Self-locking nylon 66 plastic cable tie with high locking force and preparation method of self-locking nylon 66 plastic cable tie

A plastic cable tie and self-locking technology, which is applied in packaging, flexible and slender components, transportation and packaging, etc., can solve the problems of locking failure and mechanical performance degradation, and achieve the effect of improving the locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

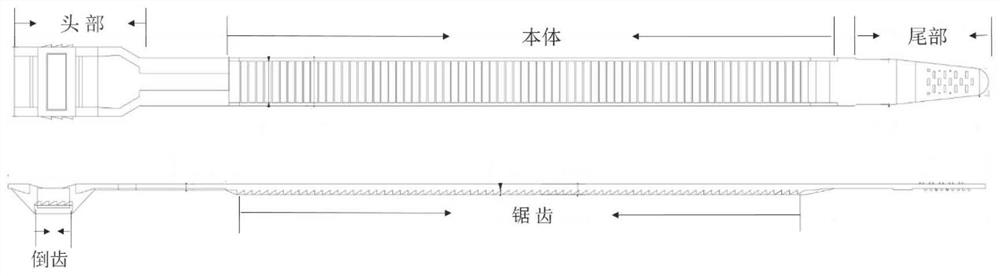

[0030] The present invention provides the preparation method of the self-locking nylon 66 plastic strap according to the above scheme, including the step of using the injection molding process to increase the touched nylon 66 into the tied mold, press preemptive and cooling, resulting in high Self-locking nylon 66 plastic strap with locking force.

[0031] The present invention is preferably added to 60 to 80 ° C for 4 to 8 hours before injection. The present invention is drying the toughen nylon 66, making the touchaen Dragon 66 easily below the injection molding process, in addition, excessive moisture can easily result in a reduced risoting force in the product.

[0032] In the present invention, the injection molding conditions include: the injection molding temperature of 280 ° C, the nozzle temperature is from 265 to 275 ° C, the injection pressure is 50 ~ 90 bar; more preferably, the nozzle temperature is 270 ° C, the injection pressure is 60 ~ 80bar. The nozzle temperature...

Embodiment 1

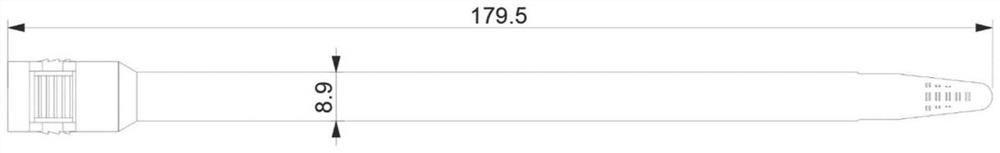

[0038] Example 1 and the ratio 1 to 2 tie were: length 179.5mm, width 8.9mm, with tooth thickness 1.9 mm, dentate thickness 0.8mm, size schematic figure 2 Indicated.

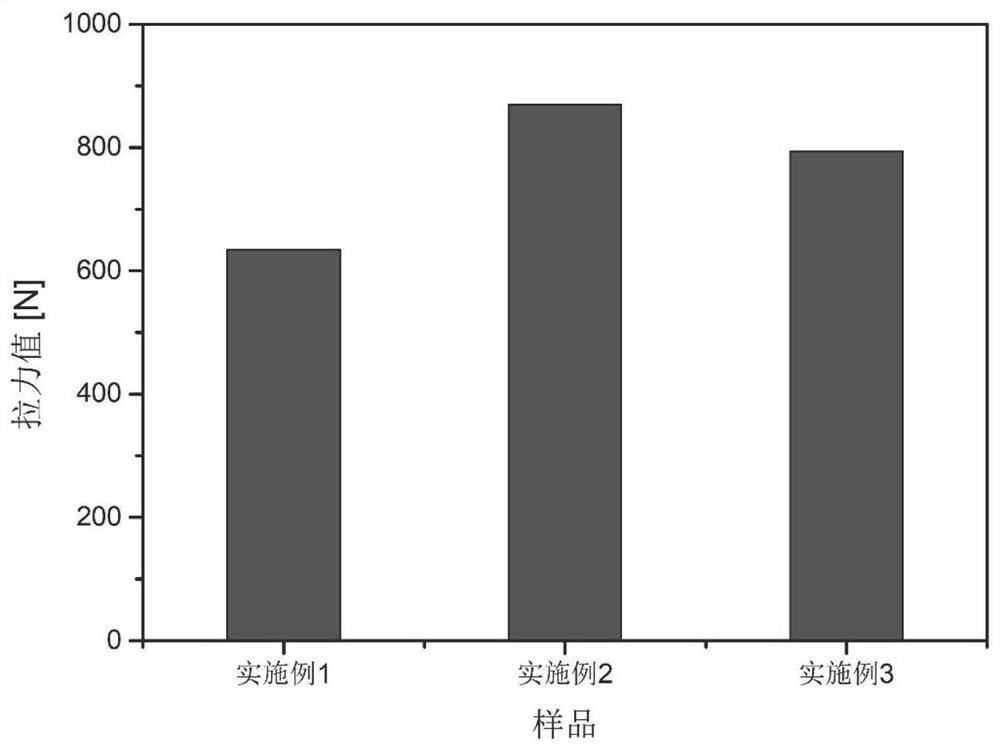

[0039] Example 1

[0040] The touchalon 66 was dried at 60 ° C. 6 hours, weigh dry touchalon 66 pellets 2kg after drying, set the mold temperature 40 ° C, injection molding temperature 280 ° C, nozzle temperature 275 ° C, injection pressure 60 bar, injection molding, Pressure 6S cooling 12s to get the strap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com