A crusher dust collector

A technology of dust collector and crusher, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of reduced filtration efficiency, easy blockage of mesh holes, and poor dredging effect of filter bags, so as to expand the filtration area , Improve the filtering effect and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

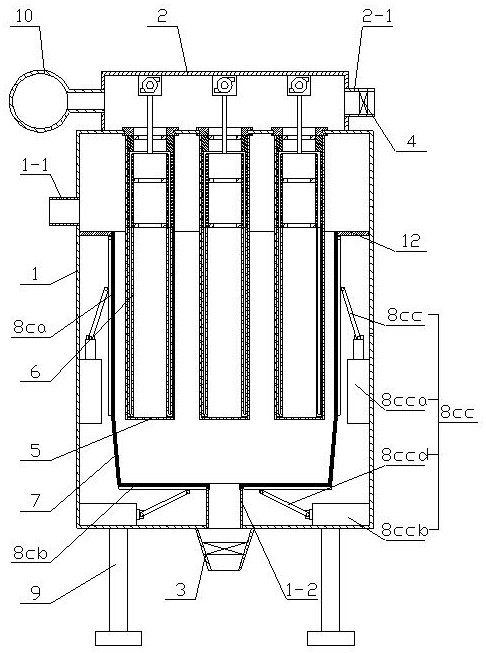

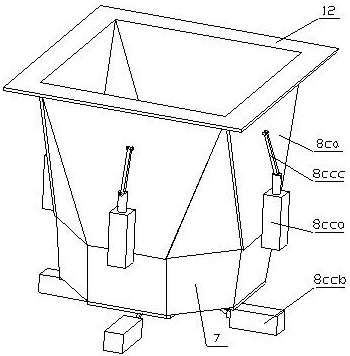

[0042] like Figure 1-9 As shown, the crusher dust collector of Example 1 includes a casing 1, an exhaust chamber 2 is connected above the casing 1, an air inlet 1-1 is opened on the side wall of the casing 1, and an ash discharge is opened at the bottom Port 1-2, an ash hopper 3 is connected below the ash discharge port 1-2; one end side wall of the exhaust chamber 2 is provided with an exhaust port 2-1, and the other end is connected with a blowing system 10, and the exhaust port 2 -1 is provided with an exhaust valve 4; the shell 1 is cylindrical, and its horizontal cross section is square, the shell 1 is provided with a filter bag 5 that communicates with the exhaust chamber 2, and the filter bag 5 is provided with a deformation support mechanism 6 The bottom of the air inlet 1-1 is provided with a dust-carrying film 7 that is sleeved outside the bottom end of the filter bag 5, and the dust-carrying film 7 is made of latex, and its outer edge passes through the looped fram...

Embodiment 2

[0053] like Figure 10 and Figure 11As shown, the crusher dust collector of Embodiment 2 is based on Embodiment 1, except that the shaping mechanism 8 includes a shaping airbag 8a and a first two-way air pump 8b that communicate with each other. The first bidirectional air pump 8b is fixed on the casing 1 in the synthesized space and connected to the ash-carrying membrane 7 .

[0054] In this embodiment, the first two-way air pump 8b is used to pump air from the shaping airbag 8a, so that the shaping airbag 8b shrinks toward the inner bottom wall and the inner side wall of the housing 1, which drives the shape of the ash-carrying film 7 to change, thereby making the ash-carrying film 7 change its shape. 7 form as Figure 10 The barrel-shaped opening shown is upward, so that a filter bag 5 with a larger filtering area can be placed in the housing 1; The center expands and drives the ash-carrying film 7 to deform, so that the ash-carrying film 7 forms such as Figure 11 In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com