Injection molded automotive sound insulation pad and manufacturing method thereof

An automotive sound insulation pad and injection molding technology, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of low effective utilization, unfavorable lightweight, energy saving and emission reduction requirements, and large material consumption, and achieves dimensional accuracy and consistency. Improved performance, significant weight reduction and energy saving, and reduced waste in corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

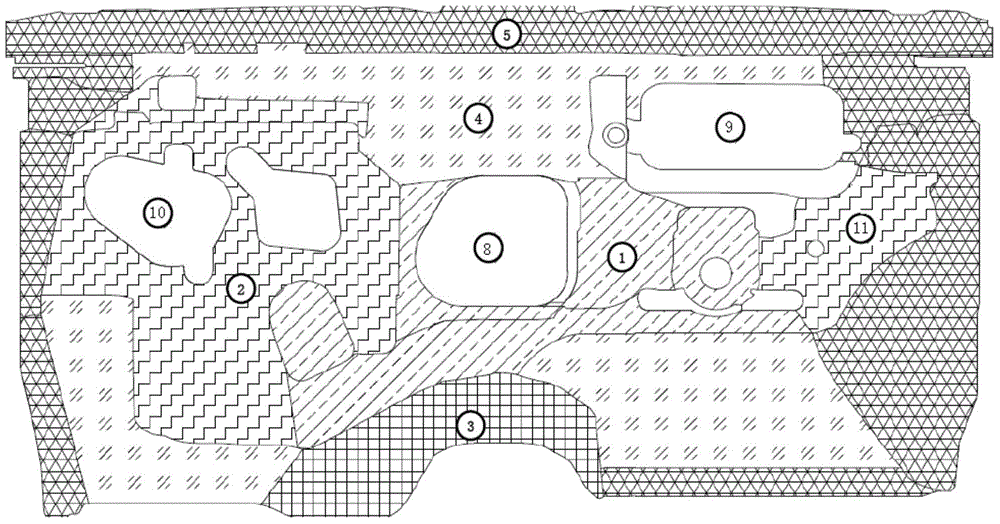

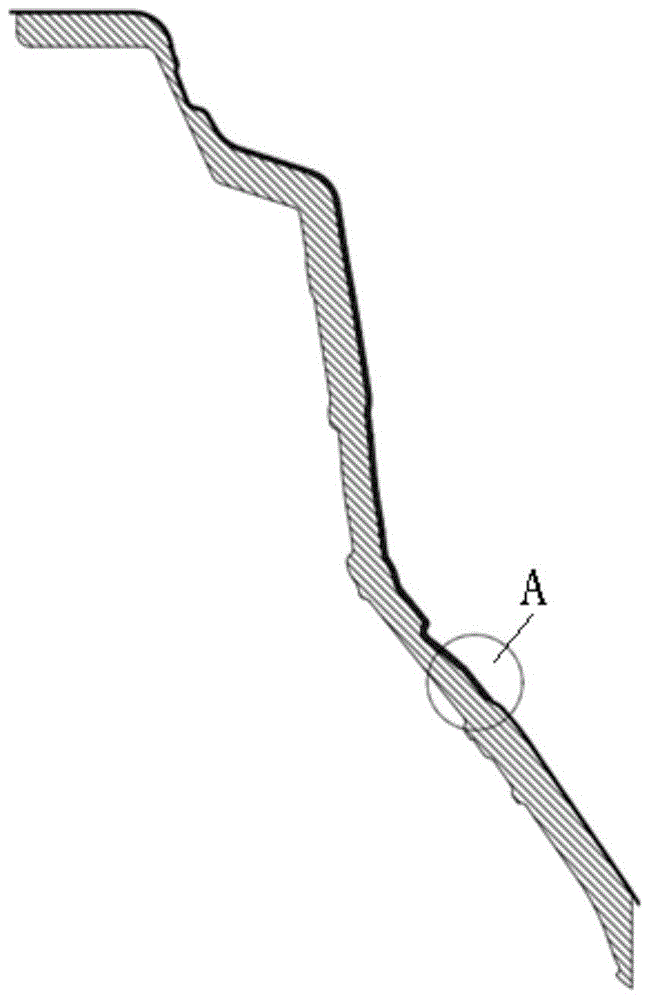

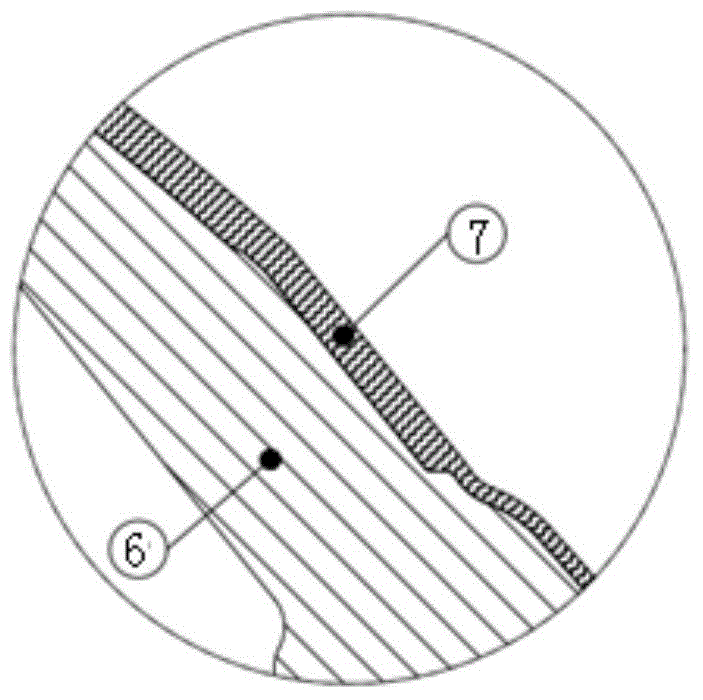

[0050] An injection-molded sound-insulating pad for automobiles comprises a double-layer structure of a heavy-layer skin and a PU foam layer.

[0051] The production method is as follows: put the elastomer particles with a density of 1.8kg / m3 in an oven, and dry them at 80°C for 2 hours; put the elastomer particles into the injection molding machine for injection molding, and the injection mold adopts needle valve type Hot runner structure, the main process parameters of injection molding are set as follows: the temperature of the injection mold is 70°C, the temperature of the hot runner is 255°C, the temperature of each injection section is 240~255°C, the injection pressure is 45Mpa, and the injection molding time is 55 seconds. Prepare the shaped skin; take out the shaped skin and put it into the shaping tool for cooling and shaping, the setting time is 2 minutes; put the shaped shaped skin on the flame treatment bracket, and use the flame treatment system for surface treatme...

Embodiment 2

[0053] An injection molded sound insulation pad for automobiles comprises a three-layer structure of a light PET felt layer, a heavy layer of skin and a PU foam layer.

[0054] The production method is as follows: put the elastomer particles with a density of 1.5kg / m3 in an oven, and dry them at 80°C for 2 hours; put the elastomer particles into the injection molding machine for injection molding, and the injection mold adopts needle valve type Hot runner structure, the main process parameters of injection molding are set as follows: the temperature of the injection mold is 70°C, the temperature of the hot runner is 250°C, the temperature of each injection section is 240~250°C, the injection pressure is 43Mpa, and the injection molding time is 50 seconds. Prepare the shaped skin; take out the shaped skin and put it into the shaping tool for cooling and shaping, the setting time is 2 minutes; put the shaped shaped skin on the flame treatment bracket, and use the flame treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com