Novel configured single-stroke furnace tube ethylene cracking furnace

An ethylene cracking furnace and furnace tube technology are applied in the field of cracking furnaces for cracking petroleum hydrocarbons to produce olefins, and can solve the problems of poor selectivity, fast coking speed, and poor thermal stress absorption of single-pass furnace tubes of type 1-1 two-pass furnace tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these examples, and the scope of the present invention is set forth in the claims.

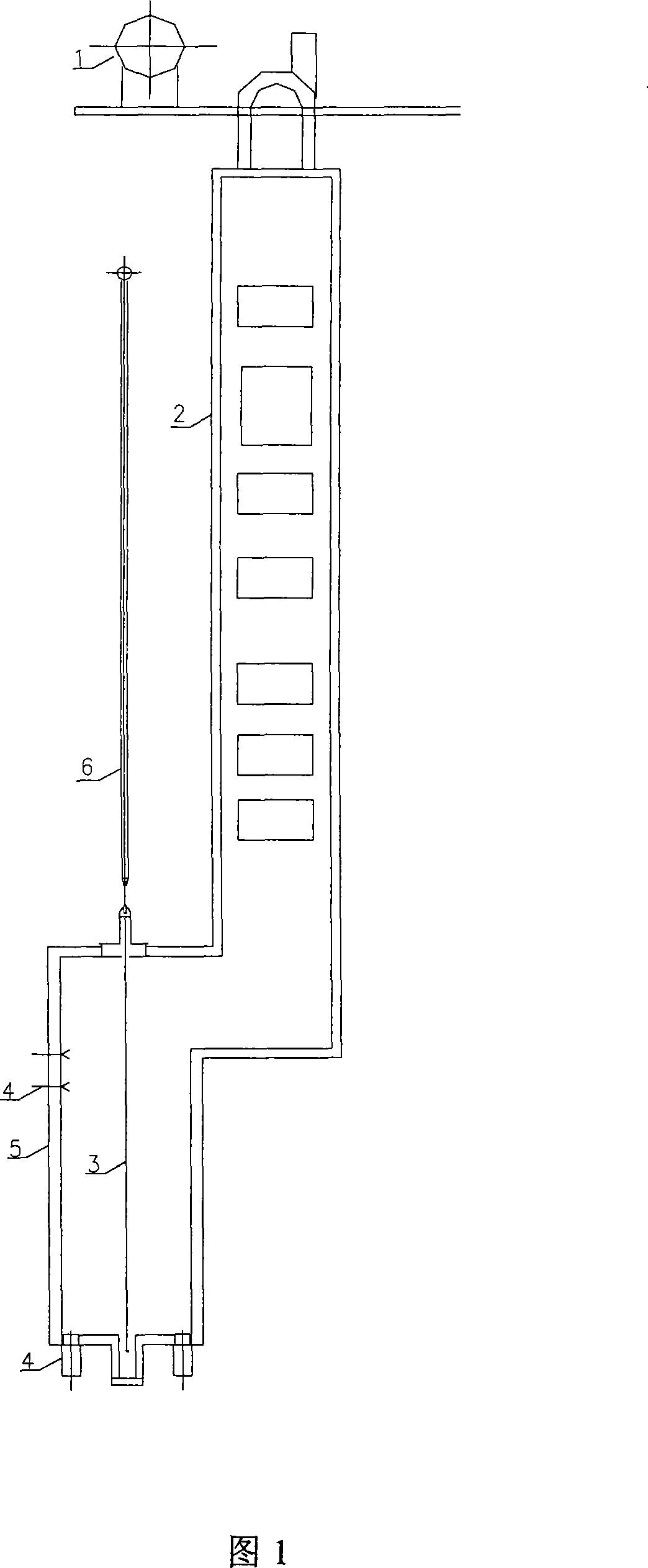

[0112] A new type of ethylene cracking furnace with single-pass furnace tube arrangement, the ethylene cracking furnace includes: a high-pressure steam drum 1, a convection section 2, a radiation section furnace tube 3, a burner 4, a radiation section 5, and a quench boiler 6;

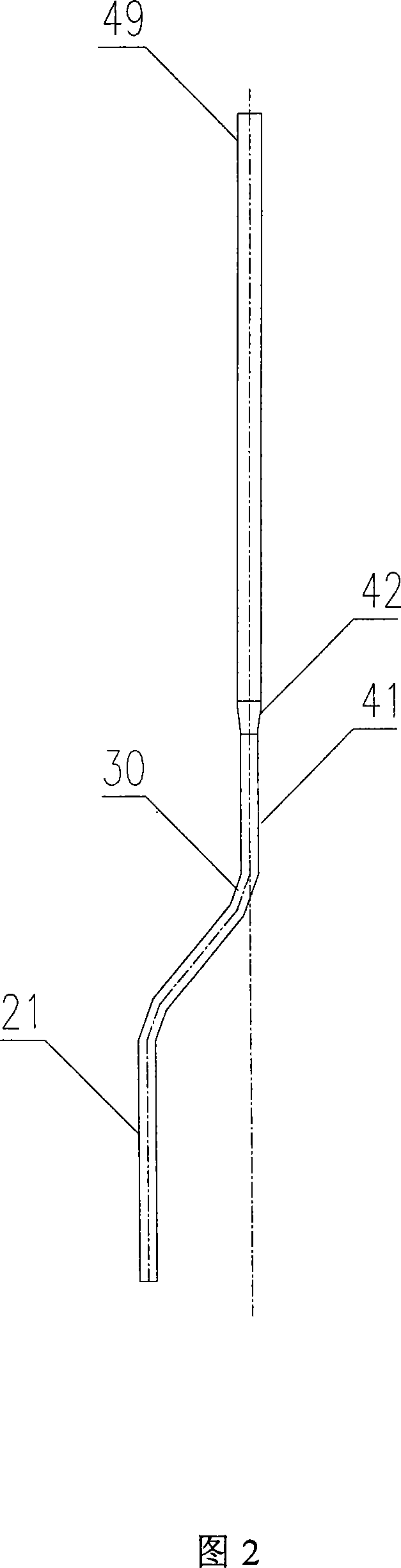

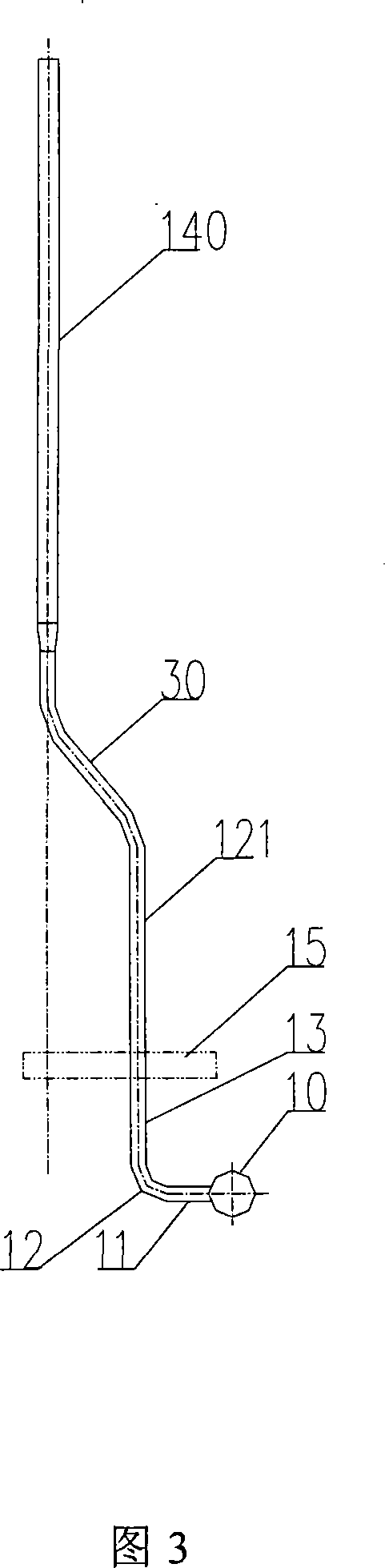

[0113] Each of the furnace tubes 3 in the radiant section is a single-pass vertical variable-diameter furnace tube, and the inner diameter of the upper end of the furnace tube is larger than the inner diameter of the lower end of the inlet tube; that is, the furnace tube is a variable-diameter furnace tube.

[0114] 24 furnace tubes in the radiant section are connected to a manifold 10 to form a furnace tube bundle; the manifold 10 is arranged outside the furnace; the cracking fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com