A low-viscosity transparent mildew-proof electronic coating adhesive and preparation method thereof

A low-viscosity, transparent technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of not being environmentally friendly, not mildew-proof, and easy to thicken, and achieve low VOCs, fast curing, and relatively good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Under the protection of nitrogen, put 29.75g octadecyldimethyl tertiary ammonium, 19.87g chloropropyltrimethoxysilane, 49.62g methyltrimethoxysilane into a three-necked flask with a condenser, raise the temperature to reflux, and keep Reflux for 32 hours, stop heating, and cool to room temperature to prepare antifungal agent FMJ-1.

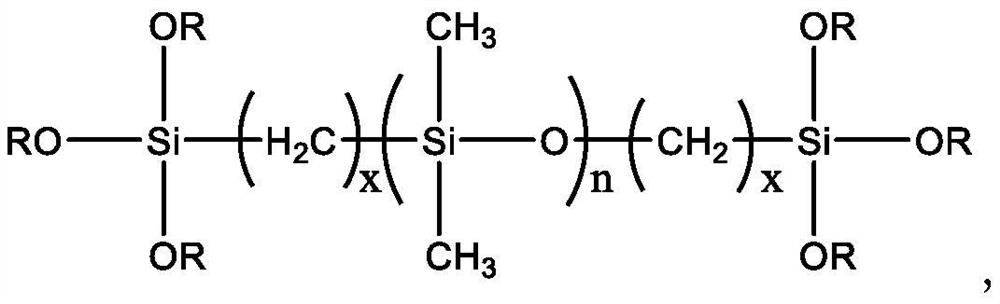

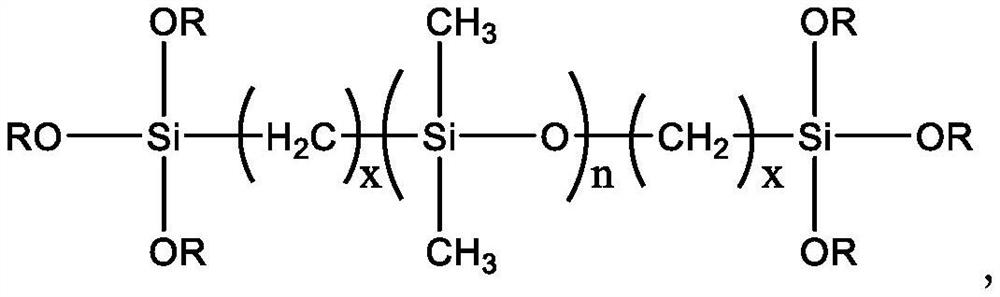

[0043] Add 100 parts of trimethoxysilyl ethyl-terminated polydimethylsiloxane with a viscosity of 300 mPa·s, and 10 parts of white carbon black treated with hexamethyldisilazane into the planetary agitator base, at a pressure of -0.9 After stirring for 15 minutes under MPa, stop the shoveling. Add 2 parts of 1,1,3,3-tetramethyl-1,3-bistrimethoxysilylethyldisiloxane (crosslinking agent) and 0.6 parts of FMJ-1 into the planetary machine, in- Stir at 0.9 MPa for 30 minutes. Add 0.3 parts of organotin catalyst and 1 part of γ-glycidyl etheroxytrimethoxysilane into the planetary machine, remove the vacuum and stir for 30 minutes, then discharg...

Embodiment 2

[0045] Under the protection of nitrogen, 21.34g of dodecyldimethyl tertiary ammonium, 18.27g of chloropropylmethyl dimethoxysilane, and 59.42g of methyltrimethoxysilane were dropped into a three-necked flask with a condenser, and the temperature was raised to Reflux, keep reflux for 24h, stop heating, cool to room temperature to prepare antifungal agent FMJ-2.

[0046] Add 100 parts of trimethoxysilyl ethyl-terminated polydimethylsiloxane with a viscosity of 500 mPa·s, and 8 parts of white carbon black treated with hexamethyldisilazane to the planetary agitator base, at a pressure of -0.9 After stirring for 30 minutes under MPa, stop the shoveling. Add 3 parts of 1,1,3,3-tetramethyl-1,3-bistrimethoxysilylethyl disiloxane (crosslinking agent) and 0.8 parts of FMJ-2 into the planetary machine, in- Stir at 0.9 MPa for 30 minutes. Add 0.3 parts of organotin catalyst and 1 part of γ-glycidyl etheroxytrimethoxysilane into the planetary machine, remove the vacuum and stir for 30 mi...

Embodiment 3

[0048] Under the protection of nitrogen, put 21.34g dodecyldimethyl tertiary ammonium, 19.87g chloropropyltrimethoxysilane, 41.21g methyltrimethoxysilane into a three-necked flask with a condenser, heat up to reflux, and keep Reflux for 28 hours, stop heating, cool to room temperature, and seal and store to obtain the fungicide FMJ-3.

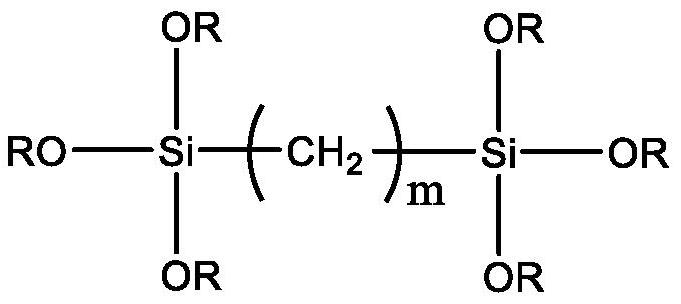

[0049] Add 100 parts of trimethoxysilyl ethyl-terminated polydimethylsiloxane with a viscosity of 1000 mPa·s, and 5 parts of white carbon black treated with hexamethyldisilazane into the planetary stirring base, at a pressure of -0.9 After stirring for 15 minutes under MPa, stop the shoveling. Add 3 parts of bistrimethoxysilylethane (crosslinking agent) and 0.8 parts of FMJ-3 into the planetary machine, and stir for 30 minutes at -0.9MPa. Add 0.3 parts of organotin catalyst and 1 part of γ-glycidyl etheroxytrimethoxysilane into the planetary machine, remove the vacuum and stir for 30 minutes, then discharge to prepare the coating gel III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com