Modified wet film, production method of modified wet film and application of modified wet film in production of heat exchange device of air conditioner external unit

A modified and wet film technology, which is applied in the application field of modified wet film and its preparation, and the production of heat exchange devices for external units of air conditioners. problems, achieve good self-cleaning performance, increase heat treatment capacity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

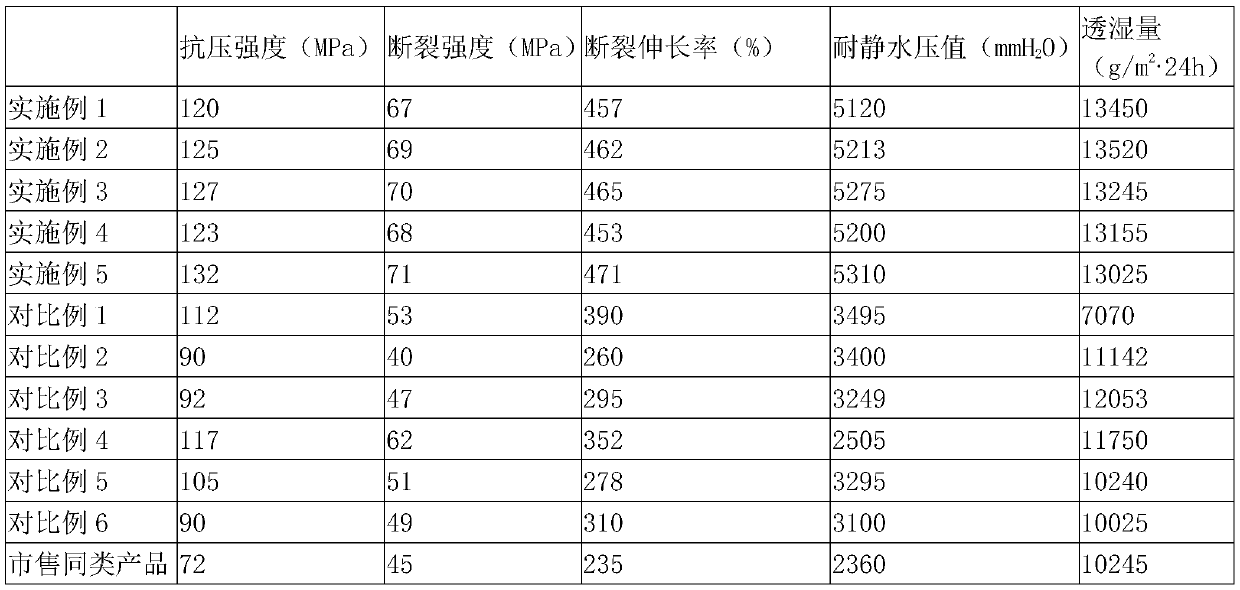

Examples

Embodiment 1

[0026] Composition of raw materials (parts by weight): 5 parts of carboxymethyl cellulose, 30 parts of polytetrafluoroethylene, 2 parts of graphene oxide, 0.1 part of silane coupling agent KH550, 0.5 part of zinc oxide, LiNO 3 2 servings, CaCl 2 4 parts, 0.5 parts of polyvinylpyrrolidone, 0.2 parts of polyvinyl alcohol, 40 parts of acetic acid, 10 parts of ethanol and 30 parts of water.

[0027] Prepare as follows:

[0028] S1. Preparation of modified inorganic filler: Mix ethanol and half of water, add silane coupling agent KH550, stir evenly, stir at a speed of 500r / min, add graphene oxide and zinc oxide while stirring, stop adding and continue Stir for 30min to obtain modified inorganic filler;

[0029] S2. Preparation of the casting solution: add the remaining water to the acetic acid, stir evenly, and the stirring speed is 500 r / min to obtain an aqueous acetic acid solution, and mix the modified inorganic filler, carboxymethyl cellulose, LiNO prepared in step S1 3, P...

Embodiment 2

[0032] Composition of raw materials (parts by weight): 15 parts of carboxymethyl cellulose, 60 parts of polytetrafluoroethylene, 5 parts of graphene oxide, 0.3 parts of silane coupling agent KH550, 1 part of mullite, 5 parts of LiCl, CaCl 2 10 parts, 1 part of polyvinylpyrrolidone, 0.5 part of polyvinyl alcohol, 50 parts of acetic acid, 20 parts of ethanol and 30-50 parts of water.

[0033] Prepare as follows:

[0034] S1. Preparation of modified inorganic filler: Mix ethanol and half of water, add silane coupling agent KH550, stir evenly, stir at a speed of 800 r / min, add graphene oxide and mullite while stirring, stop adding Continue to stir for 50min to obtain the modified inorganic filler;

[0035] S2. Preparation of film casting solution: add the remaining water to the acetic acid, stir evenly, and the stirring speed is 800 r / min to obtain an aqueous acetic acid solution, and mix the modified inorganic filler, carboxymethyl cellulose, LiCl, polymer Vinylpyrrolidone and...

Embodiment 3

[0038] Composition of raw materials (parts by weight): 7 parts of carboxymethyl cellulose, 40 parts of polytetrafluoroethylene, 3 parts of graphene oxide, 0.2 part of silane coupling agent KH550, 0.6 part of calcium oxide, Li 2 SO 4 2 servings, CaCl 2 5 parts, 0.7 parts of polyvinylpyrrolidone, 0.2 parts of polyvinyl alcohol, 42 parts of acetic acid, 12 parts of ethanol and 35 parts of water.

[0039] Prepare as follows:

[0040] S1. Preparation of modified inorganic fillers: Mix ethanol and half of water, add silane coupling agent KH550, stir evenly, stir at a speed of 600 r / min, add graphene oxide and calcium oxide while stirring, stop adding and continue Stir for 35min to obtain modified inorganic filler;

[0041] S2. Preparation of the casting solution: add the remaining water to the acetic acid, stir evenly, and the stirring speed is 600 r / min to obtain an aqueous acetic acid solution, and mix the modified inorganic filler, carboxymethyl cellulose, Li 2 SO 4 , Poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com