Efficient spray drying system for desulfurization wastewater

A desulfurization wastewater and drying system technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Manufacturing technical requirements are very high to achieve the effect of preventing ash particles from agglomerating and sticking to the wall, avoiding fouling and clogging of pipelines, and ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

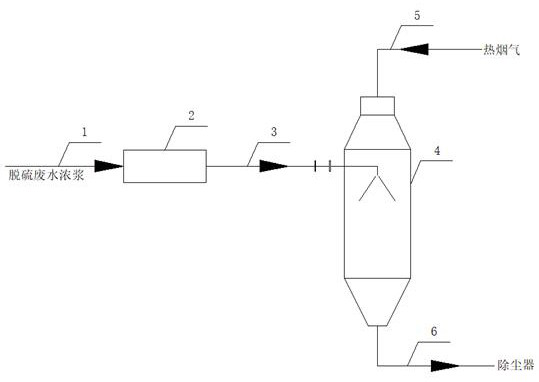

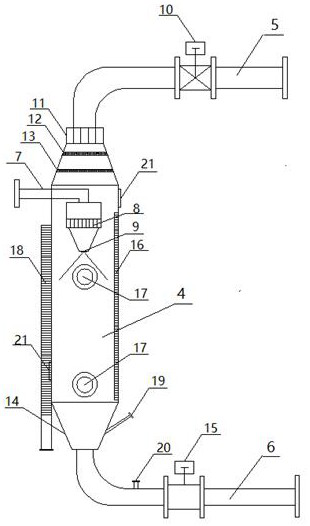

[0060] Embodiment: A high-efficiency spray drying system for desulfurization wastewater, including the following steps: input the concentrated slurry of desulfurization wastewater into the liquid inlet of slurry delivery pump 2 through the slurry delivery pipeline 1, and the slurry delivery pump 2 pressurizes the concentrated slurry into the special spray gun 7 Inside, the high-pressure connecting pipe 3 is provided with a flow transmitter and a pressure transmitter 19, which are interlocked with the frequency converter of the slurry delivery pump 2 to ensure that the pressure of the special spray gun 7 is within the constant pressure range of 2.5~4.0MPa. The damper 10, the opening of the damper is adjusted by the temperature transmitter 20 to ensure that the temperature entering the tower is 350°C, the regulated flue gas enters the hot air distributor at the top of the spray drying tower 4, and the hot flue gas is adjusted to spread evenly in the spray drying tower 4 Inside, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com