Aluminium alloy profile for lightweight mildew resistant vehicle

A technology for aluminum alloy profiles and automobiles, applied in the field of aluminum alloy profiles, can solve the problems of heavy surface attachments, intolerant of mold, etc., and achieve the effects of novel formula, high adhesion strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

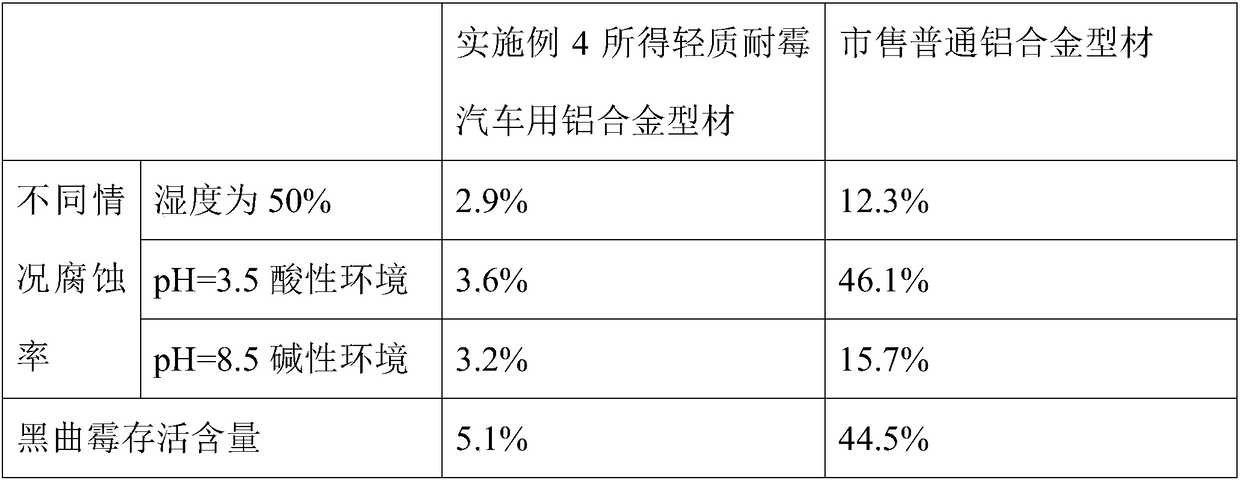

Examples

Embodiment 1

[0012] A lightweight mold-resistant aluminum alloy profile for automobiles, including the aluminum alloy profile and a composite coating coated on the surface of the aluminum alloy profile. The raw materials of the composite coating include: polyvinylidene fluoride 30kg, diethylene glycol ethyl ether 8kg, propylene glycol methyl ether 3kg, light calcium carbonate 12kg, mulberry powder 3kg, epoxy soybean oil 8kg, magnesium stearate 4kg.

Embodiment 2

[0014] A lightweight mold-resistant aluminum alloy profile for automobiles, including the aluminum alloy profile and a composite coating coated on the surface of the aluminum alloy profile. The raw materials of the composite coating include: polyvinylidene fluoride 50kg, diethylene glycol ethyl ether 4kg, propylene glycol methyl ether 7kg, light calcium carbonate 6kg, mulberry powder 7kg, epoxy soybean oil 4kg, magnesium stearate 8kg.

Embodiment 3

[0016] A light mildew-resistant aluminum alloy profile for automobiles, including the aluminum alloy profile and a composite coating coated on the surface of the aluminum alloy profile. The raw materials of the composite coating include: polyvinylidene fluoride 35kg, diethylene glycol ethyl ether 7kg, propylene glycol methyl ether 4kg, light calcium carbonate 10kg, mulberry powder 4kg, epoxy soybean oil 7kg, magnesium stearate 5kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com