Power Eccentric Chuck

An eccentric clamping, power technology, applied in clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of reduced processing efficiency, slow processing, inefficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

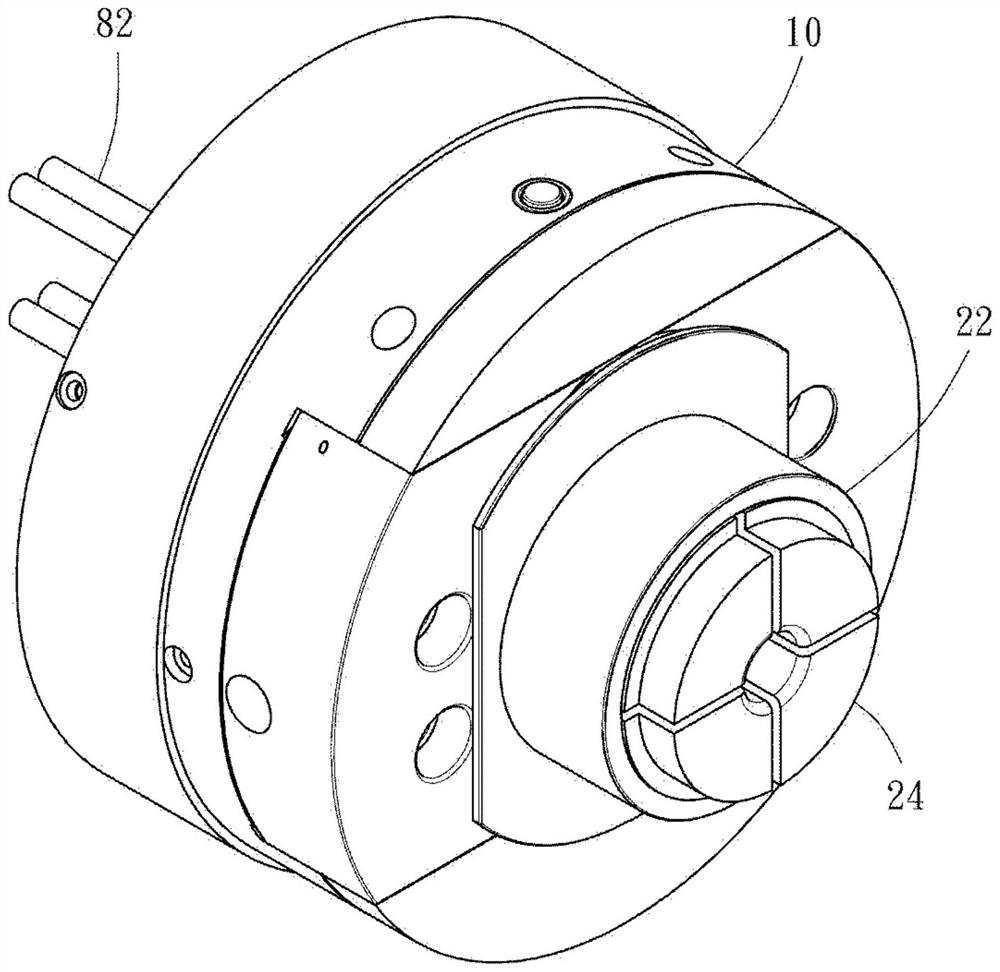

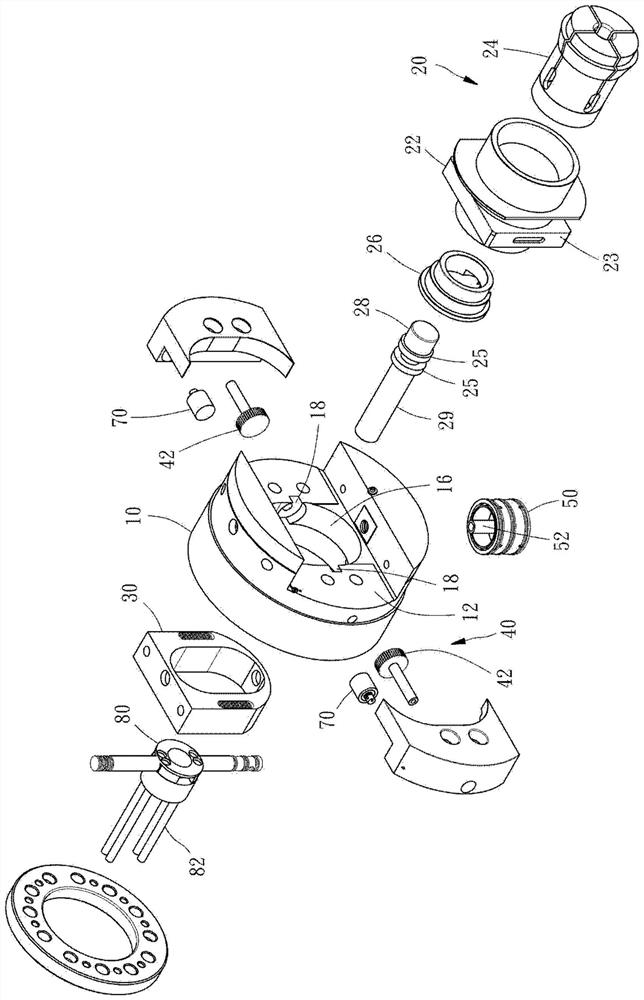

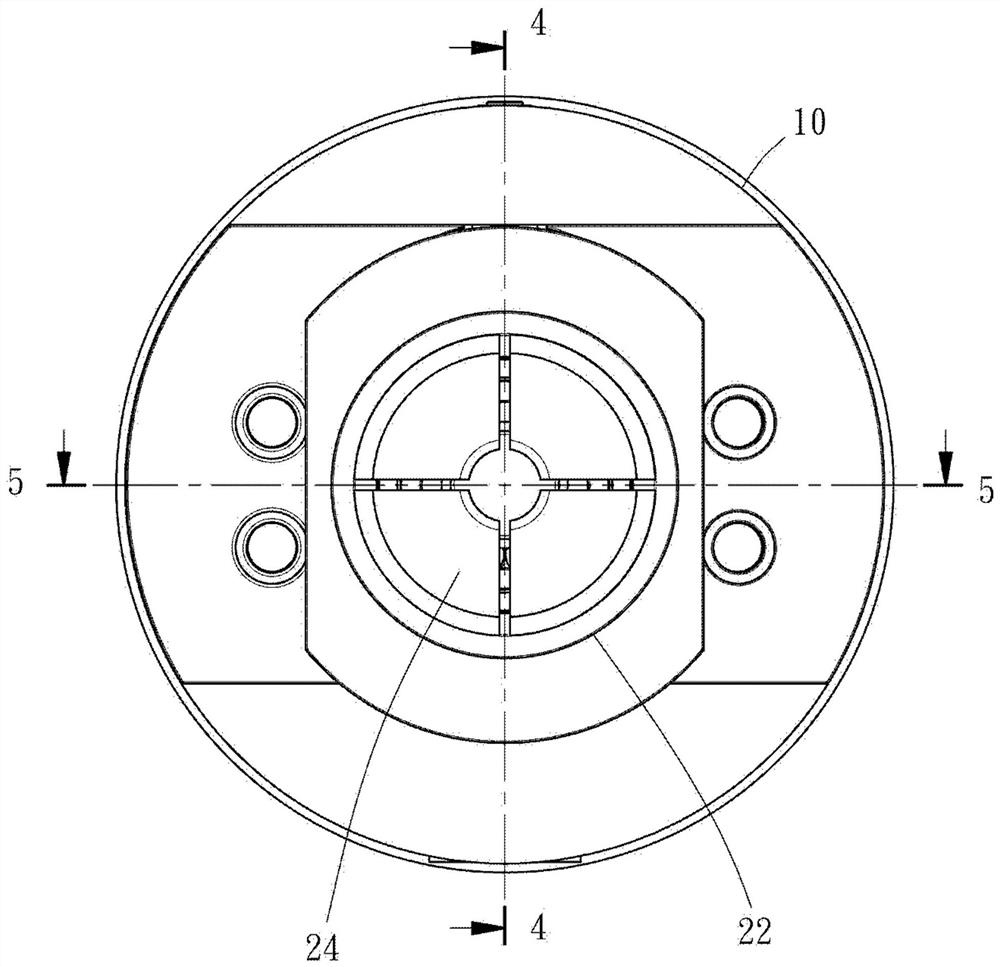

[0043] see Figure 1 to Figure 5 As shown, the dynamic eccentric chuck provided by a preferred embodiment of the present invention includes a main body 10 , a clamping device 20 , a counterweight 30 and a transmission mechanism 40 . The main body 10 has a substantially cylindrical shape and is mounted on a rotating spindle of a machine tool. The main body 10 has a front chute 12, a rear chute 14 and a central hole 16 connecting the front and rear chute 12, 14. Two chambers 18 are arranged on the peripheral wall of the main body 10, and the two chambers 18 are symmetrically located on the main body 10. on both sides. The transmission mechanism 40 includes two gear shafts 42 , and each gear shaft 42 is rotatably disposed inside each chamber 18 , and part of the teeth of the gear shafts 42 are respectively exposed to the front and rear chute 12 , 14 . The bottom side of the main body 10 is also provided with an oil pressure cylinder 50 , and the oil pressure cylinder 50 has a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com