20160016109A1Easy constructionEffective dissolutionCombination devicesGas treatmentExhaust fumesEnvironmental engineering

A vertical scrubber (1) for exhaust gas from a marine vessel is described. An exhaust gas tube (2) is substantially coaxially arranged through the bottom of a lower scrubbing chamber (3) and is released though an exhaust gas outlet (20) being coaxially arranged through the top of an upper scrubbing chamber (13). A lower scrubbing chamber deflection body (4) is arranged above the opening of the exhaust gas tube (2) for redirecting the exhaust gas towards the walls of the scrubber and create turbulent gas flow, where one or more lower chamber water injector(s) (6, 6′) is (are) arranged above the lower scrubbing chamber deflection body (4), to introduce scrubbing water, and where a lower chamber exhaust gas outlet (12) is arranged at the top of the lower scrubbing chamber (3) as a coaxial constriction, for withdrawing the partly scrubbed exhaust gas from the first scrubbing chamber and introducing the gas into the upper scrubbing chamber (13).

Owner:MARINE GLOBAL HLDG

Gas liquid contactor and effluent cleaning system and method

InactiveUS20100011956A1Large volumetric mass transport coefficientSmall sizeLaser detailsFlow mixersLiquid jetEngineering

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas. An embodiment of the invention is directed towards a gas liquid contactor module including a liquid inlet and outlet and a gas inlet and outlet. An array of nozzles is in communication with the liquid inlet and the gas inlet. The array of nozzles is configured to produce uniformly spaced flat liquid jets shaped to minimize disruption from a gas flow and maximize gas flow and liquid flow interactions while rapidly replenishing the liquid.

Owner:NEUMANN SYST GROUP

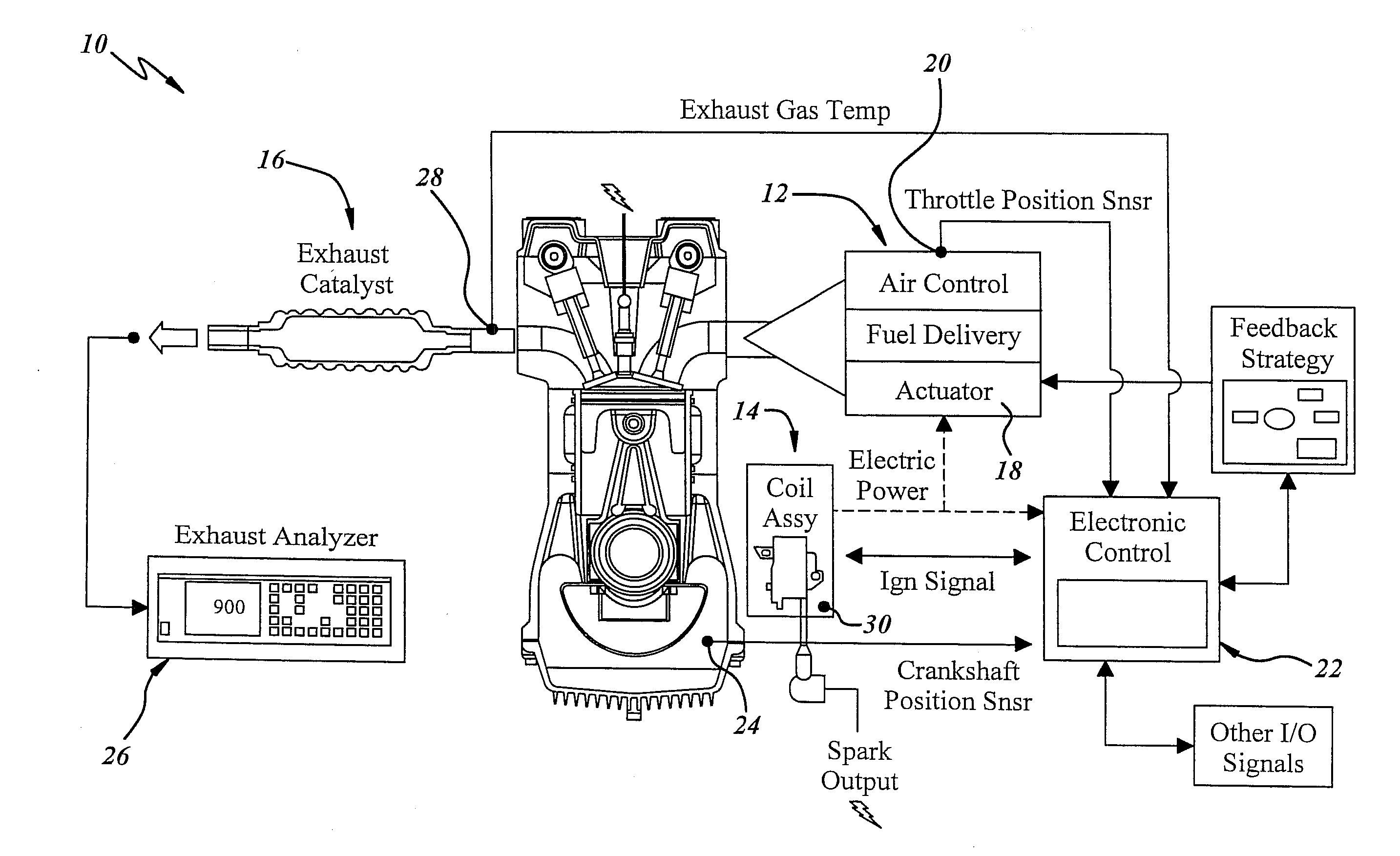

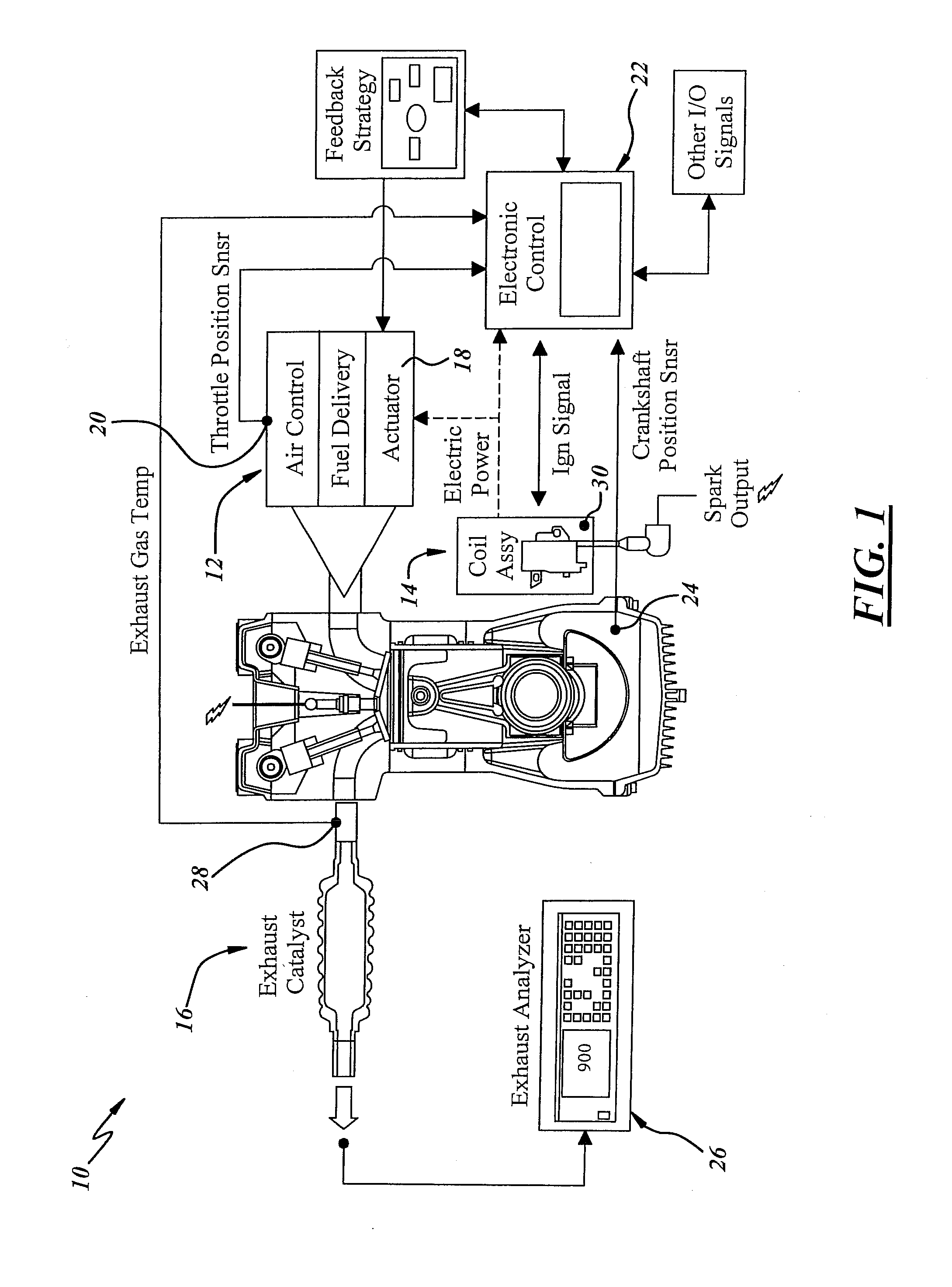

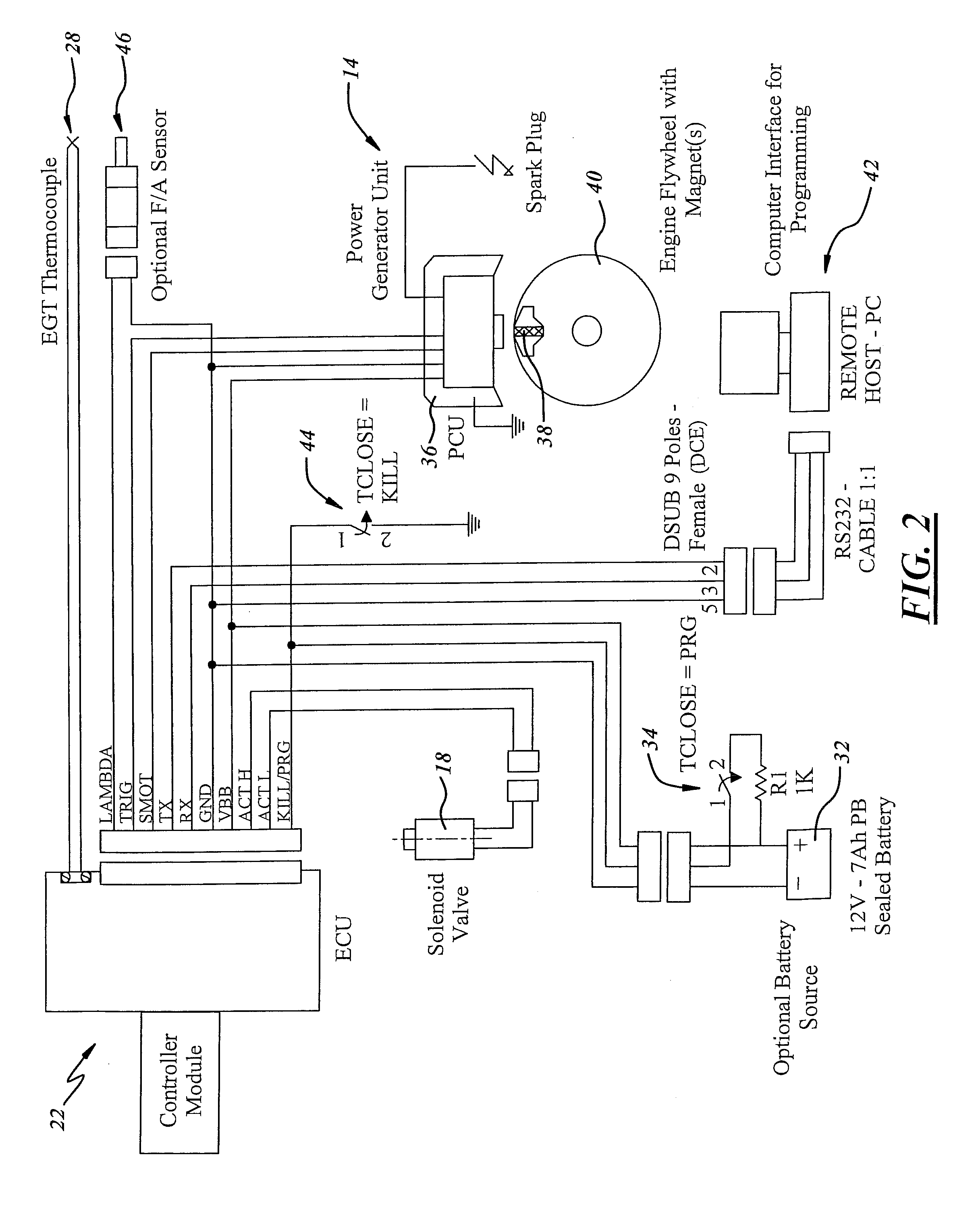

Engine fuel delivery systems, apparatus and methods

ActiveUS20100258099A1Avoid communicationAnalogue computers for vehiclesElectrical controlControl systemEngineering

A method of operating an engine is disclosed, which includes determining a peak power condition for the engine, measuring a temperature associated with the engine at said peak power condition, comparing the temperature measured with a previously determined temperature associated with a known peak power condition of the engine, determining an offset value based on the comparison made in step, controlling at least one of an air-fuel mixture delivered to the engine or ignition spark timing based on said offset value. Various engine fuel delivery systems, carburetors, fuel injection and control systems also are disclosed.

Owner:WALBRO LLC

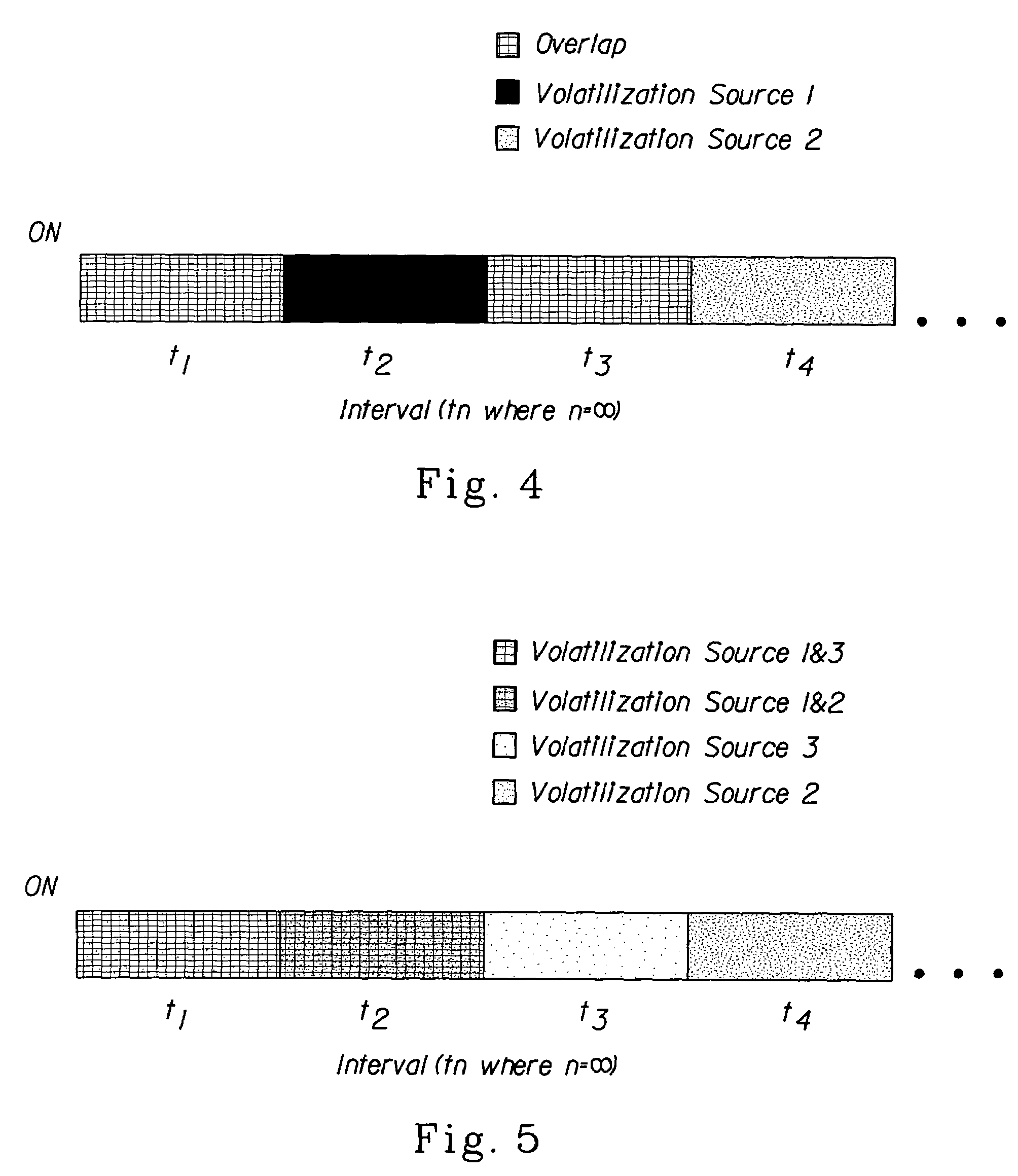

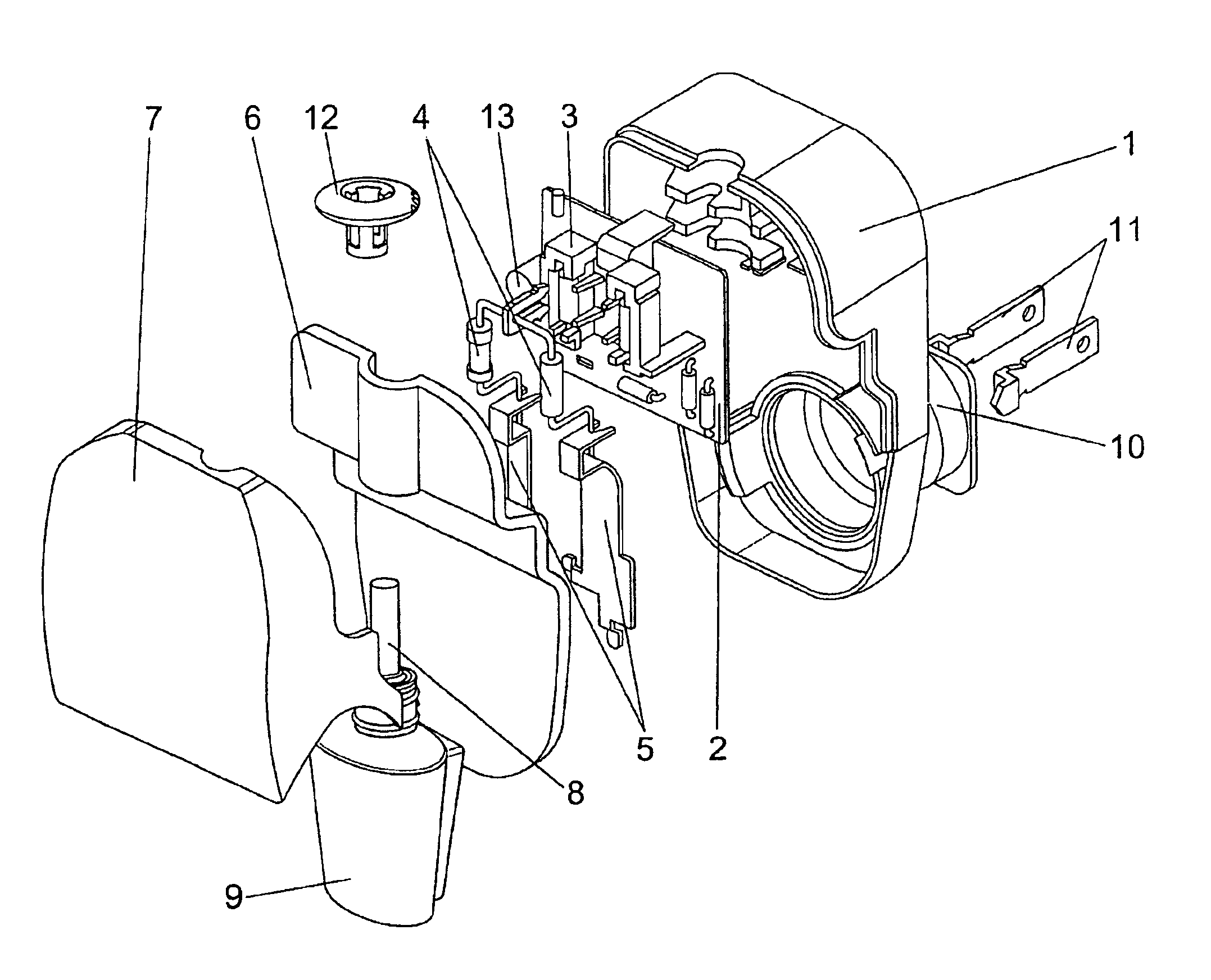

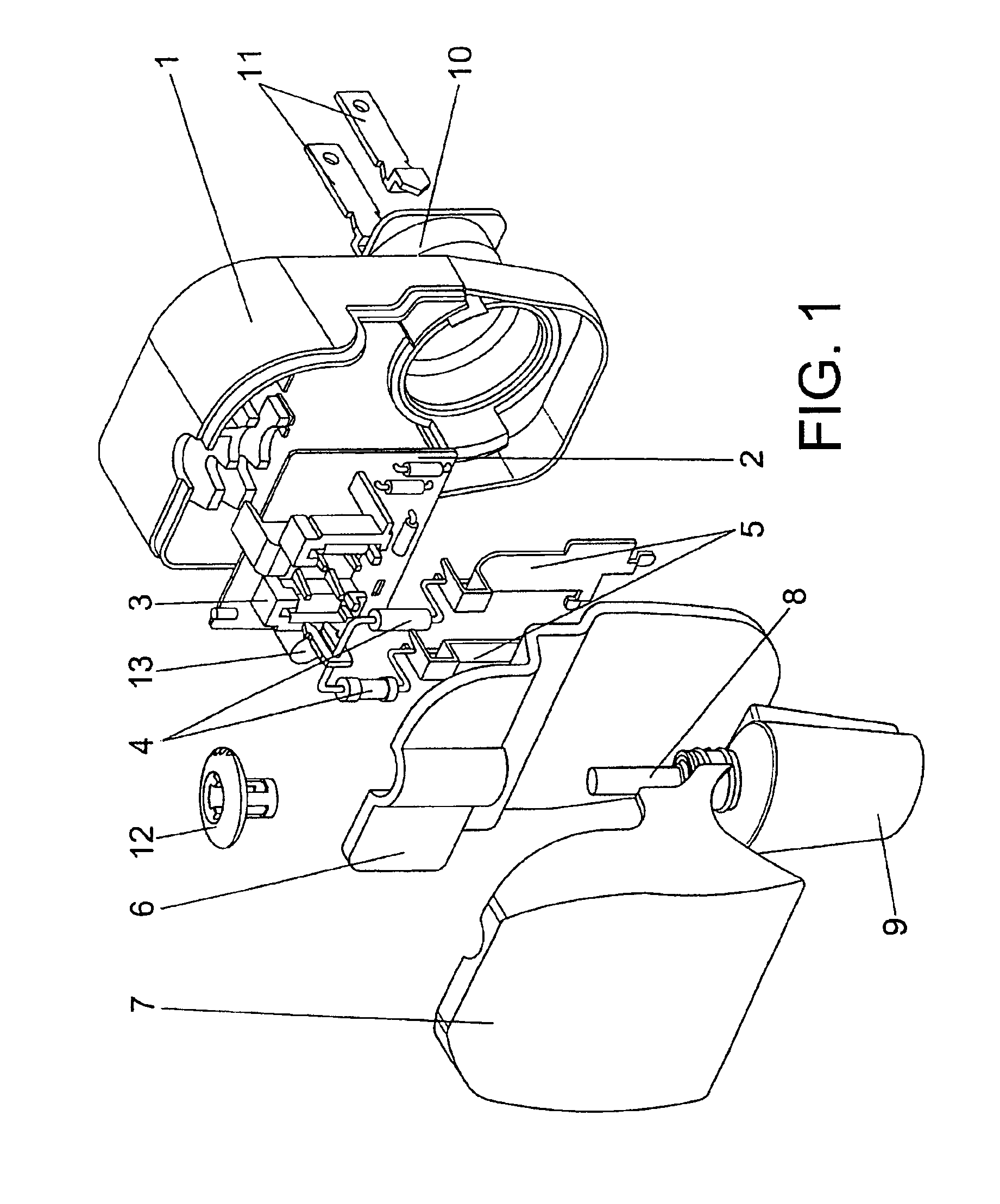

Evaporator device for active substances

InactiveUS6854717B2Lighting and heating apparatusUsing liquid separation agentEvaporationElectronic component

The device comprises a base (1) and an exchangeable case (7), between which are placed corresponding components such as a bottle (9) containing the fragrant liquid and the corresponding wick (8), as well as the heating elements (4) connected to corresponding metallic contacts (5) and mounted on a support (3), also including a platform or printed circuit (2) with electronic components that allow optimizing the diffusion of the fragrance, to prevent olfactory saturation of the user, independently of the manual actuation means that allow regulating the intensity of evaporation of the fragrant liquid itself. The device also includes the corresponding plug (10) placed in correspondence with the part near the bottom end of the base (1).

Owner:DBK ESPANA

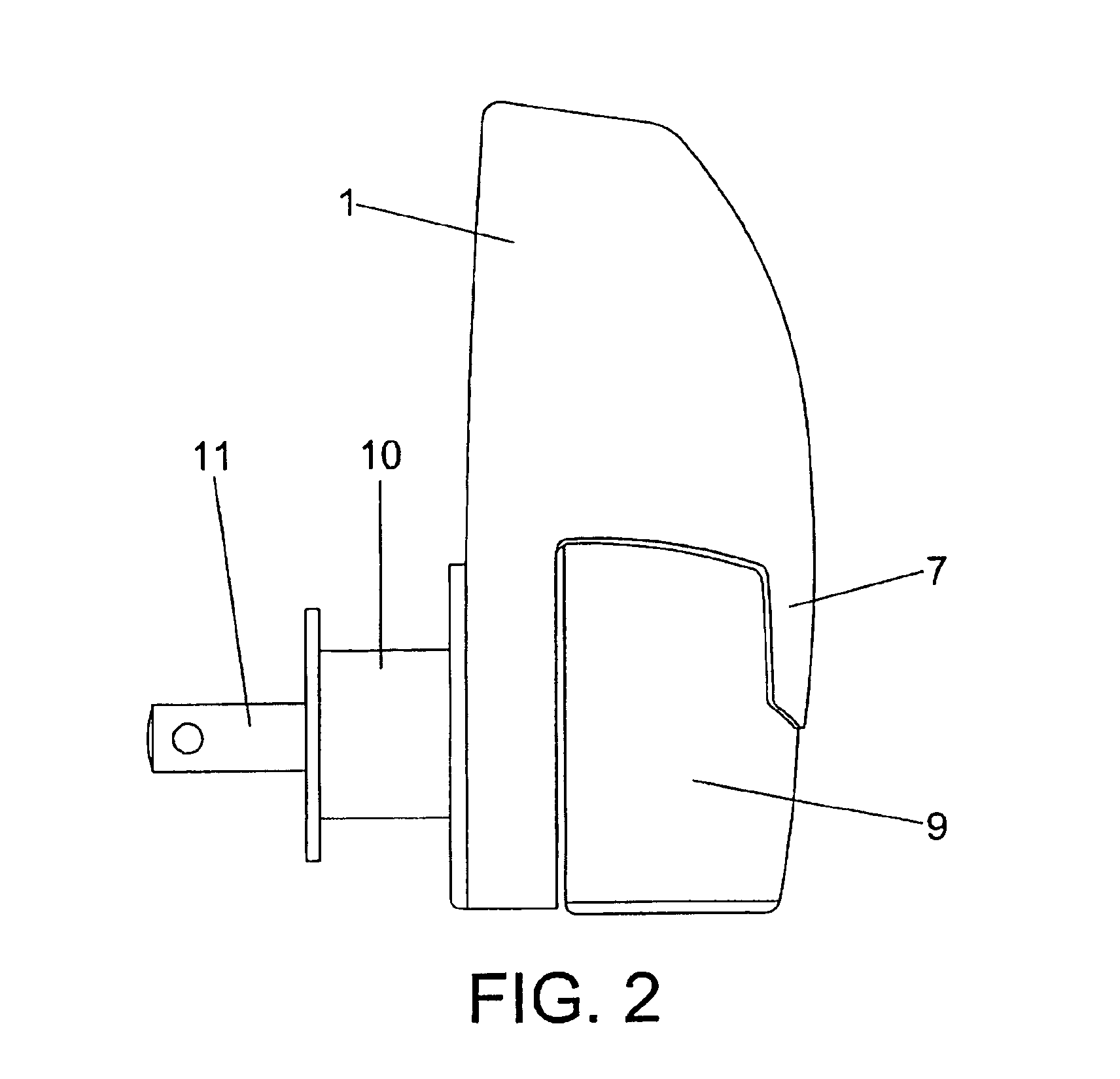

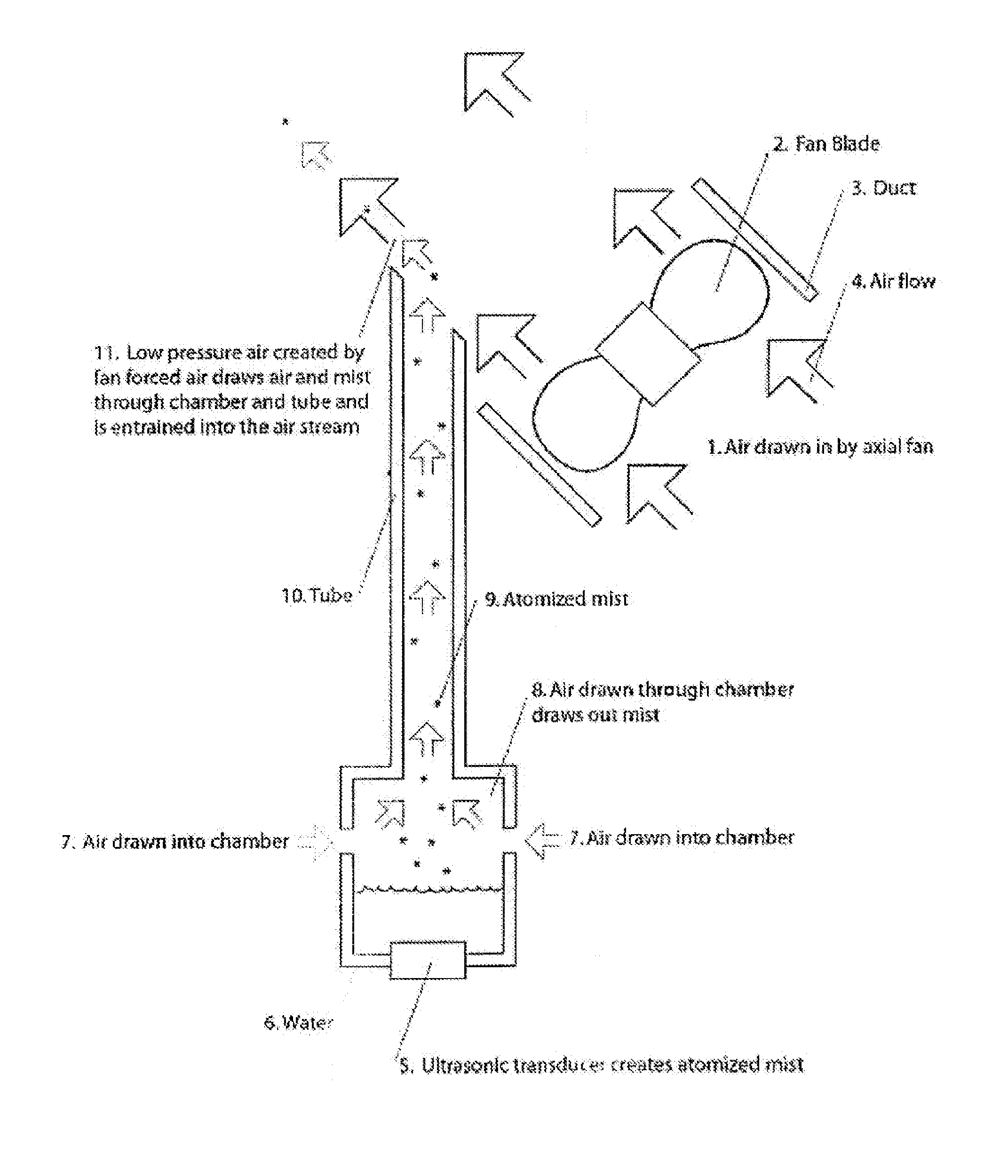

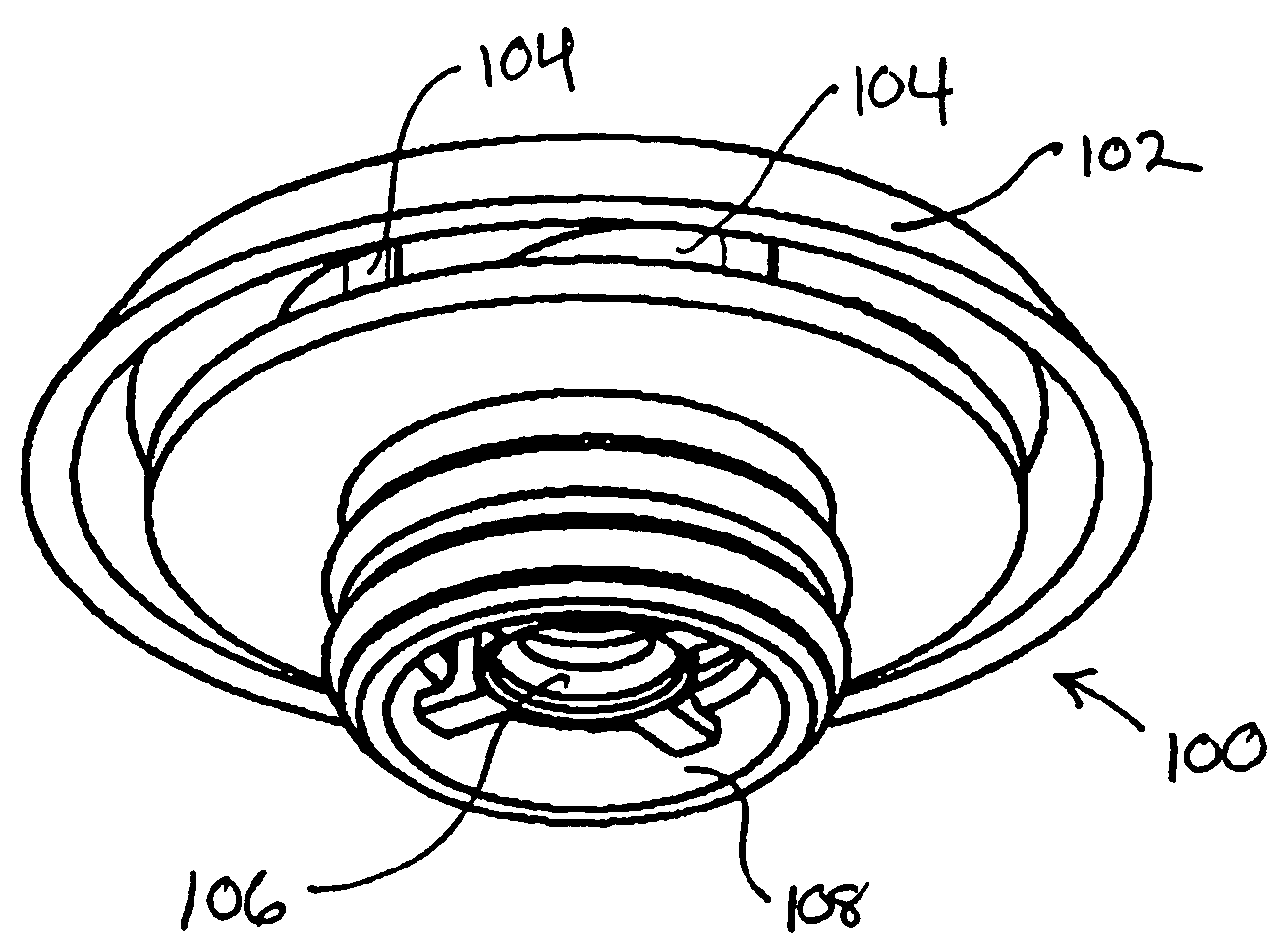

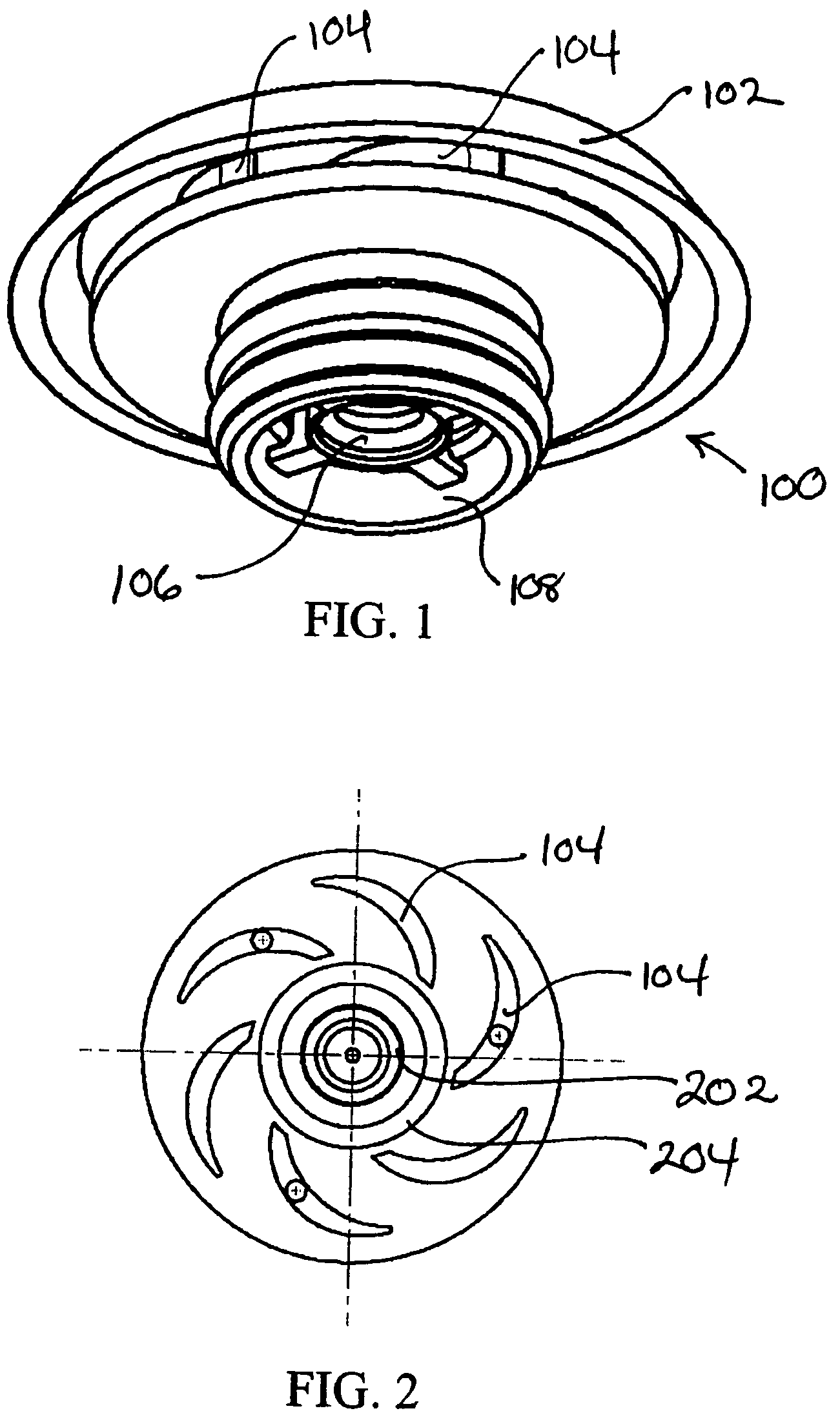

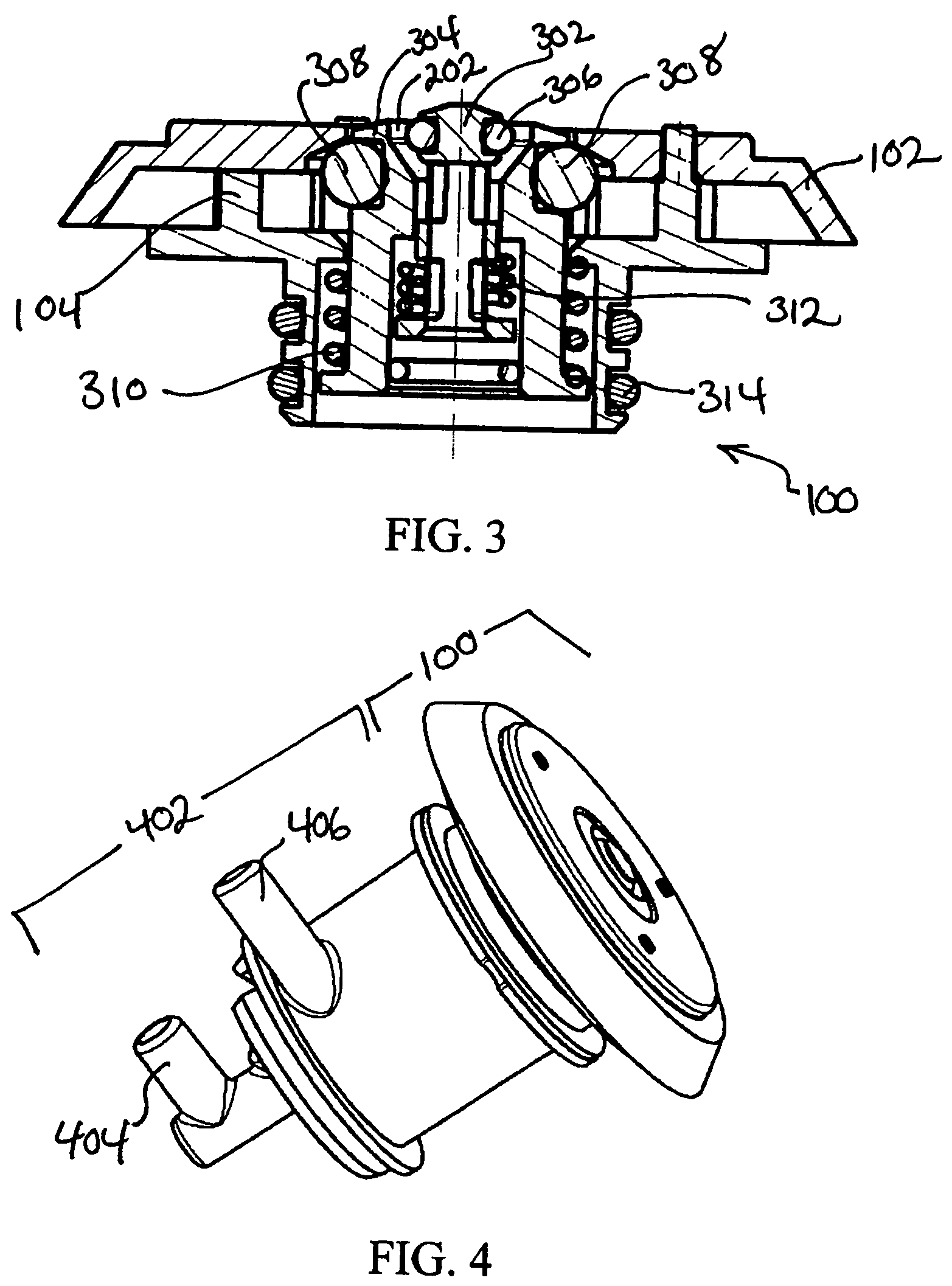

Ultrasonic humidifier

An ultrasonic humidifier is disclosed including a chamber, an ultrasonic transducer positioned at the bottom of the chamber, a passage in fluid communication with the chamber, a duct having an inlet and an outlet, the duct being in fluid communication with the passage by way of a passage outlet, a fan positioned in the duct and disposed between the duct inlet and the passage outlet. The fan is configured to propel air through the duct and over the passage outlet such that vapors in the chamber may be drawn into the duct.

Owner:VORNADO AIR LLC

Sanitization system and system components

InactiveUS7767168B2Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

Device for Removing Particulate, Various Acids, and Other Contaminants from Industrial Gases

InactiveUS20070251393A1Reducing emission of nitrous oxideReduce gas volumeCombination devicesAuxillary pretreatmentIndustrial gasParticulates

Owner:ARTEC 1

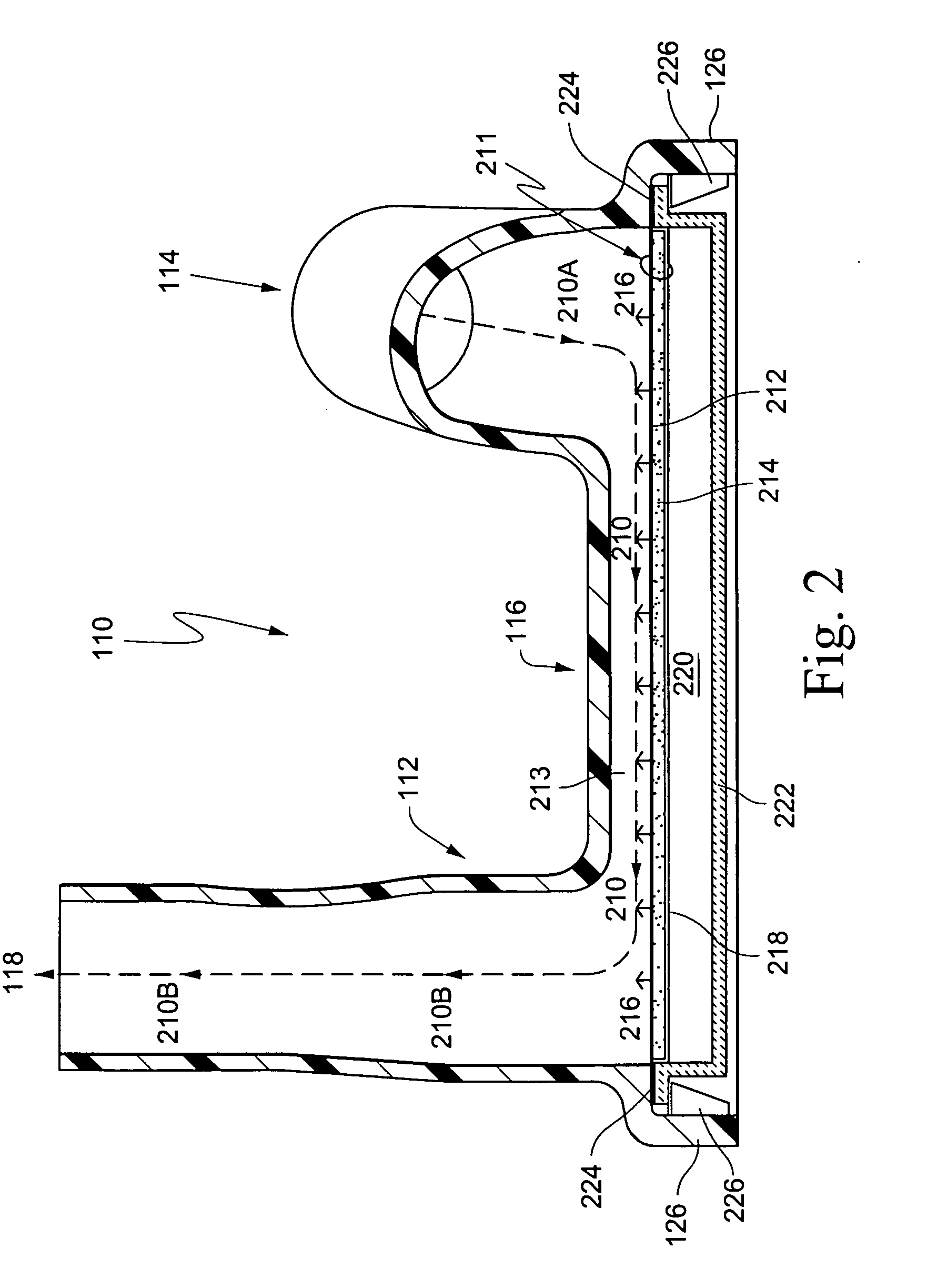

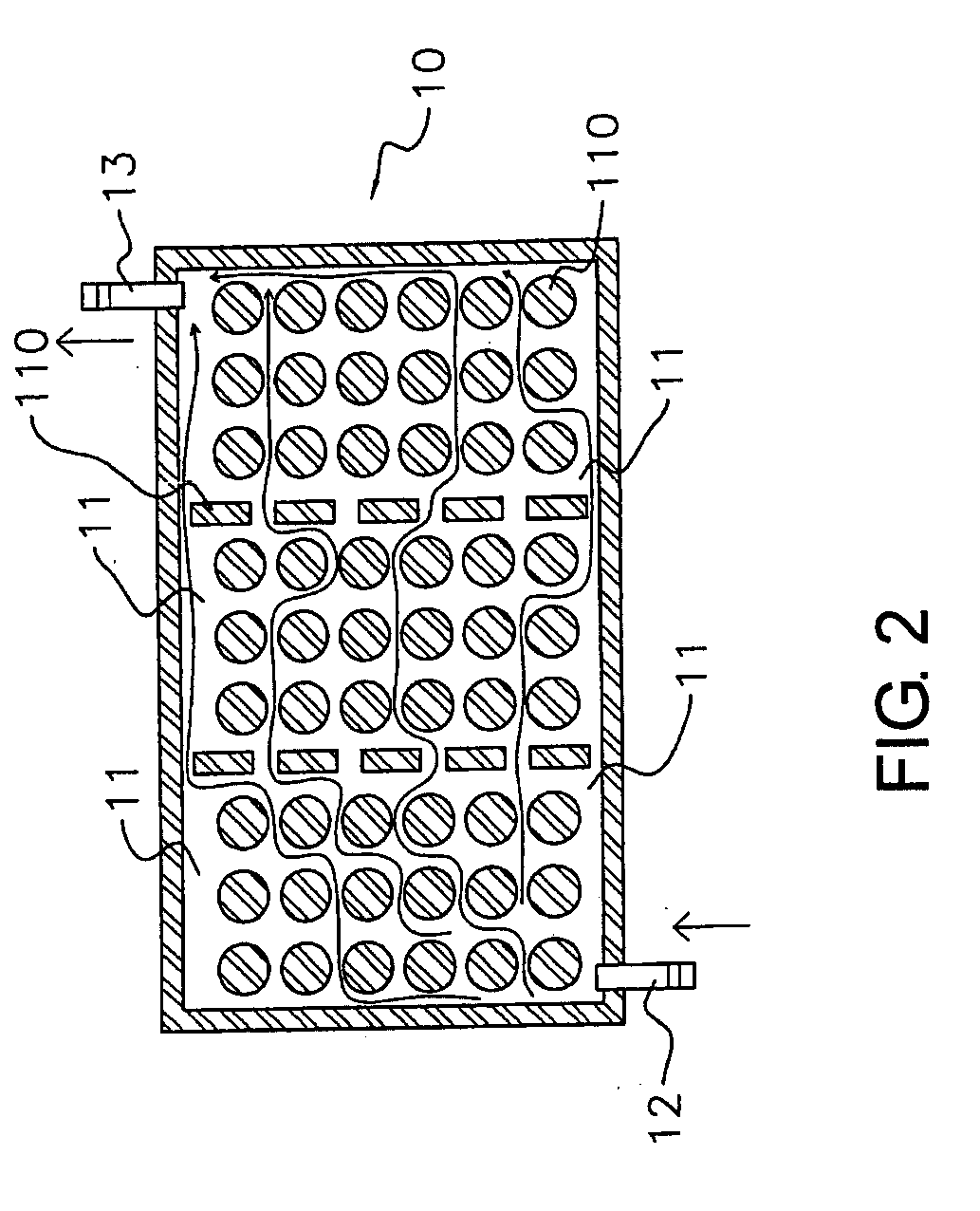

Membrane humidifier for a fuel cell

ActiveUS20080001313A1Mass transport resistance minimizedMinimized pressure dropSemi-permeable membranesMembranesFuel cellsProton

Owner:GM GLOBAL TECH OPERATIONS LLC

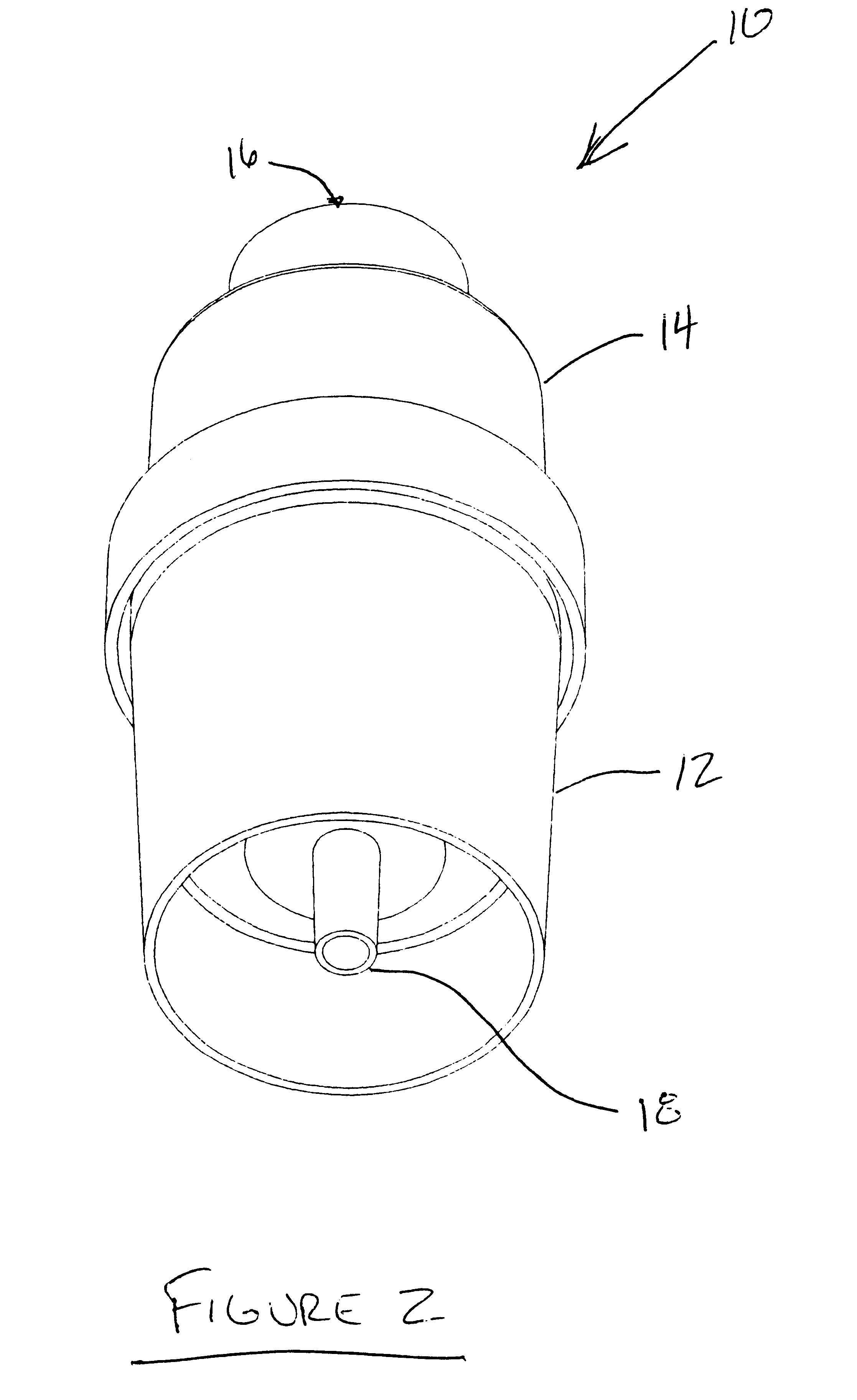

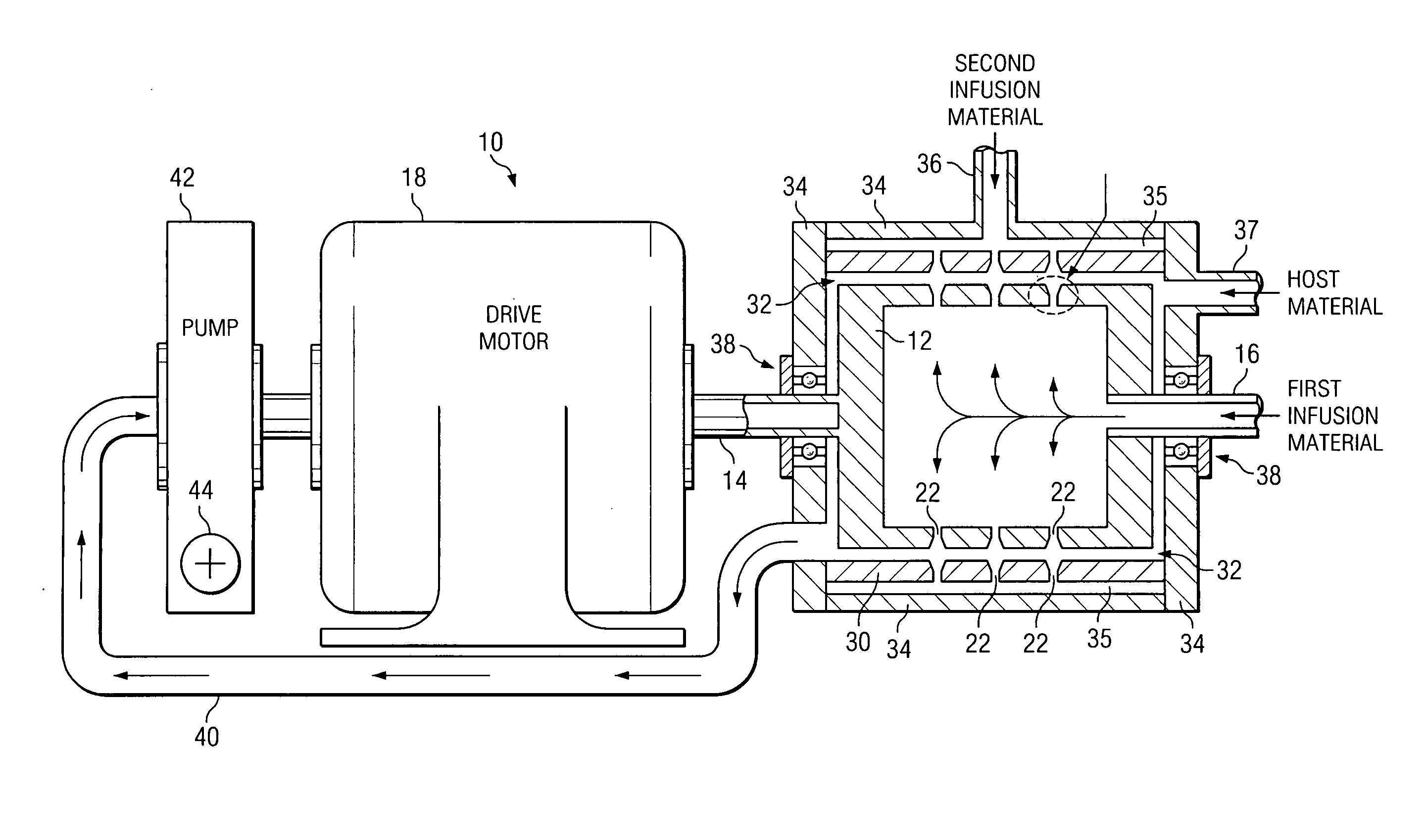

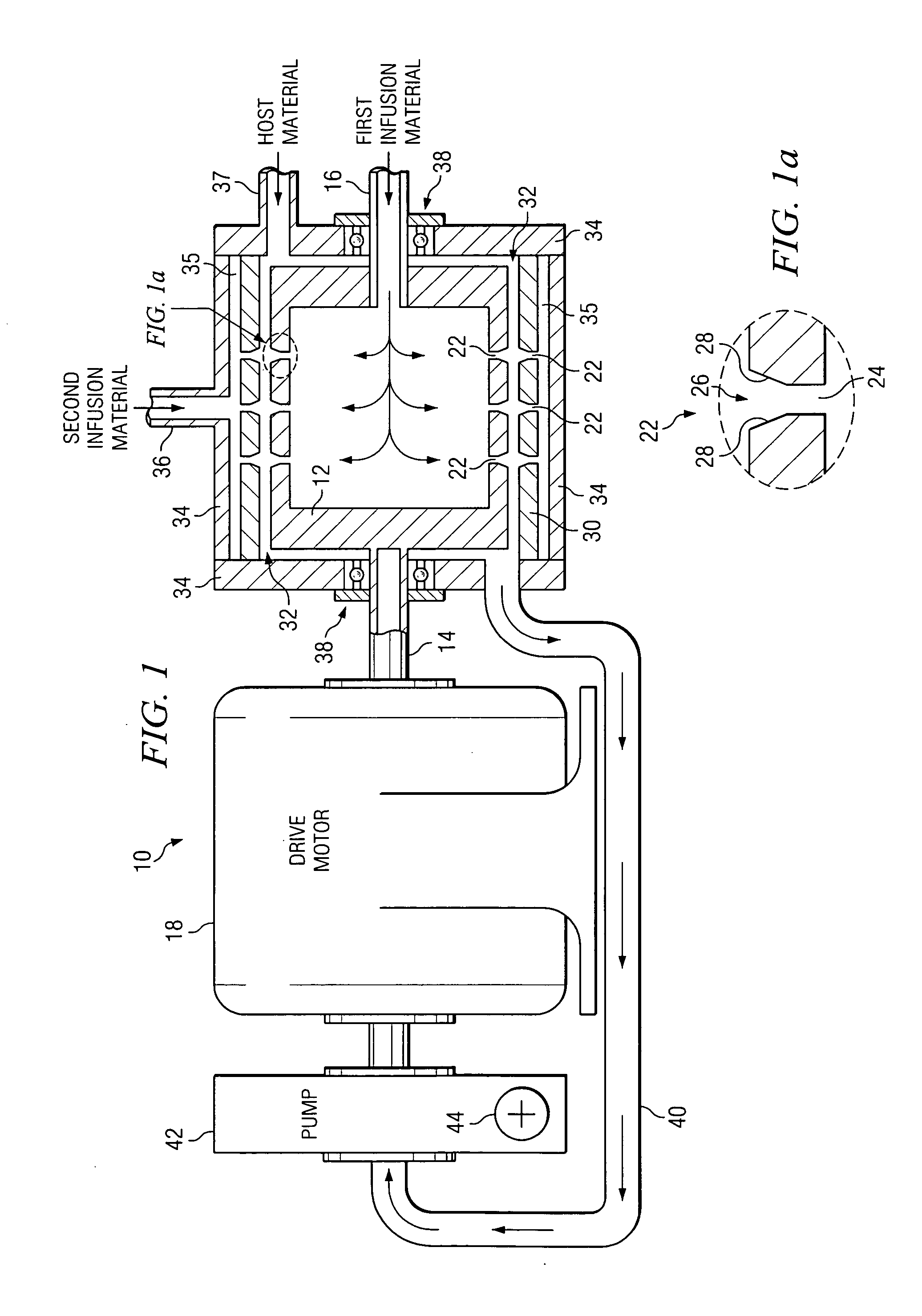

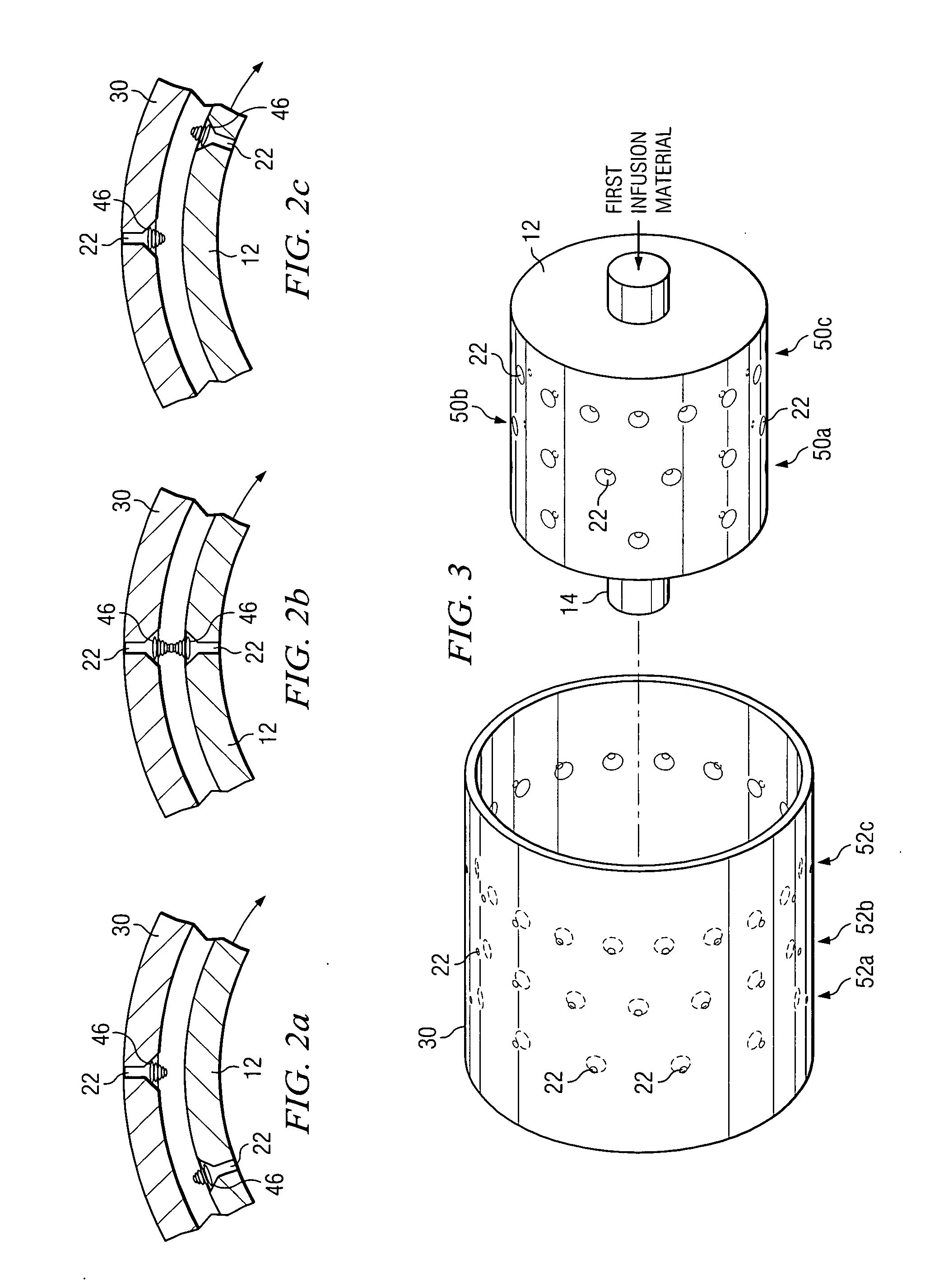

Cavitation device with balanced hydrostatic pressure

InactiveUS7360755B2Improve efficiencyEvenly distributedBurnersLiquid fuel feeder/distributionCavitationHydrostatic pressure

A method of mixing two or more dissimilar fluids such a gas and a liquid is provided. The method includes the steps of introducing one fluid into the other to form a mixture, inducing cavitation in the mixture to reduce at least one of the fluids to a large number of relatively small units, and distributing the small units uniformly throughout the mixture. In a preferred embodiment, the step of inducing cavitation comprises introducing the mixture into a chamber having a rotating disk formed with a plurality of irregularities such as bores. The irregularities on the rotating disk induce cavitation in the mixture. The cavitation also breaks down van der Waals attractions within the mixture to enhance mixing.

Owner:HYDRODYNAMICS

Cooling/heating pad

InactiveUS20060048520A1Reduce weightUsing liquid separation agentMachines/enginesElectrical conductorWater channel

A cooling / heating pad of the present invention includes a pad portion, a water reservoir system and a heat exchanger, wherein the pad portion has the pad portion is a foldable, thin, double-layered bag and has a plurality of adhered regions formed by a hot-press or ultrasonic hot melting process to form the water channel between the adhered regions; the water reservoir system has a water reservoir and a water circulating pump, the water reservoir having a water inlet and a water outlet, the water inlet of the water reservoir connected to the water outlet of the water channel, and the water circulating pump moving the cooling water in the water reservoir from the water outlet of the water reservoir to the water inlet of the water channel; and the heat exchanger includes an electrical heating semiconductor chip, and a thermal conductor mounted on one side of the electrical heating semiconductor chip; wherein the thermal conductor directly contacts the cooling water in the water reservoir, or is mounted on a water path between the water outlet of the water reservoir to the water inlet of the water channel, so that the cooling water is capable of exchanging heat with the thermal conductor.

Owner:U LONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com