An improved biofuel combustion furnace

A bio-fuel, combustion furnace technology, applied in solid heating fuels, household stoves/stoves, lighting and heating equipment, etc., can solve the problems of frequent ash discharge, difficult operation of ash discharge, affecting combustion, etc. Ashes are quick and easy and help burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

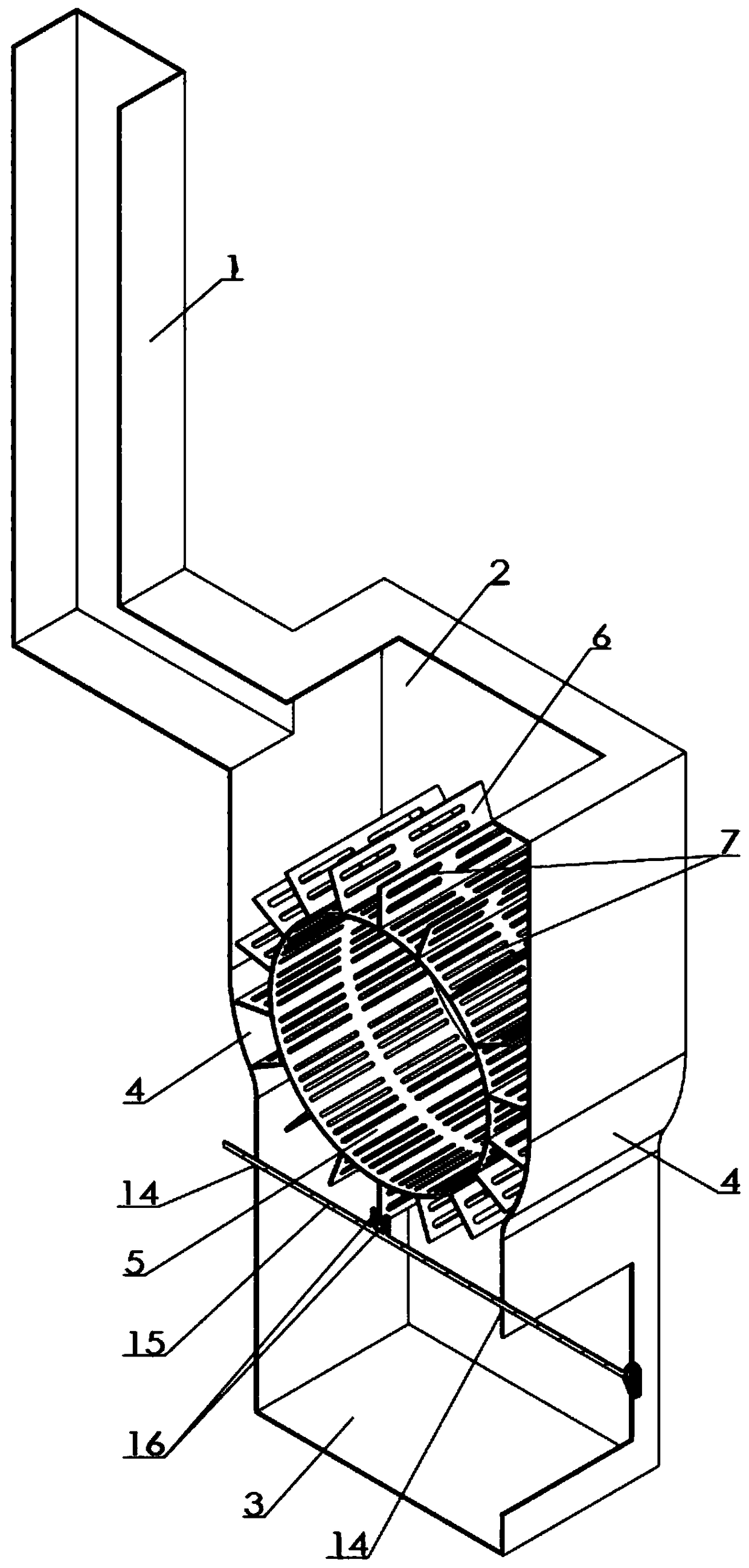

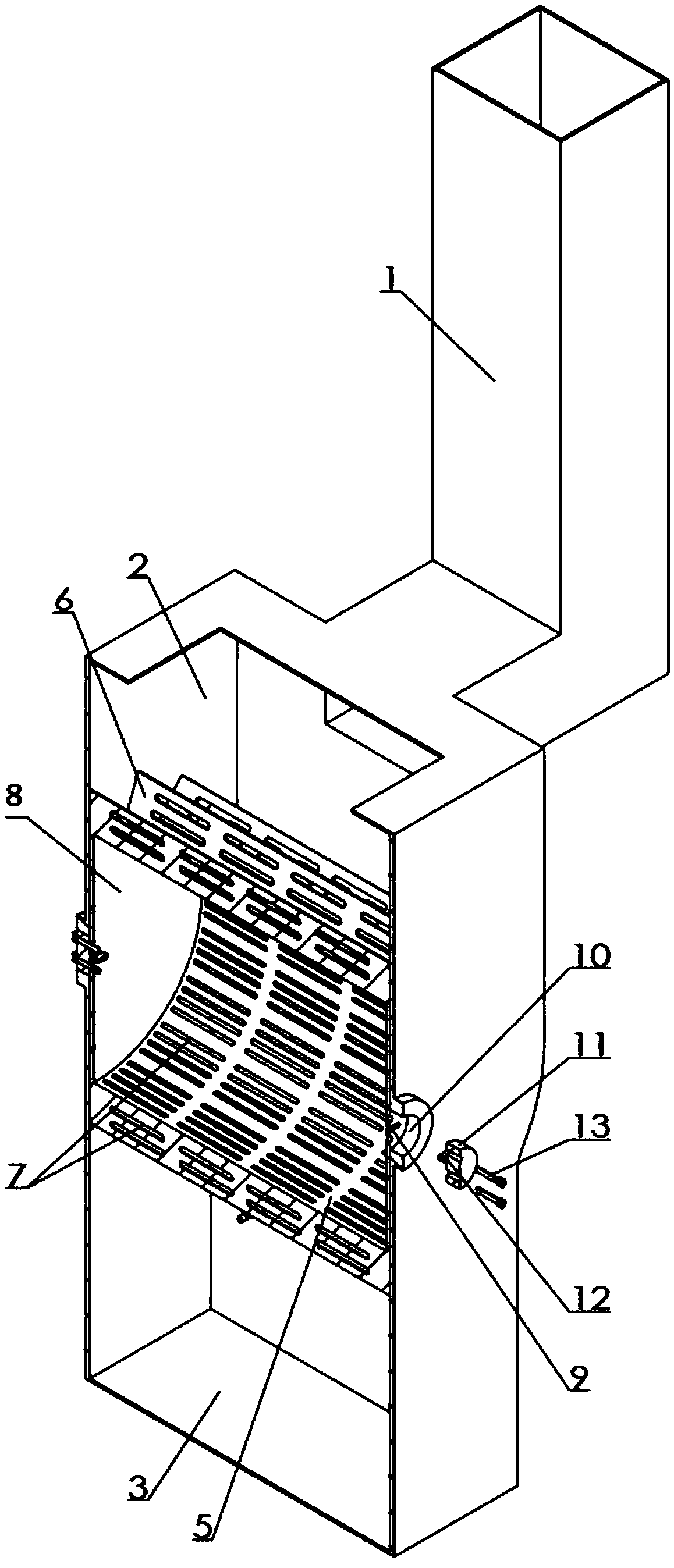

[0013] Examples of the present invention figure 1 , 2 As shown, the improved biofuel combustion furnace is provided with a furnace chamber and a smoke exhaust pipe 1, and the furnace chamber is provided with a combustion chamber 2 and an ash storage chamber 3. The arc transition plate 4 of the same size is transitionally connected with the front and rear walls of the ash storage chamber. A hollow drum 5 coaxial with the arc transition plate in the left and right directions of the axis is arranged in the combustion chamber. The clapboard 6 extending outward and parallel to the axis of the drum, the number of clapboards facing the arc-shaped transition plate on one side of the drum at any angle is at least two, to avoid open space, and the outer edge of the clapboard and the arc-shaped transition plate remain Gap, the gap is preferably 1 mm to 6 mm, as long as it is rotatable and does not fall into the granular fuel, the drum and the partition plate are provided with via holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com