Fiber reinforcement resin radical compound material drive axle

A technology of fiber-reinforced resin and composite materials, applied in shafts, shafts and bearings, mechanical equipment, etc., can solve problems such as poor salt spray resistance, poor impact resistance, and poor high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

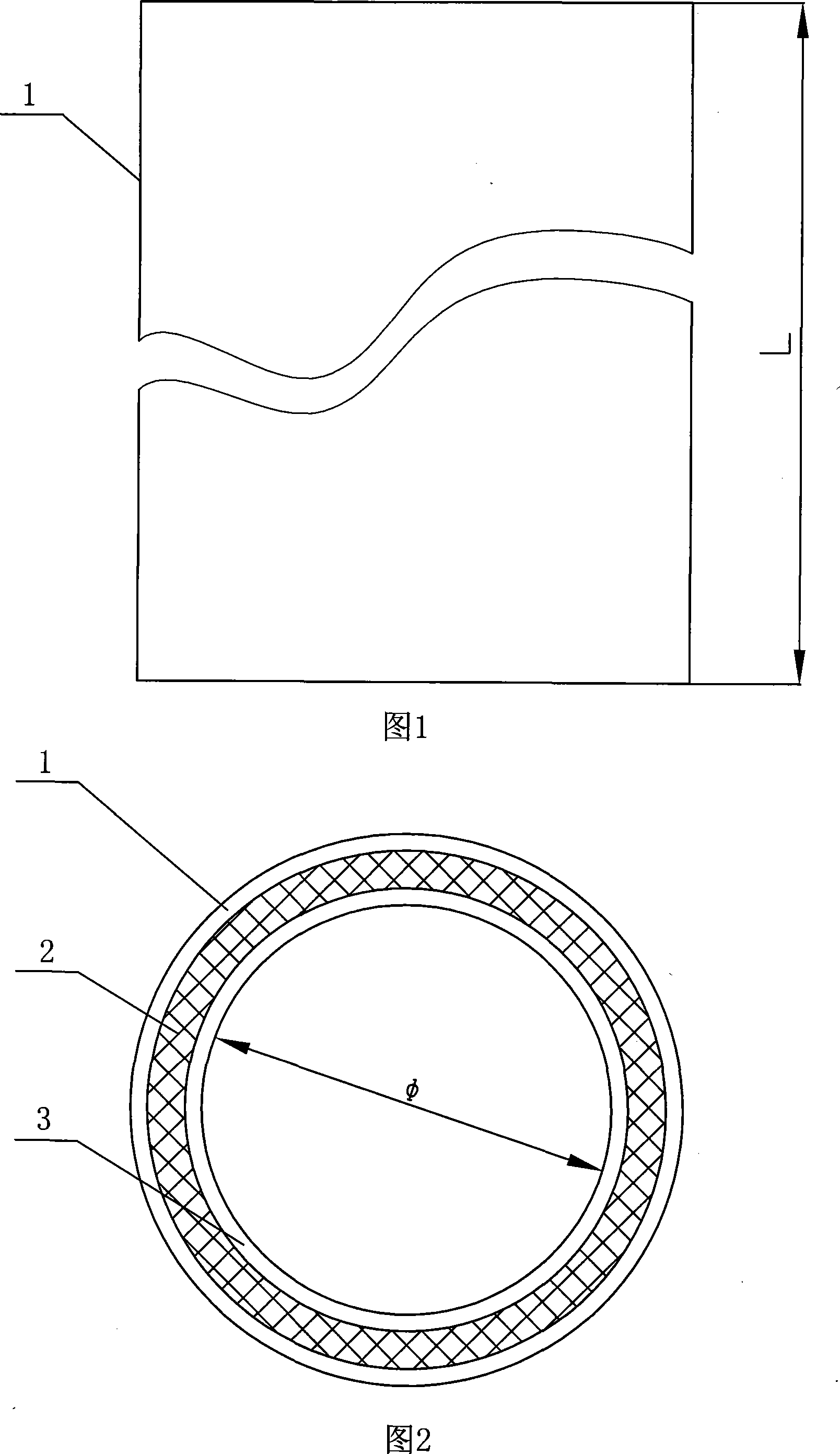

[0007] Specific embodiment 1: As shown in Figure 1 and Figure 2, the fiber reinforced resin matrix composite transmission shaft of this embodiment is composed of a structural layer 2, a surface layer 1, and an inner lining layer 3, and the structural layer is made of fiber reinforced resin The hollow shaft body 2 of composite material, the inner lining layer 3 and the surface layer 1 are respectively adhered to the inner and outer surfaces of the hollow shaft body 2 of fiber reinforced resin matrix composite material.

specific Embodiment approach 2

[0008] Embodiment 2: The hollow shaft body 2 of fiber-reinforced resin-based composite material described in this embodiment is made of one of glass fiber, carbon fiber or aramid fiber. With such materials, the strength and rigidity of the present invention can be enhanced and the overall weight can be lightened. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: The fiber-reinforced resin-based composite material hollow shaft body 2 described in this embodiment is composed of any two materials of glass fiber, carbon fiber, and aramid fiber in any ratio or a combination of the above three materials in any ratio . With such materials, the strength and rigidity of the present invention can be enhanced and the cost can be reduced. Other compositions and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter φ | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com