A flap type biofuel stove

A biofuel, flap-type technology, used in solid heating fuels, household stoves/stoves, lighting and heating equipment, etc., can solve the problems of frequent ash discharge, difficult operation of ash discharge, affecting combustion, etc. Quick and convenient, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

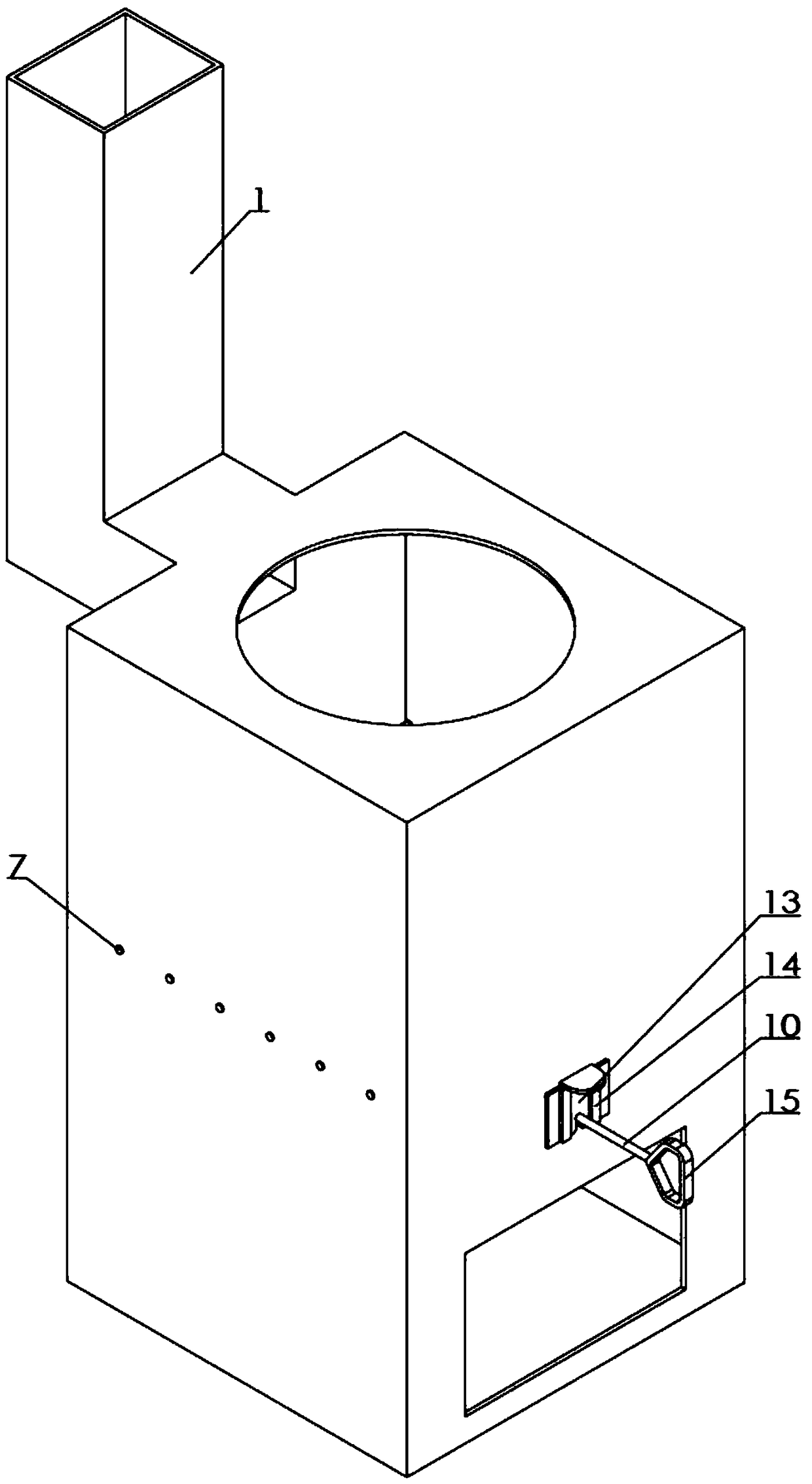

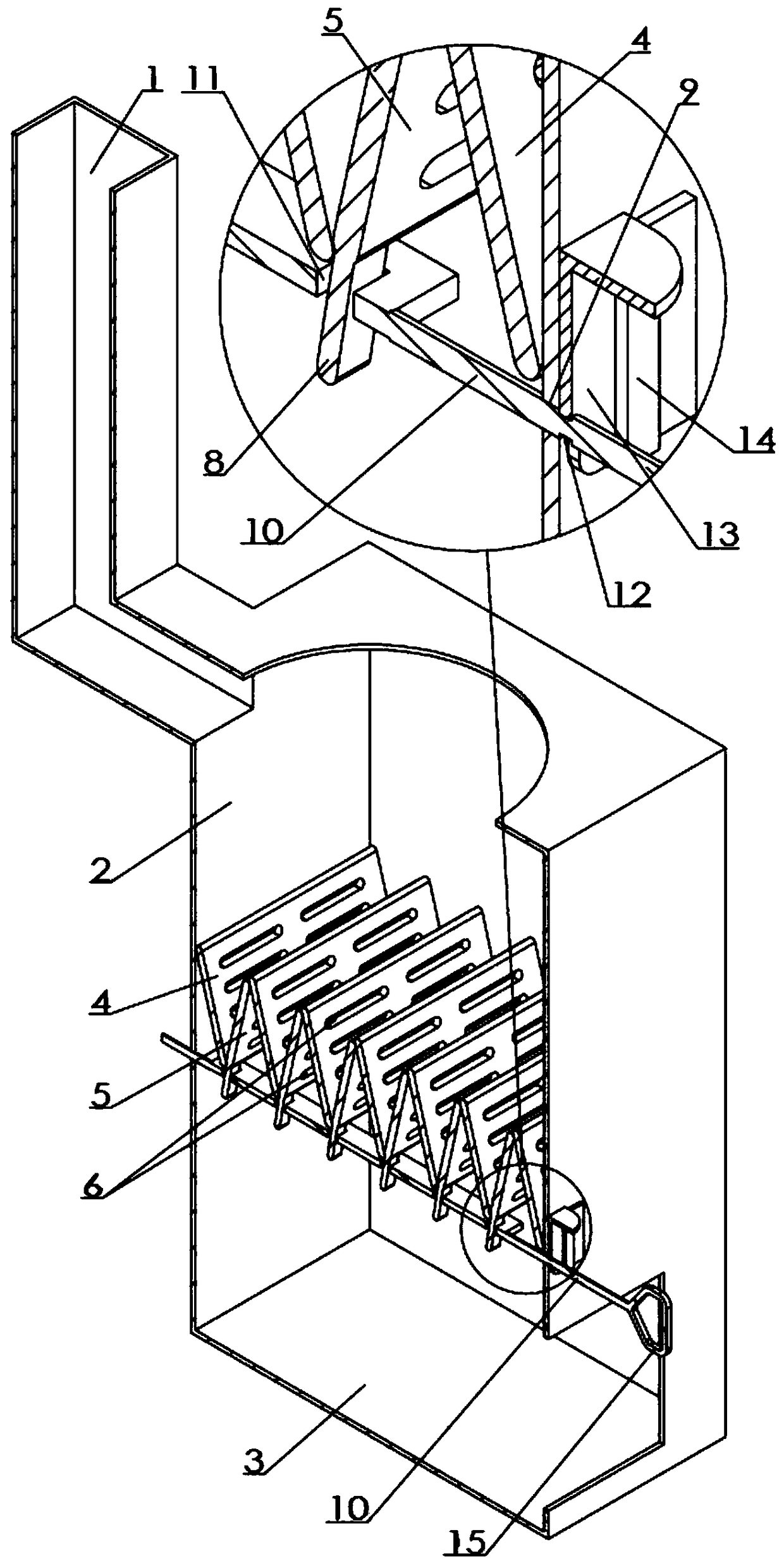

[0011] Examples of the present invention figure 1 , 2 As shown, the flap type biofuel furnace is provided with a furnace chamber and a smoke exhaust pipe 1, and the furnace chamber is provided with a combustion chamber 2 and an ash storage chamber 3, the ash storage chamber is located at the lower part of the combustion chamber, and a Fire grate, the fire grate is composed of parallel fixed grates 4 arranged equidistantly from front to back and parallel movable grates 5 distributed between adjacent fixed grates. Both the fixed grates and the movable grates are provided with ash drop holes 6, so that the ash falls The hole can be horizontal or vertical, and the two ends of the fixed grate are fixedly connected with the side wall of the combustion chamber. The upper edge of the side fixed grate is in contact with or has a gap of less than one centimeter, and the lower edge of the movable grate can be in contact with the lower edge of the fixed grate on the other side adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com