Production method for sweat-proof rattan chair armrest

A technology for rattan chairs and armrests, which is applied in the field of preparation of anti-perspiration rattan chair armrests, can solve the problems of corrosion, cracking, and fading of rattan chair armrests, and achieve the effects of shortening cooking time, enhancing mildew resistance, and strong conjunctiva

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

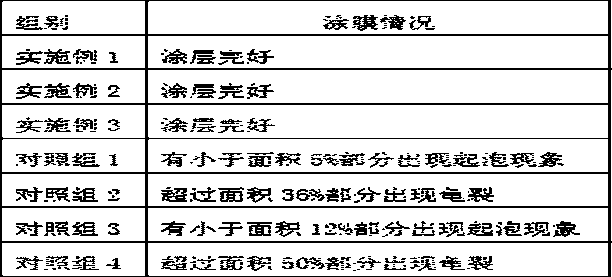

Examples

Embodiment 1

[0019] A method for preparing the armrest of a sweat-proof rattan chair, comprising the following steps: peel the harvested rattan and cut it into strips, remove the rattan knots with a cutting machine, and then polish the rattan after polishing in an anti-mildew disinfectant solution Soaking treatment, drying with circulating air after completion, and then cooking, weaving after cooking, trimming after weaving, and spraying polyurethane paint in the spraying room to obtain the product;

[0020] The anti-mildew disinfectant solution includes the following raw materials in parts by weight: 14 parts of zinc pyridine sulfate, 4 parts of sodium thiocyanate, 2 parts of iodopropynyl butylcarbamate, 4 parts of isopropanolamine, 1.5 parts of aluminum sulfate hydrate 100 parts of palm water;

[0021] The polyurethane paint comprises the following raw materials in parts by weight: 40 parts of aqueous polyurethane dispersion, 8 parts of amino-terminated hyperbranched polymer, 1.5 parts o...

Embodiment 2

[0029] A method for preparing the armrest of a sweat-proof rattan chair, comprising the following steps: peel the harvested rattan and cut it into strips, remove the rattan knots with a cutting machine, and then polish the rattan after polishing in an anti-mildew disinfectant solution Soaking treatment, drying with circulating air after completion, and then cooking, weaving after cooking, trimming after weaving, and spraying polyurethane paint in the spraying room to obtain the product;

[0030] The anti-mildew disinfectant comprises the following raw materials in parts by weight: 12 parts of zinc pyridine sulfate, 6 parts of sodium thiocyanate, 1 part of iodopropynyl butylcarbamate, 6 parts of isopropanolamine, 1 part of aluminum sulfate hydrate 100 parts of palm water;

[0031] The polyurethane paint comprises the following raw materials in parts by weight: 42 parts of aqueous polyurethane dispersion, 6 parts of amino-terminated hyperbranched polymer, 1 part of glycerin, 3 p...

Embodiment 3

[0039] A method for preparing the armrest of a sweat-proof rattan chair, comprising the following steps: peel the harvested rattan and cut it into strips, remove the rattan knots with a cutting machine, and then polish the rattan after polishing in an anti-mildew disinfectant solution Soaking treatment, drying with circulating air after completion, and then cooking, weaving after cooking, trimming after weaving, and spraying polyurethane paint in the spraying room to obtain the product;

[0040] The mildew-proof disinfectant comprises the following raw materials in parts by weight: 16 parts of zinc pyridine sulfate, 2 parts of sodium thiocyanate, 3 parts of iodopropynyl butyl carbamate, 2 parts of isopropanolamine, 2 parts of aluminum sulfate hydrate 100 parts of palm water;

[0041] The polyurethane paint comprises the following raw materials in parts by weight: 38 parts of aqueous polyurethane dispersion, 10 parts of amino-terminated hyperbranched polymer, 2 parts of glyceri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com