Preparation process of environmental-friendly cabinet board

A preparation process and plate technology, which is applied in the field of preparation process of environmentally friendly cabinet plates, can solve the problems affecting the health and development of pregnant women and children, hindering the intellectual development of children, stimulating the respiratory tract of adults, etc., and achieve excellent mechanical properties, light weight, and improved attachment. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

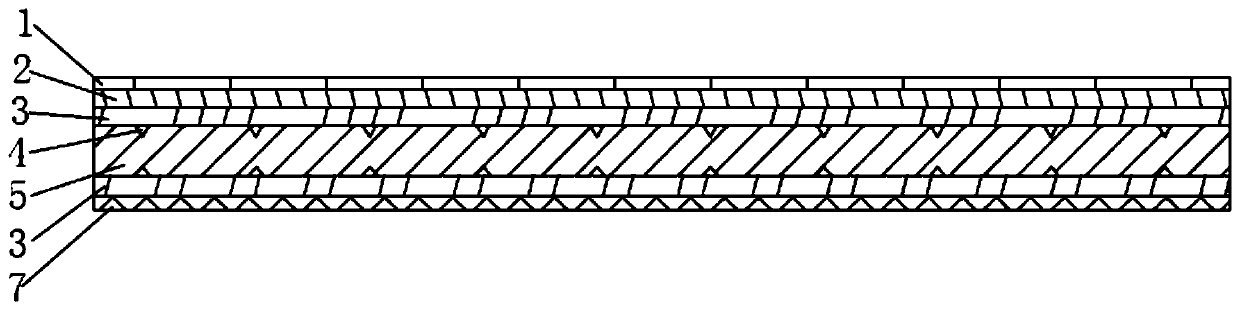

[0053] A preparation process for an environmentally friendly cabinet board. The environmentally friendly cabinet board includes a decorative layer 1, a plywood layer 2, a foamed board core layer 5 and a bottom board layer that are sequentially compounded, and between the plywood layer 2 and the foamed board core layer 5 and the foamed board. A resin reinforcing layer 3 is compounded between the core layer 5 and the base layer, and a plurality of conical protrusions 4 are provided on the side where the resin reinforcing layer 3 is combined with the foam board core layer 5, and the surface of the environmentally friendly cabinet board is sprayed with waterproof and flame-retardant coatings. Coating; the thickness of the prepared environmental protection cabinet board is 2cm, and the base plate layer and plywood layer 2 are made of cheap veneer.

[0054] The preparation process of the environmentally friendly cabinet board includes the following steps:

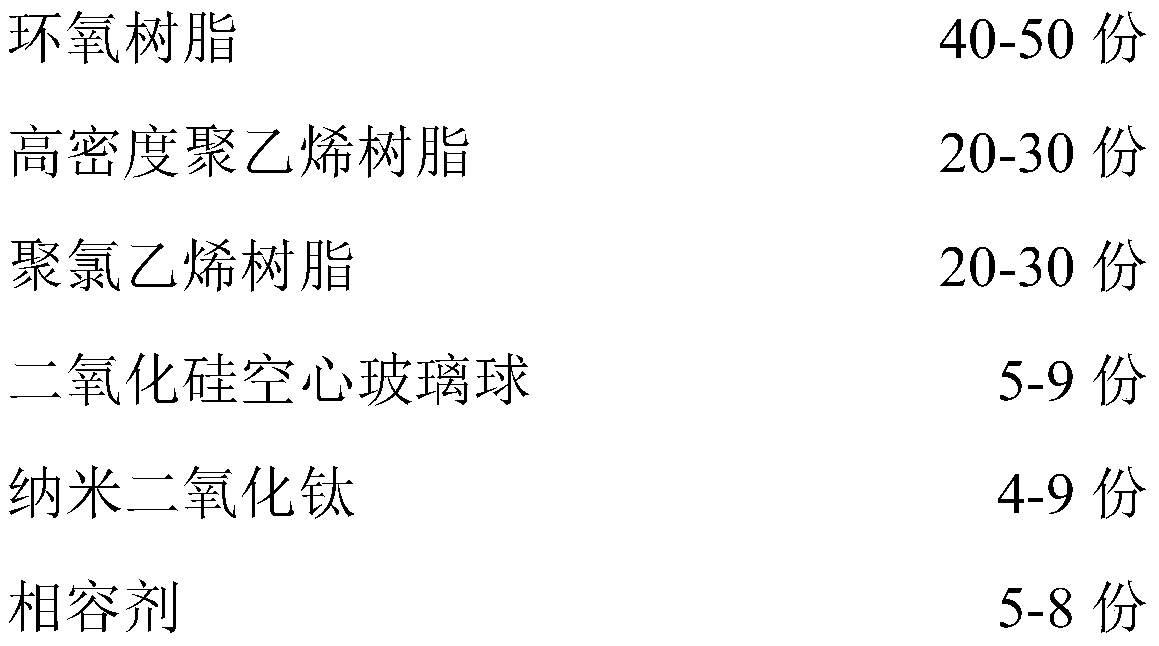

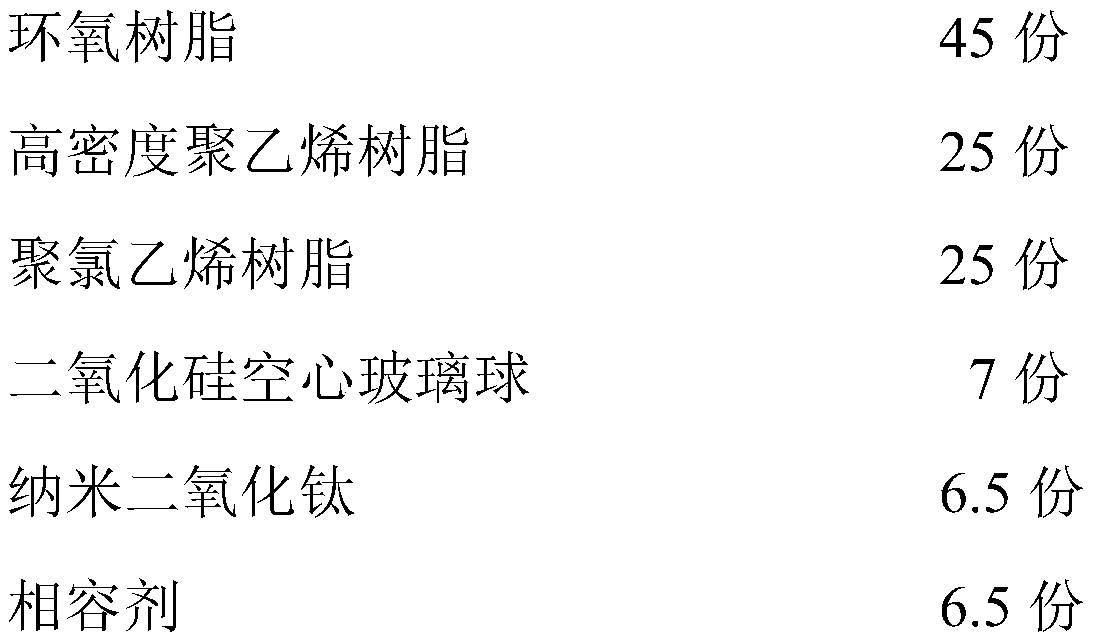

[0055] Step 1. Coating ep...

Embodiment 2

[0073] A preparation process for an environmentally friendly cabinet board. The environmentally friendly cabinet board includes a decorative layer 1, a plywood layer 2, a foamed board core layer 5 and a bottom board layer that are sequentially compounded, and between the plywood layer 2 and the foamed board core layer 5 and the foamed board. A resin reinforcing layer 3 is compounded between the core layer 5 and the base layer, and a plurality of conical protrusions 4 are provided on the side where the resin reinforcing layer 3 is combined with the foam board core layer 5, and the surface of the environmentally friendly cabinet board is sprayed with waterproof and flame-retardant coatings. Coating; the thickness of the prepared environmental protection cabinet board is 1.5cm, and the base plate layer and plywood layer 2 are made of cheap thin wood boards.

[0074] The preparation process of the environmentally friendly cabinet board includes the following steps:

[0075] Step 1...

Embodiment 3

[0092] A preparation process for an environmentally friendly cabinet board. The environmentally friendly cabinet board includes a decorative layer 1, a plywood layer 2, a foamed board core layer 5 and a bottom board layer that are sequentially compounded, and between the plywood layer 2 and the foamed board core layer 5 and the foamed board. A resin reinforcing layer 3 is compounded between the core layer 5 and the base layer, and a plurality of conical protrusions 4 are provided on the side where the resin reinforcing layer 3 is combined with the foam board core layer 5, and the surface of the environmentally friendly cabinet board is sprayed with waterproof and flame-retardant coatings. Coating; the thickness of the prepared environmental protection cabinet board is 2cm, and the base plate layer and plywood layer 2 are made of cheap veneer.

[0093] The preparation process of the environmentally friendly cabinet board includes the following steps:

[0094] Step 1. Coating ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com