Fluorine/silicon-containing silicon paint and preparation method thereof

A coating and polysiloxane technology, applied in the field of fluorine-containing silicon coatings and their preparation, can solve the problems of insufficient mechanical properties and high cost, achieve excellent weather resistance, low solvent resistance and oil resistance, and reduce losses and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

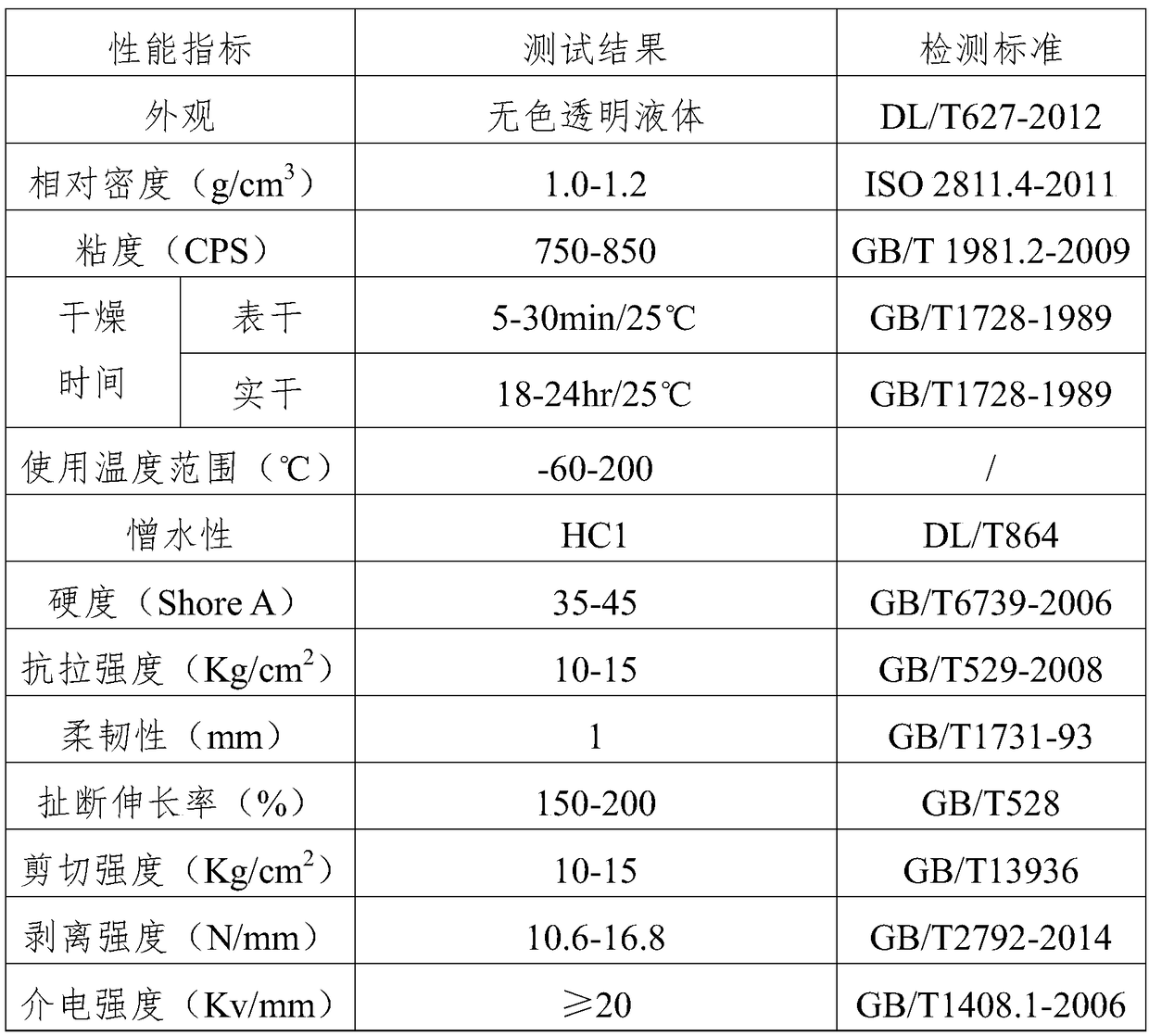

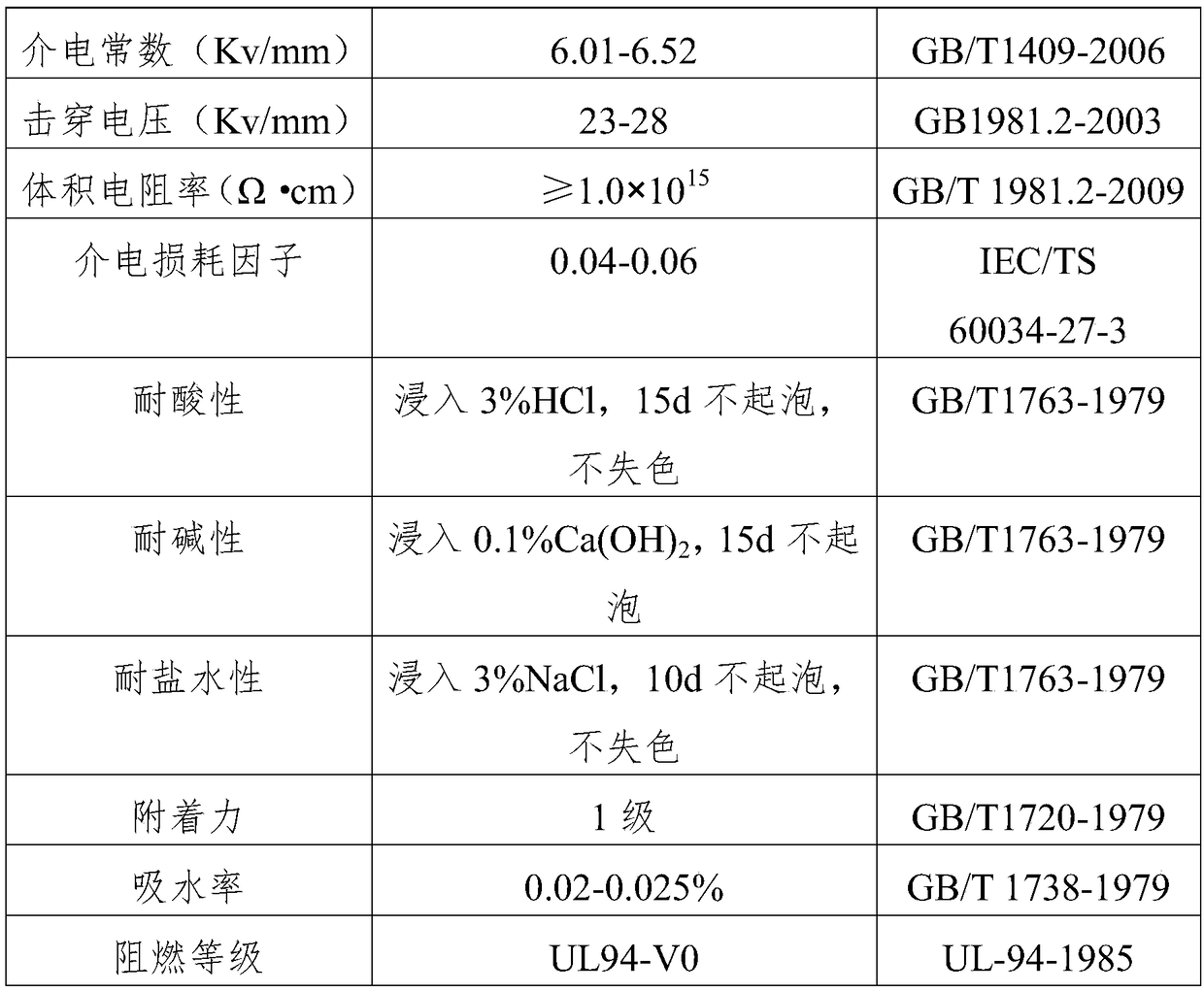

Image

Examples

Embodiment 1

[0031] The fluorine-containing silicon coating of this embodiment includes the following components in parts by weight: 10 parts of fluorine-containing acrylate monomer, 5 parts of hydroxyethyl methacrylate, 2 parts of butyl methacrylate, 1 part of isooctyl methacrylate, 1 part of methyl methacrylate, 30 parts of vinyltriethoxysilane, 8 parts of polydimethylsiloxane, 20 parts of hydroxyl silicone oil, 0.2 parts of initiator, 40 parts of solvent .

[0032] Wherein, the fluorine-containing acrylate monomer is tetrafluoropropyl methacrylate.

[0033] The solvent is selected from any one of acetone, dimethyl carbonate, ethyl acetate and methyl acetate.

[0034] The initiator is selected from any one of azobisisobutyronitrile, lauroyl peroxide, methyl ethyl ketone peroxide, dibenzoyl peroxide and azobisisoheptanonitrile.

[0035] The preparation method of the fluorine-containing silicon coating of the present embodiment comprises the following steps:

[0036] Under normal temper...

Embodiment 2

[0038] The fluorine-containing silicon coating of this embodiment includes the following components in parts by weight: 20 parts of fluorine-containing acrylate monomer, 5 parts of hydroxyethyl methacrylate, 10 parts of butyl methacrylate, 15 parts of isooctyl methacrylate, 10 parts of methyl methacrylate, 10 parts of vinyltriethoxysilane, 6 parts of polydimethylsiloxane, 2 parts of hydroxyl silicone oil, 0.8 parts of initiator, 40 parts of solvent .

[0039] Wherein, the fluorine-containing acrylate monomer is a mixture of tetrafluoropropyl methacrylate and octafluoropentyl methacrylate with a mass ratio of 1:1.

[0040] The preparation method of the fluorine-containing silicon coating of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0042] The fluorine-containing silicon coating of this embodiment includes the following components in parts by weight: 55 parts of fluorine-containing acrylate monomer, 5 parts of hydroxyethyl methacrylate, 5 parts of butyl methacrylate, 5 parts of isooctyl methacrylate, 5 parts of methyl methacrylate, 25 parts of vinyltriethoxysilane, 5 parts of polydimethylsiloxane, 10 parts of hydroxyl silicone oil, 0.2 parts of initiator, 60 parts of solvent .

[0043] Wherein, the fluorine-containing acrylate monomer is dodecafluoroheptyl methacrylate.

[0044] The preparation method of the fluorine-containing silicon coating of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com