Apparatus and method for removing smoke of boiler

A fume purification and boiler technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of increasing dust removal costs, large ash discharge, and high costs, and achieve improved service life, less water consumption, and corrosion strength. diminished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

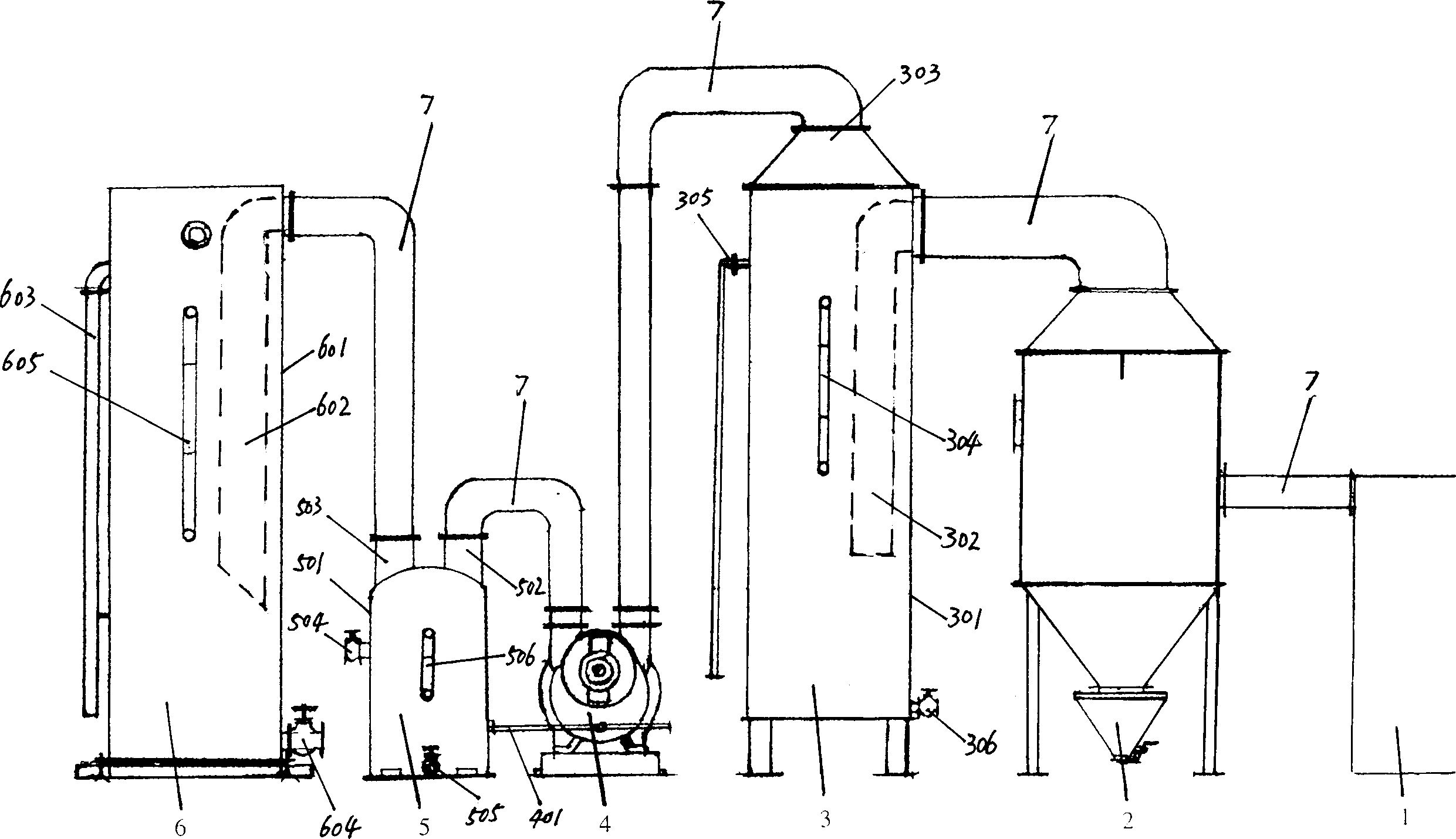

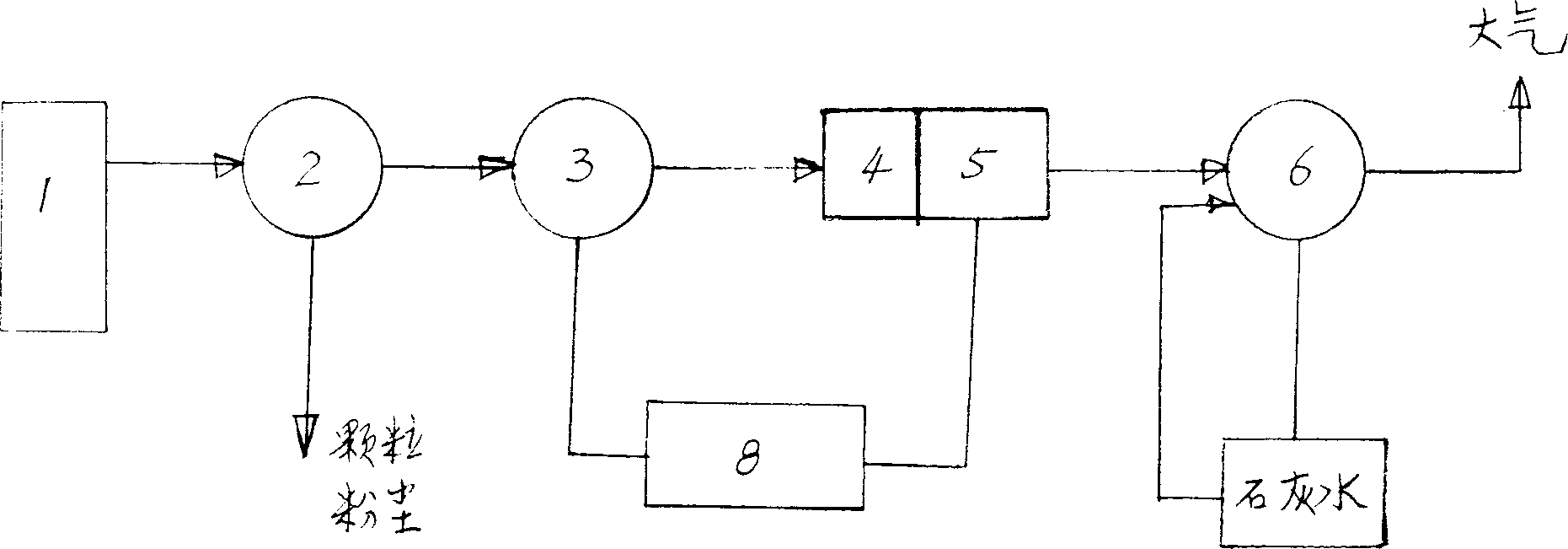

[0013] figure 1 As shown, a boiler smoke purification device includes the existing general-purpose cyclone dust collector 2 and hydraulic induced draft fan 4, as well as wet dust collector 3, steam-water separator 5, desulfurizer 6, etc., and is connected to the boiler by pipeline 7 Or industrial furnaces (such as: building materials, metallurgy, chemical industry and other industrial furnaces), cyclone dust collector, wet dust collector, hydraulic induced draft fan, steam-water separator and desulfurizer. The upper parts of the main bodies of the wet dust collector, the steam-water separator, and the desulfurizer are respectively provided with a water inlet and a water outlet at the lower part, and a water inlet pipe (401) connected with the steam-water separator is provided on the hydraulic induced draft fan.

[0014] The wet precipitator 3 is a closed container with a cylindrical shell, consisting of a shell 301, an air intake pipe 302 on its upper part, the air intake pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com