Internal combustion engine vapor supercharging waste heat recovery system

A technology of waste heat recovery system and internal combustion engine, applied in the direction of internal combustion piston engine, steam engine device, combustion engine, etc., can solve the problems of decrease in output power of internal combustion engine, increase in exhaust loss, increase in exhaust back pressure of internal combustion engine, etc. The effect of increasing the range of effective work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

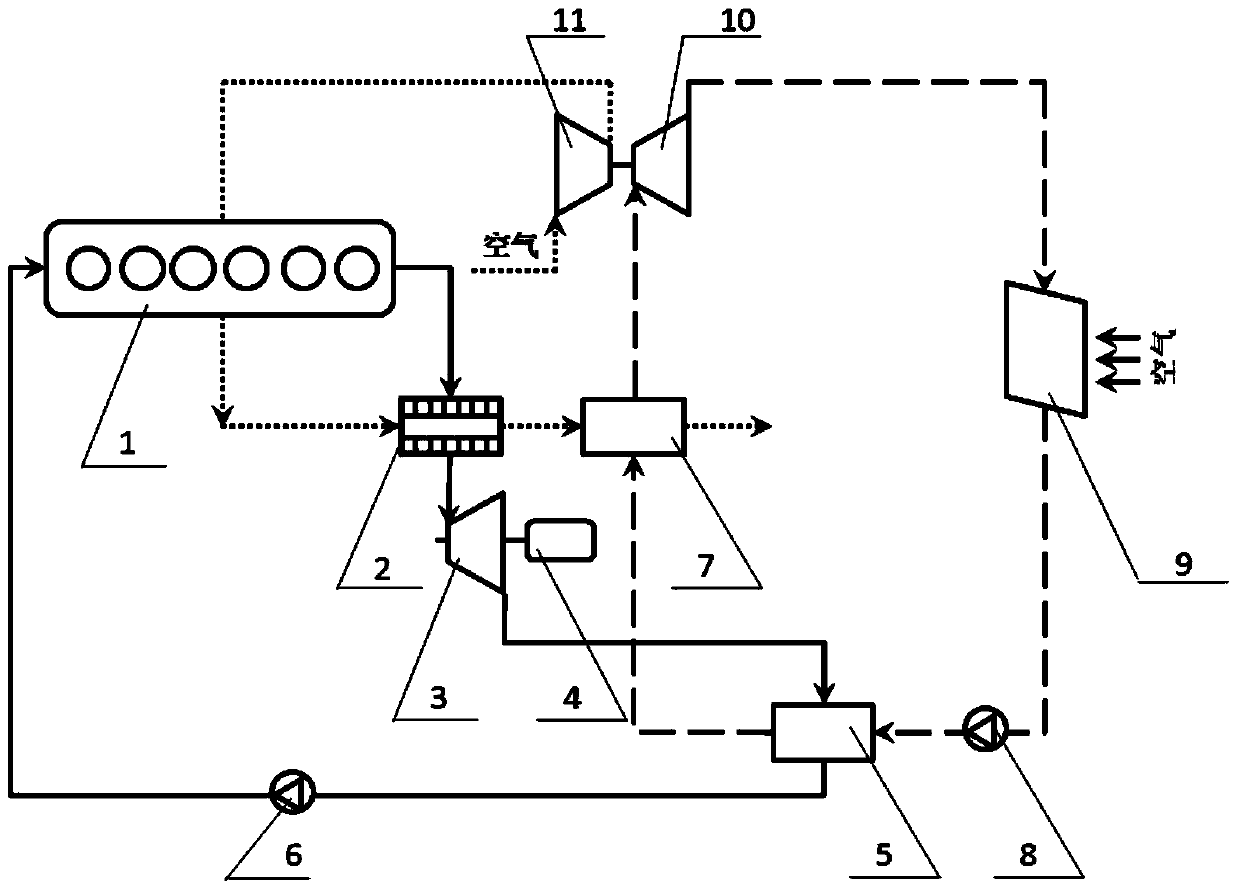

[0010] The principle and system of the present invention will be further described below in conjunction with the accompanying drawings and examples. It should be noted that this embodiment is illustrative rather than restrictive, and does not limit the protection scope of the present invention.

[0011] The internal combustion engine steam pressurized waste heat recovery system, its system composition and component connection structure are: internal combustion engine 1 cylinder liner cooling water passes through the pipeline and the cold end of the thermoelectric generator 2, the expander 3, the high temperature water side of the preheater 5, and the circulation The water pumps 6 are sequentially connected in series to form a cooling water heat utilization circulation system (solid line in the figure). The compressor 11 in the turbocharger compresses the intake air and sends it to the intake end of the internal combustion engine. The exhaust end of the internal combustion engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com