Aqueous aluminum powder paint and preparation method thereof

A kind of aluminum powder paint, water-based technology, applied in the direction of coating, anti-corrosion coating, etc., can solve pollution and other problems, achieve good gloss retention, strong adhesion, and ensure the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

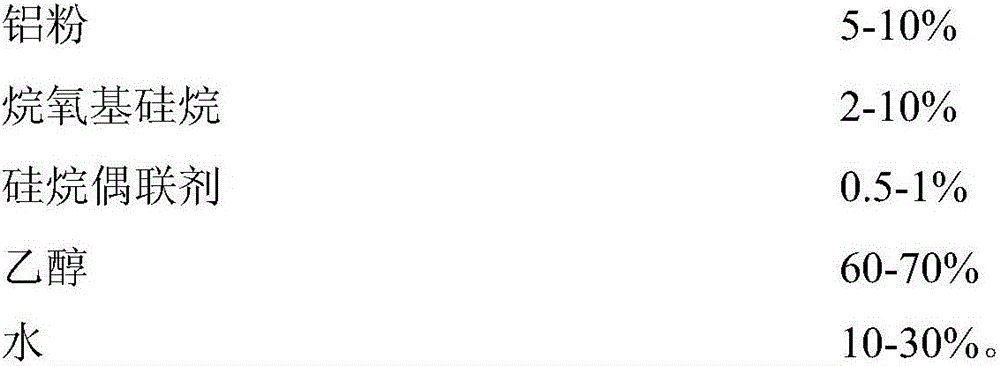

[0041] 1. Production process of modified aluminum powder:

[0042] (1) Put aluminum powder, ethyl orthosilicate, methyltriethoxysilane, silane coupling agent, ethanol and water into the dispersion tank, and stir at low speed until the dispersion is uniform. Slowly add 0.1 mol / L hydrochloric acid aqueous solution while stirring, pH=6. Use the jacket in the dispersion tank to heat to 65°C and keep it for 10 hours.

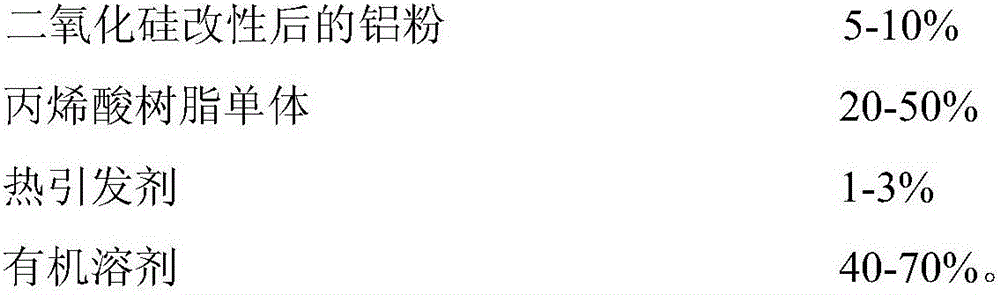

[0043] After the silica coating is finished, the silica coated aluminum powder can be obtained by centrifugation.

[0044] Use ethanol to clean the prepared aluminum powder to remove water and adjust the pH to neutral.

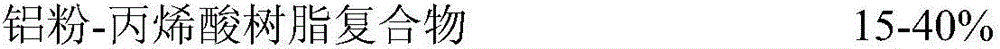

[0045] (2) Put the siloxane-coated aluminum powder into propylene glycol methyl ether, heat to 80°C, dropwise add a mixture of acrylic acid (ester), methacrylic acid (ester), and thermal initiator; after the addition is complete, Continue to react for 4h. After the reaction, it is neutralized with triethylamine, and water is added dropwise during high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com