Anticorrosion epoxy primer and preparation method thereof

An anti-corrosion primer and water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor weather resistance, long drying time, flash rust, etc., to improve comprehensive performance and reduce sagging and cracking , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

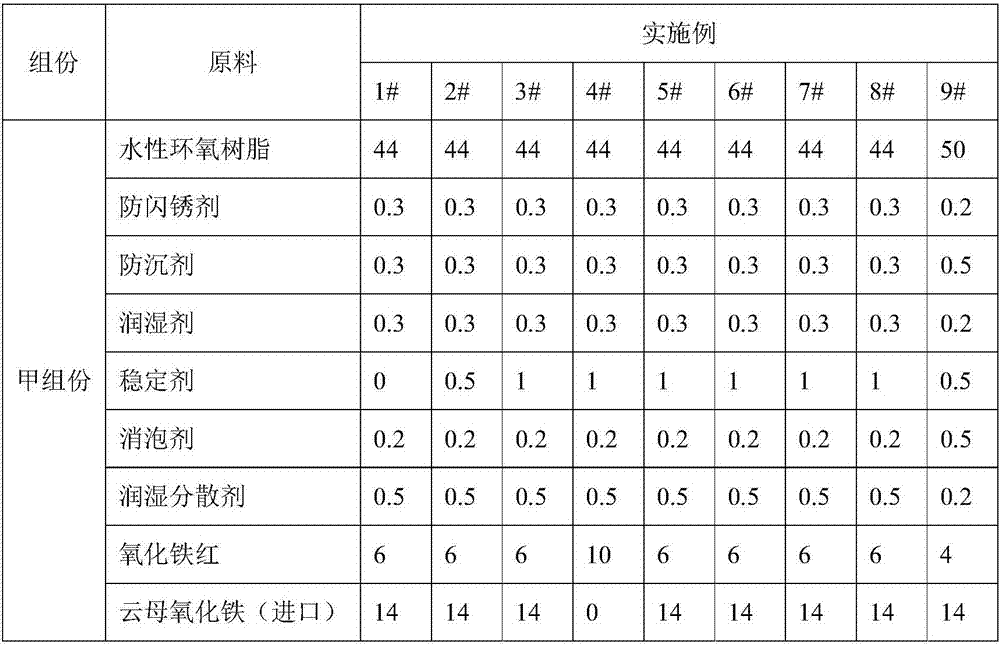

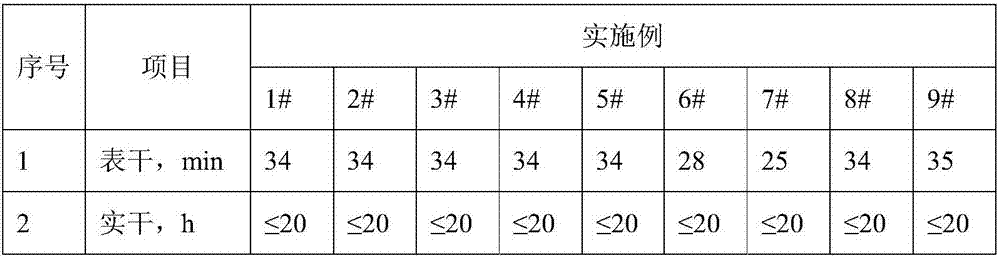

[0034] The present invention will be further described below in conjunction with specific examples, which are only used to illustrate the present invention and do not limit the scope of protection of the present invention. The experimental methods not specified in the examples are usually determined in accordance with national standards.

[0035] Table 1 is an example of the present invention, in which the content of each component is parts by weight.

[0036] Table 1

[0037]

[0038]

[0039] The raw materials of the components in Table 1 are as follows: the anti-settling agent in Example 9 is kaolin, the anti-settling agent in the remaining examples is organic bentonite (Hemmings LT), the wetting agent is Air Company 104E, and the stabilizer is Synperonic PE / F87, defoamer is BYK022, wetting and dispersing agent is BYK 154, mica iron oxide is imported flake mica iron oxide (Nubilai R02), compound phosphate is imported organically treated zinc phosphate and zinc molybdate Composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com