A kind of electromagnetic shielding coating suitable for heat shrinkable material and preparation method thereof

An electromagnetic shielding coating and thermal shrinkage technology, applied in conductive coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy wrinkling and cracking, reduce the amount of conductive fillers, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

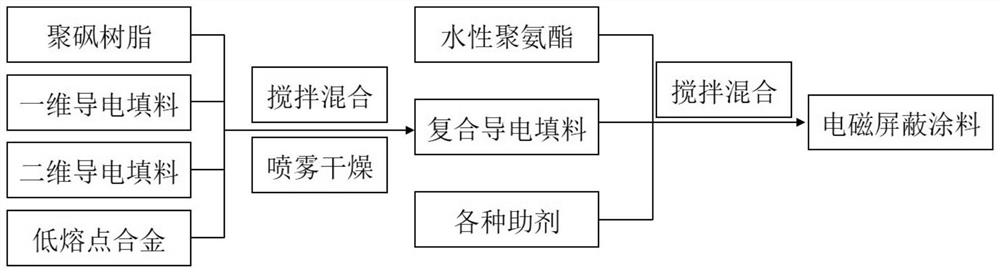

Method used

Image

Examples

Embodiment 1

[0027] 3g of bisphenol A type polyethersulfone was dissolved in 97g of tetrahydrofuran, followed by 28.5g of silver nanowires, 28.5g of flake silver powder and 11.4g of tin-bismuth alloy (43 / 57, melting point 138°C, manufacturer: Shenzhen City Junlin Technology Development Co., Ltd.) was added into the above solution, stirred evenly to obtain conductive filler dispersion, then atomized the conductive filler dispersion with a spray gun, and obtained the composite conductive filler after natural drying.

[0028] Add 100 parts of aqueous polyurethane dispersion (solid content 30%), 5 parts of organic bentonite; 70 parts of composite conductive filler; 5 parts of hydroxyethyl cellulose; Stirring for 1 h at a rotating speed to obtain a water-based polyurethane electromagnetic shielding coating.

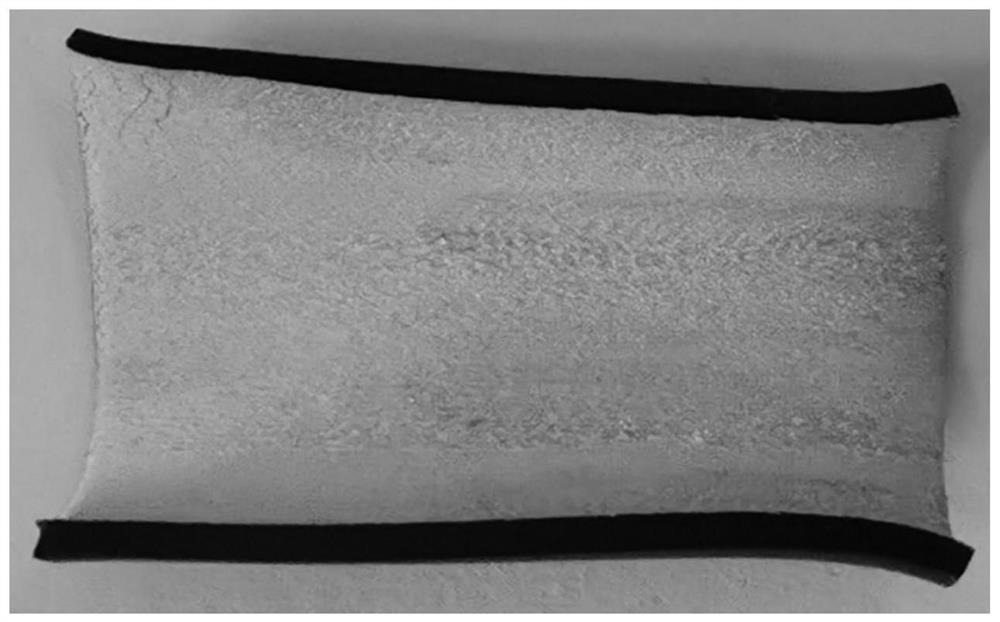

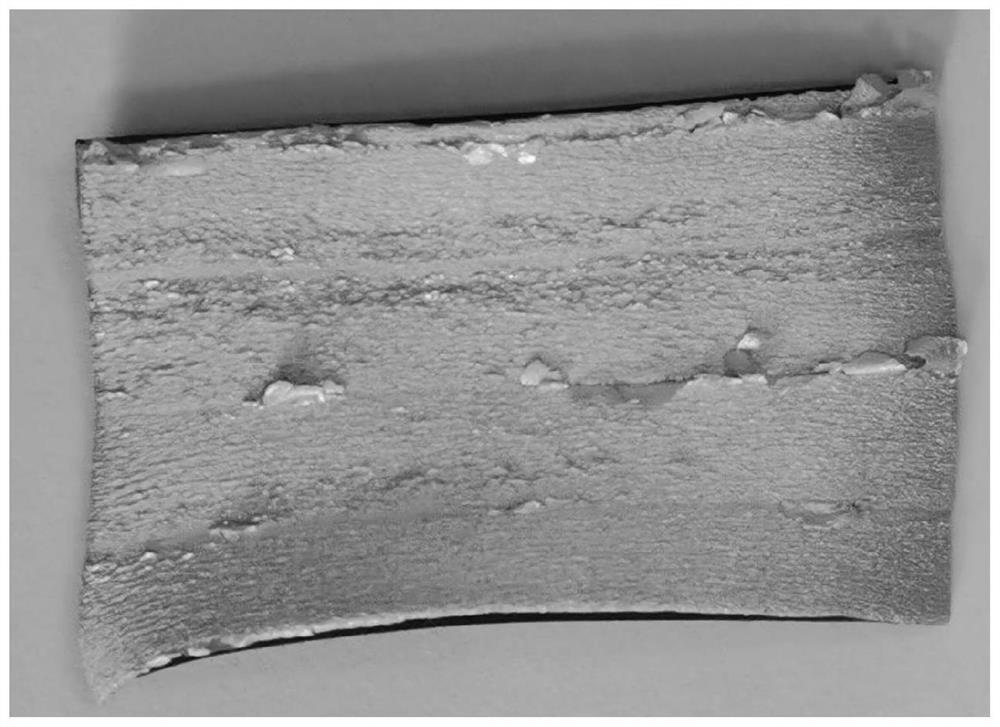

[0029] The water-based polyurethane electromagnetic shielding coating obtained in Example 1 was sprayed on the surface of the polyethylene heat-shrinkable tube, the surface was flat, the d...

Embodiment 2

[0031] 5g of biphenyl-type polyethersulfone was dissolved in 95g of tetrahydrofuran, followed by 15g of copper nanowires, 30g of flake silver-coated copper powder and 4.5g of tin-bismuth alloy (67 / 33, melting point 166°C, manufacturer: Shenzhen Junlin Technology Development Co., Ltd.) was added into the above solution, stirred evenly to obtain conductive filler dispersion, then atomized the conductive filler dispersion with a spray gun, and obtained the composite conductive filler after natural drying.

[0032] Add 100 parts of aqueous polyurethane dispersion (solid content 30%), 3 parts of fumed silica; 30 parts of composite conductive filler; 2 parts of carboxymethyl cellulose; Stir for 0.5 h at a rotating speed of 1 min to obtain a water-based polyurethane electromagnetic shielding coating.

Embodiment 3

[0034] 3g of bisphenol A type polyethersulfone was dissolved in 97g of tetrahydrofuran, then 28.5g of gold nanowires, 28.5g of flake copper powder and 11.4g of tin-bismuth alloy (43 / 57) were added to the above solution, Stir evenly to obtain a conductive filler dispersion, then atomize the conductive filler dispersion with a spray gun, and obtain a composite conductive filler after natural drying.

[0035] Add 100 parts of aqueous polyurethane dispersion (solid content 30%), 4 parts of organic bentonite; 50 parts of composite conductive filler; 4 parts of hydroxyethyl cellulose; Stirring for 1 h at a rotating speed to obtain a water-based polyurethane electromagnetic shielding coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com