Device and method for top gas enrichment utilization of blast furnace

A furnace top gas and coal gas technology, applied in the direction of blast furnaces, blast furnace details, furnaces, etc., can solve the problems of affecting the operation of gas utilization devices, the influence of gas composition and flow rate, and the high cost of recycling, so as to improve the indirect reduction rate and benefit The effect of saving energy and reducing energy consumption per ton of iron in blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

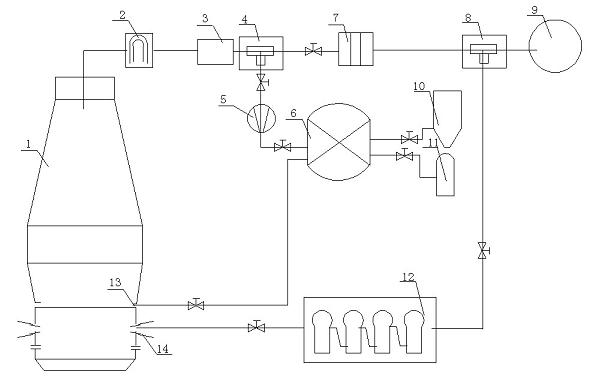

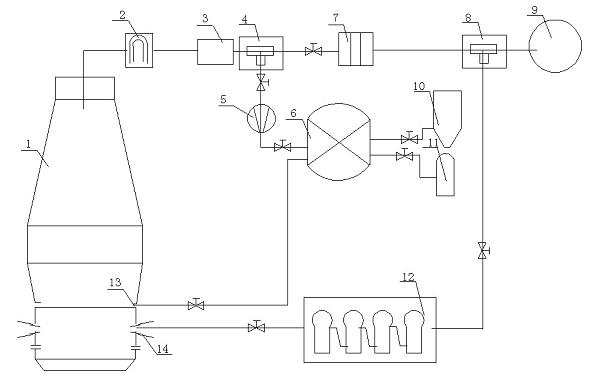

[0034] Depend on figure 1It can be seen that the blast furnace top gas enrichment utilization device, its gas primary dust removal system 2, gas purification and dust removal system 3, residual pressure turbine power generation device 7 are connected through pipelines and valves, and the pipeline between the gas purification and dust removal and residual pressure power generation device Establish tee 4. One road is connected to the pressurizing device 5 and the gasifier 6. The gasifier is equipped with an oxygen nozzle and a pulverized coal nozzle (not marked in the figure), and is connected to the pulverized coal blending device 10 and the oxygen supply device 11 with pipes and valves; the blast furnace bosh A gas return injection hole 13 is provided at the lower part and above the tuyere 14, and the gasifier is connected with the gas return injection hole pipeline and valve, and the enriched gas is sprayed into the blast furnace 1 through the return injection hole; the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com