Nano modified high-performance dynamic vulcanization thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, nano-modification technology, applied in the direction of coating, etc., can solve the problem of reduction, and achieve the effects of cost reduction, high surface atom occupancy, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

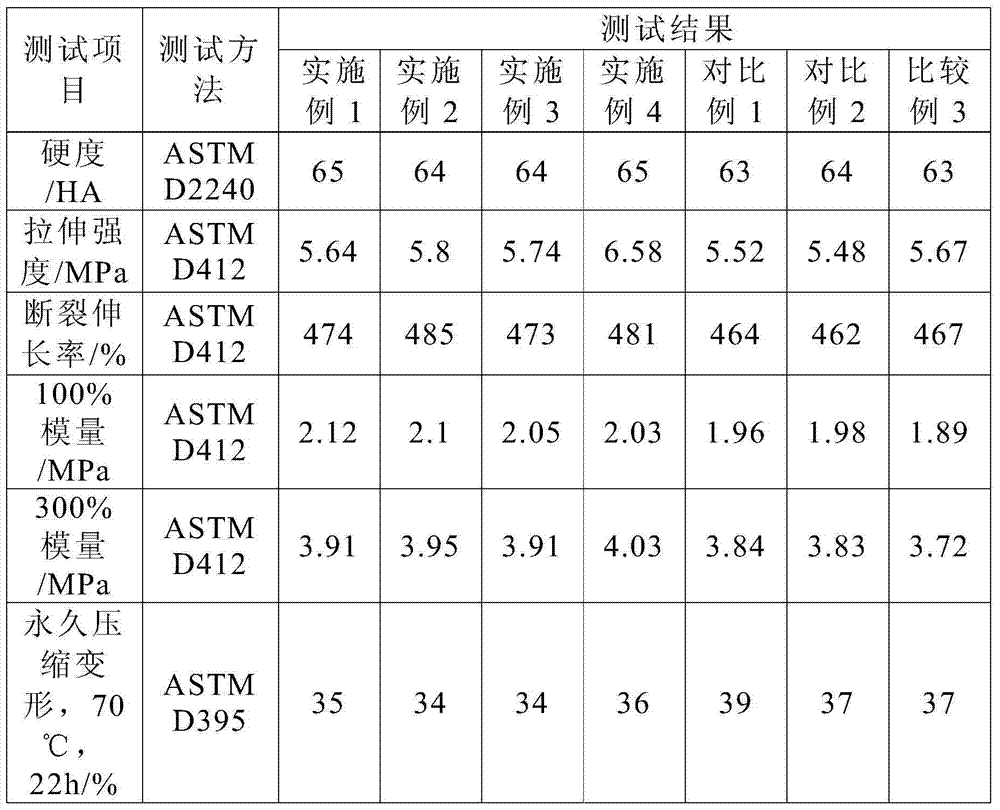

Examples

Embodiment 1

[0031] Take each raw material according to the weight percentage of the following nano-modified high-performance dynamic vulcanized thermoplastic elastomer, 30 parts of polypropylene resin, 70 parts of EPDM rubber, 80 parts of naphthenic oil, 2.4 parts of dicumyl peroxide, N - 1.2 parts of phenylmaleimide, 20 parts of calcium carbonate, 4.5 parts of other processing aids and 7 parts of nano silicon dioxide with a particle size of 30nm;

[0032] Mix other raw materials except filler oil in a high mixer for 3 minutes;

[0033] The mixed raw materials are discharged from the high mixer, poured into the feeder, fed into the twin-screw extruder by the feeder, and the filling oil is side-fed into the twin-screw extruder through the metering pump , extrusion granulation, the host speed of the twin-screw extruder is 350r / min, and the temperature of the twin-screw extruder is 200°C;

[0034] Pour the nano-modified high-performance dynamic vulcanized thermoplastic elastomer obtained by...

Embodiment 2

[0036] Weigh each raw material according to the weight percentage of the following nano-modified high-performance dynamic vulcanized thermoplastic elastomer, 25 parts of polypropylene resin, 75 parts of EPDM rubber, 75 parts of industrial white oil, di-tert-butyl peroxide cumene (BIPB) 2.6 parts, triisopropyl isocyanurate 1.3 parts, calcium carbonate 22 parts, other processing aids 4.8 parts and nano-silica with a particle size of 50nm 8 parts;

[0037] Mix other raw materials except filler oil in a high mixer for 2 minutes;

[0038] The mixed raw materials are discharged from the high mixer, poured into the feeder, fed into the twin-screw extruder by the feeder, and the filling oil is side-fed into the twin-screw extruder through the metering pump , extrusion granulation, the host speed of the twin-screw extruder is 300r / min, and the temperature of the twin-screw extruder is 180°C;

[0039] Pour the nano-modified high-performance dynamic vulcanized thermoplastic elastomer ob...

Embodiment 3

[0041] Weigh each raw material according to the weight percentage of nano-modified high-performance dynamic vulcanized thermoplastic elastomer as follows: 35 parts of polypropylene resin, 65 parts of EPDM rubber, 82 parts of naphthenic oil, 2.5 parts of di-tert-butyl peroxide (DTBP) 1.1 parts, 1.1 parts of trimethylolpropane trimethacrylate, 20 parts of calcium carbonate, 4.6 parts of other processing aids and 7 parts of nano silicon dioxide with a particle size of 30nm;

[0042] Mix other raw materials except filler oil in a high mixer for 5 minutes;

[0043] The mixed raw materials are discharged from the high mixer, poured into the feeder, fed into the twin-screw extruder by the feeder, and the filling oil is side-fed into the twin-screw extruder through the metering pump , extrusion granulation, the host speed of the twin-screw extruder is 600r / min, and the temperature of the twin-screw extruder is 230°C;

[0044] Pour the nano-modified high-performance dynamic vulcanized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| 100% modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com