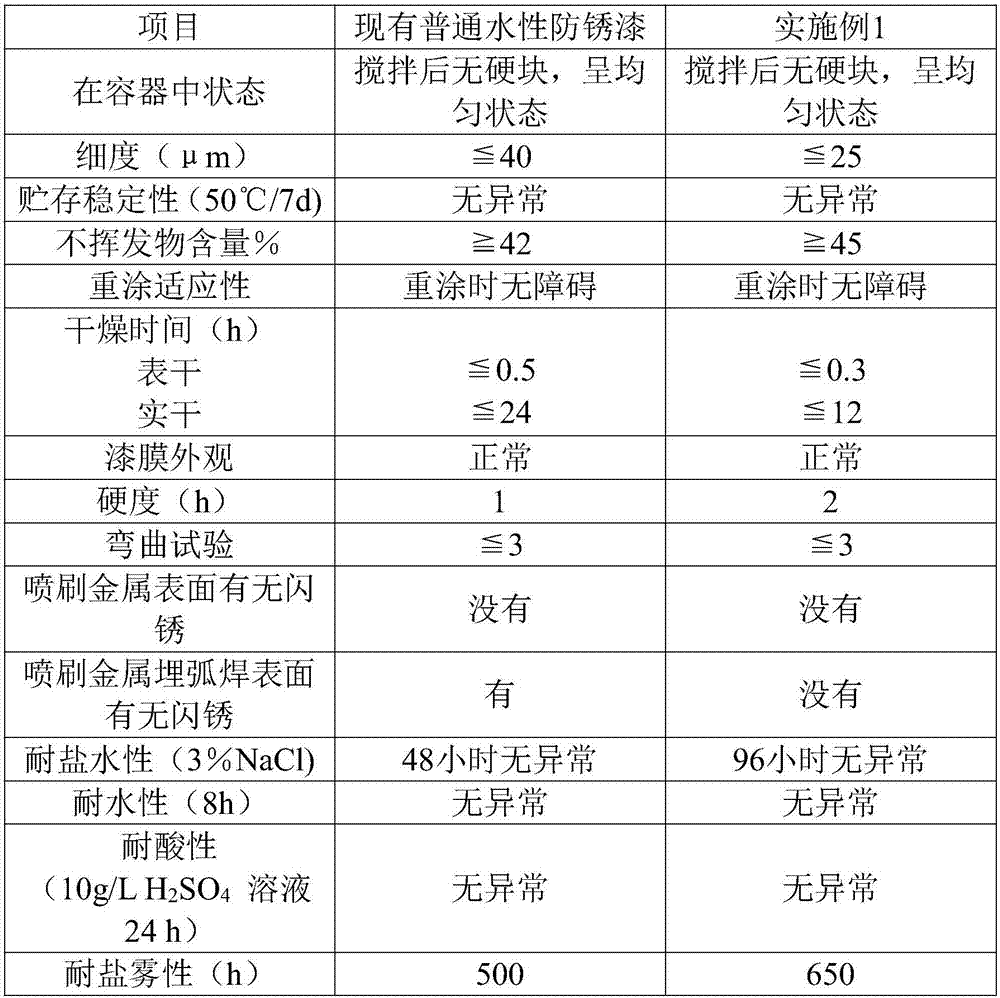

Special water-based anti-rust paint for submerged arc welding and preparation process thereof

A water-based anti-rust paint, submerged arc welding technology, applied in the direction of paint containing biocide, anti-corrosion paint, anti-fouling / underwater paint, etc. It is difficult to remove greasy and other problems, so as to achieve the effect of strong anti-rust effect, good anti-rust function and good anti-rust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

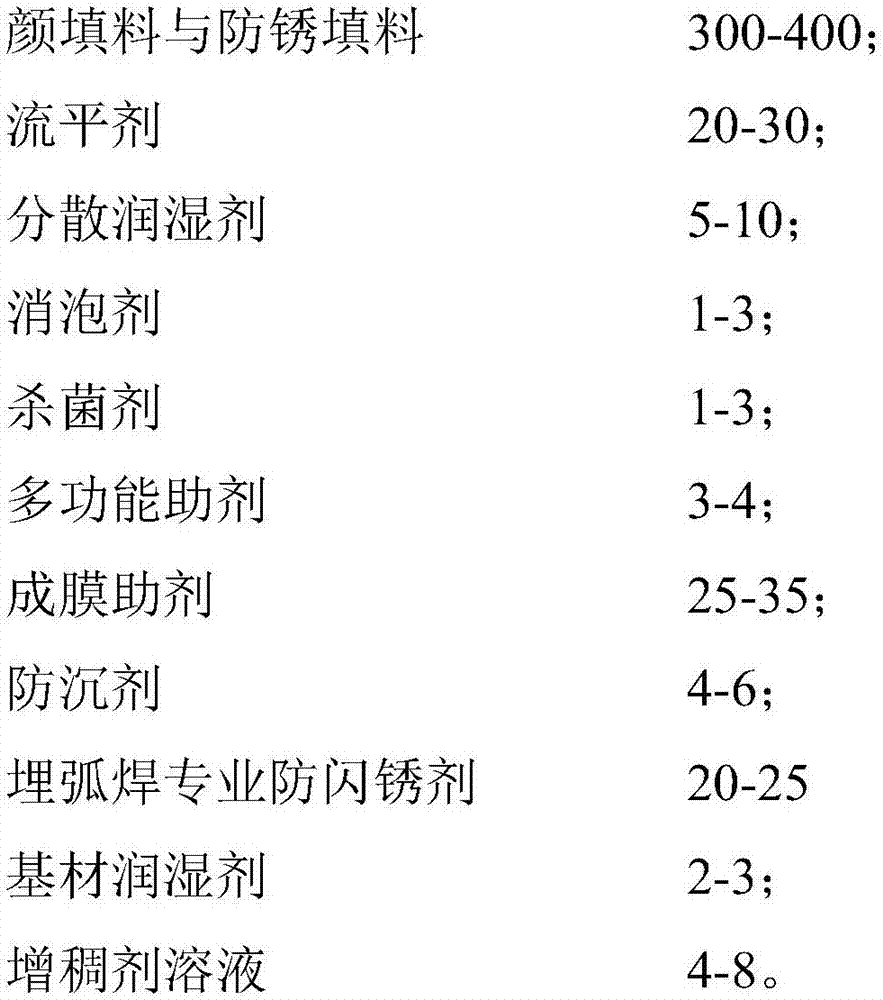

Embodiment 1

[0031] A water-based antirust paint specially used for submerged arc welding. Taking gray as an example, it includes the following raw materials in parts by weight: environmental protection water-based acrylic modified emulsion 450, deionized water 90, bactericide 1, anti-sedimentation agent 4, dispersing and wetting Agent 8, defoamer 3, film-forming aid 32, multifunctional additive 3.5, substrate wetting agent 2, titanium dioxide 120, iron oxide black 40, carbon black 20, iron-titanium powder 800 mesh 30, precipitated barium sulfate 100. Mica powder 20. Zinc phosphate 30. Talc powder 20. Submerged arc welding professional anti-flash rust agent 25. Leveling agent 30. Thickener solution 6.

[0032] The preparation method of the above-mentioned water-based antirust paint specially used for submerged arc welding comprises the following steps:

[0033] (1) Grinding and dispersing: first add the dispersing wetting agent, defoaming agent accounting for half of the total amount of de...

Embodiment 2

[0036] A water-based anti-rust paint specially used for submerged arc welding. Taking red as an example, it includes the following raw materials in parts by weight: environmental protection water-based acrylic modified emulsion 3612 emulsion 500, deionized water 100, fungicide LXE 1, anti-settling agent 3, Dispersion wetting agent 8, defoaming agent 3, film-forming aid 32, multifunctional additive 4, substrate wetting agent 2, titanium dioxide 120, iron oxide red 80, iron titanium powder 800 mesh 25, precipitated barium sulfate 110 , Mica powder 20, zinc phosphate 20, talcum powder 30, submerged arc welding professional anti-flash rust agent 20, leveling agent 20, thickener solution 5.

[0037] The preparation method of the above-mentioned water-based antirust paint specially used for submerged arc welding comprises the following steps:

[0038] (1) Grinding and dispersing: first add the dispersing wetting agent, defoaming agent accounting for half of the total amount of defoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com