Protective agent for clear water concrete

A technology of protective agent and auxiliary agent, applied in the field of protective agent of fair-faced concrete, can solve the problems of affecting the life of buildings, reducing the strength of concrete, and complex preparation process, and achieve the effects of maintaining natural texture, improving service life and increasing fullness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

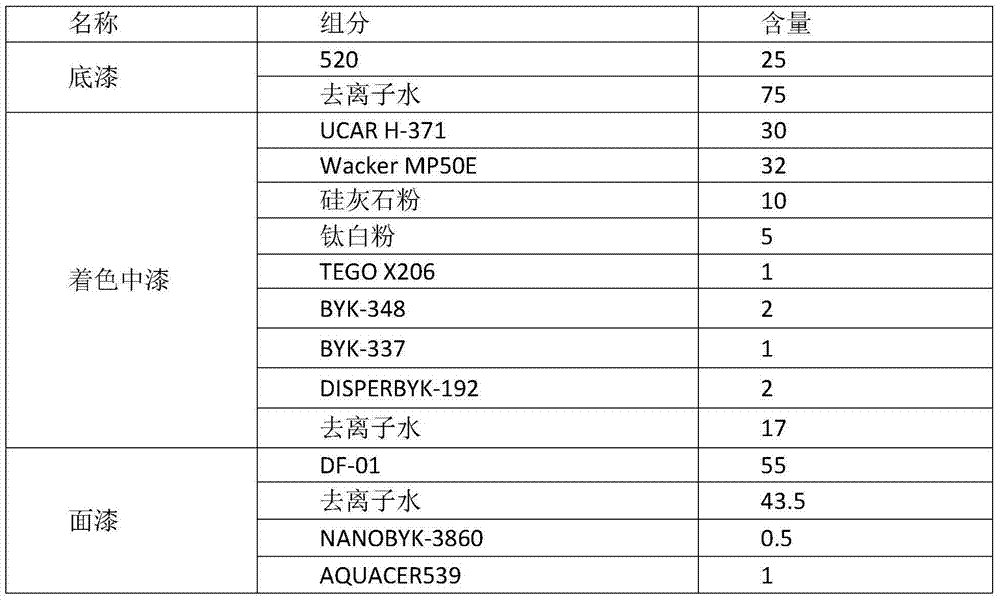

[0019] A protective agent for fair-faced concrete, the specific formula is shown in Table 1.

[0020] Table 1

[0021]

[0022] Among the above:

[0023] 520 silicone polymer emulsion, produced by Dow Corning (China) Investment Co., Ltd.;

[0024] UCAR H-371 pure acrylic emulsion, produced by Dow Chemical;

[0025] Wacker MP50E silicone emulsion, produced by Wacker Chemical;

[0026] DF-01 water-based fluorocarbon resin emulsion, Shanghai East Fluorine Chemical Technology Co., Ltd.

[0027] The preparation method of the product is as follows:

[0028] Add deionized water to the reaction kettle, add 520 silicone polymer emulsion or DF-01 water-based fluorocarbon resin emulsion under stirring, and stir at 700rpm until it is evenly dispersed to obtain a primer or topcoat.

[0029] In the reaction kettle, add deionized water, add UCAR H-371 pure acrylic emulsion and Wacker MP50E silicone emulsion respectively under stirring state, after stirring evenly, add TEGO X206, BYK-...

Embodiment 2

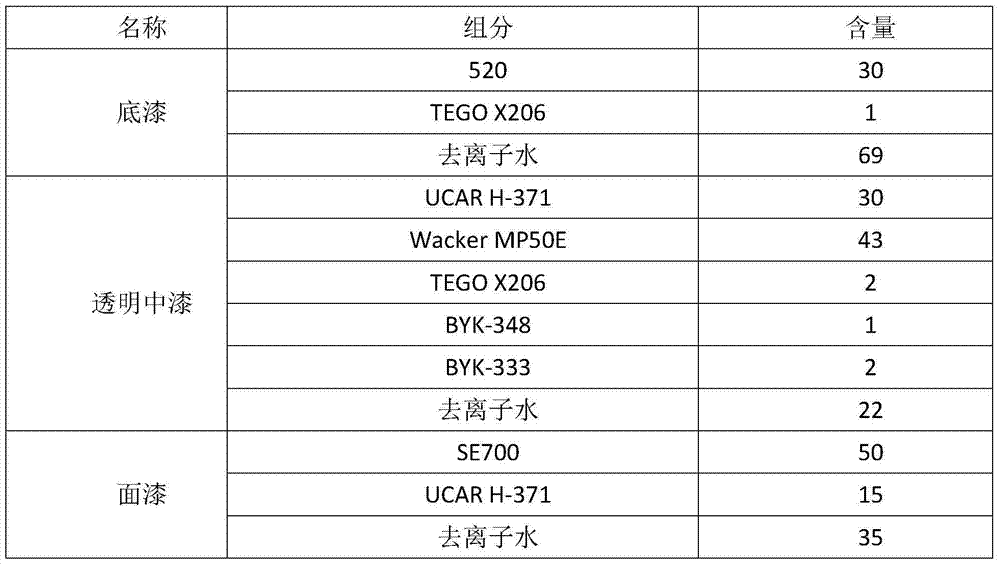

[0031] A protective agent for fair-faced concrete, the specific formula is shown in Table 2.

[0032] Table 2

[0033]

[0034] Among the above:

[0035] 520 silicone polymer emulsion, produced by Dow Corning (China) Investment Co., Ltd.;

[0036] UCAR H-371 pure acrylic emulsion, produced by Dow Chemical;

[0037] Wacker MP50E silicone emulsion, produced by Wacker Chemical;

[0038] DF-01 water-based fluorocarbon resin emulsion, Shanghai East Fluorine Chemical Technology Co., Ltd.

[0039] The preparation method of the product is as follows:

[0040] In the reaction kettle, add deionized water, add 520 silicone polymer emulsion under stirring, stir at 700rpm until it is uniformly dispersed to obtain the primer.

[0041] In the reaction kettle, add deionized water, add UCAR H-371 pure acrylic emulsion and Wacker MP50E silicone emulsion respectively under stirring state, after stirring evenly, add TEGO X206, BYK-348, BYK-333 and DISPERBYK-192 to After stirring at a spe...

Embodiment 3

[0044] A protective agent for fair-faced concrete, the specific formula is shown in Table 3.

[0045] table 3

[0046]

[0047] Among the above:

[0048] 520 silicone polymer emulsion, produced by Dow Corning (China) Investment Co., Ltd.;

[0049] UCAR H-371 pure acrylic emulsion, produced by Dow Chemical;

[0050] Wacker MP50E silicone emulsion, produced by Wacker Chemical;

[0051] SE700 water-based fluorocarbon resin emulsion, Daikin Industries Co., Ltd.

[0052] The preparation method of the product is as follows:

[0053] In the reaction kettle, add deionized water, add 520 silicone polymer emulsion under stirring state, after stirring evenly, add TEGO X206, stir evenly to get the primer.

[0054] In the reaction kettle, add deionized water, add UCAR H-371 pure acrylic emulsion and Wacker MP50E silicone emulsion respectively under stirring state, after stirring evenly, add TEGO X206, BYK-348 and BYK-333, stir at 700rpm until Disperse evenly to obtain a transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com