A bag type dust collector for industrial environmental protection dust removal

A dust collector and environmental protection technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of limiting the filtration effect of bag dust collectors on dust-laden gas, increasing the damage and replacement rate of filter bags, increasing Production costs and production safety issues, to achieve the effect of eliminating accumulation and retention, facilitating ash discharge, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

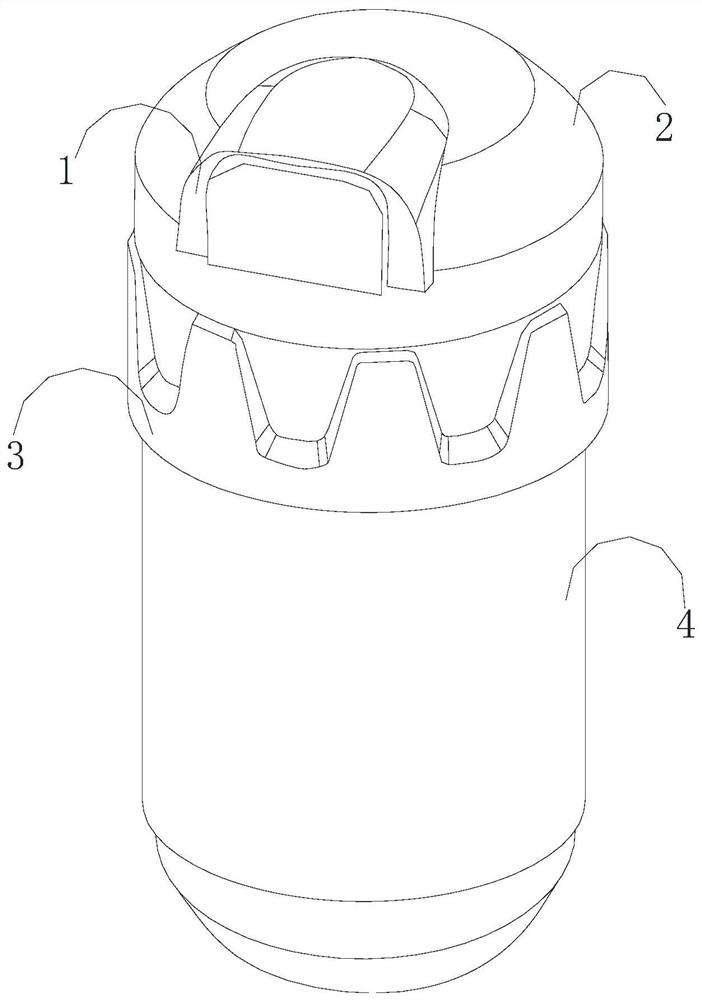

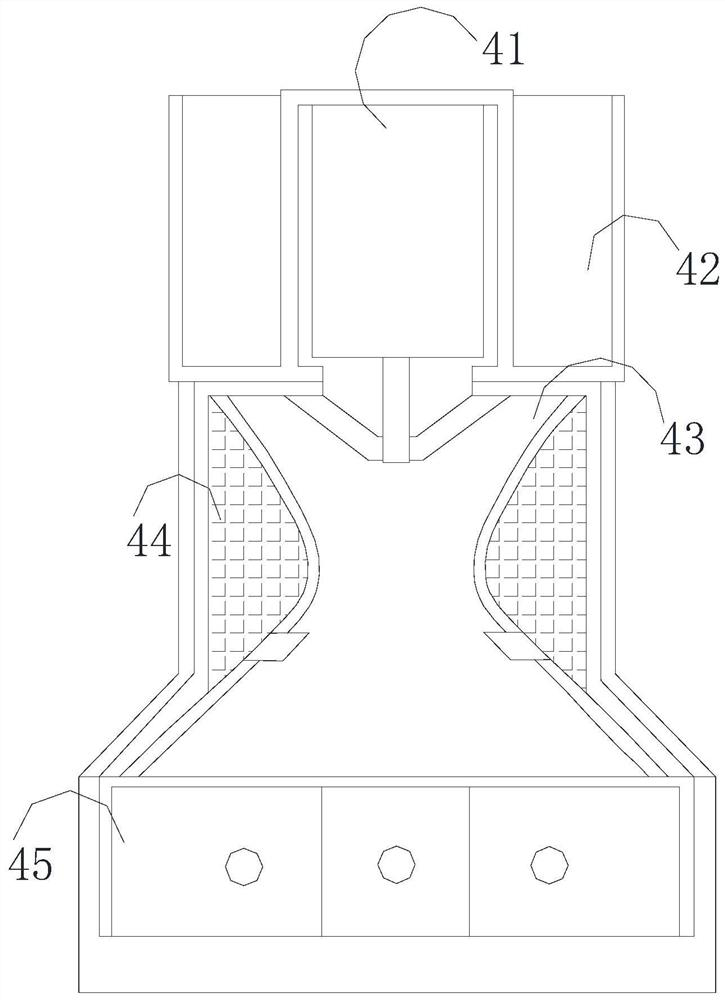

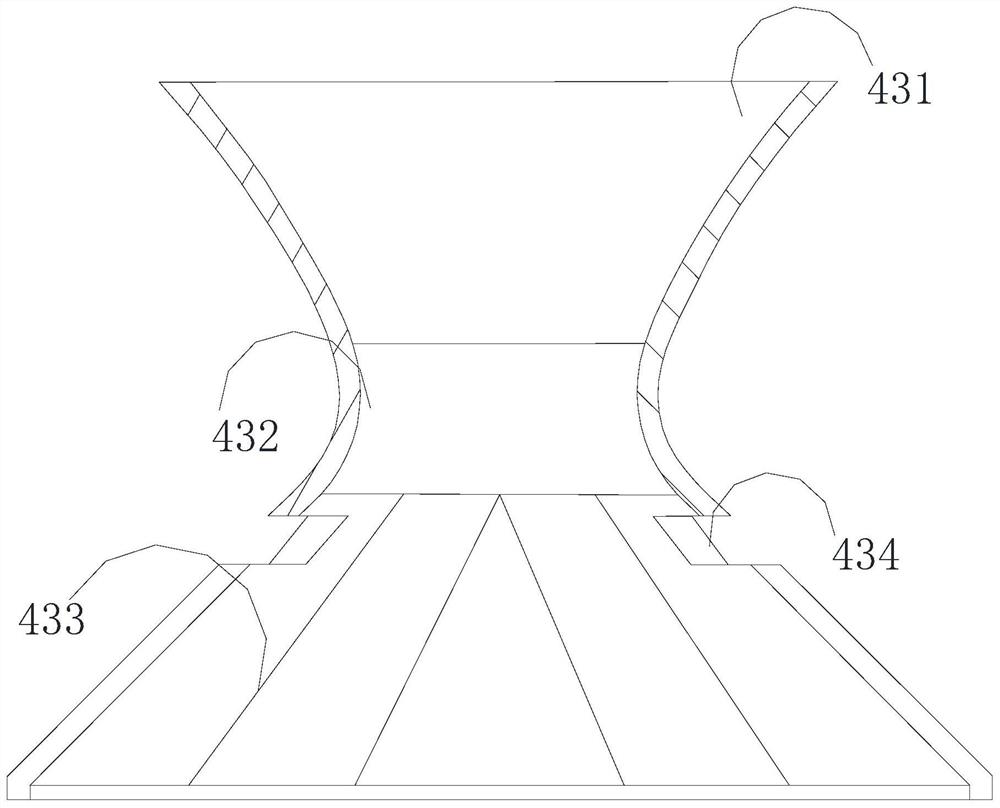

[0032] Such as Figure 1-Figure 4 As shown, the present invention provides a bag-type dust collector for industrial environmental protection dust removal, its structure includes a suction port 1, an upper cover 2, a filter cartridge 3, and a dust collector 4, the upper cover 2 is located at one end of the filter cartridge 3, and An air suction port 1 is fixedly installed on one side of the upper cover 2, the filter cartridge 3 is docked with the dust collector 4, and the two are connected internally, and the dust collector 4 includes a driver 41, an isolation gasket 42, a support guide 43, Bundle cover 44, expansion part 45, the driver 41 is embedded between the isolation gaskets 42, the isolation gasket 42 is fixedly connected with the filter cartridge 3, and the support and guide device 43 is sleeved in the bundle cover 44 , and docked with the opening and expanding part 45 installed at the bottom, the support and guide device 43 includes a dust collecting bucket 431, a disp...

Embodiment 2

[0034] as shown in the picture Figure 5-Figure 8As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The guide structure 321 includes a hollow shaft 211, a rivet 212, a fan shaft 213, a dust accumulation flow channel 214, and an anti-sticking device 215. Drain tray 216. The hollow shaft 211 is equipped with a blade shaft 213, and the outer circumference of the blade shaft 213 is equidistantly arranged with four ash accumulation channels 214 of the same structure size. The anti-sticking device 215 The rivet 212 is riveted to the drainage plate 216, and the anti-sticking device 215 includes a breaking block 151, a fixing block 152, a connecting rod 153, a perforation 154, and a reinforcing device 155, and the breaking block 151 passes through the fixing block. 152 rotates with the connecting rod 153, the connecting rod 153 is provided with a perforation 154 and a reinforcing device 155, and the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com