Numerical control grinding and polishing dual-purpose apparatus for horizontal honing

A horizontal, honing technology, which is applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of prior honing machines with only a single honing function, low efficiency and workpiece processing accuracy, and achieve simple and detachable connection, avoid The effect of eccentric vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

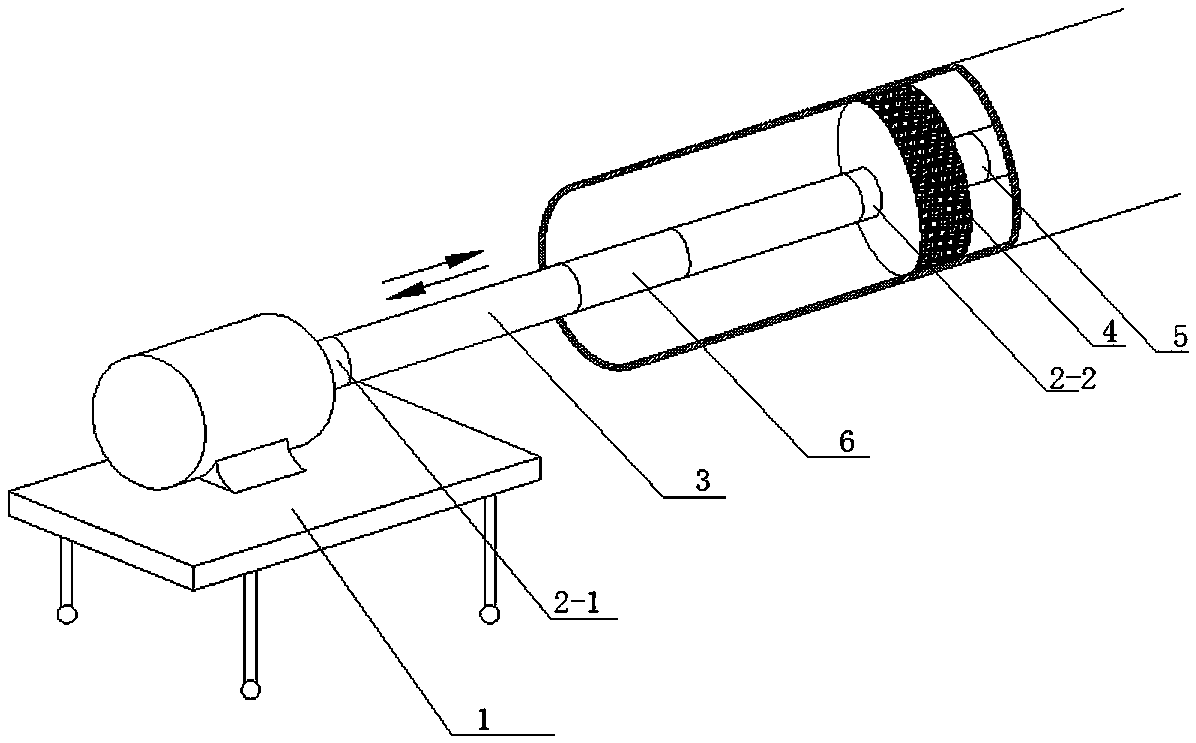

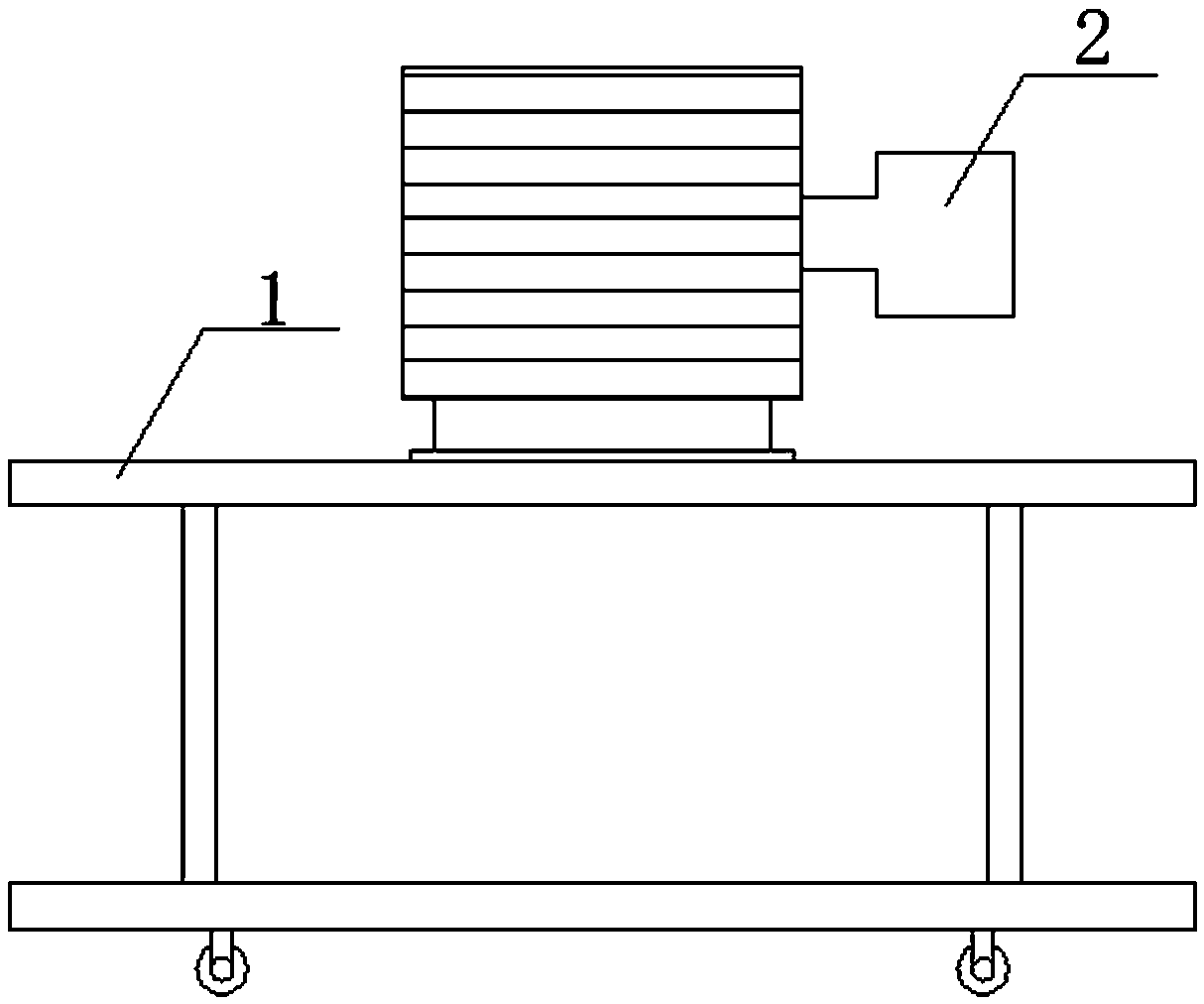

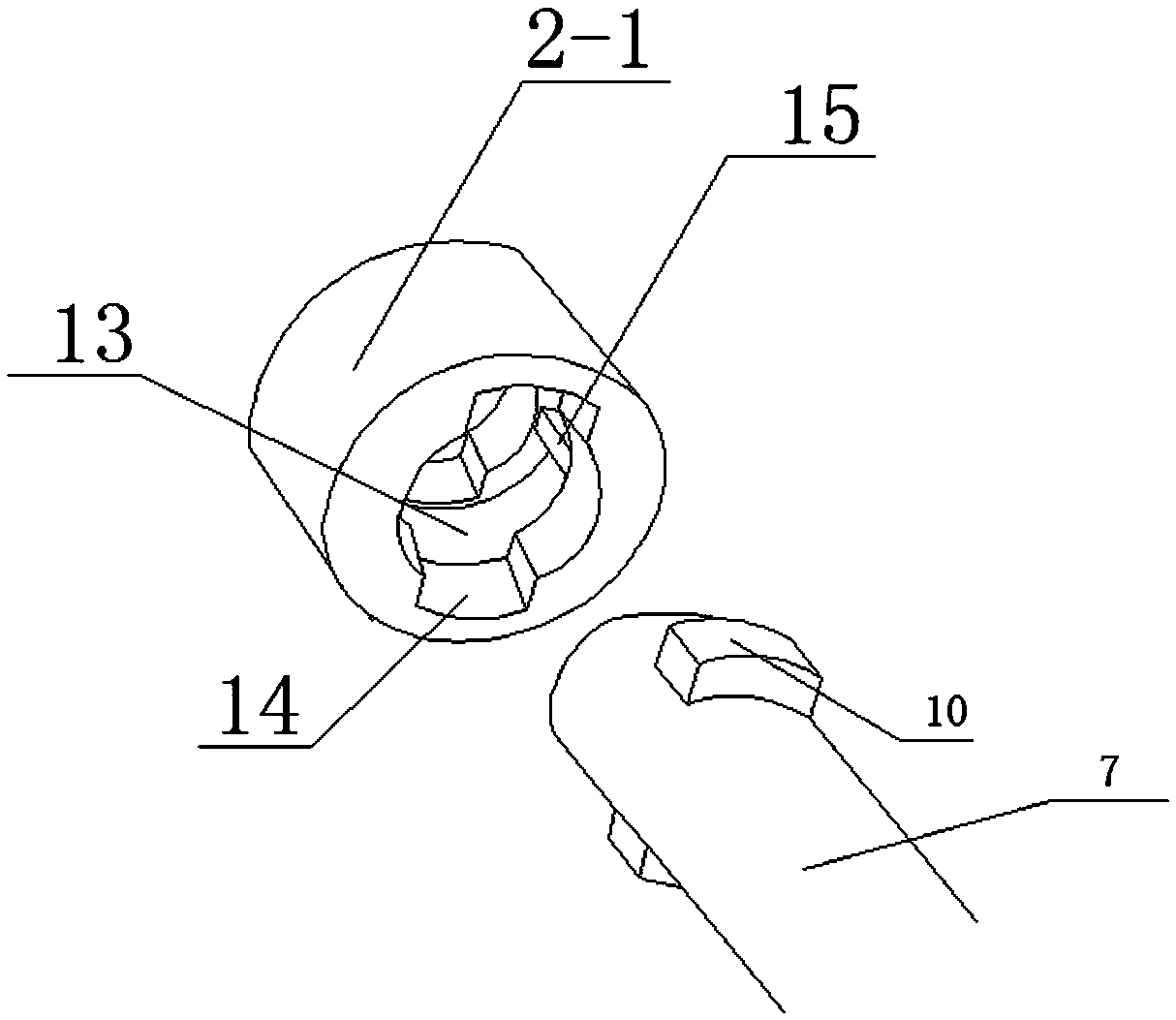

[0041]The invention provides a dual-purpose device for numerical control grinding and polishing for horizontal honing. Shaft joint 5; movable coupling 2 is divided into the first movable coupling 2-1 and the second movable coupling 2-2, the output end of the motor on the follow-up trolley 1 passes through the first movable coupling 2-1 Connect the multi-section shaft 3, the multi-section shaft 3 is a long shaft structure composed of multiple fork shafts connected together, the multi-section shaft 3 is connected to the grinding head 4 through the second movable coupling 2-2, and the grinding head 4 is connected to the belt bearing Movable coupling 5, during use, is connected to the position of connecting honing head on the horizontal honing machine with bearing movable coupling 5.

[0042] The multi-section fork shaft in the multi-section shaft 3 includes at least the first fork shaft 3-1 and the last fork shaft 3-2 connected to the grinding head 4;

[0043] The fork shafts al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com