Numerical control helical finned tube laser welding molding equipment and welding molding method thereof

A spiral-finned tube and laser welding technology, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of low bonding strength, low heat conversion efficiency, and non-corrosion resistance, and achieve high corrosion resistance and thermal stability. High conversion efficiency and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

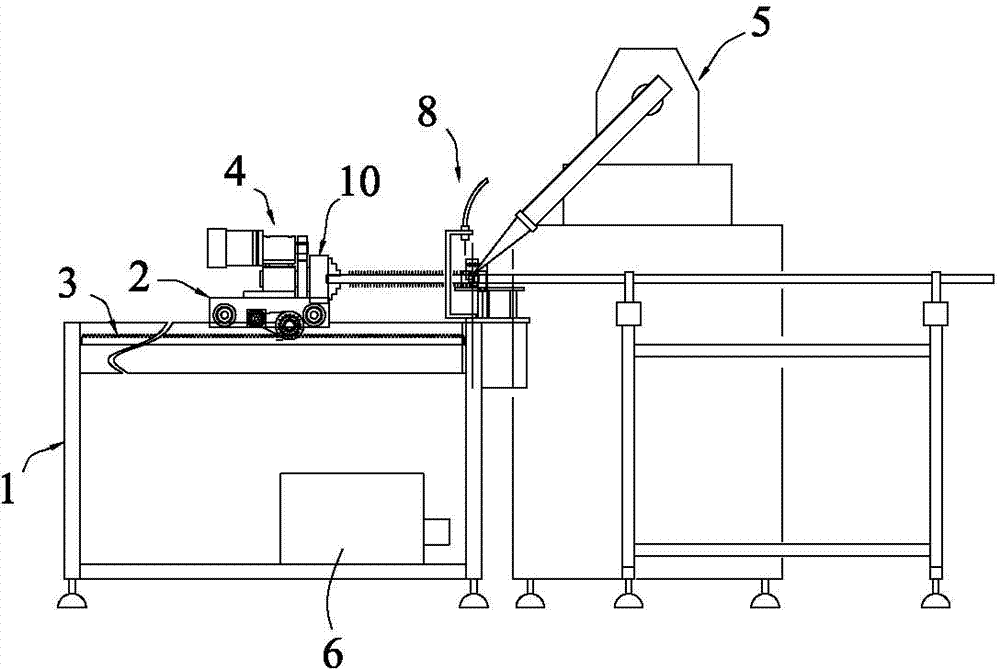

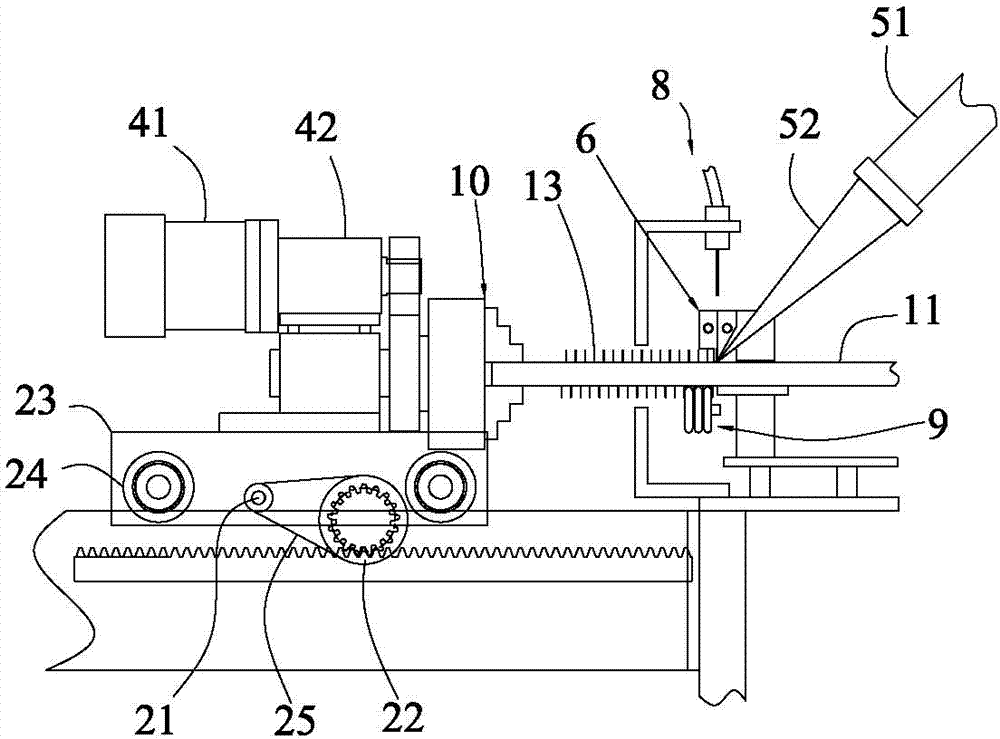

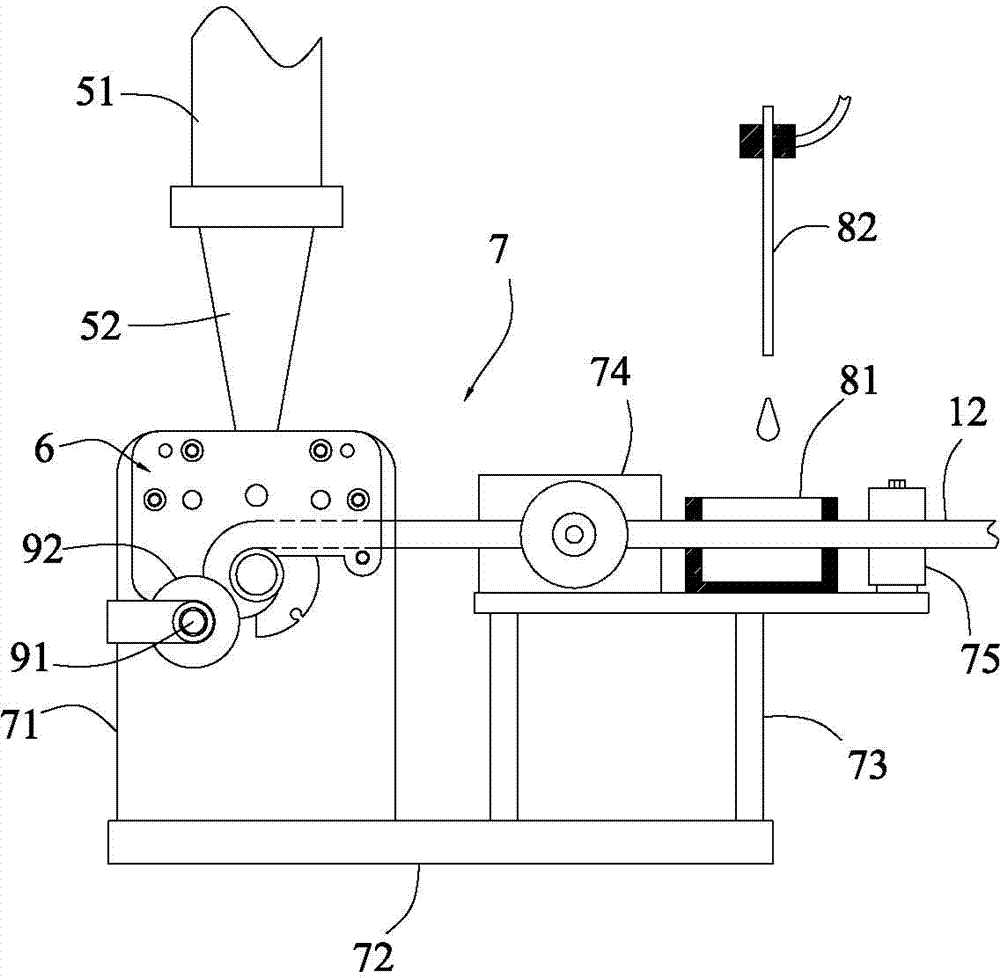

[0028] see Figure 1 to Figure 7 , a CNC spiral finned tube laser welding forming equipment provided in this embodiment, which includes a frame 1, a linear traveling trolley 2, a rack 3, a rotating device 4, a steel pipe chuck 10, a laser 5 and a steel belt conveying device 7 , the rack 3 is horizontally arranged on the frame 1, the linear traveling trolley 2 is movably arranged on the frame 1, and meshes with the rack 3, and the rotating device 4 is fixed on the On the straight-line walking trolley 2, the steel pipe chuck 10 is arranged on the output shaft of the rotating device 4, and the axis of the steel pipe 11 clamped on the steel pipe chuck 10 is aligned with the moving track of the straight-line walking trolley 2. Parallel to each other, the steel belt conveying device 7 is set on the frame 1 at the side corresponding to the steel pipe clamp 10, and is provided with a matching welding hole for the steel pipe 11 to pass through, and a steel belt forming fin is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com