Industrial waste salt system and method

An industrial waste salt and treatment system technology, applied in chemical instruments and methods, waste treatment, solid waste removal, etc., can solve problems such as ringing and agglomeration of waste salt, high temperature control requirements, and insufficient combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

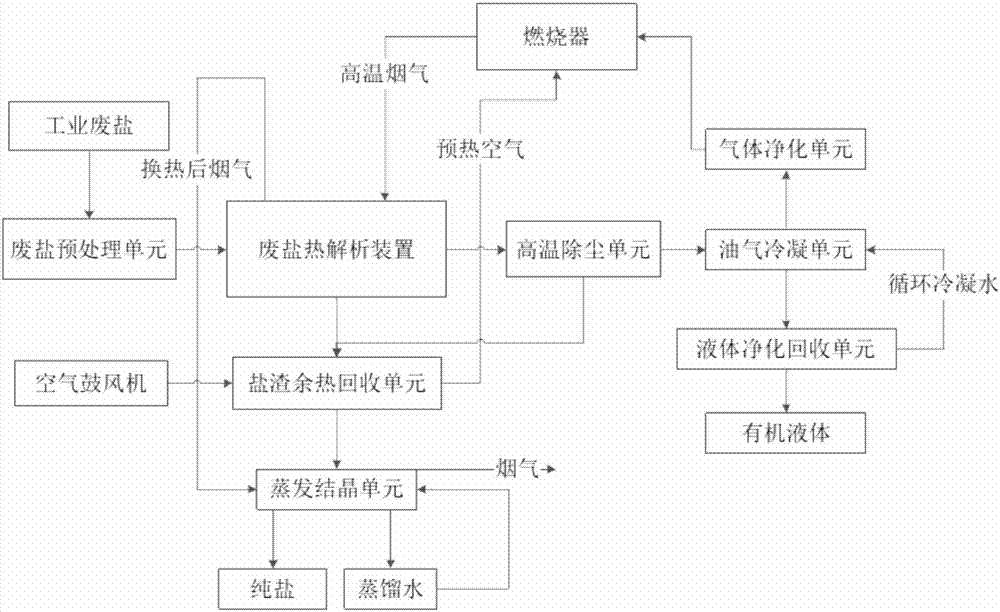

Method used

Image

Examples

Embodiment 1

[0033] Using the above process and system to process a certain industrial waste sodium salt, the main components of the waste sodium salt are p-nitrotoluene-o-sulfonic acid (PNTS), sodium sulfate, 4,4-dinitrostilbene-disulfonic acid ( DNS).

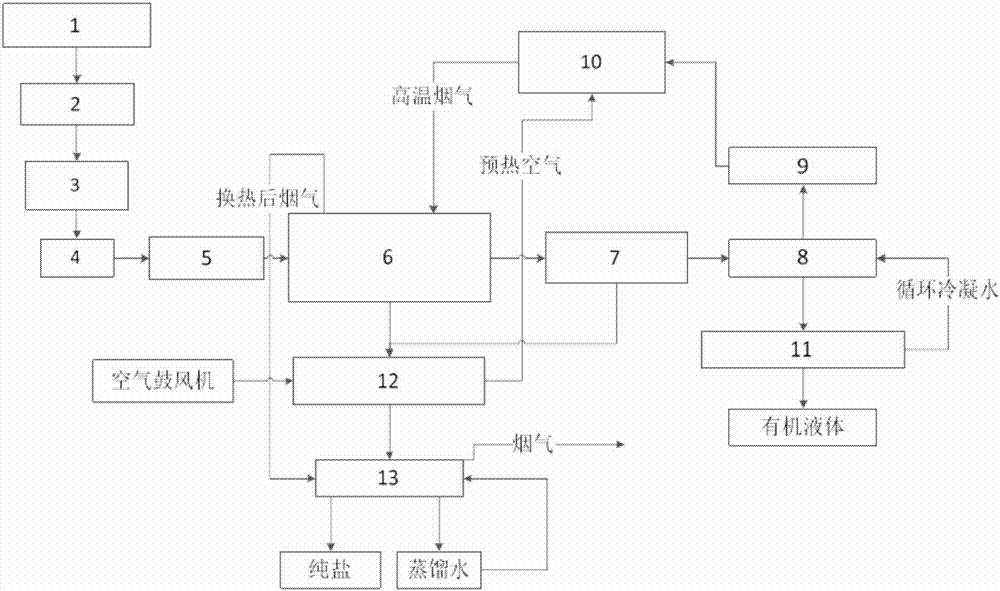

[0034] see figure 2 Taking the above-mentioned waste sodium salt as an example, industrial waste sodium salt enters the silo 1 and is transported to the crusher 2 for crushing, sieved by the vibrating screen 3, weighed by the metering scale 4, and then sent by the screw conveyor 5 with a processing capacity of 200kg / h. The multi-stage heating reactor to the waste salt thermal analysis device 6 is gradually heated under anaerobic conditions, and the reactions such as dehydration (100-120°C), organic matter evaporation (120-350°C), and organic matter cracking (350-580°C) are carried out successively , the generated oil-gas mixture enters the high-temperature dust removal unit 7 through the top pipeline for particle dust removal, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com