Ash discharge structure of solid particle fuel stove

A technology of solid particles and stoves, which is applied to solid heating fuels, household stoves/stoves, lighting and heating equipment, etc. It can solve problems such as poor ash discharge, shutdown and cleaning, and impact on firepower, so as to improve combustion efficiency and prevent fuel consumption. The effect of coking and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

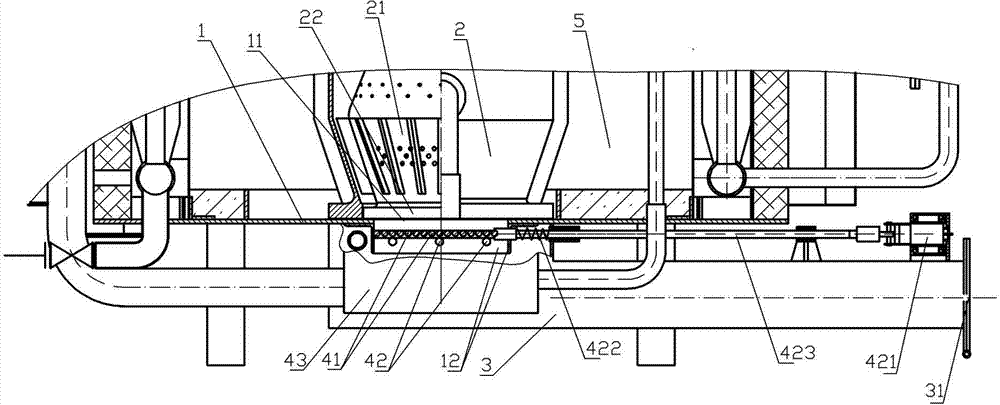

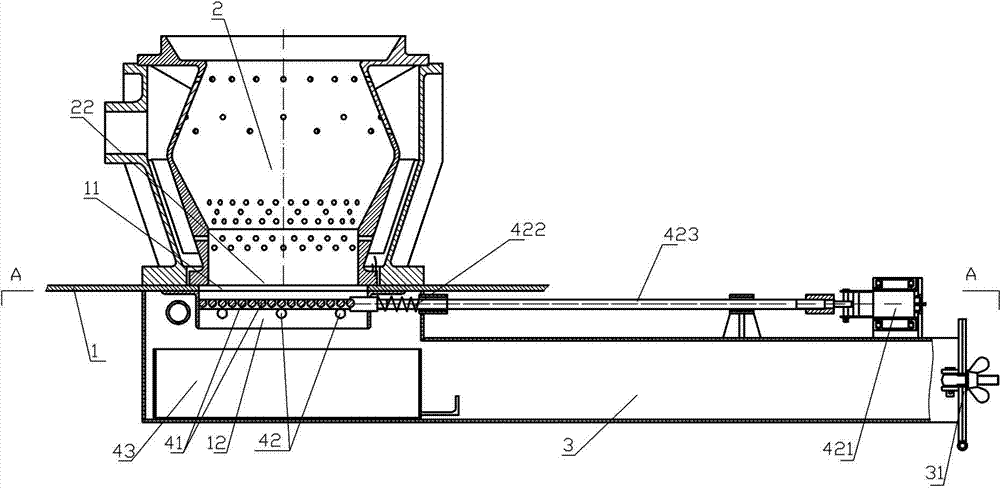

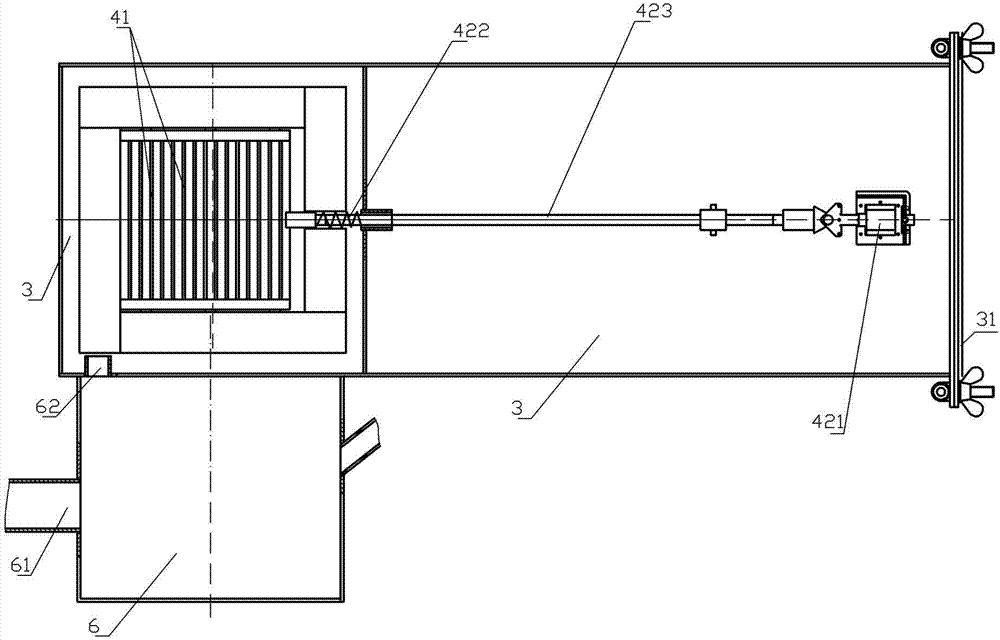

[0030] Such as Figure 1-3 Shown: an ash discharge structure of a solid particle fuel stove, which includes a furnace bottom 1, a burner 2, a bottom box 3 and an ash discharge device; Inside the burner 2 is a combustion chamber 21. There is an ash outlet 22 at the bottom of the burner 2. The ash outlet 22 is also a fuel (the fuel mentioned below generally refers to solid particle fuel) combustion air inlet; the furnace bottom 1 corresponds to the burner The position of the ash outlet 22 of 2 is provided with an ash outlet air inlet 11; the bottom box 3 is located below the furnace bottom 1 and installed on the furnace bottom 1, and the inner cavity of the bottom box 3 communicates with the ash outlet air inlet 11 of the furnace bottom 1 , is a closed cavity relative to the outside world (that is, no air leakage); the ash discharge device includes a fire grate 41, a fire grate shaking device and an ash receiving box 43, and the fire grate 41 is composed of a frame and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com