Functional gradient shield pipe sheet and producing method thereof

A shield segment and functional gradient technology, which is applied in mining equipment, shaft equipment, earth-moving drilling, etc., can solve the problems of relatively high strength requirements, high cementing material consumption, easy cracking, etc., and achieve enhanced shrinkage performance. The effect of matching ability, improving mechanical bite force and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

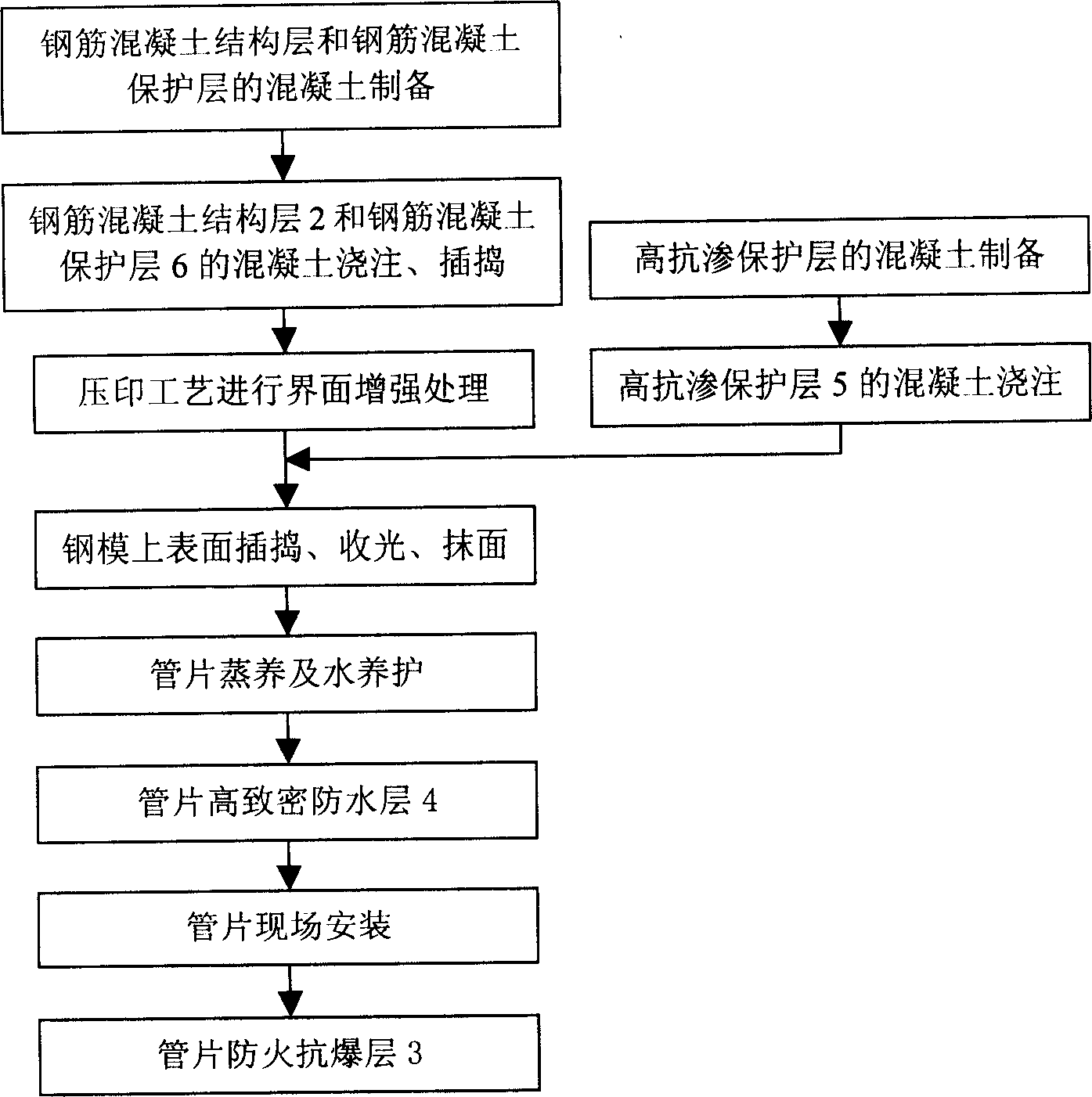

[0036] The invention is a reinforced concrete segment used in a shield tunnel. According to the principle of functional gradient material design, the segment is designed with an integrated function / structure, and it is prepared by gradient composite technologies such as two castings and one embossing. become.

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

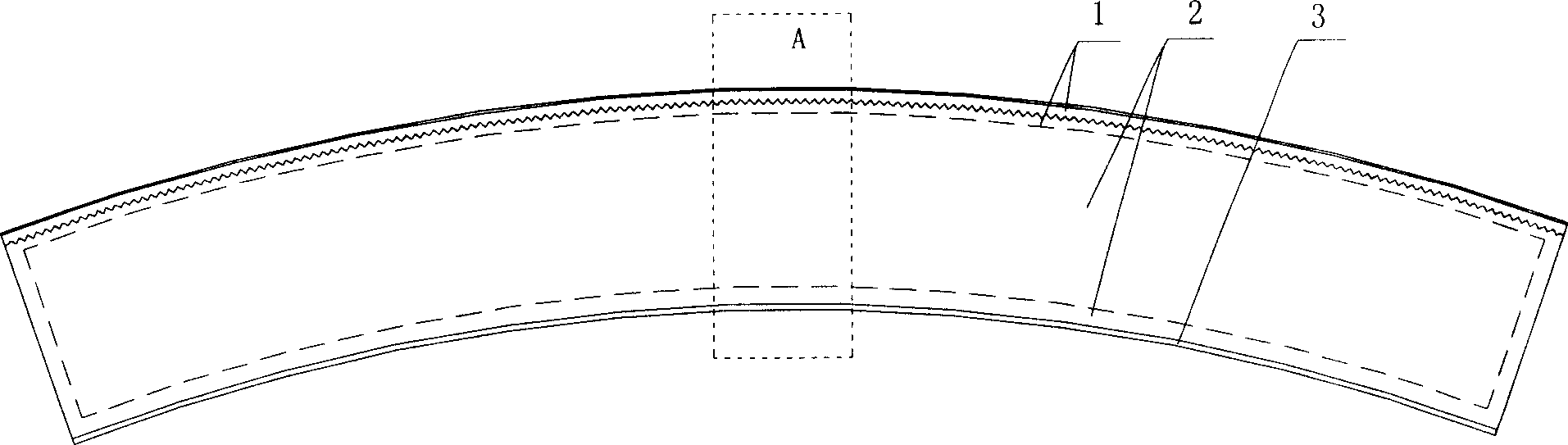

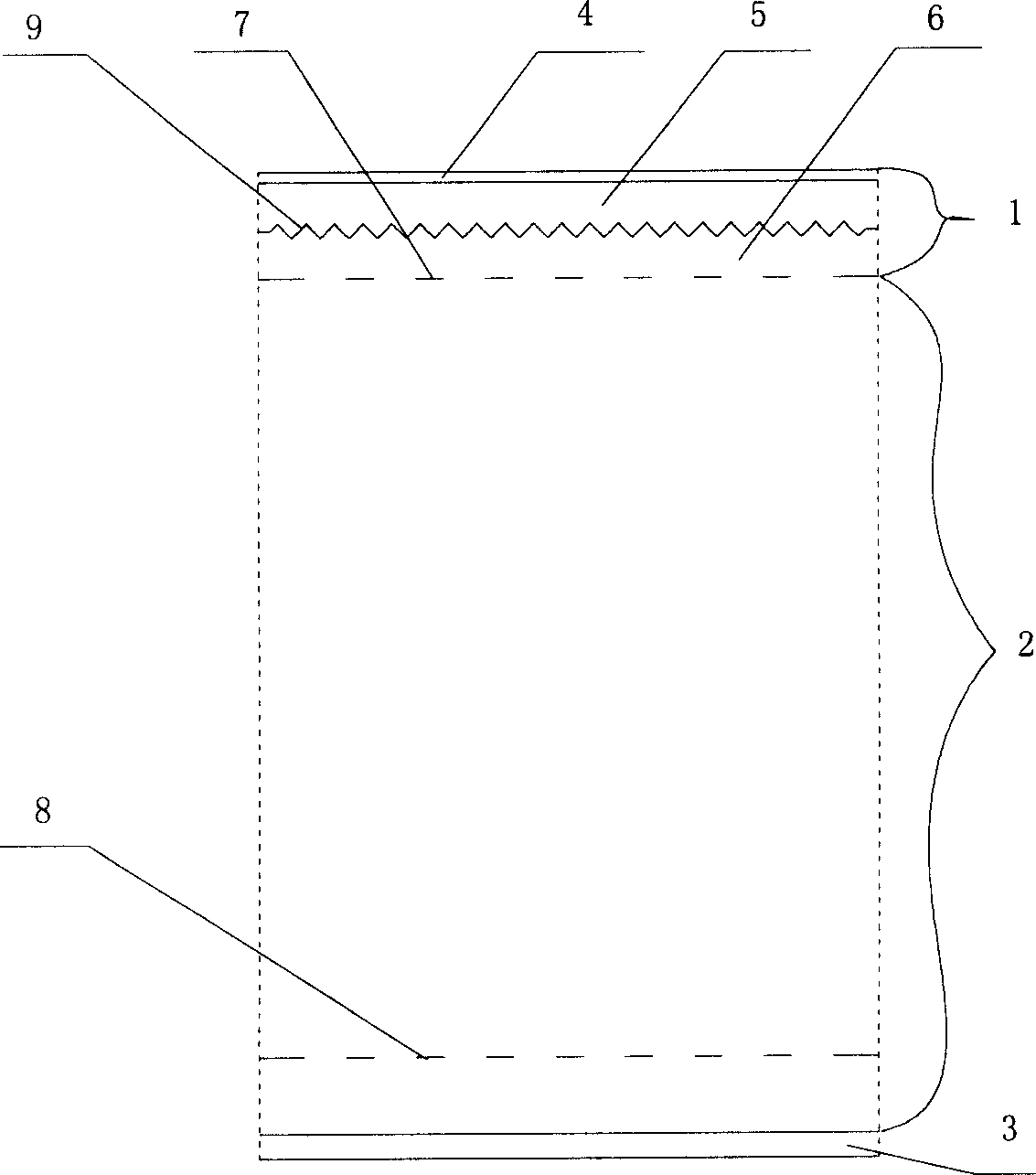

[0038]Such as figure 1 , figure 2 As shown, a functionally graded shield segment is composed of a segment outer protective layer 1, a reinforced concrete structural layer 2 and a fireproof and anti-explosion layer 3, and the segment outer protective layer 1 is located on the outer surface of the reinforced concrete structural layer 2, The fire-proof and anti-explosion layer 3 is located on the inner surface of the reinforced concrete structural layer 2; the thickness of the reinforced concrete structural layer 2 is 300.0-500.0 mm, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com