Pressure-resistant wear-resistant composite low-temperature-resistant ship shore power cable

A low-temperature-resistant, composite technology, used in insulated cables, communication cables, bendable cables, etc., can solve the problems of poor use effect, poor safety, and short use time, and achieve the effect of information management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

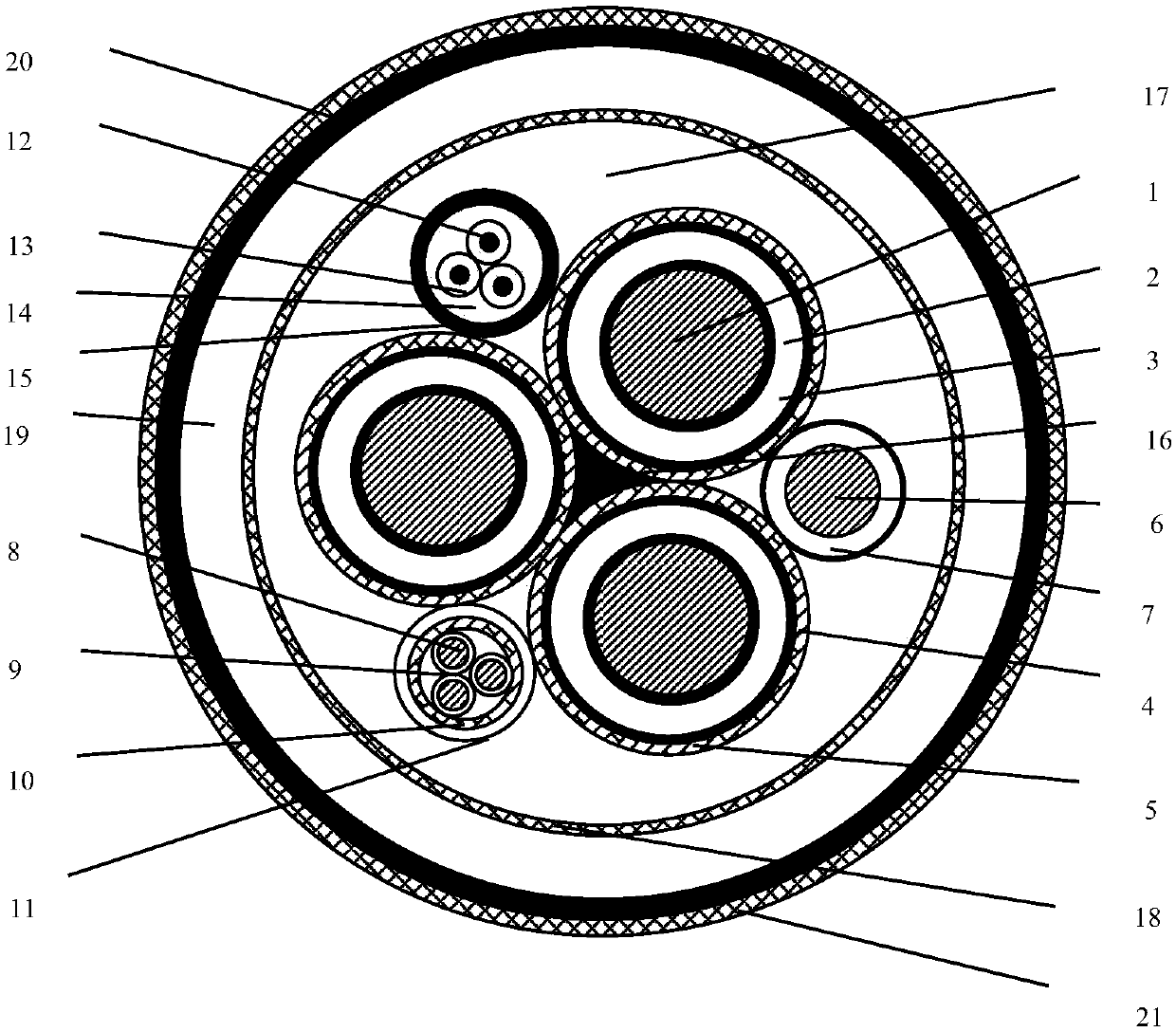

[0018] A compression-resistant and wear-resistant composite type low-temperature-resistant shore power cable for ships, including a main core, a ground core, a control core, an optical fiber assembly unit, and a filler core 16, wherein the main core includes a main core conductor 1 and a conductor shielding layer 2. Insulation layer 3, insulation shielding layer 4; ground core includes ground core conductor 6 and semi-conductive layer 7 extruded outside ground core conductor 6; main core, ground core, control core, optical fiber combination unit It is twisted together with the filler core 16, then extruded with an inner sheath 17, and the inner sheath 17 is sequentially provided with a fiber braided reinforcement layer 18 and an outer sheath 19; the main core also includes a metal shielding layer 5, a conductor Four layers of shielding layer 2, insulating layer 3, insulating shielding layer 4 and metal shielding layer 5 are placed on the main core conductor 1, and the outer she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com