Single-component wet gas curing polyurethane heavy-duty anticorrosion coating and preparation method thereof

A moisture-curing, heavy-duty anti-corrosion technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem of high volatility, achieve fast curing film formation, good storage stability, and high surface hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

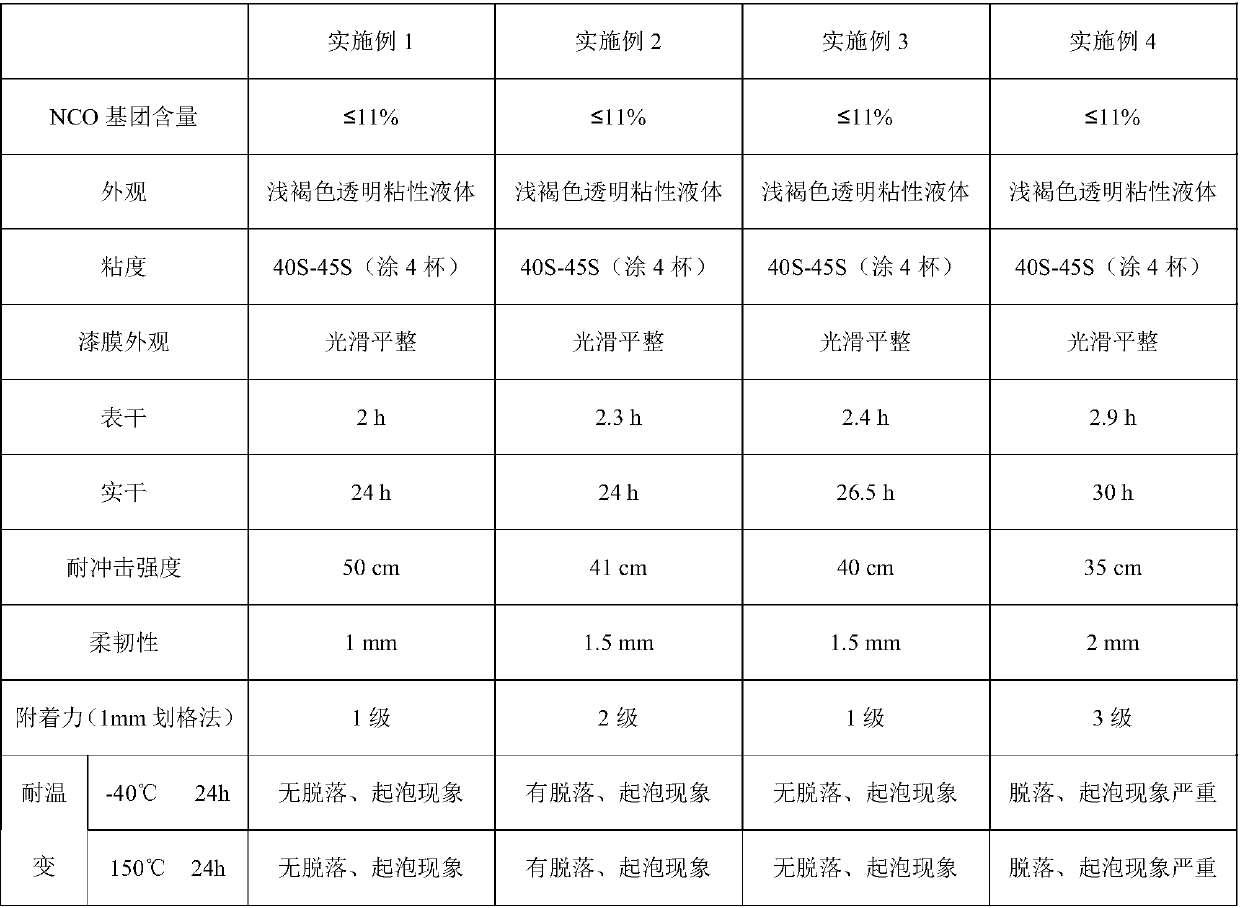

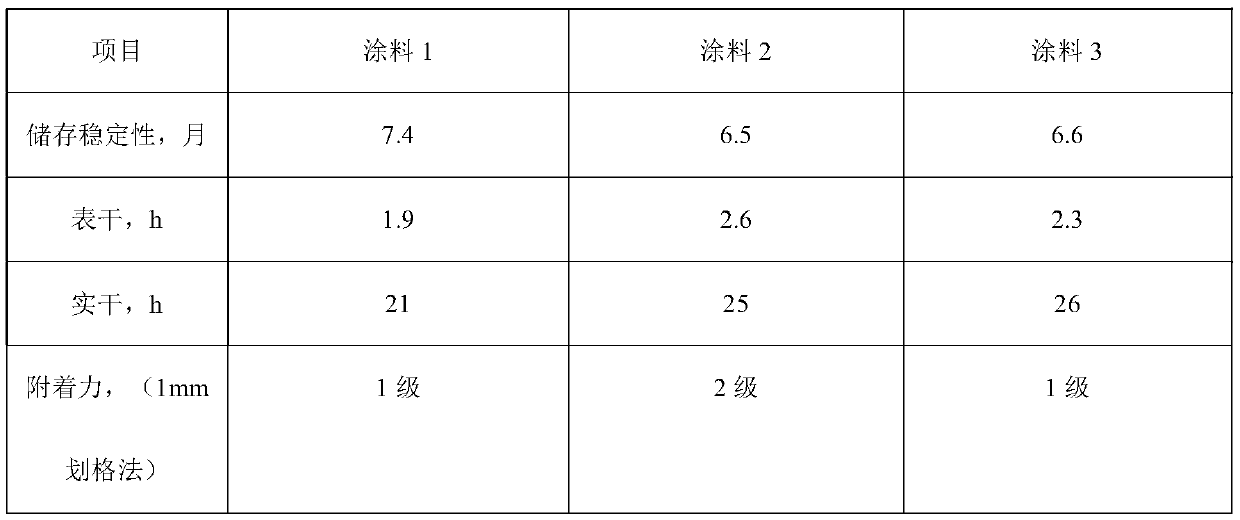

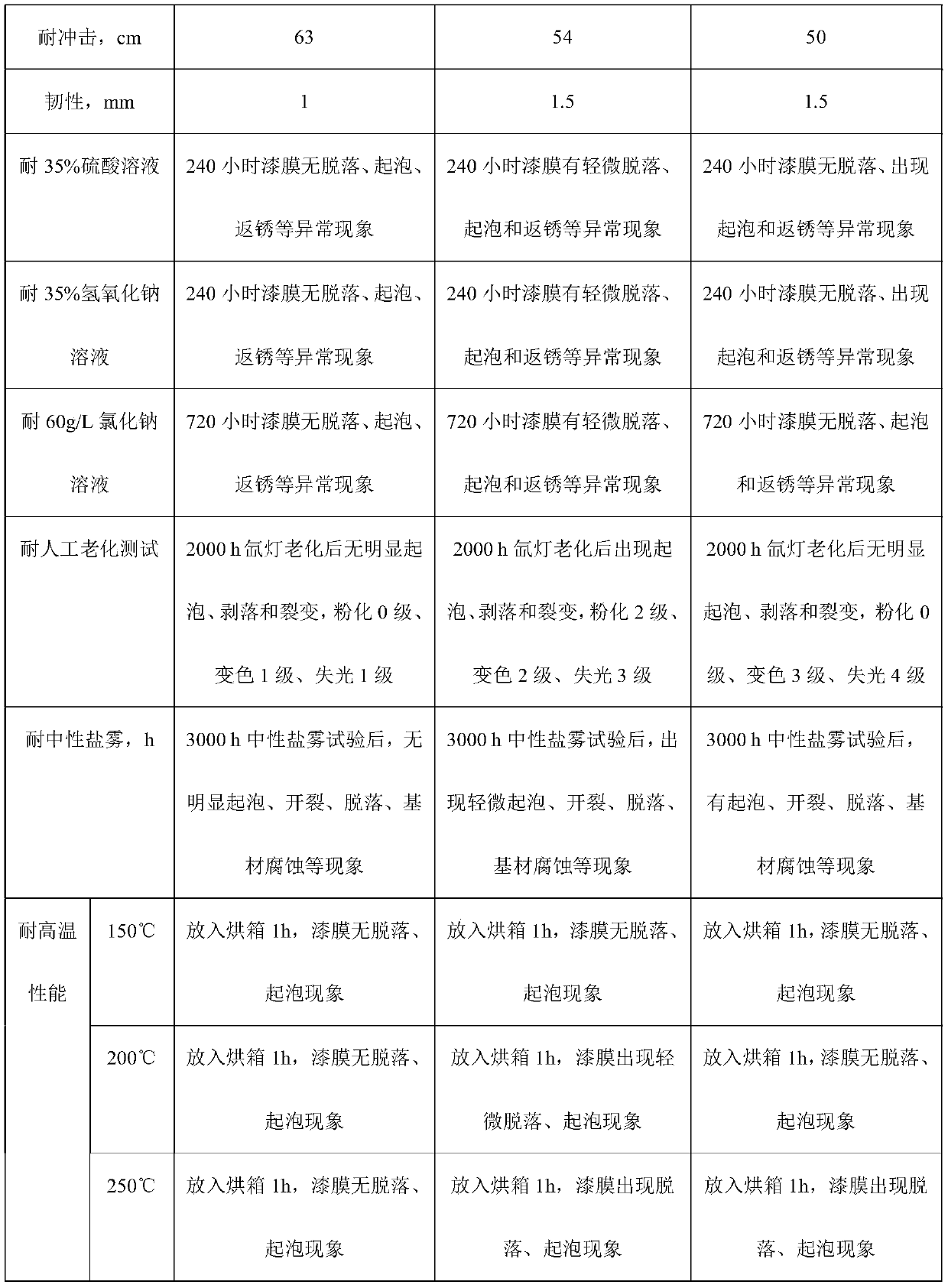

Examples

Embodiment 1

[0056] Preparation of Modified Polyurethane Prepolymer Resin

[0057] S1: Put 2.5kg of polyisocyanate MDI and 2.0kg of solvent sec-butyl acetate in a reaction vessel, heat up to 45°C, stir for 1 hour, and form material 1;

[0058] S2: Add 1.2kg of polyether polyol PPG, 0.55kg of natural castor oil with hydroxyl value OH=163mg KOH / g, 0.5kg of amino-terminated polyether D-2000, 0.1kg of acrylate-polyethylene glycol-amino and 2kg of acetic acid The sec-butyl ester was placed in a reaction vessel and stirred at room temperature for 1 h to form material 2;

[0059] S3: Add 2 g of the catalyst stannous octoate to material 1 under stirring at 45°C, slowly add material 2 dropwise to material 1 for 2 hours, raise the temperature to 85°C after the addition is completed, keep the temperature for 2.5 hours, and prepare A modified polyurethane prepolymer resin is obtained.

Embodiment 2

[0061] Preparation of Modified Polyurethane Prepolymer Resin

[0062] S1: In parts by weight, 5 parts of polyisocyanate compound MDI, 20 parts of PAPI and 20 parts of solvent sec-butyl acetate were placed in a reaction vessel, the temperature was raised to 45° C., and stirred for 1 hour to form material 1;

[0063] S2: Put 12 parts of polyether polyol PPG, 5 parts of natural castor oil with OH=163mg KOH / g, 5 parts of amino-terminated polyether D-2000 and 20 parts of solvent sec-butyl acetate in a reaction vessel, and stir at room temperature 1h, forming material 2;

[0064] S3: Add 0.02 parts of the catalyst stannous octoate to material 1 under stirring at 45°C, add material 2 dropwise to material 1, raise the temperature to 85°C after the dropwise addition, and keep the temperature for 2.5 hours to prepare a modified polyurethane pre- polymer resin.

Embodiment 3

[0065] The preparation of embodiment 3 modified polyurethane prepolymer resins

[0066] S1: Put 25 parts of polyisocyanate compound MDI and 20 parts of solvent sec-butyl acetate in a reaction vessel, heat up to 45°C, stir for 1 hour, and form material 1;

[0067] S2: 22 parts of polyether polyol PPG, 2 parts of acrylate-polyethylene glycol-amino and 20 parts of solvent sec-butyl acetate are placed in a reaction vessel, and stirred at room temperature for 1 hour to form material 2;

[0068] S3: Add 0.02 parts of the catalyst stannous octoate to material 1 under stirring at 45°C, add material 2 dropwise to material 1, raise the temperature to 85°C after the dropwise addition, and keep the temperature for 2.5 hours to prepare a modified polyurethane pre- polymer resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com