Water-based protective coating with peeling property and preparation method thereof

A technology of protective coatings and water-based coatings, applied in anti-corrosion coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as lack of weather resistance, large VOC emissions, and narrow application range, and achieve good results Stability and dispersibility, good peeling performance, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

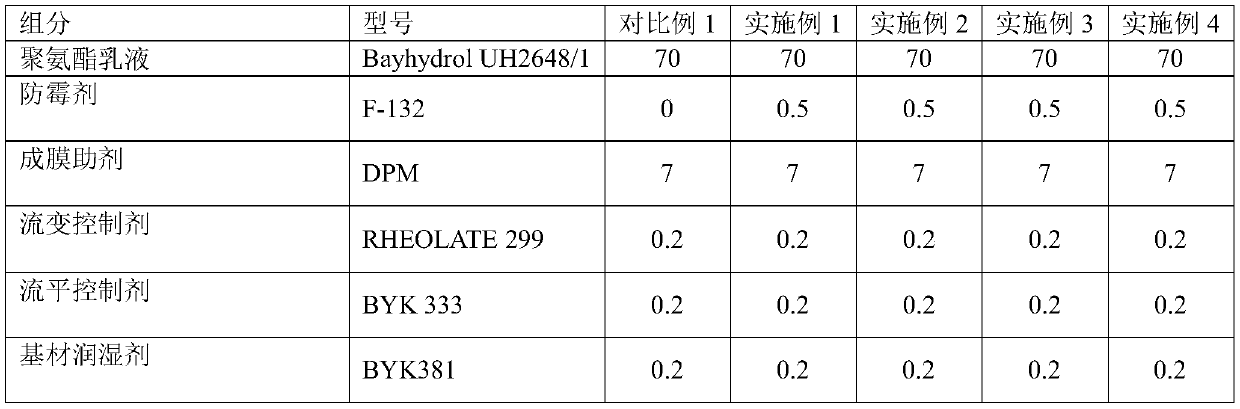

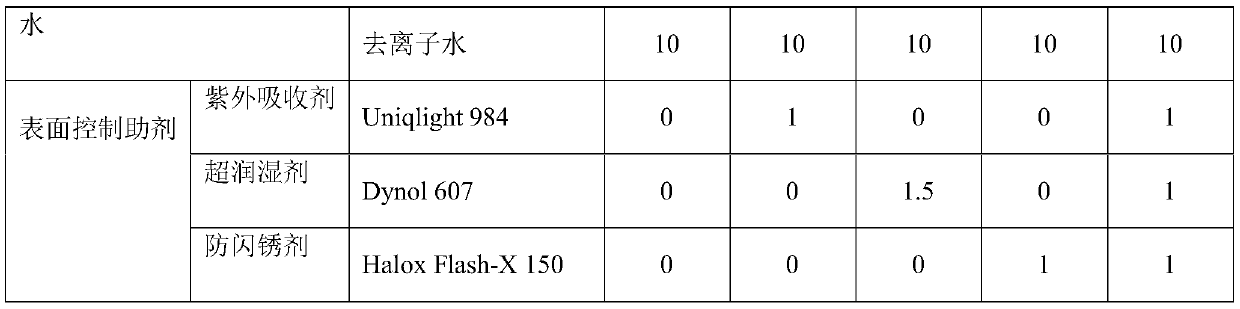

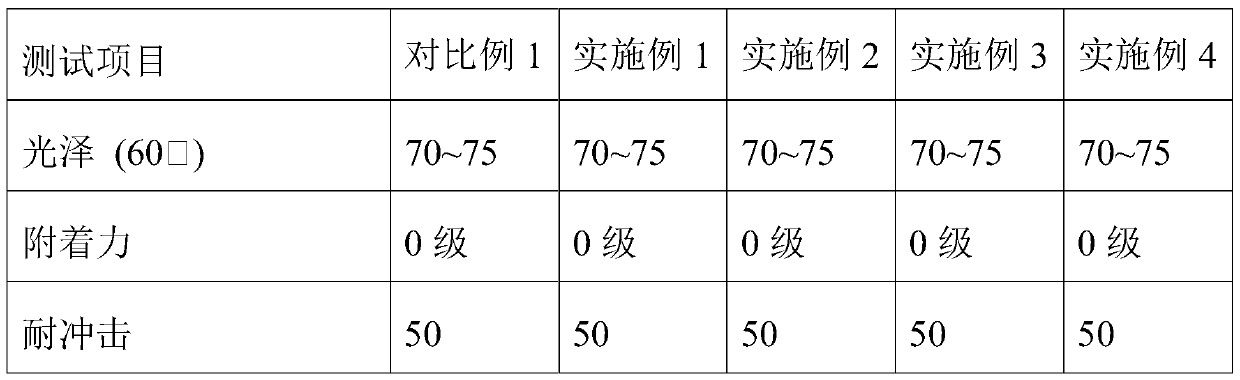

Method used

Image

Examples

Embodiment 1

[0074] Example 1: Flash rust occurs about 4 minutes after coating on substrate 1; the surface condition on substrate 2 is good; the surface cannot be wetted on substrate 3, and the phenomenon of edge shrinkage and agglomeration is serious;

Embodiment 2

[0075] Example 2: Flash rust occurs about 4 minutes after coating on substrate 1; surface condition is good on substrate 2; surface is completely wetted on substrate 3, surface condition is good;

Embodiment 3

[0076] Example 3: The surface condition on the base material 1 is good, and no flash rust occurs; the surface condition on the base material 2 is good; the surface cannot be wetted on the base material 3, and edge shrinkage and agglomeration are serious;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com