Cracking furnace of boiler tube with one-way reducing diameter

A technology for cracking furnaces and furnace tubes, which is applied in the field of cracking furnaces for the production of olefins from petroleum cracking. It can solve the problems of poor selectivity and fast coking speed of 1-1 type two-pass furnace tubes, and achieve moderate operation cycle, small furnace and cracking selection. sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

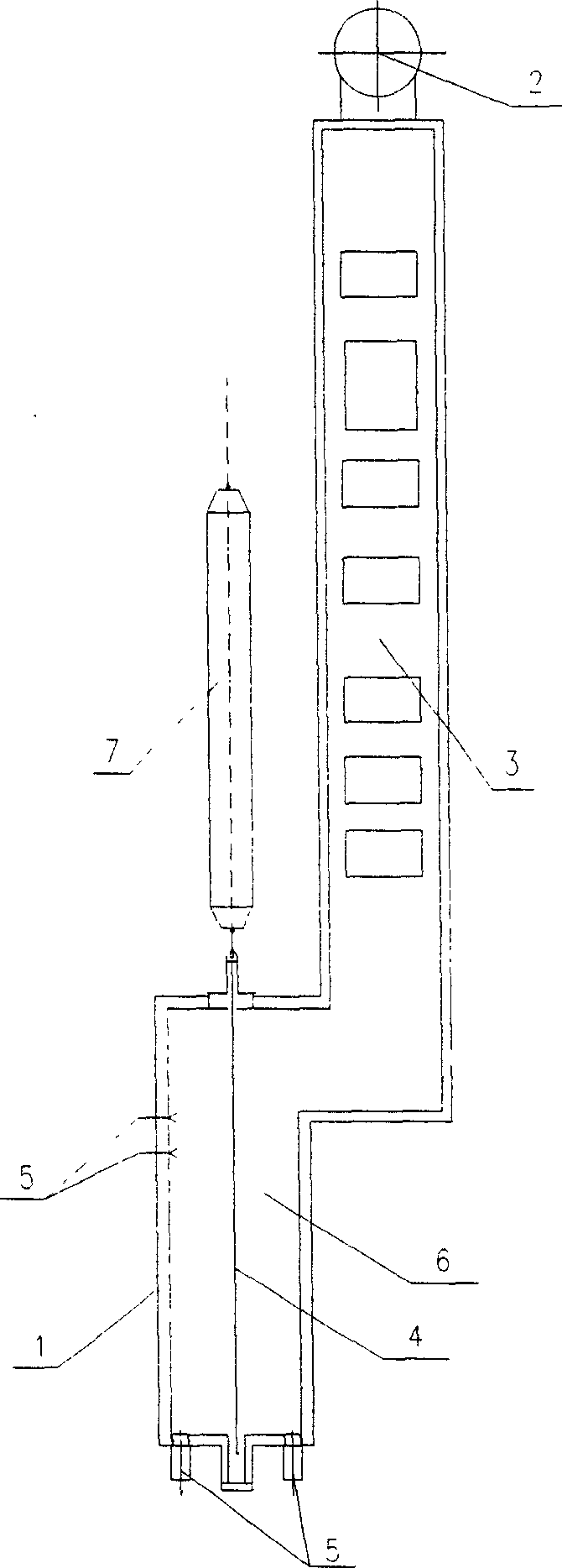

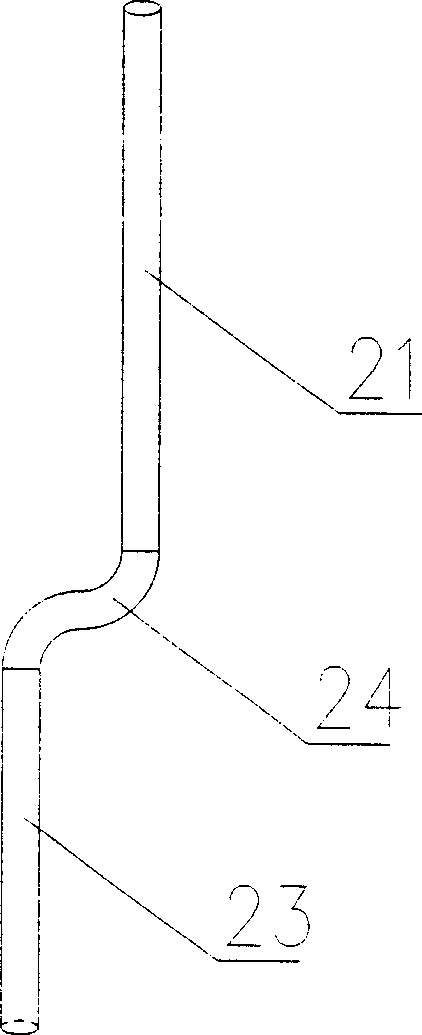

[0036] A kind of cracking furnace of one-way variable-diameter furnace tube, this cracking furnace comprises: furnace body 1, high-pressure steam drum 2, convection section 3, furnace tube 4, burner 5, combustion chamber 6, waste heat boiler 7; Described furnace tube 4 is a single pass vertical furnace tube, the internal diameter of the discharge end of the furnace tube is greater than the internal diameter of the feed end. The furnace tube is fed from the lower end and discharged from the upper end. The furnace tube is connected by upper and lower sections. The total length of the furnace tube is 10m. The length ratio is 1:1. The two sections of pipes are equal-diameter pipes, the inner diameter of the inlet section is 33mm, the inner diameter of the outlet section is 41mm, and the ratio of the inner diameter of the discharge end to the inner diameter of the feed end is 1.24. The inlet section pipe has an arc section 24, that is, with a bend, which is two elbows connected to...

Embodiment 2

[0038] A kind of pyrolysis furnace of one-way variable-diameter furnace tube, the difference with embodiment 1 is: this cracking furnace has 440 furnace tubes, is divided into 10 groups, and each group has 44 furnace tubes.

Embodiment 3

[0040] A kind of cracking furnace of one-way variable-diameter furnace tube, this cracking furnace comprises: furnace body 1, high-pressure steam drum 2, convection section 3, furnace tube 4, burner 5, combustion chamber 6, waste heat boiler 7; Described furnace tube 4 is a single pass vertical furnace tube, the internal diameter of the discharge end of the furnace tube is greater than the internal diameter of the feed end. The furnace tube is fed from the lower end and discharged from the upper end. The furnace tube is connected by upper and lower sections. The total length of the furnace tube is 10m. The length ratio is 1:1. The two sections of pipes are equal-diameter pipes, the inner diameter of the inlet section is 38mm, the inner diameter of the outlet section is 41mm, and the ratio of the inner diameter of the discharge end to the inner diameter of the feed end is 1.079. The pipe in the inlet section has an arc section, that is, with a bend, which is two elbows connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com