Process for producing fiber from peanut protein

A peanut protein and fiber technology, applied in the field of fiber fiber production, can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

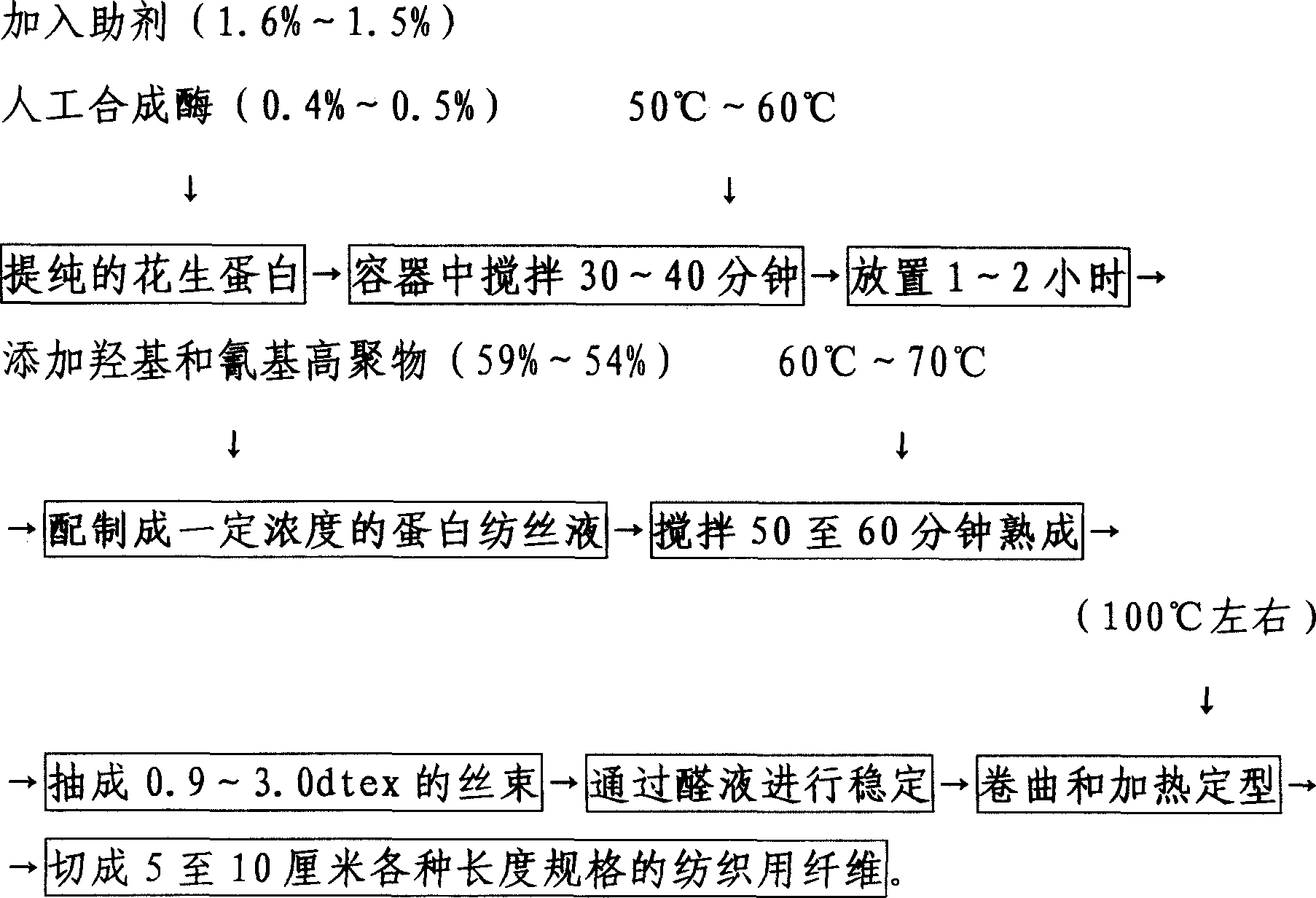

Method used

Image

Examples

Embodiment 1

[0012] Example 1 Take 1950 grams of purified peanut protein, add 80 grams of additives and 20 grams of artificial synthetic enzymes, stir in a container at a temperature of 50°C to 60°C for 30 to 40 minutes, and place it for 1 to 2 hours. After adding hydroxyl and 2,950 grams of cyanopolymer, prepared into a protein spinning solution with a certain concentration, after stirring at 60°C to 70°C for 50 to 60 minutes to mature, then pumped into tows of 0.9 to 3.0dtex, and then passed the tows through the aldehyde solution Stabilized, then crimped and heated (about 100° C.) to set the shape, and finally cut into textile fibers of various lengths ranging from 5 to 10 centimeters to obtain 5,000 grams of peanut protein fibers.

Embodiment 2

[0013] Example 2 Take 2000 grams of purified peanut protein solution, add 75 grams of additives and 22.5 grams of artificial synthetic enzyme, stir in a container at a temperature of 50°C to 60°C for 30 to 40 minutes, let it stand for 1 to 2 hours, add hydroxyl and 2900 grams of cyano polymers to prepare a protein spinning solution with a certain concentration. After stirring at 60°C to 70°C for 50 to 60 minutes, it is drawn into tows of 0.9 to 3.0 dtex, and then the tows are passed through the aldehyde solution Stabilize, then crimp and heat (about 100° C.) to set the shape, and finally cut into 5 to 10 centimeters of various length specifications of textile fibers, and finally obtain 5000 grams of peanut protein fibers.

Embodiment 3

[0014] Example 3 Take 2200 grams of purified peanut protein solution, add 75 grams of additives and 25 grams of artificial synthetic enzyme, stir in a container at a temperature of 50°C to 60°C for 30 to 40 minutes, leave it for 1 to 2 hours, and add the hydroxyl and 2,700 grams of cyano polymers to prepare a protein spinning solution with a certain concentration. After stirring at 60°C to 70°C for 50 to 60 minutes, it is drawn into a tow of 0.9 to 3.0 dtex, and then the tow is passed through the aldehyde solution Stabilize, then crimp and heat (about 100° C.) to set the shape, and finally cut into 5 to 10 centimeters of various length specifications of textile fibers, and finally obtain 5000 grams of peanut protein fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com